Академический Документы

Профессиональный Документы

Культура Документы

RTU Wind Load Example

Загружено:

nitroxx70 оценок0% нашли этот документ полезным (0 голосов)

139 просмотров12 страницWind Load calculation example for a Rooftop Unit

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документWind Load calculation example for a Rooftop Unit

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

139 просмотров12 страницRTU Wind Load Example

Загружено:

nitroxx7Wind Load calculation example for a Rooftop Unit

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 12

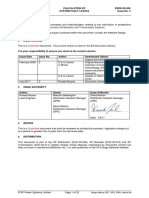

— (ices CROM CORPORATION

PRESTRES:

ED COMPOSITE TANKS:

ENGINEERING REPORT

Date: ‘April 7, 2008 Job No.: CECS Project — REV C

Job Nami Mechanical Unit Wind Analysis,

‘Subject: Wind Load Analysis of Bracket and Anchor for Installation of Mechanical Unit

Requested By: Lennox Industries, Inc.

Performed By Phuong C. Bacon, El

Reviewed By: K Ryan Harvey, PE

Purpose of Report:

The purpose of the report is to address wind loads on the brackets and anchors used for the installation of

mechanical units manufactured by Lennox Industries, Inc., and to determine if they meet the requirements of

the Florida Building Code and ASCE 7-06.

Design Requirements:

The following design standards, codes and information were used in the analysis:

1. 2007 Florida Building Code

2, ASCE 7-05 Minimum Design Loads for Buildings and Other Structures, provisions of 6.5.15 for

Design Wind Loads on Other Structures

AISC Manual of Stee! Construction, 13” Edition.

Information on the installation brackets fabricated by miami tech, inc., anchor bolts used to

install units and dimensions of units manufactured by Lennox Industries, Inc.

Ae

The following assumptions were used in the analysis

1. The maximum height of the structure above ground where the mechanical unit is mounted is 100!

2. The structure on which the unit is mounted is designed to accommodate the load due to the effects

of wind on the mechanical unit.

3. The substrate where the unit is mounted is of sufficient thickness for adequate embedment of the

anchor bolt.

A maximum wind speed of 150 MPH at a 3-second gust.

An exposure category of C.

An importance factor (1) of 1.16.

The installation of the bracket and anchors are in accordance with the manufacturer's

recommendations and the additional information provided herein.

NoOoR

Results of Analysi:

The results of the analysis of the bracket and anchor using the assumptions and information from above are as

follows:

1. The total force on the mechanical unit and subsequent forces on each bracket and anchor are shown.

in the attached calculations. Based on the force calculated, we find that the following anchor

configurations are acceptable to resist the calculated wind loads provided they are installed in

accordance with manufacturers recommendations

a. 1/4"x 1%" long Tapcon Threaded Anchor.

b. 3/6" x 2 %4" Expansion Anchor.

CcADocimeras ae Setings¥sthly Dameron PrjeslZO0CECSies! Palm Beach FL Macher! Ln#ENCINEERING REPORT #1, West Pan Bosch Fends. Wind Leadon

ecm

ENGINEERING REPORT April 21, 2009

©. 1/4" x2 %4" Expansion Anchor.

2. The total force due to wind load is shown in the attached calculations for the 14 gauge galvanized

steel bracket as manufactured by miami tech (CUTD1). Based on the calculated wind load, we find

that the bracket is acceptable for the calculated wind load.

3. The total force due to wind load on each screw used to attach the brackets is shown in the attached

calculations. Based on the calculated shear force, we find that the brackets should be attached with a

minimum of two #10 (3/16") Type AB self-tapping screws,

4, The DLXC20-60 represents the worst case for design purposes. Results of the calculations

will be the same or better for all units manufactured by Lennox, Inc. which are included in the

attached list.

k. Ryan Harvey, PE

Florida License Number: 56945

THE CROM CORPORATION

Certificate of Authorization Number: 1875

Attachments: West Palm Beach, Florida Mechanical Unit Wind Load Analysis REV A

‘West Paim Beach, Florida Mechanical Unit Wind Load Analysis REV B

Drawing for Lennox Mounting Bracket by miami tech (CUTD1)

Unit Information provided by Lennox Industries, Inc.

