Академический Документы

Профессиональный Документы

Культура Документы

13 03 Biodiesel PDF

Загружено:

anak_kambingОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

13 03 Biodiesel PDF

Загружено:

anak_kambingАвторское право:

Доступные форматы

Biotechnol. J. 2011, 6, 277285 DOI 10.1002/biot.201000117 www.biotechnology-journal.

com

Review

Prospects for microbial biodiesel production

Shuobo Shi, Juan Octavio Valle-Rodrguez, Verena Siewers and Jens Nielsen

Department of Chemical and Biological Engineering, Chalmers University of Technology, Gothenburg, Sweden

As the demand for biofuels for transportation is increasing, it is necessary to develop technologies Received 21 November 2010

that will allow for low-cost production of biodiesel. Conventional biodiesel is mainly produced Revised 3 January 2011

from vegetable oil by chemical transesterification. This production, however, has relatively low Accepted 14 January 2011

land-yield and is competing for agricultural land that can be used for food production. Therefore,

there is an increasing interest in developing microbial fermentation processes for production of

biodiesel as this will allow for the use of a wide range of raw-materials, including sugar cane, corn,

and biomass. Production of biodiesel by microbial fermentation can be divided into two different

approaches, (1) indirect biodiesel production from oleaginous microbes by in vitro transesterifi-

cation, and (2) direct biodiesel production from redesigned cell factories. This work reviews both

microbial approaches for renewable biodiesel production and evaluates the existing challenges in

these two strategies.

Keywords: Biofuel Fatty acids Metabolic engineering Microbial biodiesel Systems biology

1 Introduction current energy crisis [1, 5]. Currently, the most

widely used biofuels are biodiesel and bioethanol.

Due to population growth and industrialization, the However, bioethanol is not viewed as the ideal bio-

demand for energy has increased rapidly in recent fuel of the future because of its low energy density

years, and the world energy consumption is pro- and incompatibility with the existing fuel infra-

jected to increase by 49% from 2007 to 2035 structure [6, 7]. There is therefore much interest to

(http://www.eia.doe.gov/oiaf/ieo/highlights.html). introduce other biofuels, e.g. butanol [7, 8], that can

However, the use of fossil fuels, currently the pri- be easier blended into gasoline, are non-corrosive

mary energy source, is now widely recognized to be and hence can be implemented in the current fuel

unsustainable and fossil fuels are likely to be ex- infrastructure. There is also much interest in

hausted in the foreseeable future [1]. Moreover, biodiesel (fatty acid esters), which fits in easily into

fossil fuel emissions are believed to be a major con- the existing infrastructure and has been thorough-

tributor to global warming [2]. Consequently, ly tested as an alternative fuel on the market. As a

worldwide concerns have been raised to search for fuel, biodiesel is similar to petro-diesel in combus-

sustainable, alternative, and renewable fuels that tion properties, allowing it to work well in conven-

have a lower environmental footprint and that can tional diesel engines and making it compatible with

satisfy the energy needs in the future [1, 3, 4]. the existing fuel infrastructure [9]. Besides, bio-

The development of different biofuels as alter- diesel is better than petro-diesel in several charac-

native, sustainable fuels is expected to relieve the teristics, such as environmental friendliness, re-

newability, reduced emission, higher combustion

efficiency, improved lubricity, higher safety, etc.

Correspondence: Professor Jens Nielsen, Department of Chemical and [10].

Biological Engineering, Chalmers University of Technology, Kemivgen 10,

In light of these demands, the total world

SE-41296, Gothenburg, Sweden

E-mail: nielsenj@chalmers.se

biodiesel production has been constantly increas-

Fax: + 46-31-772-3801 ing, with a 16-fold increase over the past 10 years,

and was estimated to amount to about 4 billion gal-

Abbreviations: FAEE, fatty acid ethyl esters; TAG, triacylglycerol lons in 2009, mainly produced in the European

2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim 277

Biotechnology Biotechnol. J. 2011, 6, 277285

Journal

Figure 1. Biodiesel synthesis by (A) chemi-

cal or enzymatic transesterification reaction

using oils from plants; (B) chemical or en-

zymatic transesterification reaction using

oils from oleaginous microorganisms;

(C) direct synthesis using redesigned cell

factories; (D) transesterification reaction in-

volved in processing module of (A) and (B);

(E) FAEE (biodiesel) production pathway

involved in processing module of (C).

Union and the USA [11]. Currently, biodiesel is microbes could be used to produce fatty esters

mainly produced from plant oils by transesterifica- (biodiesel) directly from simple sugars, avoiding

tion with an alcohol (methanol or ethanol) in the using costly feedstocks [1719].

presence of a base, an acid or an enzyme catalyst Production of biodiesel using microorganisms

(Figs. 1A and 1D). Vegetable oils are mainly com- has been considered as a promising alternative so-

prised of triacylglycerol (TAG), i.e. three fatty acid lution for biodiesel production. First, it is well-

chains connected to a glycerol backbone. For cost known that many microbes, such as microalgae,

reasons methanol is the reagent most frequently bacteria, fungi or yeast, can accumulate intracellu-

used for transesterification in a molar ratio of 1:1. lar lipids (mainly TAG) to a large percent of their

The plant oils account for a large percent of the biomass (Table 1). These oils derived from oleagi-

overall production cost [12]. Currently, the high nous microbes could represent a promising raw

cost and limited availability of plant oils has be- material for biodiesel production through transes-

come a rising problem for large-scale commercial terification in line with the plant-based process

viability of biodiesel production, and different ways (Figs. 1B and 1D) [14, 17, 20]. In particular, using

have been explored to address this problem. For fast growing microbes it is possible to use a wider

example, microbial oils, genetically modified crops, variety of feedstocks such as sugar cane that has a

soapstocks, used cooking oil and animal fat could substantially larger yield per hectare compared

be explored as alternative feedstocks to lower the with rapeseed, and hence allows for biodiesel pro-

cost of biodiesel [1318]. Additionally, engineered duction with less use of arable land.

278 2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Biotechnol. J. 2011, 6, 277285 www.biotechnology-journal.com

Table 1. Lipid content of some oleaginous microorganisms On the other hand, with the help of metabolic

Microorganism Lipid content Reference engineering and synthetic biology, interest has

(% dry wt) grown to engineer well-studied microbes such as

Escherichia coli and Saccharomyces cerevisiae into

Microalgae biodiesel cell factories by introducing an ester syn-

Botryococcus braunii 2575 [23] thesizing pathway, which could lead to direct pro-

Chlorella emersonii 2563 [24] duction of fatty acid ethyl esters (FAEEs) by direct-

Dunaliella tertiolecta 1671 [25]

ly esterifying ethanol with the acyl moieties of the

Monodus subterraneus 39.3 [26]

CoA thioesters of fatty acids (Figs. 1C, 1E and Fig. 2)

Nannochloropsis sp. 3168 [27]

[19, 21, 22]. These engineered cell factories could

Neochloris oleoabundans 2965 [25]

produce biodiesel directly from cheap and widely

Nitzschia sp. 4547 [27]

Phaeodactylum tricornutum 1857 [25]

available sugars such as glucose or abundant lig-

Parietochloris incisa >35 [28] nocellulosic biomass circumventing the need for a

Schizochytrium sp. 5077 [27] transesterification process, which requires com-

plex pretreatment involving isolation and purifica-

Bacteria tion. Clearly, including the entire transformation

Arthrobacter sp. >40 [29] process in one step will be the most convenient and

Acinetobacter calcoaceticus 2738 [29] cost-effective way for large-scale production of

Bacillus alcalophilus 1824 [14] biodiesel.

