Академический Документы

Профессиональный Документы

Культура Документы

Autoclave (Steam Sterlizer) Validation - Pharmaceutical Guidelines

Загружено:

ASHOK KUMAR LENKAОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Autoclave (Steam Sterlizer) Validation - Pharmaceutical Guidelines

Загружено:

ASHOK KUMAR LENKAАвторское право:

Доступные форматы

Autoclave(SteamSterlizer)Validation

Procedure for autoclave validation including steam penetration, heat distribution and penetration, biochallenge study, estimation of F0 value and acceptance

criteria of steam sterilizer validation in pharmaceutical industry.

Sterilization process in pharmaceutical industry in an autoclave will be considered qualified for consistent and reliable performance validated on successful

completion of the following tests

Bowie Dick Test for steam penetration 3 trails.

Empty Chamber Heat distribution studies 3 trails with temperature mapping probe at different locations

of the sterilizer chamber.

Loaded chamber heat Distribution & penetration studies 3 trails for each sterilization load of fixed

loading pattern

1 Sterile area garments 20 number Garments packs, Each pack contains 01 Nos. Boiler suit, 01 Nos.

Headgear, 02 Nos booties, 01 pairs gloves

2 Glassware S.S Mannifold holder 06 holder 02 Nos, Sampling unit of Compressed air 02 Nos, 500 ml

sampling bottles 10 Nos, 250 ml sampling bottles 25 Nos, 04 Nos S.S Bin.

3 Media SCDA Medium 500 ml 09 Nos. Conical flask, SCDM 100 ml 20 Nos. tubes, FTM 100 ml 10

Nos. tubes, MSA 250 ml 01 Nos Conical flask, CA 250 ml 01 Nos Conical flask, BGA 250 ml 01 Nos

Conical flask, BSA 250 ml 01 Nos Conical flask, MCA 250 ml 01 Nos Conical flask, Peptone Water 500

ml 06 Nos. Conical flask.

With temperature mapping probes along with Biological Indicator Geobacillus stearothermophillus spore vials containing 10^6 or more spores per vials

inside the innermost possible layer of the load subjected for sterilization.

Estimation of the F0 Value achieved during the sterilization hold period at each temperature mapping probe.

To qualify these tests the equipment should fulfill the acceptance criteria described in the individual test procedures. After completion of the qualification

tests all the data generated will be compiled together to evaluate ability of the steam sterilizer to sterilize different components at the set parameters and

set loading pattern.

A Bowie Dick test for Steam Penetration

Objective

Objective of this test is to ensure that the vacuum pulses applied the sterilization hold period are sufficient to remove the entrapped air so as to facilitate

rapid and even steam penetration into all parts of the load and maintaining these conditions for the specified temperature holding time 17 minutes at 121

deg.C

If air is present in the chamber, it will collect within the Bowie Dick test pack as a bubble. The indicator in the region of the bubble will be of

different color as compared to the color on the remaining part of the test paper, because of a lower temperature, lower moisture level or both. In this

condition the cycle parameters to be reviewed and the normal sterilization cycles to be modified accordingly.

Bowie Dick cycle should be normally preceded by a warm up cycle, as the effectiveness of air removal may depend on all parts of the sterilizer being at

working temperature.

Procedure

1. Record the set parameters for the Bowie Dick test cycle in The Annexure.

2. Place one Bowie Dick test pack near the drain of the sterilization chamber.

3. Select cycle Bowie Dick on the control panel & operate the steam sterilizer.

4. The print out taken during the Bowie Dick test cycle & the Bowie Dick test indicator should be preserved.

5. Compile the observation made during the qualification test for complete evaluation of the system.

Acceptance Criteria

The Bowie Dick Test indicator should show a uniform color change, non uniform change and/or air entrapment bubble spot on the pattern indicates

inadequate air removal from the sterilization chamber.

Observation & Results

Record the observation and results in format.

Related: SOP for Steam Penetration Study by BowieDick Test

B Empty Chamber Heat Distribution Studies

Objective

Objective of this test is to ensure that, The sterilizer is capable of attaining a temperature of 121 deg.C during the sterilization hold period with steam

pressure of 1.1 to 1.2 kg/cm2.

