Академический Документы

Профессиональный Документы

Культура Документы

Pump Selection PDF

Загружено:

hairie azam Razak0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров2 страницыОригинальное название

pump_selection.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

43 просмотров2 страницыPump Selection PDF

Загружено:

hairie azam RazakАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Energy Tips Pumping Systems

Pumping Systems Tip Sheet #2 October 2005 Industrial Technologies Program

Suggested Actions Pump Selection Considerations

Accurately identify process flow

rate and pressure requirements. Understanding Your Pumping System Requirements

Measure actual head and flow rate. Pumps transfer liquids from one point to another by converting mechanical energy

Develop a system curve. from a rotating impeller into pressure energy (head). The pressure applied to the

Select a pump with high efficiency liquid forces the fluid to flow at the required rate and to overcome friction (or head)

over the expected range of losses in piping, valves, fittings, and process equipment. The pumping system designer

operating conditions. must consider fluid properties, determine end use requirements, and understand

Specify electric motors that meet environmental conditions. Pumping applications include constant or variable flow rate

the NEMA Premium full-load requirements, serving single or networked loads, and consisting of open loops

efficiency standards. (nonreturn or liquid delivery) or closed loops (return systems).

Use life cycle costing techniques to

justify acquiring high efficiency Fluid Properties

pumps and designing efficient The properties of the fluids being pumped can significantly affect the choice of pump.

systems. Key considerations include:

Acidity/alkalinity (pH) and chemical composition. Corrosive and acidic fluids

Resources can degrade pumps, and should be considered when selecting pump materials.

DOE and Hydraulic Institute,

Operating temperature. Pump materials and expansion, mechanical seal

Improving Pumping System

Performance: A Sourcebook for components, and packing materials need to be considered with pumped fluids that

Industry. are hotter than 200F.

Hydraulic InstituteHI is a non- Solids concentrations/particle sizes. When pumping abrasive liquids such as

profit industry association for pump industrial slurries, selecting a pump that will not clog or fail prematurely depends on

and pump system manufacturers; particle size, hardness, and the volumetric percentage of solids.

it provides product standards and a Specific gravity. The fluid specific gravity is the ratio of the fluid density to that of

forum for the exchange of industry water under specified conditions. Specific gravity affects the energy required to lift and

information for management decision-

move the fluid, and must be considered when determining pump power requirements.

making. In addition to the ANSI/HI

pump standards, HI has a variety Vapor pressure. A fluids vapor pressure is the force per unit area that a fluid exerts

of energy-related resources for in an effort to change phase from a liquid to a vapor, and depends on the fluids

pump users and specifiers, including chemical and physical properties. Proper consideration of the fluids vapor pressure

training, guidebooks, and more. For will help to minimize the risk of cavitation.

more information, visit www.pumps.

Viscosity. The viscosity of a fluid is a measure of its resistance to motion. Since

org, www.pumplearning.org, and

www.pumpsystemsmatter.org. kinematic viscosity normally varies directly with temperature, the pumping system

designer must know the viscosity of the fluid at the lowest anticipated pumping

U.S. Department of EnergyDOEs

temperature. High viscosity fluids result in reduced centrifugal pump performance

Pumping System Assessment Tool

(PSAT) can help you assess pumping and increased power requirements. It is particularly important to consider pump

system efficiency and estimate suction-side line losses when pumping viscous fluids.

energy and cost savings. PSAT uses

pump performance data from End Use RequirementsSystem Flow Rate and Head

Hydraulic Institute standards and The design pump capacity, or desired pump discharge in gallons per minute (gpm) is

motor performance data from the needed to accurately size the piping system, determine friction head losses, construct

MotorMaster+ database. a system curve, and select a pump and drive motor. Process requirements may be met

Visit the BestPractices Web site at by providing a constant flow rate (with on/off control and storage used to satisfy

www.eere.energy.gov/bestpractices variable flow rate requirements), or by using a throttling valve or variable speed drive

for more information on PSAT and to supply continuously variable flow rates.

for upcoming training in improving

pumping system performance and in

The total system head has three components: static head, elevation (potential energy),

becoming a qualified pumping

system specialist. and velocity (or dynamic) head. Static head is the pressure of the fluid in the system,

and is the quantity measured by conventional pressure gauges. The height of the fluid

level can have a substantial impact on system head. The dynamic head is the pressure

required by the system to overcome head losses caused by flow rate resistance in BestPractices is part of the Industrial

Technologies Program Industries of the

pipes, valves, fittings, and mechanical equipment. Dynamic head losses are approxi- Future strategy, which helps the countrys

mately proportional to the square of the fluid flow velocity, or flow rate. If the flow most energy-intensive industries improve

rate doubles, dynamic losses increase fourfold. their competitiveness. BestPractices brings

together emerging technologies and best

energy-management practices to help

For many pumping systems, total system head requirements vary. For example, in companies begin improving energy efficiency,

wet well or reservoir applications, suction and static lift requirements may vary as environmental performance, and productivity

right now.