Gordonia sp. 72 [30]

In the following, we will review the two differ-

Rhodococcus opacus 2425 [14]

ent approaches for production of biodiesel by mi-

Fungi crobial fermentation.

Aspergillus oryzae 57 [14]

Cunninghamella echinulata 35 [31]

Humicola lanuginosa 75 [14] 2 Indirect biodiesel production

Mortierella isabellina 53.2 [32] from oleaginous microbes

Mucor mucedo 62 [33]

Yeasts Oleaginous microorganisms could represent new

Candida curvata 58 [14] lipid feedstocks for biodiesel production. The oils

Cryptococcus albidus 65 [14] can be extracted from fast growing microorganisms

Cryptococcus curvatus 58 [34] and transesterified with short-chain alcohols,

Lipomyces starkeyi 68 [35] yielding high quality biodiesel esters that comply

Rhodosporidium toruloides 58 [32] with the currently existing standards [36, 37]. Be-

sides, the wide array of microbial lipids makes it

Figure 2. Overview of engi-

neered pathways for produc-

tion of biodiesel (fatty acid

ethyl ester) from hemicellu-

loses or glucose in recombi-

nant E. coli discussed in this

review. Over-expressed genes

or operons are indicated by

thick arrows; deleted or atten-

uated genes are indicated

by crosses; heterologous

pathways are highlighted in

dashed lines; introduced het-

erologous genes are xyn10B

(C. stercorarium), xsa (B. ova-

tus), pdc and adhB (Z. mobi-

lis), atfA (A. baylyi), and FAA2

(S. cerevisiae).

2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim 279

Biotechnology Biotechnol. J. 2011, 6, 277285

Journal

feasible to vary the biodiesel property so that it ex- density cultures, which implies big amounts of wa-

hibits a combination of improved fuel properties ter required, increasing the production costs [27].

such as higher cetane number and heating value

and lower viscosity [38, 39]. Added to these advan- 2.2 Bacterial biodiesel production

tages, using oleaginous microbes for the production

of biodiesel will have less consequences on the Bacteria can also be used as source for lipids pro-

production of food or products derived from ter- duction to finally obtain the esters that can consti-

restrial crops. tute biodiesel.

Most bacteria produce mainly complex lipids,

2.1 Microalgae for biodiesel production only few species can produce lipids that can be

used as precursors of biodiesel [47]. The main

Microalgae are photoautotrophic-microorganisms source of lipids in these specific bacteria are TAGs,

that can convert carbon dioxide directly to lipids of which only few genera of the actinomycetes class

that can further be used for biofuel production, can accumulate to high levels, as in the case of

particularly for biodiesel [1, 23, 40, 41], and its bio- Acinetobacter [48], Mycobacterium [49] and Strepto-

mass can be fermented to produce other fuels [1, myces [50].These TAGs accumulated inside the cell

4143]. especially when bacteria are grown on simple car-

Microalgae seem to be one of the most promis- bon sources under stress conditions [29]. It has

ing feedstock for providing large amounts of lipids been found that strains of Rhodococcus opacus can

that can be further directed to synthesize renew- accumulate up to 87% (by dry weight) [51]; the TAG

able biodiesel to substitute fossil diesel, due to a bodies of these bacteria are mainly composed of

very high oil yield and a very low land area needed TAGs (87%), diacylglycerols (~5%), free fatty acids

for its cultivation (3.4 times less land required in (~5%), phospholipids (1.2%) and proteins (0.8%)

comparison with corn growing). Furthermore, they [52]. The TAGs were mainly formed by hexade-

have a higher content of oil than macroalgae [44], canoic acid (16:0) and octadecenoic acid (18:1) [53].

they grow very quickly and some species are very Other bacteria genera, such as Gordonia sp. can ac-

rich in oil. They can double their biomass in 3.5 h cumulate up to 72% TAG with a predominant com-

during the exponential growth phase in batch cul- position of docosanoic acid (22:0) and hexanoic

tures, and their common doubling time is around acid (6:0) [30]. Genera such as Streptomyces syn-

24 h. thesize TAGs, but only in the absence of a nitrogen

The oil content of microalgae usually ranges be- source [50].

tween 20 to 60% by weight of the dry biomass With the advance of systems biology and meta-

(Table 1); and in some genera such as Botryococcus, bolic engineering, there is the possibility to engi-

Nannochloropsis and Schizochytrium it can be close neer common production hosts such as E. coli to

to 80%. Microalgae can produce many different greatly increase their fatty acids production [54].

kinds of lipids, hydrocarbons and complex oils, de- Metabolically modified E. coli can produce fatty

pending on the species [45]. Lipids with long car- acids at 2.5 g/L by knocking out the fadD gene

bon chains are satisfactory for the biodiesel pro- (encoding the fatty acyl-CoA synthetase) and by

duction. The oils produced in microalgae are main- overexpressing acetyl-CoA carboxylase and

ly unsaturated fatty acids: palmitoleic (16:1), oleic thioesterase. This effort opens the door to harness-

(18:1), linoleic (18:2) and linolenic (18:3) acids. Sat- ing multiple metabolic tools in constructing an ef-

urated fatty acids such as palmitic (16:0) and stearic ficient fatty acids-producing cell from a non-

(18:0) acids are also present in low concentration oleaginous microbe. Although bacteria accumulate

[14]. In certain species, polyunsaturated fatty acids low concentrations of lipids (compared to microal-

can be synthesized [46], but biodiesel produced gae, for example), they have other advantages re-

from these compounds oxidizes faster than petro- lated to biodiesel production: they possess a high-

leum diesel, forming sediments that affect the com- er specific growth rate (usually reaching high bio-

bustion engine. The faster the microalga grows and mass levels in 1224 h) and they are easy to culti-

the higher its oil content, the higher the biodiesel vate.

productivity will be.

Microalgae can contain high amounts of lipids, 2.3 Fungi for biodiesel production

but compared to other oleaginous microorganisms

they require large areas of land due to their photo- Fungi can also be utilized as a lipid source for bio-

synthetic activity [14]. Besides this, due to their diesel production. Some species can produce high

sunlight requirement, the daily and seasonal vari- concentrations of lipids such as Humicola lanugi-

ations affect their growth. Moreover, they need low nosa (75%) [14]. In other fungi different levels of

280 2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Biotechnol. J. 2011, 6, 277285 www.biotechnology-journal.com

lipids can be obtained: it has been reported that As- lipids were mainly oleic, palmitic, stearic and

pergillus oryzae can accumulate lipids to up to 57% linoleic acids [58].

of its cell dry weight [14], and in Mucor rouxii a lipid Lipids produced from yeasts can be converted

content of 30% was found, among these lipids the into esters to constitute biodiesel. In the case of Tri-

one that was present at highest concentration was chosporon fermentans, a high methyl esters yield

linolenic acid (317%) [55]. (92%) was obtained by transesterification of fatty

Biodiesel esters can be produced from the fila- acids extracted from cells [59]. A direct transesteri-

mentous fungus Mucor circinelloides, from which a fication process from yeast biomass could be

lipid content of 19.9 % (by wt) was reported using achieved but low yields (less than 20%) have been

for extraction a solvent mixture of chloroform and found. In a particular study, methanolysis of L.