Temperature spread with in the range of 121 deg.C to 124 deg.C during sterilization cycle will demonstrate the uniform heat distribution within the

chamber.

Any location where the temperature indicator is placed, not achieving minimum sterilization temperature of 121deg.C through out the sterilization

temperature hold will be considered as cold spot.

Procedure

1.0 Record the set parameter for the sterilization cycle to be operated during the test for empty chamber heat distribution study, in the Annexure.

2.0 Pass minimum 16 no. Temoerature mapping probe into chamber through the port of the sterilizer. Seal the port with silicone sealant so that steam

leakage does not take place. Suspend the probes in the chamber in different position so that probes do not touch any metallic. Record the position of the

probes in a respective schematic form.

3.0 Connect the probes to a suitable autoclave data logger, which can scan and print the actual temperature observed at different locations with respect to

time.

4.0 Operate the steam sterilizer and also start the autoclave data logger to record actual temperature within the sterilization chamber with respect to time.

5.0 When the sterilization cycle completes, 1 Collect printout of the sterilizer and preserve as Annexure. 2 Download the dataanalysis and printing. Record

the temperatures observed at different locations in the Annexure.

6.0 If the empty chamber heat distribution study is acceptable perform three consecutive runs to demonstrate cycle and sterilizer reproducibility.

7.0 Compile the data generated during the qualification test for complete evaluation of the system.

Acceptance Criteria

There should be uniform distribution of heat in the sterilizer chamber during the sterilization hold period and the temperature at each temperature

mapping probes should be within the range of 121 deg.C to 124 deg.C during the sterilization hold period.

Observations and Results

Record the observations and results in formats.

Related: Low Temperature Sterilization Process 115C

C Loaded Chamber Heat Distribution & Penetration Studies

Objective

Objective of this test is to ensure that, the steam is sufficiently penetrating into the innermost portions of the load subjected for sterilization to achieve

desired temperature of 121 deg.C during the complete sterilization hold period with steam pressure of 1.1 to 1.2 kg.cm2.

If Sterilization temperature 121 deg.C is not achieved through out the cycle, load configuration or size of the load has to be reviewed and cycle to be

repeated.

Temperature spread within the range of 121 deg.C to 124 deg.C during sterilization hold period indicate that, uniform heating process which is achieved in

the empty chamber heat distribution study is not affected by load. There could be the possibility of lag period for attaining 121 deg.C during heat

penetration runs as the probes are placed deep into the load.

Any location where the temperature indicator is placed, not achieving minimum sterilization temperature of 121deg.C during sterilization temperature hold

period will be considered as cold spot.

Procedure

1.0 Record the set parameter for the sterilization cycle to be operated during the test for loaded chamber heat penetration study in the Annexure.

2.0 Pass minimum 16 no. Temperature mapping probe into chamber through the port provided. Seal the port with silicone sealant so that steam leakage

does not take place. Place the probes inside the load components, which are supported to be most difficult points for steam penetration, also place

biological indicator along with temperature mapping probe 12 Nos.. Record the position of the probes and biological indicators in a representative

schematic form.

3.0 Connect the probes to a suitable data logger, which can scan and print the actual temperature with respect to time.

4.0 Operate the steam Sterilizer and also start the data logger to record the actual temperatures within the sterilization chamber with respect to time.

5.0 When the sterilization cycle completes, 1 Collect printout of the sterilizer and preserve as Annexure. 2 Download the dataanalysis and printing. Record

the temperatures observed at different locations in the Annexure. 3 Aseptically collect the exposed biological indicators and send the indicators to

microbiology lab for further incubation and observed the results.

6.0 If the load penetration study is acceptable perform three consecutive runs to demonstrate cycle and sterilizer reproducibility.

7.0 Compile the data generated during the qualification test for complete evaluation of the system.

Acceptance Criteria

There should be uniform distribution & penetration of heat in the load subjected for sterilization during the sterilization hold period and the temperature at

each temperature mapping probe should be within the range of 121 deg.C to 124 deg.C during the complete sterilization hold period.