the water surface elevations fluctuate. For return systems such as HVAC circulating

water pumps, the values for the static and elevation heads equal zero. You also need BestPractices emphasizes plant systems,

to be aware of a pumps net positive suction head requirements. Centrifugal pumps where significant efficiency improvements

and savings can be achieved. Industry gains

require a certain amount of fluid pressure at the inlet to avoid cavitation. A rule of easy access to near-term and long-term

thumb is to ensure that the suction head available exceeds that required by the pump solutions for improving the performance of

motor, steam, compressed air, and process

by at least 25% over the range of expected flow rates. heating systems. In addition, the Industrial

Assessment Centers provide comprehensive

Environmental Considerations industrial energy evaluations to small- and

Important environmental considerations include ambient temperature and humidity, medium-size manufacturers.

elevation above sea level, and whether the pump is to be installed indoors or outdoors.

Software Tools FOR ADDITIONAL INFORMATION,

PLEASE CONTACT:

Most pump manufacturers have developed software or Web-based tools to assist in

the pump selection process. Pump purchasers enter their fluid properties and system

requirements to obtain a listing of suitable pumps. Software tools that allow you to EERE Information Center

1-877-EERE-INF

evaluate and compare operating costs are available from private vendors. (1-877-337-3463)

www.eere.energy.gov

Reference

Centrifugal/Vertical NPSH Margin (ANSI/HI 9.6.1-1998), www.pumps.org, Hydraulic Industrial Technologies Program

Institute, 1998. Energy Efficiency

and Renewable Energy

U.S. Department of Energy

Washington, DC 20585-0121

About DOEs Industrial Technologies Program www.eere.energy.gov/industry

The Industrial Technologies Program, through partnerships with industry,

government, and non-governmental organizations, develops and delivers advanced

energy efficiency, renewable energy, and pollution prevention technologies for

industrial applications. The Industrial Technologies Program is part of the U.S.

Department of Energys Office of Energy Efficiency and Renewable Energy.

The Industrial Technologies Program encourages industry-wide efforts to boost

resource productivity through a strategy called Industries of the Future (IOF). IOF

focuses on the following eight energy and resource intensive industries:

Aluminum Forest Products Metal Casting Petroleum

Chemicals Glass Mining Steel

The Industrial Technologies Program and its BestPractices activities offer a wide

variety of resources to industrial partners that cover motor, steam, compressed air,

and process heating systems. For example, BestPractices software can help you decide

whether to replace or rewind motors (MotorMaster+), assess the efficiency of pumping A S TRONG E NERGY P ORTFOLIO

FOR A S TRONG A MERICA

systems (PSAT), compressed air systems (AirMaster+), steam systems (Steam Scoping

Tool), or determine optimal insulation thickness for pipes and pressure vessels (3E Energy efficiency and clean, renewable

Plus). Training is available to help you or your staff learn how to use these software energy will mean a stronger economy, a

cleaner environment, and greater energy

programs and learn more about industrial systems. Workshops are held around the independence for America. Working

country on topics such as Capturing the Value of Steam Efficiency, Fundamentals with a wide array of state, community,

and Advanced Management of Compressed Air Systems, and Motor System industry, and university partners, the U.S.

Management. Available technical publications range from case studies and tip sheets Department of Energys Office of Energy

Efficiency and Renewable Energy invests in

to sourcebooks and market assessments. The Energy Matters newsletter, for example, a diverse portfolio of energy technologies.

provides timely articles and information on comprehensive energy systems for industry.

You can access these resources and more by visiting the BestPractices Web site at

www.eere.energy.gov/ industry/bestpractices or by contacting the EERE Information DOE/GO-102005-2156

October 2005

Center at 877-337-3463 or via email at www.eere.energy.gov/informationcenter/. Pumping Systems Tip Sheet #2

Вам также может понравиться

- Suppression of Coke Formation in The Steam Cracking of Alkanes Ethane and PropaneДокумент16 страницSuppression of Coke Formation in The Steam Cracking of Alkanes Ethane and Propanehairie azam RazakОценок пока нет

- Barden Bearing Failures Us enДокумент15 страницBarden Bearing Failures Us enIbrahimElKelany100% (1)

- Storage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim GalalaДокумент10 страницStorage Tank Design Calculations - Seismic Design & Overturning Moment - by Abdel Halim Galalamarkfgt57% (7)

- Syah Hafiz Bin Mohd Nor 15034 - SIT ReportДокумент44 страницыSyah Hafiz Bin Mohd Nor 15034 - SIT Reporthairie azam RazakОценок пока нет

- Ethylene PlantДокумент7 страницEthylene PlantVerryNoerОценок пока нет

- Amine Best Practices GuideДокумент63 страницыAmine Best Practices GuideJerold100% (2)