methanol (at a 2:1 ratio). There were two proce- starkeyi biomass was performed under mediation of

dures followed for the formation of esters: trans- alkali metal hydroxides under heating at 70C for

formation of extracted lipids and direct transfor- 24 h [32]. Another option that can be applied is uti-

mation of dry fungal biomass. The transesterifica- lizing different mineral acids (H2SO4, HCl and

tion reaction was realized during 8 h at 65C in the H3PO4) as catalysts. The reaction was started mix-

presence of an acid catalyst (in this case, BF3, ing powdered cells with a methanolic solution of a

H2SO4 or HCl). Surprisingly, the direct method pro- mineral acid and heated at 70C. The yields of

duced fatty acid methyl esters at a higher yield and methyl esters were 60 and 53%, for H2SO4 at 0.1 M

purity (>99% for all catalysts) than the one using and HCl at 0.2 M, respectively, in a reaction with a

the two steps process (91.498.0%). These esters biomass: methanol ratio of 1:20 (w/v) for 16 h [32].

produced can be used directly as biodiesel [56]. The factors influencing this esterification yield

Among fungi, oleaginous yeasts are distin- are acid catalyst selected and its concentration,

guished by their capacity to accumulate high con- time course of the reaction, temperature and bio-

centrations of lipids (over 20% of their biomass). mass:methanol ratio.

Species such as Rhodosporidium toruloides and As mentioned above, in order to process the

Lipomyces starkeyi have been found to accumulate transesterification reaction with the oils from

lipids at around 60 and 70% of dry cell weight oleaginous microbial cells, several unit operations

(Table 1); these lipids are mainly constituted by should be performed. Conventionally, the transes-

TAGs [57]. Besides conventional batch culture, oth- terification is performed with the alcohol (methan-

er fermentative systems applied to Rhodosporidium ol) and triacylglycerides extracted from dried mi-

toruloides can achieve a higher productivity of lipid crobial biomass, but a novel single-step method has

synthesis (0.54 g/L/h in fed-batch culture). These been developed that transesterifies lipids by direct

Figure 3. Process followed to synthesize

biodiesel esters from oleaginous mi-

croorganisms by conventional trans-

esterification with extracted lipids from

cells or by direct transesterification of

the microbial biomass obtained.

2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim 281

Biotechnology Biotechnol. J. 2011, 6, 277285

Journal

alcoholysis of dried microbial biomass, without though the metabolism needs to be further opti-

previous lipid extraction (Fig. 3) [25, 32]. However, mized.

even the single-step method requires an addition- Furthermore, Steen et al. [19] harnessed the ex-

al expense for the pretreatment of biomass. It tensively investigated fatty acid metabolism in bac-

would further reduce the cost of the inexpensive teria to engineer Escherichia coli to produce

oleaginous microbe feedstock, if methods without biodiesel directly from simple sugars. The flux

drying of the biomass could be developed. The cur- through the fatty acid pathway was increased to

rent catalysts used for transesterification are improve production of free fatty acids and acyl-

chemical catalysts, due to their high conversion ef- CoAs by eliminating -oxidation, by overexpress-

ficiency at low costs, but they involve complex op- ing thioesterases and acyl-CoA ligases. Biodiesel

erations such as treatment of contaminated water was produced by expressing a wax ester synthase

and recovery of biodiesel esters. Recently, biocat- and ethanol-producing genes (Fig. 2). In the pres-

alytic transesterification techniques using lipases ence of glucose, the yield of produced biodiesel

have been presented as a less energy intensive and could reach 674 mg/L. By further introducing xy-

environmentally friendly method, and with yields lanases, the engineered E. coli could produce

exceeding 90% [60]. Biocatalytic transesterification biodiesel to 11.6 mg/L directly from hemicellulose,

has therefore received much attention, especially a major component of plant-derived biomass, with

in the area of immobilization [61] and whole-cell 2% xylan addition.

biocatalysis [62, 63]. Production of biodiesel directly from micro-

organisms has also been reported in recent patent

applications [6567], all owned by LS9 Inc. (Fig. 2).

3 Direct biodiesel production Briefly, the metabolically engineered E. coli strain

from engineered cell factories was manipulated to be able to produce biodiesel

and fatty acid derivatives thereof (short and long

Many research efforts have focused on direct pro- chain alcohols, hydrocarbons, fatty alcohols, waxes,

duction of biodiesel through microbial conversion etc). The fadE gene was first disrupted in E. coli,

from abundant and cost-effective renewable re- which was then not capable of degrading fatty acids

sources without any additional modifications, and and fatty acyl-CoAs. Then, the enforced fatty acid

this became feasible with the finding of a novel bi- biosynthesizing ability and fatty acid derivatives

functional wax ester synthase/acyl-CoA:diacyl- production ability were accomplished through the

glycerol acyltransferase (WS/DGAT), which could overexpression of several genes encoding enzymes

synthesize wax esters from alcohols and fatty acid like thioesterase (tesA), acyl-CoA synthase (fadD),

coenzyme A thioesters (acyl-CoA) [64]. Biodiesel acetyl-CoA carboxylase (accABCD), fatty acid syn-

produced in this process are primarily FAEEs, thase (fabH, fabD, fabG, fabF), acyl carrier protein

which have better performances than fatty acid (acpP), wax synthase (atfA), alcohol acyltrans-

methyl esters (FAMEs). Furthermore, methanol ferase, alcohol dehydrogenase, and different kinds

used for transesterification is largely derived from of fatty alcohol forming acyl-CoA reductases. To

non-renewable natural gas and is toxic and haz- further enhance fatty acids production, genes

ardous (Figs. 1A and 1B), and there are therefore aceEF had been suggested to express in a produc-

many benefits for producing biodiesel (FAEEs) di- tion host, accompanied by attenuating glycerol-3-

rectly using a redesigned microbial cell factory phosphate dehydrogenase (gpsA), lactate dehydro-

(Fig. 1C). Currently, the two model organisms, E. coli genase (ldhA), pyruvate formate lyase I (pflB),

and S. cerevisiae, are being used to develop direct phosphate acetyltransferase (pta), pyruvate oxi-

biodiesel production. dase (poxB), acetate kinase (ackA), and glycerol-3-

The idea of wax ester production was first ap- phosphate O-acyltransferase (plsB). Later, in US

plied effectively by Kalscheuer et al. [21].They suc- patent publication 2010/0071259 inventors from

cessfully expressed the WS/DGAT gene (atfA) from the same company showed that by adding a mix-

the Acinetobacter baylyi strain ADP1 in combina- ture of at least two different alcohols to a medium

tion with the ethanol production genes (pdc and containing the engineered fatty esters-producing

adhB) from Zymomonas mobilis in E. coli and used E. coli strain, at least two different fatty esters could

the recombinant E. coli for biodiesel production be produced. In particular, by selecting various

(Fig. 2). A final FAEE content of 1.28 g/L was types and/or amounts of alcohols, it was possible to

achieved after 72 h of fermentation supplemented produce a desired fatty ester composition, i.e. de-

with exogenous fatty acids. This research is an ex- signed biodiesel, which would possess improved

cellent demonstration of the feasibility for direct fuel properties, such as desired cloud point, cetane

production of fatty acid esters by microbes al- number, viscosity and lubricity [68].

