Академический Документы

Профессиональный Документы

Культура Документы

Temporary Repair Authorization Form - Revised

Загружено:

HamzaNouman100%(2)100% нашли этот документ полезным (2 голоса)

689 просмотров2 страницыTemporary Repair Authorization Form

Авторское право

© © All Rights Reserved

Доступные форматы

DOCX, PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документTemporary Repair Authorization Form

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

100%(2)100% нашли этот документ полезным (2 голоса)

689 просмотров2 страницыTemporary Repair Authorization Form - Revised

Загружено:

HamzaNoumanTemporary Repair Authorization Form

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате DOCX, PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

TEMPORARY REPAIR/CHANGE AUTHORIZATION FORM

Permanenet Repair Work Order No. ---------------------

Temporary Repair Work Order No. ---------------------

TR No.____________

Temporary repair implementation date 10-07-2016

(Given by inspection)

EQUIPMENT / PIPING / INSTRUMENT / ELECTRICAL

2001-JCT After Cooler

TAG NO. /LOCATION

DESCRIPTION OF PROBLEM: REASON FOR TEMPORARY REPAIR

Seepage from 16 No. Tubes (02 Nos. Tubes above Due to plant start up, Re-tubing is not feasible in short

acceptable limit) in the cooler. time.

SUGGESTED TEMPORARY REPAIRS (Use separate sheet for sketches)

Plugging of seeping tubes.

PROPOSED PERMANENT SOLUTION

Fabrication of new tube bundle.

PROPOSED CHANGE IN PERMANENT SOLUTION

Date by which Temporary repair would be 31-Dec-2016 Extended

removed removal date

Monitoring Checks Frequency Responsibility

Monitoring of Air outlet temperature Daily Operations

REQUESTED BY REVIEWED BY

Maint/E &I Engineer/Prod. Engr/Civil Engr Relevant Section Head/UM Project Engg. S.H.

FUNCTIONAL REVIEWS initial (Signature) (Comments)

Operations U.M/Section Head

Process Engr (Where

applicable)

U.M Inspection

UM Safety

APPROVED BY

Relevant SUB SOC CHAIRMAN

The above Temporary repair has been removed on

Requestor Verified by Operations & Inspection Engineer

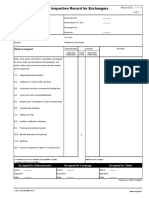

CHECKLIST FOR TEMPORARY REPAIRS (MECHANICAL) REVIEW

TR NO. ___________________ DATE :_______________

Is it a confirmatory Temporary repair? YES NO

No. ITEM YES NO S

N/A REMARKS

1 HAS INSPECTION ASSIGNED THE TEMPORARY REPAIR

NUMBER TO THIS JOB?

2 DOES THE TEMPORARY REPAIR INVOLVE MATERIAL

CHANGE?

3 DOES THE REPAIR INVOLVE ANY TEMPORARY

MODIFICATIONS? IF YES, HAS IT BEEN REVIEWED BY

PROCESS/ PROCESS SUB-SOC?

4 DOES THE TEMPORARY REPAIR INVOLVE MACHINERY?

HAS IT BEEN REVIEWED BY MACHINERY ENGINEER/SH

/UM?

5 HAS THE BOX UP BEEN DESIGNED FOR ALL

COMBINATIONS OF INTERNAL AND EXTERNAL LOADING

AS PER RELEVANT VESSEL AND PIPING CODE?

6 IS BOX UP DESIGNED FOR ALL MODES OF OPERATIONS

e.g. START-UP, SHUTDOWN ETC.?

7 HAVE INSPECTION REQUIREMENTS BEEN REVIEWED BY

INSPECTION ENGINEER/UM OR ANY OTHER

INTERFACES?

8 IS WELDING PROCEDURE PROVIDED WITH NECESSARY

SPECIFICATIONS?

9 IS WELDING DESIGN IN ACCORDANCE WITH CODE

REQUIREMENTS?

10 ARE ALL SMALL PIPING CONNECTIONS ADEQUATELY

GUSSETED?

11 IS THERE ADEQUATE WORKING SPACE FOR FIELD

WORK?

12 WOULD ANY ADDITIONAL LIGHTING BE REQUIRED IF

WORK AT SITE HAS TO BE CARRIED OUT DURING

NIGHT?

13 THE EXECUTION OF BOX UP/TEMPORARY REPAIR WILL

BE DONE UNDER THE DIRECT SUPERVISION OF

EXPERIENCED MAINTENANCE PERSONNEL?