Design Wind Loads on Other Structures THE CROM CORPORATION Job #: CECS

‘West Palm Beach, Florida

Mechanical Unit Wind Loads

Design Wind Loads on Other Structures

Reference: ASCE 7-05 Minimum Design Loads for Buildings and Other Structures

2007 Florida Building Code

Bracket, Mechanical Unit and Mounting Information Provided by Lennox Industries

AISC Manual of Steel Construction, 13th Edition

Objectives:

+ To determine the wind load on an Mechanical Unit using Design Wind Loads on Other Structures (ASCE 6.5.15)

+ To Check Bracket and Bolt Capacity Against Wind Loadings

|. Input:

i. Geometry:

hex 100-8 Height of mechanical unit on roof top.

ye 47in Vertical dimension of unit

Jr 365in Distance between anchor bolts

Api= 39.Sein47-in Largest face area subjected to wind load

Horizontal dimension of unit

Length of bracket side

Thickness of bracket (14 gauge Galvanized Steel)

Diameter of bolt used to anchor unit

distancegge = I-in Distance from center of bolt to edge of bracket

ii, Material Proy

Fy = 36ksi Yield strength of steel

Fy S8ksi Ultimate strength of steel

Uniform tensile stress in block shear (AISC J.4.3)

Modulus of elasticity of steel

3/16" Self Tapping screw major diameter.

4, = 141-in 3/16" Self Tapping screw minor diameter

Conservatively taken as 60% of yield strength for carbon steel screw

Mee 150-mph Basic Wind Speed

West Palm Beach, Florida Mechanical Unit 1 Designed By: Phuong Bacon, EI

‘Wind Load Analysis Rev B.xmed Reviewed By: K.R-Harvey, PE.

Design Wind Loads on Other Structures

K,= 1.26

Ky i= 0.90

Ls LS

Gx 085

h

2 -7}(2-14)

(2-7)e-19

Chie 14+

& 25-7

Il. Calculation:

i, Wind Loadings:

sf

ag = 0.00256-K, Koy Ky Vb

mph’

Bom We GCp Ap

H+2

sean (82

sa (22)

Thott

Vscrews

so

Check Bracket:

a. Check Minimum Edge Distance:

0.875-in

distanceedge mi

checkedgedistance = Hf(distancegdae min < distanceedges"0k" s"NG")

b. Check Block Shear Strenath:

West Palm Beach, Florida Mechanical Unit

Wind Load Analysis Rev B.xmed

THE CROM CORPORATION

West Palm Beach, Florida

Mechanical Unit Wind Loads

Job #: CECS

Velocity Pressure Exposure Coefficient

(ASCE7 6.5.6.6 - Table 6-3, Exp C, 100 ft)

Topographic Factor (ASCE7 6.5.7.2)

Wind Directionality Factor (ASCE7 6.5.4.4 - Table 6-4, Similar Structures)

Importance Factor (ASCE7 Table 6-1 - Category II!)

Gust Factor (0.85 is a conservative value ASCET 6.5.8)

Force Coefficients (ASCE7 Fig 6-21) 2 =3038 © Cp=2.179

a

D

Velocity Pressure at Height H=100 ft (ASCE7 6.5.10) q, = 75.12psf

Force from Wind Load on AC Unit F=17941be

Shear on Each Bolt Voi = 448.5 1bF

Tension on Each Bolt Tpoit = S77 If

Calculate shear on each screw at bracket

Minimum Distance from Center of Bolt to Edge of

Bracket (AISC Table J3.4 3/8" diameter bolt)

‘chetkedgedistance = "0"

Factor of Safety for Block Shear Strength

Service Tensile Load on Bracket Ra = 448 Ibe

2 Designed By: Phuong Bacon, El

Reviewed By: KR. Harvey, P.E.

Design Wind Loads on Other Structures THE CROM CORPORATION Job #: CECS

West Palm Beach, Florida

Mechanical Unit Wind Loads

Gross Area Subject to Shear Agy = 004:in?

Net Area Subject to Tension Age = 0.03:in?

Net Area Subject to Shear Any = 0.03:in?

w Ane 6 Fy Agy + Ups FuAni)

Nominal Block Shear Strength (J4.3.3) Ry = 2571 1bF

Allowable Block Shi Sa

rear Strength = = 12861bf

2 Rg,"OK" ne] ‘checkpiocky = "OK"

¢. Check Bearing Strenath:

Barz 2.0 Factor of Safety for Bearing Strength at Bolt Hole

Lawtd Clear Distance between the Edge Hole and as

ary Edge of Bracket L,=0375in

Bait min( 1 S-LetFy,3.0-d-tFy) Nominal Bearing Strength

1289-166 Allowable Bearing Strength at Bolt Hole

Rn

checkpearing = if] Go 2 Ray "OK" "NG"

d. Check Shear Strength of Screws:

2

dino " 2

Pere Minor area of 1/4" self tapping screw Ascrew = 0.016-in"

Vattow ‘= Fv Ascrew Calculation of allowable capacity of screw in shear

Checkscreweapacity = if(Vatiow > Vserewss "OK" s "Increase Serew Size")

‘Chia papacity = 70K”

West Palm Beach, Florida Mechanical Unit 3 Designed By: Phuong Bacon, E!