282 2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Biotechnol. J. 2011, 6, 277285 www.biotechnology-journal.com

On the one hand, it should be noticed that cost-effective, sustainable alternative. Press re-

ethanol, one of the two substrates for biodiesel, is leases from several different companies indicate

not naturally produced by E. coli. Establishment of that there are several microbial biodiesel projects

heterologous ethanol biosynthesis is a prerequisite ongoing, e.g. at ExxonMobil Corp., Dow Chemical

for an E. coli biodiesel producer. In this regard, a far Co., LS9 Inc., Amyris Biotechnologies Inc., Codexis

better choice of microbial cell factory for industrial Inc, BP and Martek Biosciences Corp.

production of biodiesel would be the yeast S. cere- The application of microorganisms for efficient

visiae, which is a well-known organism used in the production of biodiesel will require a significant

production of ethanol through the fermentation of de-regulation of lipid metabolism, which repre-

glucose [69]. sents a big challenge due to its complexity and the

Using the same principle as for E. coli, it has limited knowledge of the field [19, 71, 72]. Recent

been reported that novel lipids, including FAEEs progress in synthetic biology and systems biology

and fatty acid isoamyl esters (FAIEs), could be pro- has accelerated the ability to analyze and imple-

duced in S. cerevisiae H1246 with oleic acid addition ment metabolic pathways with unprecedented pre-

by expressing the A. baylyi bifunctional WS/DGAT cision [7375], and provide useful strategies for

enzyme [70]. This study indicated that the non- system-level metabolic engineering by creating

specificity of WS/DGAT from A. calcoaceticus ADP1 and modifying genetic systems [76, 77]. More im-

could lead to the biosynthesis of a large variety of portantly, in silico metabolic models enabled the

lipids in vivo in a eukaryotic expression host. systematic elucidation and design of biology sys-

A recent patent application, namely US patent tems with desired and more predictable properties

2009/0117629 by Schmidt-Dannert and Holtzapple [7678], e.g. enhanced lipid accumulation, or engi-

[21] describes a method for the production of neered pathways for de novo biodiesel production

biodiesel and wax esters by heterologous expres- in vivo, making microorganism an ideal platform

sion of wax synthase (WS2) from Marinobacter hy- for future biodiesel production.

drocarbonoclasticus in S. cerevisiae by exogenous

supply of fatty acids. The WS2 from M. hydrocar-

bonoclasticus performs a higher wax synthase ac- We acknowledge financial support from the Chal-

tivity for ethanol compared the A. baylyi bifunc- mers Foundation, Knut and Alice Wallenberg Foun-

tional WS/DGAT enzyme. Moreover, unlike the A. dation, the European Research Council and the Mex-

baylyi bifunctional WS/DGAT enzyme, the WS2 ican National Council of Science and Technology.

does not have DGAT activity, which catalyzes the

formation of TAG from fatty acids. TAG synthesis The authors have declared no conflict of interest.

would function as a competitive pathway for

biodiesel production. Hence, the WS2 from M. hy-

drocarbonoclasticus is very suitable for the particu- 5 References

lar purpose of producing biodiesel, and gives a titer

of ethyl oleate to approximately 62 mg/L in the [1] Carioca, J. O. B., Biofuels: Problems, challenges and per-

oleate added (0.11%, w/v). spectives. Biotechnol. J. 2010, 5, 260273.

[2] International Energy Agency, World Energy Outlook, OECD

Publication Service, Paris, 2008.

[3] Hirsch, R. L., Bezdek, R., Wendling, R., Peaking of World Oil

4 Conclusions and perspectives Production and Its Mitigation. AIChE J. 2006, 52, 28.

[4] Kerr, R. A., CLIMATE CHANGE: Global warming is chang-

The use of biodiesel has grown dramatically during ing the world. Science 2007, 316, 188190.

the last few years, and is believed to increase even [5] Schubert, C., Can biofuels finally take center stage? Nat.

further in the future. The conventional production Biotech. 2006, 24, 777784.

[6] Stephanopoulos, G., Challenges in engineering microbes for

of biodiesel through transesterification of TAGs de-

biofuels production. Science 2007, 315, 801804.

rived from plant oils requires the involvement of [7] Atsumi, S., Hanai,T., Liao, J., Non-fermentative pathways for

limited plant resources and petro-chemically de- synthesis of branched-chain higher alcohols as biofuels.

rived methanol (Fig. 1A). Furthermore, the high Nature 2008, 451, 8689.

costs involved in the use of plant resources associ- [8] Lee, S. Y., Park, J. H., Jang, S. H., Nielsen, L. K. et al., Fermen-

ated, as well as the issue of using food/feed grade tative butanol production by clostridia. Biotechnol. Bioeng.

2008, 101, 209228.

products for fuel production, are prohibitive for

[9] Demirbas, A., Diesel fuel from vegetable oil via transesteri-

large-scale biodiesel production using the conven- fication and soap pyrolysis. Energy Sources 2002, 24, 835

tional technology. 841.

Biodiesel production through microbial systems [10] Demirbas, A., Importance of biodiesel as transportation

is therefore receiving increasing attention as a fuel. Energy Policy 2007, 35, 46614670.

2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim 283

Biotechnology Biotechnol. J. 2011, 6, 277285

Journal

[11] Brown, L., Plan B 4.0: mobilizing to save civilization, W.W.

Norton & Company, New York 2009.

[12] Miao, X., Wu, Q., Biodiesel production from heterotrophic Professor Jens Nielsen received his

microalgal oil. Bioresour. Technol. 2006, 97, 841846. M.Sc in Chemical Engineering from the

[13] Canakci, M., Sanli, H., Biodiesel production from various Technical University of Denmark in

feedstocks and their effects on the fuel properties. J. Ind. Mi- 1986. In 1989, he received his PhD in

crobiol. Biotechnol. 2008, 35, 431441. Biochemical Engineering from the

[14] Meng, X., Yang, J., Xu, X., Zhang, L. et al., Biodiesel produc-

Technical University of Denmark, and

tion from oleaginous microorganisms. Renew. Energ. 2009,

did postdoctoral work at Universitt

34, 15.

[15] Vega-Snchez, M. E., Ronald, P. C., Genetic and biotechno- Hannover for 1 year. In 1990, he joined

logical approaches for biofuel crop improvement. Curr. the Department of Biotechnology at

Opin. Biotechnol. 2010, 21, 218224. Technical University of Denmark as As-

[16] Lin, L., Cunshan, Z., Vittayapadung, S., Xiangqian, S., Ming- sociate Research Professor, where he became Professor in 1998. Re-

dong, D., Opportunities and challenges for biodiesel fuel. cently, in 2008, he joined the Department of Chemical and Biological

Appl. Energ. 2010, DOI: 10.1016/j.apenergy.2010.09.029.