14 IS THERE A FIRE HAZARD DURING FIELD WORK?

15 HAVE ADEQUATE MEASURES (PLACING OF ADDITIONAL

FIRE EXTINGUISHERS / HOSES) BEEN TAKEN IN CASE

THE AREA IS NOT COVERED BY EXISTING FIRE WATER

FACILITY? REQUIREMENT SHOULD BE MENTIONED IN

WORK PERMIT..

16 HAVE THE REQUISITIONS/RESERVATIONS MADE TO

REVERT THE TEMPORARY REPAIR?

17 HOT PERMIT REQUIRED IN HAZARDOUS AREA?

18 RELEVANT SKETCHES AND DIAGRAM PROVIDED WITH

TR FORM?

19 TEST PROCEDURES FOR TR ARE AVAILABLE IF

REQUIRED?

20 DOES THE JOB EXECUTION REQUIRED JSA?

21 DOES THE JOB REQUIRE ANY SPECIAL TRAINING FOR

OPERATIONS / MAINTENANCE PERSONNEL?

22 DOES THE JOB REQUIRE ANY SAFETY AUDIT /PSSR?

(BASED ON CONSEQUENCE ANALSIS)

23 DOES THE REPAIR REQUIRE ANY BARRICADING,

MARKING OR LABELLING IN THE FIELD?

PROJECT ENGINEER / MAINTENANCE ENGINEER/CIVIL ENGINEER

Вам также может понравиться

- Control of Work Training For Performing AuthoritiesДокумент35 страницControl of Work Training For Performing AuthoritiesbutahraОценок пока нет

- Corrective And Preventative Action A Complete Guide - 2020 EditionОт EverandCorrective And Preventative Action A Complete Guide - 2020 EditionОценок пока нет

- Temporary Repair RegisterДокумент6 страницTemporary Repair Registerعصمت ضيف اللهОценок пока нет

- Lead Awareness Toolbox TalkДокумент2 страницыLead Awareness Toolbox Talkarunengg100% (1)

- Human Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveОт EverandHuman Factor and Reliability Analysis to Prevent Losses in Industrial Processes: An Operational Culture PerspectiveОценок пока нет

- Risk Assessment for Human Metal Exposures: Mode of Action and Kinetic ApproachesОт EverandRisk Assessment for Human Metal Exposures: Mode of Action and Kinetic ApproachesОценок пока нет

- HSE Management in Petroleum Facilities-2Документ59 страницHSE Management in Petroleum Facilities-2tissaanuradhaОценок пока нет

- General Osha Compliance Checklist 3Документ7 страницGeneral Osha Compliance Checklist 3Adnin SyazaОценок пока нет

- Ogp Risk Assessment Data DirectoryДокумент26 страницOgp Risk Assessment Data Directoryandrew_chen5758Оценок пока нет

- MP Information Sheet - Planned Maint.Документ2 страницыMP Information Sheet - Planned Maint.joydeepОценок пока нет

- Six Sigma DMAIC MeasureДокумент16 страницSix Sigma DMAIC MeasureRaul Hoan DauОценок пока нет

- CCPS Monograph Reflections From Global Process Safety LeadersДокумент29 страницCCPS Monograph Reflections From Global Process Safety LeadersKiranОценок пока нет

- Compressed Gas CylinderДокумент70 страницCompressed Gas CylinderIrvansyah RazadinОценок пока нет

- Pressure Relief Valve Inspection and MaintenanceДокумент1 страницаPressure Relief Valve Inspection and Maintenance@@ngОценок пока нет

- HSE Exception Request Form Rev.1Документ1 страницаHSE Exception Request Form Rev.1Dhimaz YudiОценок пока нет

- Eye Wash STD and ProceduresДокумент14 страницEye Wash STD and ProceduresBrijendra Pratap Singh0% (1)

- Blank PSM & RMP Audit FormДокумент298 страницBlank PSM & RMP Audit Formclashu2Оценок пока нет

- TN 015 Overrides 15Документ8 страницTN 015 Overrides 15Luis SantosОценок пока нет

- Safety Questions For ExaminationДокумент1 страницаSafety Questions For ExaminationAkeem Dwayne Ralph NoelОценок пока нет

- Process Safety InformationДокумент7 страницProcess Safety InformationMohammed Zubair100% (1)