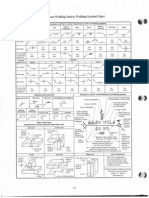

- AWS Weld Symbol ChartДокумент1 страницаAWS Weld Symbol ChartExsan OthmanОценок пока нет

- Ethylene PlantДокумент7 страницEthylene PlantVerryNoerОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Flue Gas CalculationДокумент2 страницыFlue Gas CalculationhcorpdgpОценок пока нет

- Conduct An In-Plant Pumping System Survey PDFДокумент2 страницыConduct An In-Plant Pumping System Survey PDFsuilanroОценок пока нет

- Mikemueller ResumeДокумент1 страницаMikemueller Resumeapi-267946794Оценок пока нет

- Sustainable Alternative Fuel Feedstock Oportunities, Challenges and Roadmaps For Six US RegionsДокумент5 страницSustainable Alternative Fuel Feedstock Oportunities, Challenges and Roadmaps For Six US RegionsCamila Colhado GalloОценок пока нет

- OpenText User Guide PDFДокумент101 страницаOpenText User Guide PDFSrabani Mohanty100% (1)

- H2@Scale New Markets FOA 2229 - Mod 0002Документ120 страницH2@Scale New Markets FOA 2229 - Mod 0002Bikram Basu RoychowdhuryОценок пока нет

- Chemical Bandwidth ReportДокумент40 страницChemical Bandwidth ReportterumistarОценок пока нет

- Steam15 BenchmarkДокумент2 страницыSteam15 BenchmarkGustavo Garces GuerreroОценок пока нет

- Energy Technology SolutionsДокумент94 страницыEnergy Technology SolutionsAlper KoçerОценок пока нет

- Enhanced Geothermal SystemsДокумент8 страницEnhanced Geothermal SystemshafidzadiОценок пока нет

- Compressed AirДокумент52 страницыCompressed AirpradeepbooОценок пока нет

- Weatherization-A Test CaseДокумент18 страницWeatherization-A Test CaseCarnegie Endowment for International Peace100% (1)

- Compressed Air System Design, Operating and MaintenanceДокумент29 страницCompressed Air System Design, Operating and Maintenanceibrahim1961Оценок пока нет

- IAEMP Energy 2022 Vision DocumentДокумент82 страницыIAEMP Energy 2022 Vision DocumentBhupal Singh100% (5)

- Best Practices in Energy Data Collection and Tracking - FinalДокумент35 страницBest Practices in Energy Data Collection and Tracking - FinalmahОценок пока нет

- Proposal Rough 4Документ10 страницProposal Rough 4api-316780587Оценок пока нет

- Hydrogen Class8 Long Haul Truck TargetsДокумент31 страницаHydrogen Class8 Long Haul Truck TargetsHannu JaaskelainenОценок пока нет

- SunShot Vision StudyДокумент320 страницSunShot Vision StudyTom CotterОценок пока нет

- US Cleantech Profile GuideДокумент48 страницUS Cleantech Profile GuideMokhsein AbdullahОценок пока нет

- Material and Manufacturing Successes and Future Opportunities To Drive Inexpensive Solar ElectricityДокумент33 страницыMaterial and Manufacturing Successes and Future Opportunities To Drive Inexpensive Solar ElectricityABCDОценок пока нет

- Auto Blowdown ControlДокумент2 страницыAuto Blowdown ControlIan B. YtomОценок пока нет

- Energy: Wind - The History of Wind Energy, Electricity Generation from the Wind, Types of Wind Turbines, Wind Energy Potential, Offshore Wind Technology, Wind Power on Federal Land, Small Wind Turbines, Economic and Policy Issues, Tax Policy (Excerpt)Документ159 страницEnergy: Wind - The History of Wind Energy, Electricity Generation from the Wind, Types of Wind Turbines, Wind Energy Potential, Offshore Wind Technology, Wind Power on Federal Land, Small Wind Turbines, Economic and Policy Issues, Tax Policy (Excerpt)TheCapitol.Net100% (5)

- Turbulators para Calderas CostosДокумент2 страницыTurbulators para Calderas Costoshbarrios100% (2)

- MDM Motor Planning Kit PDFДокумент24 страницыMDM Motor Planning Kit PDFFUCKUОценок пока нет

- US DOE Energy Tips On CDAДокумент2 страницыUS DOE Energy Tips On CDADarrenkjcОценок пока нет

- Mining Industry Energy BandwidthДокумент47 страницMining Industry Energy BandwidthAnonymous ntE0hG2TPОценок пока нет

- Chilled Water System Analysis Tool Fact SheetДокумент2 страницыChilled Water System Analysis Tool Fact SheetTen TengОценок пока нет

- PV Grid PenetrationДокумент182 страницыPV Grid PenetrationgivepleaseОценок пока нет

- Waste Heat Recovery FactsheetДокумент2 страницыWaste Heat Recovery FactsheetMajid JafariОценок пока нет