Engineering at Chalmers University of Technology as a Professor. Pro-

[17] Li, Q., Du, W., Liu, D., Perspectives of microbial oils for

biodiesel production. Appl. Microbiol. Biotechnol. 2008, 80, fessor Nielsen is now the head of the Systems and Synthetic Biology

749756. Group. Professor Nielsens research focuses on studying regulatory

[18] Peralta-Yahya, P. P., Keasling, J. D., Advanced biofuel pro- pathways that are conserved in the eukaryotic domain, developing effi-

duction in microbes. Biotechnol. J. 2010, 5, 147162. cient cell factories (yeast and Aspergilli) for sustainable production of

[19] Steen, E., Kang, Y., Bokinsky, G., Hu, Z. et al., Microbial pro- chemicals, and developing metabolic models for eukaryotic cells in

duction of fatty-acid-derived fuels and chemicals from

order to understand global responses to nutrients and disease.

plant biomass. Nature 2010, 463, 559562.

[20] Ahmad, A. L., Yasin, N. H. M., Derek, C. J. C., Lim, J. K., Mi-

croalgae as a sustainable energy source for biodiesel pro-

duction: A review. Renew. Sustain. Energ. Rev. 2011, 15, 584

593. Dr. Shuobo Shi received his B.Sc. in

[21] Kalscheuer, R., Stolting, T., Steinbuchel, A., Microdiesel: Es-

Biochemical Engineering from Hebei

cherichia coli engineered for fuel production. Microbiology

University of Technology in 2004. He

2006, 152, 25292536.

[22] Schmidt-Dannert, C., Holtzapple, E. K., Isoprenoid wax es- was awarded his PhD in Biochemical

ter synthases, isoprenoid acyl CoA-synthetases, and uses Engineering from Tianjin University in

thereof, US patent 2009/0117629. 2009. 2009, and then did postdoctoral work

[23] Banerjee, A., Sharma, R., Chisti, Y., Banerjee, U., Botryococ- in Professor Nielsens group at

cus braunii: A renewable source of hydrocarbons and other Chalmers University of Technology. He

chemicals. Crit. Rev. Biotechnol. 2002, 22, 245279.

is presently working in the laboratory of

[24] Illman, A. M., Scragg, A. H., Shales, S.W., Increase in Chlorel-

la strains calorific values when grown in low nitrogen medi- Professor Nielsen, where his research interest lies in lipid regulation

um. Enzyme Microb. Technol. 2000, 27, 631635. and biofuel.

[25] Mata, T. M., Martins, A. A., Caetano, N. S., Microalgae for

biodiesel production and other applications: A review. Re-

new. Sustain. Energ. Rev. 2010, 14, 217232. [33] Certk, M., Baltszov, L., Sajbidor, J., Lipid formation and -

[26] Khozin-Goldberg, I., Cohen, Z., The effect of phosphate linolenic acid production by Mucorales fungi grown on sun-

starvation on the lipid and fatty acid composition of the flower oil. Lett. Appl. Microbiol. 1997, 25, 101105.

fresh water eustigmatophyte Monodus subterraneus. Phyto- [34] Ratledge, C., Wynn, J., The biochemistry and molecular biol-

chemistry 2006, 67, 696701. ogy of lipid accumulation in oleaginous microorganisms.

[27] Chisti, Y., Biodiesel from microalgae. Biotechnol. Adv. 2007, Adv. Appl. Microbiol. 2002, 51, 144.

25, 294306. [35] Angerbauer, C., Siebenhofer, M., Mittelbach, M., Guebitz, G.

[28] Khozin-Goldberg, I., Bigogno, C., Shrestha, P., Cohen, Z., Ni- M., Conversion of sewage sludge into lipids by Lipomyces

trogen starvation induces the accumulation of arachidonic starkeyi for biodiesel production. Bioresour. Technol. 2008,

acid in the freshwater green alga Parietochloris incisa (Tre- 99, 30513056.

bouxiophyceae). J. Phycol. 2002, 38, 991994. [36] Vicente, G., Bautista, L. F., Gutierrez, F. J., Rodrguez, R. A. et

[29] Alvarez, H., Steinbchel, A., Triacylglycerols in prokaryotic al., Direct transformation of fungal biomass from sub-

microorganisms. Appl. Microbiol. Biotechnol. 2002, 60, 367 merged cultures into biodiesel. Energy Fuels 2010, 24, 3173

376. 3178.

[30] Gouda, M., Omar, S., Aouad, L., Single cell oil production by [37] Xu, H., Miao, X., Wu, Q., High quality biodiesel production

Gordonia sp. DG using agro-industrial wastes. World J. Mi- from a microalga Chlorella protothecoides by heterotrophic

crobiol. Biotechnol. 2008, 24, 17031711. growth in fermenters. J. Biotechnol. 2006, 126, 499507.

[31] Chen, H.-C., Chang, C.-C., Production of -linolenic acid by [38] Knothe, G., Dependence of biodiesel fuel properties on the

the fungus Cunninghamella echinulata CCRC 31840. Biotech- structure of fatty acid alkyl esters. Fuel Process. Technol.

nol. Prog. 1996, 12, 338341. 2005, 86, 10591070.

[32] Liu, B., Zhao, Z., Biodiesel production by direct methanoly- [39] Demirbas, A., Progress and recent trends in biodiesel fuels.

sis of oleaginous microbial biomass. J. Chem. Technol. Energy Convers. Manage. 2009, 50, 1434.

Biotechnol. 2007, 82, 775780.

284 2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim

Biotechnol. J. 2011, 6, 277285 www.biotechnology-journal.com

[40] Roessler, P. G., Brown, L. M., Dunahay, T. G., Heacox, D. A. et [60] Parawira, W., Biotechnological production of biodiesel fuel

al., Genetic engineering approaches for enhanced produc- using biocatalysed transesterification: A review. Crit. Rev.

tion of biodiesel fuel from microalgae, Enzymatic Conversion Biotechnol. 2009, 29, 8293.

of Biomass for Fuels Production, American Chemical Society [61] Tan, T., Lu, J., Nie, K., Deng, L., Wang, F., Biodiesel produc-

1994, pp. 255270. tion with immobilized lipase: A review. Biotechnol. Advances

[41] Beer, L., Boyd, E., Peters, J., Posewitz, M., Engineering algae 2010, 28, 628634.

for biohydrogen and biofuel production. Curr. Opin. Biotech- [62] Gao, B., Su, E., Lin, J., Jiang, Z. et al., Development of recom-

nol. 2009, 20, 264271. binant Escherichia coli whole-cell biocatalyst expressing a

[42] Ohlrogge, J., Allen, D., Berguson, B., DellaPenna, D. et al., novel alkaline lipase-coding gene from Proteus sp. for

Driving on Biomass. Science 2009, 324, 10191020. biodiesel production. J. Biotechnol. 2009, 139, 169175.

[43] Mussgnug, J. H., Klassen, V., Schlter, A., Kruse, O., Microal- [63] Fukuda, H., Hama, S.,Tamalampudi, S., Noda, H.,Whole-cell

gae as substrates for fermentative biogas production in a biocatalysts for biodiesel fuel production. Trends Biotechnol.

combined biorefinery concept. J. Biotechnol. 2010, 150, 51 2008, 26, 668673.

56. [64] Kalscheuer, R., Steinbchel,A.,A novel bifunctional wax es-

[44] Shay, E. G., Diesel fuel from vegetable oils: Status and op- ter synthase/acyl-CoA: diacylglycerol acyltransferase me-

portunities. Biomass Bioener. 1993, 4, 227242. diates wax ester and triacylglycerol biosynthesis in Acineto-

[45] Guschina, I. A., Harwood, J. L., Lipids and lipid metabolism bacter calcoaceticus ADP1. J. Biol. Chem. 2003, 278, 8075.

in eukaryotic algae. Prog. Lipid Res. 2006, 45, 160186. [65] Del Cardayre, S., Cockrem, M., Charles, M., Systems and

[46] Thomas, W., Tornabene, T., Weissman, J., Screening for lipid methods for the production of fatty esters, WO2009009391

yielding microalgae: activities for 1983. SERI/STR-231- 2009.