Wind Load Analysis Rev 8.xmed Reviewed By: K.R.Harvey, PE.

Design Wind Loads on Other Structures THE CROM CORPORATION Job #: CECS

‘West Palm Beach, Florida

Mechanical Unit Wind Loads

Design id Loads on Other Structures

Reference: ASCE 7-05 Minimum Design Loads for Buildings and Other Structures

2007 Florida Building Code

Bracket, Mechanical Unit and Mounting Information Provided by Lennox Industries

AISC Manual of Steel Construction, 13th Edition

Objectives

+ To determine the wind load on an Mechanical Unit using Design Wind Loads on Other Structures (ASCE 6.5.15)

+ To Check Bracket and Bolt Capacity Against Wind Loadings

1. Input:

|. Geometry:

b= 100-8 Height of mechanical unit on roof top.

ys 47in Vertical dimension of unit

y= 365in Distance between anchor bolts

Ag:= 39.5-in-47-in Largest face area subjected to wind load

D:= 39.5-in Horizontal dimension of unit

Aye bin Length of bracket side

t= 079-in ‘Thickness of bracket (14 gauge Galvanized Steel)

d= 0375-in Diameter of bolt used to anchor unit

Distance from center of bolt to edge of bracket

Yield strength of steel

Ultimate strength of steel

Uniform tensile stress in block shear (AISC J.4.3)

Modulus of elast

ity of steel

3/18" Self Tapping screw major diameter.

3/16" Self Tapping screw minor diameter

Conservatively taken as 60% of yield strength for carbon steel screw

iii, Wind Load Info:

50-mph Basic Wind Speed

West Palm Beach, Florida Mechanical Unit 1 Designed By: Phuong Bacon, EI

Wind Load Analysis Rev A.xmed Reviewed By: K.R.Harvey, P.E.

Design Wind Loads on Other Structures ‘THE CROM CORPORATION Job #: CECS

‘West Palm Beach, Florida

Mechanical Unit Wind Loads

Design id Loads on Other Structures

Reference: ASCE 7-05 Minimum Design Loads for Buildings and Other Structures

2007 Florida Building Code

Bracket, Mechanical Unit and Mounting Information Provided by Lennox Industries

AISC Manual of Steel Construction, 13th Edition

Objective:

+ To determine the wind load on an Mechanical Unit using Design Wind Loads on Other Structures (ASCE 6.5.15)

+ To Check Bracket and Bolt Capacity Against Wind Loadings

1. Input:

|. Geometry:

hs= 100-8 Height of mechanical unit on roof top.

ys 47-in Vertical dimension of unit

y= 365in Distance between anchor bolts

Ag:= 39.5:in-47-in Largest face area subjected to wind load

Horizontal dimension of unit

Length of bracket side

Thickness of bracket (14 gauge Galvanized Steel)

d:= 0375-in Diameter of bolt used to anchor unit

istancegdge = I-in Distance from center of bolt to edge of bracket

{i, Material Properties:

Yield strength of steel!

Ultimate strength of steel

Uniform tensile stress in block shear (AISC J.4.3)

E,:= 29000-ksi Modulus of elasticity of stee!

3 7

Sega in 3/16" Self Tapping screw major diameter.

d, ‘= .141-in 3/16" Self Tapping screw minor diameter

Conservatively taken as 60% of yield strength for carbon steel screw

Wind Load Info:

Mg= 150:mph Basic Wind Speed

West Palm Beach, Florida Mechanical Unit 4 Designed By: Phuong Bacon, El

Wind Load Analysis Rev A.xmed Reviewed By: K.R.Harvey, P.E.

Design Wind Loads on Other Structures THE CROM CORPORATION Job #: CECS

West Palm Beach, Florida

Mechanical Unit Wind Loads

n

= 1.26 Velocity Pressure Exposure Coefficient

(ASCE7 6.5.6.6 - Table 6-3, Exp C, 100 ft)

Topographic Factor (ASCE7 6.5.7.2)

Ky = 0.90 Wind Directionallty Factor (ASCE7 6.5.4.4 - Table 6-4, Similar Structures)

Importance Factor (ASCE7 Table 6-1 - Category I!)