Observations and Results

Record the observations and results in formats enclosed as Attachement

D Biochallenge studies

Objective

The steam sterilization process in pharmaceutical industry, when challenged with Geobacillus stearothermophillus Biological indicator spore vial, spore

population of NLT 106 spores/vial, should reduce bacterial load by mean of Sterility Assurance Level SAL 106

On incubation of the loaded biological indicator, if growth is observed, then the sterilization cycle parameters to be reviewed.

Procedure

1.0 Determine the initial counts of biological indicator.

2.0 Collect the exposed indicator during the loaded chamber heat distribution & heat penetration studies by using sterile forceps and scissors in a 100 ml

beaker and then send to microbiology lab for incubation Incubate the vial at 55 to 60 deg.C for 48 hours

3.0 Keep one vial as a negative control provided by the Mfg of biological indicator as well as one vial as a positive control unexposed vial biological

indicator.

4.0 Observe any growth purple color sterile, yellow color Non sterile in the vial daily. Record the observations on daily basic in the Annexture.

5.0 Compile the data generated during the qualification test for complete evaluation of the system.

Acceptance Criteria

No bacterial growth should observed during the incubation period of 48 hours at 55 to 60 deg.C.

Observations and Results

Record the observations and results in formats enclosed as Attachement.

E Estimation of F0 Value

Objective

The calculated F0 value should not be less than the biological F0 value at all temperature mapping locations during the sterilization hold period.

Procedure

1.0 Record the temperature at all temperature mapping probes during the sterilization hold period in the Annexure.

2.0 Calculate the F0 value at each temperature mapping probe by using the equation as below.

3.0 Record the F0 value Results in the Annexure.

4.0 Compile the data generated during the qualification test for complete evaluation of the system.

Calculation

F0 = dt S10T121/z

Where

dt = Time interval between two following temperature measurements 1 minutes.

T = The observed Temperature at that particular time.

Z = The change in the heat resistance of Geobacillus stearothermophillus spores as temperature is changed 10 deg.C.

Acceptance Criteria

The calculated minimum F0 value by equation should be more than biological F0 value for the biological indicator vial exposed for the biochallenge

studies.

The biological F0 value for the specific biological indicator spore vial is calculated as per the following equation

F0 = D121 Log A Log B

Where

D121 = D value of the of the biological indicator at 121 deg.C.

A = Biological indicator concentration or spore population.

B = Desired level of non sterility. 10 deg.C

Click here for further details

Related: Steam Sterilization Heating in an Autoclave

Related: Steam Sterilization Heating in an Autoclave

Ankur Choudhary is India's first professional pharmaceutical blogger, author and founder of Pharmaceutical Guidelines, a widelyread pharmaceutical

blog since 2008. Signup for the free email updates for your daily dose of pharmaceutical tips.

Need Help: Ask Question

Offline

20082017 All rights reserved to Ankur Choudhary and data may not be reproduced on other websites. Designed by Pharmaceutical Guidelines.

Privacy Policy Disclaimer

Вам также может понравиться

- Validation Protocall For AutoclaveДокумент7 страницValidation Protocall For AutoclaveBalakrishnan S NadarОценок пока нет

- Autoclave ValidationДокумент7 страницAutoclave ValidationMohanad Alashkar100% (1)

- Autoclaves - Proper Operation and ValidationДокумент7 страницAutoclaves - Proper Operation and Validationgrace holmОценок пока нет

- 17 QuestionsДокумент34 страницы17 Questionsmuzammil21_ad100% (1)

- Autoclave Validation ProtocolДокумент4 страницыAutoclave Validation Protocolsalluraj100% (2)

- Autoclave Validation - What Is Really RequiredДокумент4 страницыAutoclave Validation - What Is Really Requiredwadhwa_shailОценок пока нет

- PQ Sterile TunnelДокумент10 страницPQ Sterile TunnelReza JafariОценок пока нет

- How To Validate An AutoclaveДокумент3 страницыHow To Validate An AutoclaveqhpuongОценок пока нет

- Autoclave Validation Protocol1Документ7 страницAutoclave Validation Protocol1inesdupres100% (2)