2207. p. 31 1984. [66] Keasling, J., Hu, Z., Somerville, C., Church, G. et al., Produc-

[47] Shaojin, Y., Yiping, Z., Research and application of oleagi- tion of fatty acids and derivatives thereof, WO2007136762

nous microorganism. China Foreign Energy 2006, 11, 9094. 2007.

[48] Makula, R. A., Lockwood, P. J., Finnerty, W. R., Comparative [67] Hu, Z., Valle, F., Enhanced production of fatty acid deriva-

analysis of the lipids of Acinetobacter species grown on tives, WO2008119082 2008.

hexadecane. J. Bacteriol. 1975, 121, 250258. [68] Knothe, G., Designer biodiesel: optimizing fatty ester com-

[49] Barksdale, L., Kim, K., Mycobacterium. Bacteriol. Rev. 1977, position to improve fuel properties. Energy Fuels 2008, 22,

41, 217372. 13581364.

[50] Olukoshi, E. R., Packter, N. M., Importance of stored triacyl- [69] Bro, C., Regenberg, B., Forster, J., Nielsen, J., In silico aided

glycerols in Streptomyces: possible carbon source for antibi- metabolic engineering of Saccharomyces cerevisiae for im-

otics. Microbiology 1994, 140, 931943. proved bioethanol production. Metab. Eng. 2006, 8, 102111.

[51] Alvarez, H. M., Kalscheuer, R., Steinbchel, A., Accumula- [70] Kalscheuer, R., Luftmann, H., Steinbchel, A., Synthesis of

tion and mobilization of storage lipids by Rhodococcus opa- novel lipids in Saccharomyces cerevisiae by heterologous

cus PD630 and Rhodococcus ruber NCIMB 40126 Appl. Mi- expression of an unspecific bacterial acyltransferase. Appl.

crobiol. Biotechnol. 2000, 54, 218223. Environ. Microbiol. 2004, 70, 71197125.

[52] Alvarez, H. M., Mayer, F., Fabritius, D., Steinbchel, A., For- [71] Prather, K. L. J., Martin, C. H., De novo biosynthetic path-

mation of intracytoplasmic lipid inclusions by Rhodococcus ways: rational design of microbial chemical factories. Curr.

opacus strain PD630. Arch. Microbiol. 1996, 165, 377386. Opin. Biotechnol. 2008, 19, 468474.

[53] Waltermann, M., Luftmann, H., Baumeister, D., Kalscheuer, [72] Mukhopadhyay, A., Redding, A. M., Rutherford, B. J.,

R., Steinbuchel, A., Rhodococcus opacus strain PD630 as a Keasling, J. D., Importance of systems biology in engineer-

new source of high-value single-cell oil? Isolation and ing microbes for biofuel production. Curr. Opin. Biotechnol.

characterization of triacylglycerols and other storage lipids. 2008, 19, 228234.

Microbiology 2000, 146, 11431149. [73] Gibson, D., Glass, J., Lartigue, C., Noskov,V. et al., Creation of

[54] Lu, X., Vora, H., Khosla, C., Overproduction of free fatty a bacterial cell controlled by a chemically synthesized

acids in E. coli: Implications for biodiesel production. Metab. genome. Science 2010, 329, 52.

Eng. 2008, 10, 333339. [74] Tyo, K., Alper, H., Stephanopoulos, G., Expanding the meta-

[55] Somashekar, D., Venkateshwaran, G., Sambaiah, K., Lokesh, bolic engineering toolbox: more options to engineer cells.

B. R., Effect of culture conditions on lipid and gamma- Trends Biotechnol. 2007, 25, 132137.

linolenic acid production by mucoraceous fungi. Proc. [75] Stephanopoulos, G., Alper, H., Moxley, J., Exploiting biologi-

Biochem. 2003, 38, 17191724. cal complexity for strain improvement through systems bi-

[56] Vicente, G., Bautista, L. F., Rodrguez, R., Gutirrez, F. J. et al., ology. Nat. Biotechnol. 2004, 22, 12611267.

Biodiesel production from biomass of an oleaginous fungus. [76] Holtz, W. J., Keasling, J. D., Engineering static and dynamic

Biochem. Eng. J. 2009, 48, 2227. control of synthetic pathways. Cell 2010, 140, 1923.

[57] Ma, Y., Microbial oils and its research advance. Chin. J. Bio- [77] Kim,T.Y., Sohn, S. B., Kim, H. U., Lee, S.Y., Strategies for sys-

process. Eng. 2006, 4, 711. tems-level metabolic engineering. Biotechnol. J. 2008, 3, 612

[58] Li,Y., Zhao, Z., Bai, F., High-density cultivation of oleaginous 623.

yeast Rhodosporidium toruloides Y4 in fed-batch culture. [78] Senger, R. S., Biofuel production improvement with

Enzyme Microb. Technol. 2007, 41, 312317. genome-scale models:The role of cell composition. Biotech-

[59] Zhu, L.Y., Zong, M. H.,Wu, H., Efficient lipid production with nol. J. 2010, 5, 671685.

Trichosporon fermentans and its use for biodiesel prepara-

tion. Bioresour. Technol. 2008, 99, 78817885.

2011 Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim 285

Вам также может понравиться

- Prospects For Microbial Biodiesel Production: ReviewДокумент9 страницProspects For Microbial Biodiesel Production: ReviewSrinivas ReddyОценок пока нет

- COBiotec 13-1 Met Eng YeastДокумент7 страницCOBiotec 13-1 Met Eng YeastWalter Cisneros YupanquiОценок пока нет

- 1 s2.0 S266682112200045X MainДокумент31 страница1 s2.0 S266682112200045X MainIrfani Mauludiyah FitriОценок пока нет

- Biogas Technology in Sub Saharan AfricaДокумент13 страницBiogas Technology in Sub Saharan AfricaUTHSO NANDYОценок пока нет

- A Review of Current Technology For Biodi20160513-1422-6vyimn-With-Cover-Page-V2Документ23 страницыA Review of Current Technology For Biodi20160513-1422-6vyimn-With-Cover-Page-V2olufowobi olumuyiwaОценок пока нет

- Flowsheet Bonito de Cristalizacion - A Techno-Economic Analysis of Biodiesel Biorefineries Assessment of IntegratedДокумент13 страницFlowsheet Bonito de Cristalizacion - A Techno-Economic Analysis of Biodiesel Biorefineries Assessment of IntegratedYamilet SalasОценок пока нет

- Bioprospecting of Microbial STДокумент22 страницыBioprospecting of Microbial STazwir anharОценок пока нет

- Biodiesel As An Alternative Fuel - by Asst. Prof. Shashi SahuДокумент1 страницаBiodiesel As An Alternative Fuel - by Asst. Prof. Shashi SahuSuyashsahuОценок пока нет