(Gi= 0.85 Gust Factor (0.85 is a conservative value ASCET 6.5.8)

Cpe lat Force Coefficients (ASCE7 Fig6-21) 2-30.38 Cp=2.179

D

IL Calculation:

i, Wind Loadings:

= 0.00256-K, Velocity Pressure at Height H=100 ft (ASCE7 6.5.10) q, = 75.12 psf

% 2 Rar Ka % P

R= a:6-CpAp Force from Wind Load on AC Unit 794 bE

Shear on Each Bolt Vpott = 448-SibF

Tension on Each Bolt Thon = S766

Thott

Calculate shear on each screw at bracket ee |

Vscrews

ii, Check Bracket:

a. Check Minimum Edge Distance:

distaneeggge min’ 087Sin Minimum Distance from Center of Bolt to Edge of

: Bracket (AISC Table J3.4 3/8" diameter bol)

checkedgedistance = if(distancredge min S distanceaage,"0k” "NG") checkdgedisance 7 "2"

b. Check Block Shear Strength:

N= 20 Factor of Safety for Block Shear Strength

Service Tensile Load on Bracket R, = 448 Ibf

‘West Palm Beach, Florida Mechanical Unit 2 Designed By: Phuong Bacon, El

‘Wind Load Analysis Rev Axmed Reviewed By: K.R Harvey, P.E.

Design Wind Loads on Other Structures THE CROM CORPORATION Job #: CECS

West Palm Beach, Florida

Mechanical Unit Wind Loads

Agy = (1+ 2)4 Gross Area Subject to Shear Agy = 004:in?

Age = ( sh: Net Area Subject to Tension Ang = 0.025:

Agyi= ( - 3) n Net Area Subject to Shear

tin(0.6Fy gy + Ugg Fy Ay O.5Fy Agy + UpgFy'Ay)

Nominal Block Shear Strength (J4.3.3) Ry = 2285 Ibi

Allowable Block Shear Strength Sn = 11431bf

:

| ROK" NG } sae OR

ct Bearing Strength:

Q. 2.0 Factor of Safety for Bearing Strength at Bolt Hole

Bei

Clear Distance between the Edge Hole and

313m

2 Edge of Bracket

Bait min(LS-LotFy,3.0-d--F,) Nominal Bearing Strength 148 Ibe

Rp Rn

— = 074. 0F Allowable Bearing Strength at Bolt Hole — = 1074168

2, Ry

checlyearing heckbearing = "OK"

d. Check Shear Strength of Screws:

F4zingr 7

Aerew = Minor area of 1/4" self tapping screw A 0.016:

Vattow = FyAscrew Calculation of allowable capacity of screw in shear Vatioy, = 337.273-bf

Checkserewcapaity = #(Vattow > Vserews:"OK" "ncrease Serew Size

(Checked) SPOR”

West Palm Beach, Florida Mechanical Unit 3 Designed By: Phuong Bacon, EI

Wind Load Analysis Rev Axmed Reviewed By: K.R.Harvey, PE.