- Performance Qualification Protocol (PQP) For (Autoclave), Located inДокумент17 страницPerformance Qualification Protocol (PQP) For (Autoclave), Located inlouayОценок пока нет

- Dynamic Pass Box-PqДокумент5 страницDynamic Pass Box-PqjaimurugeshОценок пока нет

- Cleanroom Technology: Fundamentals of Design, Testing and OperationОт EverandCleanroom Technology: Fundamentals of Design, Testing and OperationОценок пока нет

- Pharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersОт EverandPharmaceutical Industry Documents: 90 Pharmaceutical Quality Assurance Interview Questions & AnswersОценок пока нет

- Autoclave Validation: Presented by Paul Yeatman Bsc. MicrobiologistДокумент17 страницAutoclave Validation: Presented by Paul Yeatman Bsc. Microbiologistzfo302Оценок пока нет

- The Study of The Design of Production Systems of Purified Water For The Pharmaceutical IndustryДокумент19 страницThe Study of The Design of Production Systems of Purified Water For The Pharmaceutical IndustryAndreaVargasОценок пока нет

- Lyophilization PDFДокумент6 страницLyophilization PDFrouss1906Оценок пока нет

- Autoclave Validation PresentationДокумент17 страницAutoclave Validation PresentationprakhyaatОценок пока нет

- SOP of SamplingДокумент8 страницSOP of SamplingaKureishiОценок пока нет

- AHU Val ProtocolДокумент53 страницыAHU Val ProtocolPalani Arumugam100% (1)

- Aseptic Process Validation (By Media Fill Trial)Документ19 страницAseptic Process Validation (By Media Fill Trial)ziaddd100% (2)

- Autoclave Validation MSPDAДокумент35 страницAutoclave Validation MSPDAYessine Mrabet100% (1)

- Aseptic FillingДокумент15 страницAseptic Fillingsushaantb400100% (2)

- Checklist of Validation of Dy Heat SterilizerДокумент8 страницChecklist of Validation of Dy Heat Sterilizersami2210Оценок пока нет

- Validation of Terminal Sterilization PDFДокумент14 страницValidation of Terminal Sterilization PDFjpabloqf100% (1)

- Sanitization of Pharmaceutical FacilitiesДокумент14 страницSanitization of Pharmaceutical FacilitiesTim Sandle100% (1)

- Protocol For Perfomance Qualification of Water For Injection Generation, Storage and Distribution System - Pharmaceutical GuidanceДокумент7 страницProtocol For Perfomance Qualification of Water For Injection Generation, Storage and Distribution System - Pharmaceutical Guidancedecio ventura rodrigues miraОценок пока нет

- BioburdenДокумент95 страницBioburdenTumma RamaraoОценок пока нет

- SOP Aseptic Filling PDFДокумент6 страницSOP Aseptic Filling PDFSandraОценок пока нет

- 1116 Usp 32 Microbiological Evaluation of Clean Rooms and Other Controlled EnvironmentsДокумент29 страниц1116 Usp 32 Microbiological Evaluation of Clean Rooms and Other Controlled EnvironmentsMauricio Dimaté CamargoОценок пока нет

- PQ WfiДокумент9 страницPQ Wfisami2210Оценок пока нет

- DI IQ OQ ReportДокумент11 страницDI IQ OQ ReportVemulapalli SaibabuОценок пока нет

- Validation VialWasher OQ NIHДокумент30 страницValidation VialWasher OQ NIHcongacon3aОценок пока нет

- IQOQ ProtocolДокумент4 страницыIQOQ ProtocolVijay RajaindranОценок пока нет

- Prot OQ HVACДокумент12 страницProt OQ HVACamrinОценок пока нет

- Pharmaceutical Cleaning A Comprehensive Approach - 0Документ15 страницPharmaceutical Cleaning A Comprehensive Approach - 0Mina Maher MikhailОценок пока нет

- Standard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemДокумент20 страницStandard Operating Procedure: Validation of Heating Ventilation and Air Conditioning (Hvac) SystemMaryanthony Namyalo100% (3)