- Bioresource Technology: Jon K. Pittman, Andrew P. Dean, Olumayowa OsundekoДокумент9 страницBioresource Technology: Jon K. Pittman, Andrew P. Dean, Olumayowa OsundekoTeodor CostacheОценок пока нет

- Biotechnology Reports: Jaspreet Kaur, Anil Kumar Sarma, Mithilesh Kumar Jha, Poonam GeraДокумент23 страницыBiotechnology Reports: Jaspreet Kaur, Anil Kumar Sarma, Mithilesh Kumar Jha, Poonam GeraolaragoncОценок пока нет

- Catalytic Processes Towards The Production of Biofuels in A Palm Oil and Oil Palm Biomass-Based BiorefineryДокумент12 страницCatalytic Processes Towards The Production of Biofuels in A Palm Oil and Oil Palm Biomass-Based BiorefineryMiftahFakhriansyahОценок пока нет

- Recent Research and Developments in Biodiesel Production From Renewable BioresourcesДокумент11 страницRecent Research and Developments in Biodiesel Production From Renewable BioresourcesRohit YadavОценок пока нет

- Biodiesel Production From Waste Cooking Oil in A Magnetically Fluidized Bed Reactor Using Whole-Cell BiocatalystsДокумент9 страницBiodiesel Production From Waste Cooking Oil in A Magnetically Fluidized Bed Reactor Using Whole-Cell BiocatalystsFrancisco André Mayorga YuntulОценок пока нет

- 81 A Review On Influencing Parameters of Biodiesel Production andДокумент6 страниц81 A Review On Influencing Parameters of Biodiesel Production andSergio CaicedoОценок пока нет

- 2018 Biofuels PhucДокумент9 страниц2018 Biofuels PhucThuan HuynhОценок пока нет

- Fermentation 08 00319Документ6 страницFermentation 08 00319Петро ПавлишинОценок пока нет

- Utilization of A Vegetable Oil Species Residue For Biogas ProductionДокумент10 страницUtilization of A Vegetable Oil Species Residue For Biogas ProductionMahendra Kumar MОценок пока нет

- Catalytic Technologies For Biodiesel Fuel Production and Utilization of Glycerol A ReviewДокумент32 страницыCatalytic Technologies For Biodiesel Fuel Production and Utilization of Glycerol A ReviewBaskarrajaОценок пока нет

- Impact of Abiotic Factors On Biodiesel Production by MicroalgaeДокумент11 страницImpact of Abiotic Factors On Biodiesel Production by MicroalgaeSayuri GuevaraОценок пока нет

- Impact of Abiotic Factors On Biodiesel Production by MicroalgaeДокумент11 страницImpact of Abiotic Factors On Biodiesel Production by MicroalgaeSayuri GuevaraОценок пока нет

- 1 s2.0 S2590123022003152 MainДокумент10 страниц1 s2.0 S2590123022003152 MainsandraОценок пока нет

- Experimental Investigation On The Influence of Palm Oil Biodiesel in A Diesel EngineДокумент9 страницExperimental Investigation On The Influence of Palm Oil Biodiesel in A Diesel EngineEditor IJTSRDОценок пока нет

- Biofuel Alternatives To Ethanol: Pumping The Microbial WellДокумент7 страницBiofuel Alternatives To Ethanol: Pumping The Microbial WellAshrafNamamuTeratasОценок пока нет

- Biodiesel Production - A Mini Review PDFДокумент13 страницBiodiesel Production - A Mini Review PDFyohannesОценок пока нет

- Renewable and Sustainable Energy Reviews: SciencedirectДокумент16 страницRenewable and Sustainable Energy Reviews: SciencedirectajitsssОценок пока нет

- Metabolic Engineering For Biofuels Production - REVIEW Dec 2008Документ8 страницMetabolic Engineering For Biofuels Production - REVIEW Dec 2008jeyankarunanithiОценок пока нет

- Pretratamiento de Residuos Lignocelulosicos para La Obtencion de BiocombustiblesДокумент15 страницPretratamiento de Residuos Lignocelulosicos para La Obtencion de BiocombustiblesElena FloresОценок пока нет

- Biodiesel From Microalgae Environmental AspectsДокумент4 страницыBiodiesel From Microalgae Environmental AspectsNaty RubilarОценок пока нет

- Zeleni Dizel PDFДокумент19 страницZeleni Dizel PDFPero DugićОценок пока нет

- Separation Biodiesel ReviewДокумент7 страницSeparation Biodiesel ReviewAdi permadiОценок пока нет

- Bioresource Technology: Raveendran Sindhu, Parameswaran Binod, Ashok PandeyДокумент7 страницBioresource Technology: Raveendran Sindhu, Parameswaran Binod, Ashok PandeyMuhammad Fakhrizal Fahmi100% (1)

- 2007 - Huber Et Al. - Synergies Between Bio and Oil Refineries For The Production of Fuels From Biomass PDFДокумент18 страниц2007 - Huber Et Al. - Synergies Between Bio and Oil Refineries For The Production of Fuels From Biomass PDFMayank KumarОценок пока нет

- Furtado Et Al-2014-Plant Biotechnology JournalДокумент13 страницFurtado Et Al-2014-Plant Biotechnology JournalJonathan Iskandar AbbasОценок пока нет

- Renewable and Sustainable Energy ReviewsДокумент9 страницRenewable and Sustainable Energy ReviewsAndreea MadalinaОценок пока нет

- Approach To Microalgal Biodiesel Production: Insight Review On Recent Advancements and Future OutlookДокумент19 страницApproach To Microalgal Biodiesel Production: Insight Review On Recent Advancements and Future OutlookRuth Noemy Ruiz MangandiОценок пока нет

- Cleaner Engineering and Technology: Andrew Nosakhare Amenaghawon, Kessington Obahiagbon, Victor Isesele, Fauzan UsmanДокумент11 страницCleaner Engineering and Technology: Andrew Nosakhare Amenaghawon, Kessington Obahiagbon, Victor Isesele, Fauzan UsmanNurSarah NabihahОценок пока нет

- 149 Ijmperdjun2019149Документ8 страниц149 Ijmperdjun2019149TJPRC PublicationsОценок пока нет

- Lipid Technology - 2014 - Karmee - Lipids From Food Waste As Feedstock For Biodiesel Production Case Hong KongДокумент4 страницыLipid Technology - 2014 - Karmee - Lipids From Food Waste As Feedstock For Biodiesel Production Case Hong KongnityaОценок пока нет

- Chapter 7 Metabolic Engineering Strategies To Convert CA 2016 Biofuels ForДокумент40 страницChapter 7 Metabolic Engineering Strategies To Convert CA 2016 Biofuels ForVladimir Silva LealОценок пока нет

- Exploitation of Oil-Bearing Microalgae For BiodieselДокумент10 страницExploitation of Oil-Bearing Microalgae For BiodieselJeevan KumarОценок пока нет

- Biochemical Engineering Journal: Regular ArticleДокумент9 страницBiochemical Engineering Journal: Regular ArticlePiter Mamani LimaОценок пока нет

- AlgaeДокумент18 страницAlgaeAhmed mohamedОценок пока нет

- Lata's ProjectДокумент36 страницLata's Projectzekariyasa3Оценок пока нет

- Biochemical Engineering JournalДокумент13 страницBiochemical Engineering JournalolaragoncОценок пока нет

- Transesterification Reaction and ComparativeДокумент13 страницTransesterification Reaction and ComparativeKa HinaОценок пока нет