- Datasheet Briosil Primer 6-7360P - Eng - 25-08-11Документ3 страницыDatasheet Briosil Primer 6-7360P - Eng - 25-08-11SUBODHОценок пока нет

- Health, Safety & Environment: Understanding Oil and Gas BusinessДокумент34 страницыHealth, Safety & Environment: Understanding Oil and Gas BusinessMadhur ChopraОценок пока нет

- Vehicle Inspection: Administrative Procedures & GuidelinesДокумент1 страницаVehicle Inspection: Administrative Procedures & GuidelinesAdi Mbah Rowo WibowoОценок пока нет

- Safety ManualДокумент74 страницыSafety ManualKentDemeterio100% (1)

- Chemical SpillДокумент28 страницChemical Spillecoenv100% (1)

- SimOps Plan Form Pigging 10'' NMDL - MGTДокумент2 страницыSimOps Plan Form Pigging 10'' NMDL - MGTUnknown JihadОценок пока нет

- Doe STD 1197 2011Документ123 страницыDoe STD 1197 2011Marco RangelОценок пока нет

- Fire Policy 1Документ2 страницыFire Policy 1caleb99Оценок пока нет

- KPI Process SafetyДокумент6 страницKPI Process SafetyKrishnan RajappanОценок пока нет

- Petroleum Industry Act 2021 Key Highlights 230821Документ33 страницыPetroleum Industry Act 2021 Key Highlights 230821Ebene ChimaОценок пока нет

- API Specification Q1 9th Edition Errata 3 20191017Документ1 страницаAPI Specification Q1 9th Edition Errata 3 20191017shifaОценок пока нет

- Management of Change (Moc)Документ6 страницManagement of Change (Moc)kheireddine fekrouneОценок пока нет

- CartridgeSelectionPoster English HRДокумент1 страницаCartridgeSelectionPoster English HRTg TarroОценок пока нет

- Kelvin TOP-SET Investigation Report TemplateДокумент7 страницKelvin TOP-SET Investigation Report TemplateMohamedSaidОценок пока нет

- Machine Guarding: NotesДокумент6 страницMachine Guarding: NotesMBAHОценок пока нет

- Chemical Spill Procedure: 1. PurposeДокумент2 страницыChemical Spill Procedure: 1. PurposeWalter A. Mustafa Takeo100% (1)

- 70management System Standards Comparison Between IAEA GSR3 and ASME NQA12008 and NQA1a2009 Addenda PDFДокумент76 страниц70management System Standards Comparison Between IAEA GSR3 and ASME NQA12008 and NQA1a2009 Addenda PDFMarian GumielОценок пока нет

- Instructions: Installation, Operation, and Maintenance of Medium Power Substation TransformersДокумент24 страницыInstructions: Installation, Operation, and Maintenance of Medium Power Substation TransformersDixie VictoriaОценок пока нет

- Safety Resume Without Certificate PDFДокумент4 страницыSafety Resume Without Certificate PDFSAFETY RОценок пока нет

- Ethanol Tank Fire Incident ReportДокумент20 страницEthanol Tank Fire Incident ReportN P Srinivasarao100% (1)

- PTW Check ListsДокумент30 страницPTW Check ListsRoshin99100% (1)

- Wastes Disposal ProcedureДокумент11 страницWastes Disposal ProcedureTao QuОценок пока нет

- Weekly Facility Inspection ChecklistДокумент1 страницаWeekly Facility Inspection ChecklistWalid SonjiОценок пока нет

- First Line Supervisor Safety ResponsibilitiesДокумент8 страницFirst Line Supervisor Safety ResponsibilitiesSughanyaa VeОценок пока нет

- HAZID PresentationДокумент11 страницHAZID PresentationAlvian FachrurroziОценок пока нет

- Indicators of Process Safety Through The Lens of MacondoДокумент44 страницыIndicators of Process Safety Through The Lens of Macondoasya100% (1)

- CSP2017-Safety Audit PlanДокумент14 страницCSP2017-Safety Audit PlanGaryОценок пока нет

- Manual: Procedure Titel: HSE-ManualДокумент11 страницManual: Procedure Titel: HSE-ManualGeetha_jagadish30Оценок пока нет

- Objectives: CareerДокумент14 страницObjectives: CareerHedi Ben MohamedОценок пока нет

- Balance Plot FormДокумент1 страницаBalance Plot FormHamzaNoumanОценок пока нет

- Acceptance Criteria of Weld Defects As Per Different CodesДокумент17 страницAcceptance Criteria of Weld Defects As Per Different CodesShubham ShuklaОценок пока нет