- GSOP6.2.001 C 4/26/2011 76336 Quality Controlled Environments For ManufacturingДокумент18 страницGSOP6.2.001 C 4/26/2011 76336 Quality Controlled Environments For ManufacturingRickz2k8100% (1)

- 2-4 ProcessValidationДокумент37 страниц2-4 ProcessValidationlouish9175841100% (2)

- A Cleanroom Contamination Control SystemДокумент8 страницA Cleanroom Contamination Control SystemTorres XiaОценок пока нет

- Biocontamination Control for Pharmaceuticals and HealthcareОт EverandBiocontamination Control for Pharmaceuticals and HealthcareРейтинг: 5 из 5 звезд5/5 (1)

- F0 What It Means - How To Calculate It - How To Use Itv3 PDFДокумент34 страницыF0 What It Means - How To Calculate It - How To Use Itv3 PDFJosé Manuel Pais-Chanfrau100% (1)

- Validation For Automated Washing Systems: Aaron Mertens, Paul Lopolito, Olivier Van Houtte, and Marcel Dion, SterisДокумент2 страницыValidation For Automated Washing Systems: Aaron Mertens, Paul Lopolito, Olivier Van Houtte, and Marcel Dion, SterisVenkatraj CОценок пока нет

- Cleaning Validation (CV) Procedure and Protocol - Guideline SOPsДокумент30 страницCleaning Validation (CV) Procedure and Protocol - Guideline SOPsDeepakОценок пока нет

- Usp 1116 em For Aseptic ProcessingДокумент11 страницUsp 1116 em For Aseptic ProcessingKraken Ur100% (1)

- Fo ValueДокумент1 страницаFo Valuej.k.kumar100% (12)

- URS Lab Scale Counter Pressure Autoclave (Rev 1b)Документ12 страницURS Lab Scale Counter Pressure Autoclave (Rev 1b)puneetogupta100% (2)

- Establishing A Complete Set of Target, Alert, and Action Limits For Microbial Counts in Purified WaterДокумент8 страницEstablishing A Complete Set of Target, Alert, and Action Limits For Microbial Counts in Purified WaterSagi Nguyen100% (2)

- IQДокумент12 страницIQManish Shah0% (1)

- PQ - Autoclave (HPHV Steam Sterilizer)Документ26 страницPQ - Autoclave (HPHV Steam Sterilizer)hbhatt88100% (5)

- Qualification of Purified Water Systems PDFДокумент12 страницQualification of Purified Water Systems PDFMario Vazquez B100% (1)

- Clean Val Protocol 1Документ8 страницClean Val Protocol 1krishnavkkОценок пока нет

- SOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesДокумент2 страницыSOP For Testing of Compressed Air and Nitrogen Gas For Viable Count - Pharmaceutical GuidelinesAnonymous FZs3yBHh7Оценок пока нет

- Sampling Water Table ContentsДокумент2 страницыSampling Water Table Contentsraju1559405Оценок пока нет

- Temperature Mapping Study and QualificationДокумент19 страницTemperature Mapping Study and QualificationJewel Hernandez100% (2)

- The Qualification of Controlled Temperature ChambersДокумент1 страницаThe Qualification of Controlled Temperature ChambersNate Roman0% (1)

- Production of Plasma Proteins for Therapeutic UseОт EverandProduction of Plasma Proteins for Therapeutic UseРейтинг: 3 из 5 звезд3/5 (5)

- Usp 1116 Usp 36 NF31S1 PDFДокумент11 страницUsp 1116 Usp 36 NF31S1 PDFASHOK KUMAR LENKAОценок пока нет

- Ajit Kumar Rout: Curriculam VitaeДокумент3 страницыAjit Kumar Rout: Curriculam VitaeASHOK KUMAR LENKAОценок пока нет

- PLAN Vs ACHIEVEMENT (26.12.16) : Department: MicrobiologyДокумент1 страницаPLAN Vs ACHIEVEMENT (26.12.16) : Department: MicrobiologyASHOK KUMAR LENKAОценок пока нет

