Академический Документы

Профессиональный Документы

Культура Документы

Safelok Product Brochure

Загружено:

Sabikun NaharОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Safelok Product Brochure

Загружено:

Sabikun NaharАвторское право:

Доступные форматы

The safest fitting

Philmac Pty Ltd

47-59 Deeds Road

on the planet.

North Plympton

South Australia

AUSTRALIA 5037

Customer Service Australia

Telephone 1800 755 899

Facsimile 1800 244 688

Customer Service International

Telephone +61 (8) 8300 9217

wdm_15835

www.philmac.com.au

The connection you can trust.

INTRODUCTION Providing a safe workplace is the obligation of every employer, no matter the industry. There are

fewer industries on the planet that are as demanding on pipelines as the mining industry, and

this can make providing a safe environment so much harder.

Recognising the tough conditions in the mining industry, Philmac has developed and is proud to

introduce a truly unique compression tting for the connection of polyethylene pipes Safelok.

Made from a special formulation of polypropylene for unrivalled strength and performance, and

with its distinct orange nuts for extra-high visibility, Safelok truly is the safest compression tting

on the planet.

BENEFITS HOW IT WORKS

Safety Impact Resistance: Safelok ttings are Chemical Resistance: Standard FULLY OPEN

Air Line Safety: made from a high grade of polypropylene compression ttings are supplied with Fitting is pre-assembled ready to use in the

Philmac strongly recommends that ttings to provide signicant resistance to impact. nitrile seals which fail when they come open position with 3 threads showing.

should never be disconnected on a live In mining conditions risk of impact is always into contact with acids. Safelok ttings

air line. However in the event that work high so the tting must be tough and are supplied with EPDM seals which

commences on an air line before the air durable to provide a long life. At the same means that the ttings can withstand a

supply is switched off, the use of Philmac time if in the unlikely circumstances that wide range of chemicals without having

Safelok ttings will ensure that a warning the material should fail due to impact, it to switch components.

is given to the user that the line is live. will result in a ductile rather than a brittle

Designed to minimise pipe twist: The

The user can then switch off the air supply failure. This means that there is no risk of

tting has been designed to minimise pipe

and continue working on the line in a safe injury through a tting explosion when

twist as the nut is tightened. Maximum pipe

manner. used in a compressed air application. Clearance between the pipe and tting

twist is approximately three quarters of a

When the nut is tightened on a Safelok Fast and easy installation turn compared to one and a half turns with allows for easy insertion of the pipe.

tting, not only is the end of the pipe Slide & Tighten: No pipe preparation many other ttings. Pipe twist can impact

secured, but it also fully compresses the is needed and no force is required to on not only the connection you have just Split ring which is in the relaxed position.

o-ring and creates a seal. This means that push the pipe past the seal, so installation made but also on the connection at the

if a user mistakenly works on a live air line couldnt be faster or easier. Simply insert other end of the line. O-ring which is in the relaxed position.

and starts to loosen the nut on a Safelok the pipe into the tting until the rst point The pipe sits against the tapered wedges

tting, there will be a loud release of air at of resistance is felt and then tighten the High performance which minimise pipe rotation.

the point when two threads are exposed. nut until it butts against the ange of the

Made from advanced thermoplastic

Importantly, the grip will still be retained on tting body. This means that even making

materials: Safelok is manufactured from

the pipe so the user can take action re- a 110mm joint with pipe hanging from the FULLY CLOSED

lightweight, high performance thermoplastic

tighten the nut and switch off the air supply tunnel roof becomes a one man job.

materials with outstanding impact, chemical,

preventing an extremely dangerous

Complete security corrosion and UV resistance.

situation from occurring.

Visual Stop: The ange on the body of Rated to 1600 kpa: Safelok ttings are

Colour: Safelok ttings are supplied the Safelok tting provides a visual stop pressure rated to 1600 kpa (PN16)

with orange coloured nuts. In the dark to indicate when the nut is fully tightened. across all sizes.

conditions that exist underground they This removes any uncertainty from the

stand out when light is shone on them installation process. 50 year+ design life: Built to withstand

reducing the chance of accidental collision the toughest conditions to ensure longevity

and making identication and therefore No loose components: Although and durability, Safelok ttings have a Split ring bites into the pipe providing

maintenance easier. dis-assembly of the tting is not required 50 year+ design life. end load resistance.

for installation, if the nut is removed

there is no danger of losing components Complete coverage

Positive internal stop when nut reaches

as they are all retained within the nut. Full range: The Safelok range is ange of the body.

Losing components in the dark becomes comprehensive; straight and reducing

a thing of the past. couplers, tees, elbows, threaded connectors, Nut, split ring and then spacer has forced

end caps, ange adaptors and shouldered o-ring into the compression chamber

and then fully compressed it. O-ring

adaptors ranging from 63mm to 110mm. compression is achieved by exploiting the

mechanical advantage of the nut thread.

High degree of o-ring compression

provides more tolerance to scuffed,

scratched or oval pipe.