- Helium Leak Detector Vs Pressure Decay Leak DetectionДокумент2 страницыHelium Leak Detector Vs Pressure Decay Leak DetectionHamzaNoumanОценок пока нет

- Best Practices in Machinery InstallationДокумент2 страницыBest Practices in Machinery InstallationHamzaNoumanОценок пока нет

- 2005 Nondestructive Testing GuideДокумент8 страниц2005 Nondestructive Testing GuideHamzaNoumanОценок пока нет

- H Hole MesaurmentДокумент2 страницыH Hole MesaurmentHamzaNoumanОценок пока нет

- The ABC of NDTДокумент5 страницThe ABC of NDTHamzaNoumanОценок пока нет

- Confirmation - Check-InДокумент1 страницаConfirmation - Check-InHamzaNoumanОценок пока нет

- Shift 2 Schedule (Sept 12 - Sept 20 '22)Документ1 страницаShift 2 Schedule (Sept 12 - Sept 20 '22)HamzaNoumanОценок пока нет

- Bayyinat ArticleДокумент4 страницыBayyinat ArticleHamzaNoumanОценок пока нет

- Nbo-Tc NewДокумент24 страницыNbo-Tc NewHamzaNoumanОценок пока нет

- Certificate of Completion: Hafiz NomanДокумент1 страницаCertificate of Completion: Hafiz NomanHamzaNoumanОценок пока нет

- Fluid Handling System PriceДокумент2 страницыFluid Handling System PriceHamzaNoumanОценок пока нет

- 7 22 2022 Mech - 19596Документ1 страница7 22 2022 Mech - 19596HamzaNoumanОценок пока нет

- MC LiftRigBestPractices Poster 11X17Документ1 страницаMC LiftRigBestPractices Poster 11X17HamzaNoumanОценок пока нет

- Advance Cash For Cricket PitchДокумент1 страницаAdvance Cash For Cricket PitchHamzaNoumanОценок пока нет

- Congratulations On Your Completion: Hamza NomanДокумент1 страницаCongratulations On Your Completion: Hamza NomanHamzaNoumanОценок пока нет

- Manpower Workshop Garage CraftДокумент7 страницManpower Workshop Garage CraftHamzaNoumanОценок пока нет

- Onboarding Checklist IGДокумент1 страницаOnboarding Checklist IGHamzaNoumanОценок пока нет

- Sr. No. Description Unit: Workshop / Garage Craft IssuesДокумент14 страницSr. No. Description Unit: Workshop / Garage Craft IssuesHamzaNoumanОценок пока нет

- Cylinder Test-Certification-ProceduresДокумент3 страницыCylinder Test-Certification-ProceduresHamzaNoumanОценок пока нет

- Unit Conversion All in OneДокумент7 страницUnit Conversion All in OneSuyenthan SathishОценок пока нет

- Scaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedДокумент42 страницыScaffolding: Submitted By, Akhilesh.A Production Operator (TR), Forbes Bumiarmada LimitedHamzaNoumanОценок пока нет

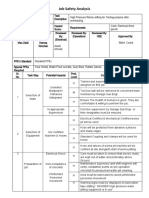

- JSA For Woma Jet TestingДокумент2 страницыJSA For Woma Jet TestingHamzaNoumanОценок пока нет

- Contract Extension of Hafiz Hussain 2021Документ2 страницыContract Extension of Hafiz Hussain 2021HamzaNoumanОценок пока нет

- Mechanical Workshop: Inspection & Test PlanДокумент4 страницыMechanical Workshop: Inspection & Test PlanHamzaNoumanОценок пока нет

- D Level Safety Meeting Quality Checklist - RevisedДокумент1 страницаD Level Safety Meeting Quality Checklist - RevisedHamzaNoumanОценок пока нет

- Incident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00Документ2 страницыIncident / Injury Occurrence Report Part A:: Form No: SAF/2/001 Date Prepared: 29 / 09 / 08 Revision: 00HamzaNoumanОценок пока нет

- MCBU - Lifting & Rigging Questions and AnswersДокумент15 страницMCBU - Lifting & Rigging Questions and AnswersBhaiJan59Оценок пока нет

- PC Help Desk Form: Pakarab Fertilizers Ltd. MultanДокумент1 страницаPC Help Desk Form: Pakarab Fertilizers Ltd. MultanHamzaNoumanОценок пока нет