- 58 66 (Ajpr)Документ9 страниц58 66 (Ajpr)ASHOK KUMAR LENKAОценок пока нет

- 2500Документ4 страницы2500ASHOK KUMAR LENKAОценок пока нет

- Water System DrawingДокумент1 страницаWater System DrawingASHOK KUMAR LENKAОценок пока нет

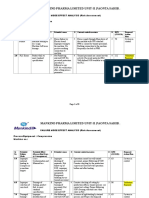

- Mankind Pharma Limited Unit-Ii, Paonta Sahib .: 1.0 PowerДокумент9 страницMankind Pharma Limited Unit-Ii, Paonta Sahib .: 1.0 PowerASHOK KUMAR LENKA100% (1)

- List of Instru - EquipДокумент2 страницыList of Instru - EquipASHOK KUMAR LENKAОценок пока нет

- Vap1.7 MSDSДокумент10 страницVap1.7 MSDSASHOK KUMAR LENKAОценок пока нет

- Communications Officer 61-11 - JDДокумент15 страницCommunications Officer 61-11 - JDASHOK KUMAR LENKAОценок пока нет

- Purchase Order PO1718N-00016Документ1 страницаPurchase Order PO1718N-00016ASHOK KUMAR LENKAОценок пока нет

- A4c - NAM Registration GuidelineДокумент92 страницыA4c - NAM Registration GuidelineASHOK KUMAR LENKAОценок пока нет

- 03-09-2017 Sorbitol Soluction 70%Документ1 страница03-09-2017 Sorbitol Soluction 70%ASHOK KUMAR LENKAОценок пока нет

- DayQuil Cold Flu Relief LiquiCaps Drug Facts-New1Документ1 страницаDayQuil Cold Flu Relief LiquiCaps Drug Facts-New1ASHOK KUMAR LENKAОценок пока нет

- 26.12.16 Revised Embossing Letter RequirementДокумент4 страницы26.12.16 Revised Embossing Letter RequirementASHOK KUMAR LENKAОценок пока нет

- Requirement of Embossing Letter Details For Blister Packing Change PartsДокумент2 страницыRequirement of Embossing Letter Details For Blister Packing Change PartsASHOK KUMAR LENKAОценок пока нет

- AutoCAD Tutorial 002 PDFДокумент54 страницыAutoCAD Tutorial 002 PDFskannanmecОценок пока нет

- XL - PC Report - 2,3,4,5,6 - Feb - 17Документ84 страницыXL - PC Report - 2,3,4,5,6 - Feb - 17ASHOK KUMAR LENKAОценок пока нет

- Suppliers ListДокумент3 страницыSuppliers ListASHOK KUMAR LENKAОценок пока нет

- Job Descriptions Roles and ResponsibilitiesДокумент7 страницJob Descriptions Roles and ResponsibilitiesASHOK KUMAR LENKAОценок пока нет

- Amit ResumeДокумент5 страницAmit ResumeASHOK KUMAR LENKAОценок пока нет

- List of Instru - Equip.Документ2 страницыList of Instru - Equip.ASHOK KUMAR LENKAОценок пока нет

- Stability: Basic CoarseДокумент79 страницStability: Basic CoarseASHOK KUMAR LENKAОценок пока нет

- 14MA GarciaДокумент10 страниц14MA GarciaMusab Hashmi100% (1)

- Procurement: Balance Capacity Least Count Type of Balance No. of Items Placement Digit of Display RequirementДокумент2 страницыProcurement: Balance Capacity Least Count Type of Balance No. of Items Placement Digit of Display RequirementASHOK KUMAR LENKAОценок пока нет

- Nicotinamide COAДокумент2 страницыNicotinamide COAASHOK KUMAR LENKAОценок пока нет

- Annexure 01 Job Responsbility FormДокумент1 страницаAnnexure 01 Job Responsbility FormASHOK KUMAR LENKAОценок пока нет

- Annexure 01 Job Responsbility FormДокумент1 страницаAnnexure 01 Job Responsbility FormASHOK KUMAR LENKAОценок пока нет

- Polysorb 85 - 70 - 00 RM COAДокумент2 страницыPolysorb 85 - 70 - 00 RM COAASHOK KUMAR LENKAОценок пока нет