SC or Lennox

Siz ig. HP Catt Model Dimensions (HxWxD) _Series Warranty __db Notes

1s SO Sa —TERCD-OTE aoa aaa zee ——WERIT ——SPARTSI5 CONP 78

2 SC SEM70.—«Y3ACD-024044x24-1Mx2814 MERIT. —SPARTSISCOMP 78

28 SC SBM? Y2ACD.030 © 04M4x24-Mx24-14 MERIT. «—«SPARTSISCOMP 78

3 SC BEM72.—«T2ACD-0383314x24Mx 24-14 MERIT. —«SPARTSISCOMP 8D

38 SC BeM72.««12ACD-042 SOAHax2A-tm4x24-1 MERIT. —-«SPARTSISCOMP 80

4 SC B6M74.TRACD.O4 AB x28-14x28-1 MERIT. «—-«SPARTSISCOMP 80

5 SC__86M7S_12AGD.060__43-14x28-144x.28-1___MERIT_SPARTSISCOMP_60,

is ‘SO wanloa—TaACK US aaa ori ae-1i@ MERITS PARTSS COMP 78

2 SC 99MOS“19ACK-024 —-20-44x24-1i4x2Hi4 MERIT. «—-«SPARTSISCOMP. 78

28 SC 99M0G.12ACK-030 —«28-1i4x24-tlax 24-1 MERIT.—-««BPARTSISCOMP. 78,

3 SC 9OMO7T9ACKO96. SBMA 2414x2414 MERIT. —«-SPARTSGGOMP 78

35 SC 9OMI0. —19ACKO82 53-14 x24-1ld 24d MERIT. —-—“SPARTSISCOMP 80,

4 SC OMI. SACKS OMA DETI4x 76-14 MERIT. ~—-SPARTSISCOMP 80

5 SC__S0MI7_13ACX.060__ at 4i4 x26-1i4x 26.14 ___MERIT___SPARTSISCOMP_£0

7s SC aaa taaCx018 gota ETA MERIT 5 PARTSIG COMP

2 SC 22W82“WACK24 — Zo.tex 2414x2044 MERIT —SPARTSISCOMP 78

23 SC 22W83 —“{4ACK080 «20-1 x20114x2044 MERIT —-«-SPARTSISCOMP 78

3 SC 22Wes14ACK0N6 OHA x2BNI4x 2814 «MERIT. «—«SPARTSISCOMP 76

35 SC 22W8S 14ACK042 OMIA x2BHiAx 784 «MERIT... SPARTSISCOMP. 78

4 SC 22WS14AGKO48 TIA x2ENi4x 2614 MERIT. «—«SPARTSISCOMP 78

5 SC__Z2Wer__14AGX-060__ Sala xA2tidx 321M __MERIT_SPARTS/5COMP__ 60

7s SC cahiad —ACiSO18 3107 x28 ELITE 5 PARTS/I0 COMP 78

2 SC BMS ACI3.026 35.07 x28 ELITE SPARTSNOCOMP 76

25 SC 984s §—-ACI3.020 31307 28 ELITE SPARTSHOGOMP 76

3 SC goMa7 §—ACI3-036, 31327%28 ELITE SPARTS/OCOMP 76.

a5 SC oBkMB ACIS.042 35x 27x28 ELITE SPARTS/OCOMP 75,

4 SC ses © ACIS-O48 3930-172 x35 ELITE SPARTS/OCOMP 78

5 SC__seMs0__AC13.060, 395 30-172 38 ELITE __SPARTS/IOCOMP__76

TF SO aehso ROIS oe aT Sixzr x28 ELITES PARTSI10 COMP 7

2 SC Somer xCI3-024-230 35x27 x28 FLITE —SPARTSHOCOMP 74

25 SC okt62 —xC13-090-290 31x27 x28 FLITE BRARTSMOCOMP 76

is SC 9k63xC13-036-200 35x 27x28 ELITE SPARTSOCOMP 76,

38 SC weMed XCI3.042290 Bi x02 35 ELITE SPARTSNOCOMP 76

4 SC eM XCIB04e290 31 x30/2x35 ETE — SPARTSNOCOMe 76

5 SC_s9hiss _XxG12.060-290 31 xs0-i2x35 ELITE __SPARTS/I0GOMe 76

15 ‘SC panes —XCIa 018290 S127 x28, ELITES PARTS/I0 COMP 71