Вам также может понравиться

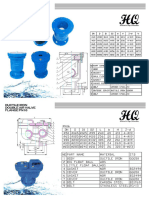

- Air Vent HQДокумент1 страницаAir Vent HQSabikun NaharОценок пока нет

- Head Loss ValveДокумент2 страницыHead Loss ValveSabikun NaharОценок пока нет

- Flange Adaptor & Coupling With Grip For Hdpe Pipe-1Документ3 страницыFlange Adaptor & Coupling With Grip For Hdpe Pipe-1Sabikun NaharОценок пока нет

- 851 41 001 - OptДокумент3 страницы851 41 001 - OptSabikun NaharОценок пока нет

- Faq No5 Galling PDFДокумент2 страницыFaq No5 Galling PDFSabikun NaharОценок пока нет

- 01 Water Catalogue 2013 EN PDFДокумент217 страниц01 Water Catalogue 2013 EN PDFSabikun NaharОценок пока нет

- Torque-Tension Chart For B7Документ1 страницаTorque-Tension Chart For B7Ramón C. Silva H.Оценок пока нет

- Faq No5 Galling PDFДокумент2 страницыFaq No5 Galling PDFSabikun NaharОценок пока нет

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Unit 1 2marksДокумент5 страницUnit 1 2marksLokesh SrmОценок пока нет

- Area Access Manager (Browser-Based Client) User GuideДокумент22 страницыArea Access Manager (Browser-Based Client) User GuideKatherineОценок пока нет

- ITSCM Mindmap v4Документ1 страницаITSCM Mindmap v4Paul James BirchallОценок пока нет

- Overall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarДокумент2 страницыOverall Dimensions and Mounting: Solar Water Pump Controller Mu - G3 Solar Mu - G5 Solar Mu - G7.5 Solar Mu - G10 SolarVishak ThebossОценок пока нет

- Philippine Architecture, Film Industry EvolutionДокумент4 страницыPhilippine Architecture, Film Industry EvolutionCharly Mint Atamosa IsraelОценок пока нет

- Expert Business Analyst Darryl Cropper Seeks New OpportunityДокумент8 страницExpert Business Analyst Darryl Cropper Seeks New OpportunityRajan GuptaОценок пока нет

- Calc Fields Networking and Sharing: Welcome ToДокумент42 страницыCalc Fields Networking and Sharing: Welcome Toprashant adhikariОценок пока нет

- Milwaukee 4203 838a PB CatalogaciónДокумент2 страницыMilwaukee 4203 838a PB CatalogaciónJuan carlosОценок пока нет

- Compilation of CasesДокумент121 страницаCompilation of CasesMabelle ArellanoОценок пока нет

- Entrepreneurship WholeДокумент20 страницEntrepreneurship WholeKrizztian SiuaganОценок пока нет

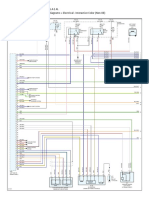

- Engine Controls (Powertrain Management) - ALLDATA RepairДокумент4 страницыEngine Controls (Powertrain Management) - ALLDATA Repairmemo velascoОценок пока нет

- AKTA MERGER (FINAL) - MND 05 07 2020 FNLДокумент19 страницAKTA MERGER (FINAL) - MND 05 07 2020 FNLNicoleОценок пока нет

- Spouses Mariano Z. Velarde and Avelina D. VELARDE, Petitioners, vs. COURT OF Appeals, David A. RAYMUNDO and GEORGE RAYMUNDO, RespondentsДокумент11 страницSpouses Mariano Z. Velarde and Avelina D. VELARDE, Petitioners, vs. COURT OF Appeals, David A. RAYMUNDO and GEORGE RAYMUNDO, RespondentsRobyn JonesОценок пока нет

- CompactLogix 5480 Controller Sales GuideДокумент2 страницыCompactLogix 5480 Controller Sales GuideMora ArthaОценок пока нет

- Banas Dairy ETP Training ReportДокумент38 страницBanas Dairy ETP Training ReportEagle eye0% (2)

- Fabric Bursting StrengthДокумент14 страницFabric Bursting StrengthQaiseriqball100% (5)

- CSEC IT Fundamentals of Hardware and SoftwareДокумент2 страницыCSEC IT Fundamentals of Hardware and SoftwareR.D. Khan100% (1)

- CST Jabber 11.0 Lab GuideДокумент257 страницCST Jabber 11.0 Lab GuideHải Nguyễn ThanhОценок пока нет

- Sav 5446Документ21 страницаSav 5446Michael100% (2)

- An4856 Stevalisa172v2 2 KW Fully Digital Ac DC Power Supply Dsmps Evaluation Board StmicroelectronicsДокумент74 страницыAn4856 Stevalisa172v2 2 KW Fully Digital Ac DC Power Supply Dsmps Evaluation Board StmicroelectronicsStefano SalaОценок пока нет

- Cars Should Be BannedДокумент3 страницыCars Should Be BannedIrwanОценок пока нет

- 9IMJan 4477 1Документ9 страниц9IMJan 4477 1Upasana PadhiОценок пока нет

- WitepsolДокумент21 страницаWitepsolAnastasius HendrianОценок пока нет

- Organisation Study Report On Star PVC PipesДокумент16 страницOrganisation Study Report On Star PVC PipesViswa Keerthi100% (1)

- ANDRITZ Company Presentation eДокумент6 страницANDRITZ Company Presentation eAnonymous OuY6oAMggxОценок пока нет

- EU Letter To Liz Truss 2016Документ2 страницыEU Letter To Liz Truss 2016MadeleineОценок пока нет

- Q&A Session on Obligations and ContractsДокумент15 страницQ&A Session on Obligations and ContractsAnselmo Rodiel IVОценок пока нет

- Analytical DataДокумент176 страницAnalytical DataAsep KusnaliОценок пока нет

- Arizona Supreme CT Order Dismisses Special ActionДокумент3 страницыArizona Supreme CT Order Dismisses Special Actionpaul weichОценок пока нет

- Haryana Retial GarmentsДокумент8 страницHaryana Retial Garmentssudesh.samastОценок пока нет