- Alumni Placment 2014 2021Документ131 страницаAlumni Placment 2014 2021samyakОценок пока нет

- TDA2003 BridgeДокумент10 страницTDA2003 BridgeMartinaxMgmОценок пока нет

- Vi Editor Cheat SheetДокумент1 страницаVi Editor Cheat SheetChris HarkerОценок пока нет

- A Tours and Travels Management SystemДокумент19 страницA Tours and Travels Management SystemZeenat SiddiqueОценок пока нет

- Cisco SIEM Deployment GuideДокумент19 страницCisco SIEM Deployment GuideShruthi Kavya KОценок пока нет

- Nate Holt's Blog On Electrical CAD, Etc enДокумент51 страницаNate Holt's Blog On Electrical CAD, Etc enMario FriscoОценок пока нет

- SB 273 014 Engine Sensor Locations Nov 19 2008 1 PDFДокумент4 страницыSB 273 014 Engine Sensor Locations Nov 19 2008 1 PDFImade EmadeОценок пока нет

- Railways Docks Harbor EngineeringДокумент4 страницыRailways Docks Harbor Engineeringsanthoshkumar2012Оценок пока нет

- SC 37 Operating Instructions 0928Документ148 страницSC 37 Operating Instructions 0928Pranav PatilОценок пока нет

- Shichun Yang Xinhua Liu Shen Li Cheng Zhang: Advanced Battery Management System For Electric VehiclesДокумент318 страницShichun Yang Xinhua Liu Shen Li Cheng Zhang: Advanced Battery Management System For Electric VehiclesDennis FielОценок пока нет

- 120scmapi PDFДокумент1 680 страниц120scmapi PDFSasidhar Bhagavan SunkaraОценок пока нет

- Brochure Berkeley Data VisualizationДокумент13 страницBrochure Berkeley Data VisualizationCosmin IonutОценок пока нет

- Components DetailsДокумент14 страницComponents DetailssukanyagggОценок пока нет

- CEMS A 10 Part I APPXДокумент80 страницCEMS A 10 Part I APPXaldairlopesОценок пока нет

- Solutions in Power Conditioning: Vertex - 3 kVA - 150 kVAДокумент2 страницыSolutions in Power Conditioning: Vertex - 3 kVA - 150 kVAfinhasОценок пока нет

- PC5108FLR v2.0 Installation Instructions: General EnclosuresДокумент2 страницыPC5108FLR v2.0 Installation Instructions: General EnclosuresMario Gabriel MoralliОценок пока нет

- KX-TGFA30: Additional Digital Cordless HandsetДокумент16 страницKX-TGFA30: Additional Digital Cordless HandsetAntonio OrtizОценок пока нет

- Portable Smart Phone Charger Using HumanДокумент6 страницPortable Smart Phone Charger Using HumanKipkoech FrankОценок пока нет

- Irjet V6i492Документ5 страницIrjet V6i492GunawanОценок пока нет

- 9852 1007 01d Maintenance Instr COP 1840HE, HEXДокумент19 страниц9852 1007 01d Maintenance Instr COP 1840HE, HEXButnariu CristianОценок пока нет

- GM 5L40E Automatic Diagrams and ListДокумент9 страницGM 5L40E Automatic Diagrams and ListBrayan Aragon diego100% (1)

- What IsДокумент3 страницыWhat IsmajidalishahОценок пока нет

- Student Handbook - Tech Course IДокумент4 страницыStudent Handbook - Tech Course I5129 SRI RAM SОценок пока нет

- RG Board ListДокумент15 страницRG Board ListAura Bella FioraОценок пока нет

- Case Study: Reverse Engineering FacemojiДокумент16 страницCase Study: Reverse Engineering Facemojizappergod100% (1)

- Datasheet FG2F009Документ2 страницыDatasheet FG2F009hanswurstpeter12Оценок пока нет

- 3BUR001977R3701revA AdvaBld AdminДокумент198 страниц3BUR001977R3701revA AdvaBld Adminjose_alberto2Оценок пока нет

- ISTQB Sample Paper - 500 QuestionsДокумент66 страницISTQB Sample Paper - 500 QuestionsIna Arsova100% (1)

- Bcom Sem 3 Comp App PDFДокумент1 страницаBcom Sem 3 Comp App PDFPallabiОценок пока нет

- NNDL LabДокумент33 страницыNNDL LabPrince KumarОценок пока нет