2 SC owes X0i4024-200 34x27 128 cuiTe SPARTSMOCOMP 71

25 SC paWs0 xCi4020-20 © Si xa0N/2x35 ELITE SPARTSNOCOMP 71

3 SC awe xcH4026-290 © a1 x30/2x35 ETE —SPARTSHOCOMe 70

38 SC mawsz Xots0t2230 31 x20172 38 ELITE — SPARTSHioCOMe 73,

4 SC 22W93 XCI-045200 SOK SO/2 35 ETE SPARTSHOcOMe 73

5 SC__22Wwo4 _XC14.000-250 95 x05-172x96-122 ELITE __SPARTS/I0COMP _73

z ‘SO Towa XC 024-290 B1x27 x28 ELITE 5 PARTSI10 COMP

3 SC tswai XO18.096.200 © SOK 301/2x35 ELITE SPARTS/OCOMP 78

4 SC 15WA2 XCIB048-290 © SO.xS0I235 FLITE —-SPARTSHOCOMP 78

5 SC 15W43_XC16.080.290 ___ 30x5-172x58-90 ELITE __SPARTSHocOMP__78

z SO War Kets 028290 STXSEIB SEE ‘DLSCTDPARTS/ 10;COMP ex

25 SC wee XCIs0s0250 © 37x58/2 36-12 DISC 10PARTS/10COMP 4

3 SC 1759 XCIBGI620 ST AUEHI2 S52 DLSC {DPARTS/10GOMP 68

38 SO A7WO0 XOISOH2 290 ST XEH/2 S52 DISC 1DPARTS/10GOMP 68

4 SC iW XOISOMB 280 47 xo8-i2K35-12 DISC {OPARTS/ 10GOMP 70.

5 SC__s7we2 _Xc15.000.250_ 47 xs8:12 36-12 DLSC__10PARTS/19GOMP_70.

z SC eahlos — XC21-024-290 97 x 95-172 30-172 ‘LSC 1D PARTS 10 COMP 68

3 SC BaNos XCP.096290 aT xasHiPxSO-2 DISC {DPARTS/10COMP 71

4 SC eaMor | xC21048.290 47 xs5-12 «30-12 LSC {DPARTS/10GOMP 73.

5 SC__s4Moa _XG21.060.290 47x85: 80-12 LSC __{0PARTS/10GOMP_73

SC or Lennox

Size Refrig. HP Cat# Model Dimensions (HxWxD) _Series Warranty __db Notes

Ts | R22 HP adMias —TaHPD OTE ss-Taaatexaaime MERIT 5 PARTS COMP 76

2 | Rez HP 94N4s—13HPD-024 © SG-1/a x24-Vax26-1!4 MERIT. © SPARTSISCOMP 78

2s] R22 HP 8447 12HPD.030 20-4 x24-Ia x48 © MERIT. ©—«SPARTSISCOMP 76

3 | Raz HP oaMda—T3HPD-036.«33-1/ax26-Vaxze-14 = MERIT. «= SPARTSISCOMP 78

35] Ree HP eaN491QHPD.o«2 35-14 28-118,08-74 © MERIT-«—«SPARTSISCOMP 80

4 | R22 HP oantso — 13HPD-048 197 ¥28-18 128-114 MERIT —SPARTSISCOMP 80

s | Roz poets taHPD-080_ 49x 92-144 92.444 MERIT SPARTSISCOMP__60

TE" RAGA AP gaat SHPROIe | se a.cawaxaeie MERIT SPARTSIS COMP 76

2 | RAioA HP geM22TOHPKOM © 33-/e24-t/4@etd MERIT. ~—--SPARTSISCOMP 78

25 | RAIA HP 9623.“ TSHPX-090 20-14 24-Vaxzetig | MERIT. © SPARTSISCOMP. 76

3 | RAGA HP OMA TSHPX.098-—S3742e-tacat4 «MERIT. «—-SPARTS/SCOMP 76

as | RAIA HP 90M? TSHEX.0@2§—SStlaae-ezetd «= MERIT © SPARTSISCOMP 80

4 | Rega HP 90M30.—sHPXo4s 37 28-1 28-114 MERIT SPARTSISCOMP 50

5 | ReIOK HP 90MG4 —1SHPX-080 © as-tle ze-tin@e-vq = MERIT. SPARTSISCOMP 80.