- 84 Comparision of Fuel Properties of Biodiesel Fuels Produced From Different OilsДокумент7 страниц84 Comparision of Fuel Properties of Biodiesel Fuels Produced From Different OilsSergio CaicedoОценок пока нет

- Assignment #1Документ3 страницыAssignment #1Mahmoud AbuzaidОценок пока нет

- Renewable Energy: Xiaolei Zhang, Song Yan, Rajeshwar D. Tyagi, Rao Y. SurampalliДокумент12 страницRenewable Energy: Xiaolei Zhang, Song Yan, Rajeshwar D. Tyagi, Rao Y. SurampalliArif HidayatОценок пока нет

- 1 s2.0 S0016236121022146 MainДокумент9 страниц1 s2.0 S0016236121022146 MainARSALAN AHMADОценок пока нет

- Wevj 04 00804Документ5 страницWevj 04 00804Talha AkhtarОценок пока нет

- Bio Ethanol The Fuel of Tomorrow From The Residues of Today-With-Cover-Page-V2Документ9 страницBio Ethanol The Fuel of Tomorrow From The Residues of Today-With-Cover-Page-V2Tutus RonyОценок пока нет

- Sustainable Environment ResearchДокумент10 страницSustainable Environment Researchmaryam khalidОценок пока нет

- Renewable Energy PaperДокумент22 страницыRenewable Energy PaperSatyajeet VishwakarmaОценок пока нет

- Journal of Cleaner Production: Rui Diao, Chu Wang, Zejun Luo, Xifeng ZhuДокумент11 страницJournal of Cleaner Production: Rui Diao, Chu Wang, Zejun Luo, Xifeng ZhuAbdisalamОценок пока нет

- Biodiesel Production From Low FFA Waste Cooking Oil Using PDFДокумент7 страницBiodiesel Production From Low FFA Waste Cooking Oil Using PDFZata AmaliaОценок пока нет

- Bioresource TechnologyДокумент4 страницыBioresource TechnologyIsabela Karina Della-FloraОценок пока нет

- Different Techniques For The Production of Biodiesel From Waste Vegetable OilДокумент31 страницаDifferent Techniques For The Production of Biodiesel From Waste Vegetable OilShreyank Deepali GoelОценок пока нет

- Biodisel OdfДокумент6 страницBiodisel OdfMari AlvesОценок пока нет

- Report On BiodieselДокумент32 страницыReport On BiodieselEmmanuelОценок пока нет

- Advances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsОт EverandAdvances in Biofeedstocks and Biofuels, Volume 2: Production Technologies for BiofuelsLalit Kumar SinghОценок пока нет

- Lab Manual 02Документ158 страницLab Manual 02Stephen VivekОценок пока нет

- Lesson 2 Leaves - The Food Factory of PlantsДокумент4 страницыLesson 2 Leaves - The Food Factory of PlantsRama Nathan0% (2)

- Combustion Lecture Midterm ExamДокумент3 страницыCombustion Lecture Midterm ExamNazareno Religioso MateoОценок пока нет

- Is 248-1987 Ra 2021Документ14 страницIs 248-1987 Ra 2021Aadarsh Kumar ShitalОценок пока нет

- D 2295 - 96 R02 - RdiyotuДокумент3 страницыD 2295 - 96 R02 - RdiyotuJorgeОценок пока нет

- CEP Refresher Problem Set5Документ6 страницCEP Refresher Problem Set5Alyssa Camille Malig-onОценок пока нет

- Essential Variables API 1104Документ4 страницыEssential Variables API 1104Madidj_2014Оценок пока нет

- PowerPoint PresentationSNLДокумент6 страницPowerPoint PresentationSNLAfifah N AhmedОценок пока нет

- Alat (GPT) Fs (Ifcc Mod.) : Mindray BS300Документ1 страницаAlat (GPT) Fs (Ifcc Mod.) : Mindray BS300armasfernandoОценок пока нет

- NAAMM EMMA 557-20 Standards For Expanded MetalДокумент18 страницNAAMM EMMA 557-20 Standards For Expanded MetalScott NorrisОценок пока нет

- Alphabetic List of Iran Refinery Plant PDFДокумент108 страницAlphabetic List of Iran Refinery Plant PDFBambang Kardito100% (1)

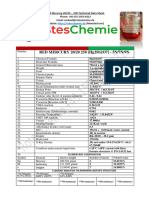

- Red Mercury 2020 Technical Data SheetДокумент2 страницыRed Mercury 2020 Technical Data SheetThe UniversОценок пока нет

- Loxiol® A 2 PDFДокумент24 страницыLoxiol® A 2 PDFXuân Giang NguyễnОценок пока нет

- Stabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Документ5 страницStabilityindicating HPTLC Method For Simultaneous Estimation of Amoxicillin Trihydrate and Ambroxol Hydrochloride in Bulk and Pharmaceutical Dosage Form 2153 2435-4-261Fadhil Muhammad AwaluddinОценок пока нет

- 1.TDS MIXO Plast D100Документ2 страницы1.TDS MIXO Plast D100mohamed ragabОценок пока нет

- Oring CatalogueДокумент90 страницOring Cataloguedoan lucОценок пока нет

- Benzene: Training On The Hazards of Benzene in The WorkplaceДокумент26 страницBenzene: Training On The Hazards of Benzene in The WorkplaceAgung RahmadaniОценок пока нет

- Exp 10 - Exp 7 A Green Synthesis of Camphor UploadДокумент4 страницыExp 10 - Exp 7 A Green Synthesis of Camphor UploadUyen V. NguyenОценок пока нет

- SilaneCouplingAgents eДокумент24 страницыSilaneCouplingAgents eElisabeth Kurnia Bloom100% (1)

- IR in Coil CoatingДокумент3 страницыIR in Coil CoatingJanine Ellyze EvangelistaОценок пока нет

- Solef Hylar PVDFДокумент60 страницSolef Hylar PVDFribeiro30Оценок пока нет

- Accepted Manuscript: Trends in Food Science & TechnologyДокумент54 страницыAccepted Manuscript: Trends in Food Science & TechnologySara CerdanОценок пока нет

- Lydia 1-S2.0-S0022391320301669-MainДокумент9 страницLydia 1-S2.0-S0022391320301669-MainCherifОценок пока нет

- Vacancy-Induced Fano Resonances in Zigzag Phosphorene NanoribbonsДокумент9 страницVacancy-Induced Fano Resonances in Zigzag Phosphorene NanoribbonsAntonio GaleoteОценок пока нет

- Astm E1640 - 1 (En)Документ5 страницAstm E1640 - 1 (En)Sainath AmudaОценок пока нет

- 02 Torque and Socket OptimizeДокумент26 страниц02 Torque and Socket OptimizeANDI SETIAWANОценок пока нет

- Lignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFДокумент62 страницыLignocellulosic Biomass A Sustainable Platform For Production of Bio-Based - Isikgor2015 PDFNatasha Mgt JoharОценок пока нет

- التجربة الثانية الانكسارДокумент3 страницыالتجربة الثانية الانكسارAymen AbdulrahmanОценок пока нет

- L9 Fastening System PDFДокумент6 страницL9 Fastening System PDFMarcel BaqueОценок пока нет

- Spark TestingДокумент23 страницыSpark TestingJad MacintoshОценок пока нет