- Peanut Oil RM COAДокумент2 страницыPeanut Oil RM COAASHOK KUMAR LENKAОценок пока нет

- Computer GraphicsДокумент14 страницComputer GraphicsNitish SandОценок пока нет

- Java LabДокумент67 страницJava Labشیخ صاحبОценок пока нет

- Driver PDFДокумент211 страницDriver PDFAjay DhamijaОценок пока нет

- AndroidДокумент61 страницаAndroidNamithaОценок пока нет

- Mark Scheme: June 2018Документ12 страницMark Scheme: June 2018BethanyОценок пока нет

- Choking vs. Clutch Performance: A Study of Sport Performance Under PressureДокумент19 страницChoking vs. Clutch Performance: A Study of Sport Performance Under Pressuremensrea0Оценок пока нет

- X L W C: Motor Shaft CapacitiveДокумент14 страницX L W C: Motor Shaft CapacitiveMuhammad Fauzan Ansari Bin AzizОценок пока нет

- Ambit ManiforlДокумент6 страницAmbit Maniforlmd_taheriОценок пока нет

- Machine Design-II Question BankДокумент9 страницMachine Design-II Question BankProf. Avinash MahaleОценок пока нет

- ESDS312, ESDS314 Data-Line Surge and ESD Protection Diode ArrayДокумент20 страницESDS312, ESDS314 Data-Line Surge and ESD Protection Diode ArrayBenОценок пока нет

- 13 38 Casing Preparation and Running ChecklistДокумент3 страницы13 38 Casing Preparation and Running ChecklistrajkumarfОценок пока нет

- Center of Biomedical Engineering Medical Radiation Physics (Phys-2223)Документ6 страницCenter of Biomedical Engineering Medical Radiation Physics (Phys-2223)Sador YonasОценок пока нет

- NUS Past Year PaperДокумент8 страницNUS Past Year PaperSteven KuaОценок пока нет

- Gajendra Singh (ONGC Training Report)Документ55 страницGajendra Singh (ONGC Training Report)Gajju12567% (6)

- Uncertainty in Tensile TestДокумент11 страницUncertainty in Tensile TestDavidAlejandroGaonaОценок пока нет

- Chemistry Leuco DyesДокумент312 страницChemistry Leuco Dyeskarel470% (1)

- SH 60 TD enДокумент98 страницSH 60 TD enCésar David Pedroza DíazОценок пока нет

- Implementation of Integrated OBD-II Connector Whith External NetworkДокумент7 страницImplementation of Integrated OBD-II Connector Whith External NetworkKelvin PárragaОценок пока нет

- API TutorialДокумент22 страницыAPI TutorialKomarudinОценок пока нет

- Software Quality EngineeringДокумент26 страницSoftware Quality EngineeringSYED SUMAIR AHMED JAFFRIОценок пока нет

- LiftCell User ManualДокумент4 страницыLiftCell User ManualEdini ZenaОценок пока нет

- Penlon-Paragon AV-S-Ventilator - User ManualДокумент72 страницыPenlon-Paragon AV-S-Ventilator - User Manualrkillian44Оценок пока нет

- ADAT Optical Audio Data Generator and Encoder V1401Документ8 страницADAT Optical Audio Data Generator and Encoder V1401mylitalindaОценок пока нет

- Communication Engineering 2 MarksДокумент38 страницCommunication Engineering 2 MarksNandhini100% (2)

- Application Note: Vishay General SemiconductorДокумент4 страницыApplication Note: Vishay General SemiconductorMamoon AlrimawiОценок пока нет

- 03b.sch B Ded Ugcrp1 01Документ181 страница03b.sch B Ded Ugcrp1 01RANA. ADNANОценок пока нет

- Practical Exercise 02Документ17 страницPractical Exercise 02FeRro ReniОценок пока нет

- Digital Microelectronic Digital Microelectronic Circuits Circuits ( (Документ24 страницыDigital Microelectronic Digital Microelectronic Circuits Circuits ( (Gowtham HariОценок пока нет

- Metron PS-410 Patient SimulatorДокумент2 страницыMetron PS-410 Patient SimulatorismailshajjiОценок пока нет