se_| Raia HP ASHPKO61 43.1420. 126-4/4__MERIT__SPARTSISCOMP__80

Ts | ROA AP -2oWIS —TaHPXOTa —__2e-Vax2etaKaeTa MERIT SPARTSIBCOMP 76

2 | Raia HP 2aWOR NAHPKO2 294x244 x21 MERIT «SPARTSISCOMP 70

25 | Raion HP 2057 4HPXOGD = SB-4x32414xS2-1/4 MERIT. «—«SPARTSISCOMP 70

3 | Raia HP OWES t4HPX.099.20-14xa2-1/axa21 MERIT. —«SPARTSISCOMP 79

a5 | RAIA HP 22Wo9 MHPX-O2 87 x 92-14x90-114 MERIT‘ SPARTSISCOMP 78

4 | RAIA HP ZeWn0 T4HPKO48 a7 x 92-14 x 92414 MERIT SPARTSISCOMP 80

3 [Raion He 2awor__s4hexoco aati x32-1/4 3214 MERITS PARTSIS COMP _80

3 | R22 He —ooMst —HP1s-076-200 35x27 x25 ELITE 5 PARTS/0 COMP 76

2 | Ro HP gamez HP13-024.200 35107 x28 ELITE SPARTSHOCOMP 78

25 | R22 HP oaks HP19-090.230 31107 x28 ELITE SPARTSi10COMP_ 78

3 | R22 HP 9eMS4 HPs-036-230 35x27 x28 ELITE —SPARTS/10COMP 76

35] R22 HP 9aMs5 HP 18-042-230 388 x30-12x95 ELE —SPARTS!10COMP 78

4 | R22 HP entss HPts.048-280 85x 30-112x35 ELIE —SPARTS/10COMP 78

s_|_ Roz HP__oans7_HPt3.060.290 99x 35-12 x38-1/2 ELITE __SPARTSi10COMP_76

Ts | RATOA HP vars XPTSAOTE BaD STH aS ELE SPARTSO‘COME 74

2 | ReiA HP anna xPH8A-024-230 31 xt x28 ELITE SPARTS/10COMP 74

2s | Reina HP 93h75._xPIaA.030-280 31x27 x20 ELITE —SPARTS'10COMP 78

3 | Reta HP GaN7e XPI3A.086-230 35907 x28 ELITE SPARTS(10COMP 78

3+ | Rata HP 20WG7 XPISAG7-230 —_95x90-172x95 ELITE —SPARTSIIOCOMP 78.

a5 | Rein HP GMT XPISA0M2290 © 38x 304/285, ELITE SPARTSMOGOMP 76

4 | ain HP ooM7S XPIBAO46-220 98x 2041295, ELITE SPARTSIV0COMP 78

5 | Raion He oantva_XPi9A.060.20 45x 20-1235, ELITE __SPARTS0 COMP_ 75,

Te [Ran HP _aawo2— xPIaoT8200 STAT Rae EINE SPARTSNO COMP TT

2 | Raion. Hp zawos xP14.024-230 3142728 ELIE SPARTSHHOCOMP 71

25| Rein HP 2aWW04 _xPt4.050-200 6x27 28 ELIE SPARTSMI0GOMe 71

2 | Raia HP aWW05 xPI4S6-250 gt xse-12x 98112 ELITE SPARTSH#0COMP 71

35 | Raion HP 2aWW0sXPI4.047-200 90.96-112x30-172 ELITE SPARTSHOGOMP 71

4 | Reta HP 2awWO?. xPIAogs-230 © 98x36-1/2 38112 ELITE SPARTS‘10COMP 79

s_| Raton He __25Woa_xPisiog0.230__ 4536-122 39:12 ELITE __SPARTS#10 COMP_73.

2] RAGA HP —tswaa xP I6-074750 SIXT ELE SPARTSIIO COMP 74

3 | RétoA HP twas xP16-036-290 85 X20-412 x35 ELITE SPARTSIOGOMP 78

4 | Reton HP twas xP16-088.290 45% 90172435 ELITE SPARTSIIOCOMP 78

5_| Reta HP __1wa7_xPi6.080230 so xas12x90.908 ELITE __SPARTSIOGOMP__78

2] RAIA HP ——t7wes xPI6z4200 ST x Se-Vax5-1l2 DLS¢ 10 PARTS/10 COMP 64

25] ReWOA HP trwsa xPIS-030200 Sr xaetlaxa5-2 DLSC © 1PARTSHIOCOMP. oa

3 | Rava HP i7Wes XPIBGs8-200 Gx 99-112x95-112 DESC © 1PARTS"OCOMP. 5B

38 | ReWA HP f7We8 xPI6-042-20 Sr xB9daxI5-t DESC 10PARTS/IOCOMP. aa

4 | RawA HP 7wey XPi6-048-200 47x 99-112x35-1R DESC 10 PARTSH0cOMP 70

3 | paica He Azwon_xpt9.000.250___47 x 39-122 535-12 DLSG__10 PARTSO. COMP _ 70.

Z| RaioR HP —eaMog xP ie028280 87x 35-112x 90-110 ‘DSc 10 PARTSMO COMP 6

3 | Raion HP Batti. xPI¢.096-20 37 38-112x90-119 DSC © 1PARTSHOCOMP 73

4 | Raa HP ealttd xPrende-230 47x 95-112x90-112 DSC 10 PARTS0COMP. 73

5 [Raton HP _satti2 _xPi9.060-230 47 x35-112x39-1/2 DLSC___ 10 PARTSH10 COMP_73

sow w 1

Gen warner

COON, RULE PHIRI ALA

pone: son—eae Noe Hat 305-865-819

‘nr em arte

elnt! SAiBvobusereen cow

PRODUCT SPECIFICATIONS

PAGE

10F1

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Seismic Design Manual PDFДокумент881 страницаSeismic Design Manual PDFelidstone@hotmail.comОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- AvДокумент300 страницAvJeff NettlesОценок пока нет

- Sulfuric Acid 93-Pct WT-SA15 SDSДокумент6 страницSulfuric Acid 93-Pct WT-SA15 SDSnitroxx7Оценок пока нет

- Chilis Menu StreetsideДокумент16 страницChilis Menu Streetsidenitroxx7Оценок пока нет

- Area Moment of Inertia Common Shapes High ResДокумент5 страницArea Moment of Inertia Common Shapes High Resnitroxx7Оценок пока нет

- Polymer Component A WT-5533A SDSДокумент6 страницPolymer Component A WT-5533A SDSnitroxx7Оценок пока нет

- Polymer Component B WT-5640CT SDSДокумент6 страницPolymer Component B WT-5640CT SDSnitroxx7Оценок пока нет

- Spec-493h 400mbtuhrДокумент1 страницаSpec-493h 400mbtuhrnitroxx7Оценок пока нет

- Coagulant WT-SR460 SDSДокумент6 страницCoagulant WT-SR460 SDSnitroxx7Оценок пока нет

- Controlled: Design Manual (SPT, SPD, SPM) : Section 9aДокумент32 страницыControlled: Design Manual (SPT, SPD, SPM) : Section 9aAntonio Solís MurilloОценок пока нет

- FBPE - Additional Discipline ApplicationДокумент4 страницыFBPE - Additional Discipline Applicationnitroxx7Оценок пока нет

- User Manual: Electromagnetic Flow MeterДокумент56 страницUser Manual: Electromagnetic Flow Meternitroxx7Оценок пока нет

- 300 Series 400 Amp Service Entrance Sub PackageДокумент67 страниц300 Series 400 Amp Service Entrance Sub Packagenitroxx7Оценок пока нет

- EE PE Exam NCSU 1 PDFДокумент134 страницыEE PE Exam NCSU 1 PDFnitroxx7Оценок пока нет

- Tabel Tingkat Suku BungaДокумент32 страницыTabel Tingkat Suku BungaFhadjroel AntekОценок пока нет

- C7.1 125-200kW Marketing Spec Sheet LEHE1586-04Документ8 страницC7.1 125-200kW Marketing Spec Sheet LEHE1586-04nitroxx7Оценок пока нет

- Guy Wire Anchor DetailДокумент1 страницаGuy Wire Anchor Detailnitroxx7Оценок пока нет

- Planning of Electric Power Distribution Technical PrinciplesДокумент6 страницPlanning of Electric Power Distribution Technical Principlesgl1188Оценок пока нет

- Abb-1742-Wpo Nec Tap RulesДокумент6 страницAbb-1742-Wpo Nec Tap RulesMinor Rojas SolisОценок пока нет

- 26 05 73 Short Circuit Analysis-Coord StudyДокумент8 страниц26 05 73 Short Circuit Analysis-Coord Studynitroxx7Оценок пока нет

- 300kVA XFMR Installation Project DrawingsДокумент5 страниц300kVA XFMR Installation Project Drawingsnitroxx7Оценок пока нет

- Bacnet Verification System Pre-Functional Checklist: Statement of ReadinessДокумент10 страницBacnet Verification System Pre-Functional Checklist: Statement of Readinessnitroxx7Оценок пока нет

- Wind Exposure CategoriesДокумент3 страницыWind Exposure CategoriesShadin Asari ArabaniОценок пока нет

- Domestic Water Heat Exchangers Pre-Functional Checklist: Statement of ReadinessДокумент3 страницыDomestic Water Heat Exchangers Pre-Functional Checklist: Statement of Readinessnitroxx7Оценок пока нет

- Final Commissioning Report Outline & Contents: Section DescriptionДокумент5 страницFinal Commissioning Report Outline & Contents: Section Descriptionnitroxx7Оценок пока нет

- Variable-Air Volume Units (Multiple) Pre-Functional ChecklistДокумент10 страницVariable-Air Volume Units (Multiple) Pre-Functional Checklistnitroxx7Оценок пока нет

- Engine Generators Functional Performance Test: System DescriptionДокумент29 страницEngine Generators Functional Performance Test: System Descriptionnitroxx7Оценок пока нет

- Domestic Water Heat Exchangers Pre-Functional Checklist: Statement of ReadinessДокумент3 страницыDomestic Water Heat Exchangers Pre-Functional Checklist: Statement of Readinessnitroxx7Оценок пока нет

- AppendixK PFC 262300LowVoltageSwitchgearДокумент3 страницыAppendixK PFC 262300LowVoltageSwitchgearnitroxx7Оценок пока нет

- Bacnet Verification System Pre-Functional Checklist: Statement of ReadinessДокумент10 страницBacnet Verification System Pre-Functional Checklist: Statement of Readinessnitroxx7Оценок пока нет