Академический Документы

Профессиональный Документы

Культура Документы

C12 Chapter 12 Fan Engineering Technick

Загружено:

Nereo SpenglerОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

C12 Chapter 12 Fan Engineering Technick

Загружено:

Nereo SpenglerАвторское право:

Доступные форматы

Chapter 12

Fan Laws

The fan laws are a particular version of the more general similarity laws

that apply to all classes of turbomachinery. They express the relationships

among the performance variables for any two fans that have similar flow

conditions. The variables include: fan size D , fan speed N , fan air density

, fan flow rate Q , fan total pressure pFT , fan velocity pressure pFV , fan

static pressure pFS , fan input power Ps , fan total efficiency T , fan static

efficiency S , compressibility coefficient K p , and sound power level LW .

Alternative variables include: fan mass flow rate m instead of fan volume

flow rate Q and fan specific energy (or fan work) y F instead of the various

fan pressures pFT , pFV , and pFS . The symbols chosen here to represent the

various fan performance variables are a compromise between the simplest and

the most clear. For maximum clarity, each of the symbols should have a

subscript F; however, this has been omitted from many for simplicity. The

subscript F is retained as part of the fan pressure symbols to avoid any possi-

bility of confusion with the pressure at a point. In some works, the distinction

between fan pressure and pressure at a point is made by using P for the former

and p for the latter. In this handbook, however, all pressures are denoted by

p . The symbol for power is P with subscript i designating impeller power,

subscript s designating shaft power, and subscript o designating output power.

Derivation

The fan laws, like the similarity laws, can be derived by various methods

of reasoning. Closely examining the momentum equations will lead to the

correct conclusions. Dimensional analysis can also be used. Various texts

present these methods in various ways. The fan laws can be based on either

compressible or incompressible flow. Although incompressible-flow fan laws

are sufficiently accurate for many fan-engineering applications, compressible-

flow fan laws should be used whenever the difference due to compressibility

coefficient exceeds the accuracy desired for the calculation.

1

R. Jorgensen and H. R. Bohanon, "Compressibility and Fan Laws," ASHRAE Paper No.

2333, presented at Atlantic City, 1975. This derivation is based on an assumed polytropic

process through the fan based on the total pressures, total temperatures, and total densities at

the inlet and outlet. The fan air density is taken to be the stagnation air density at the fan

inlet. The fan flow rate is the volume flow rate based on fan air density.

#1999 Howden Buffalo, Inc.

12-2 FAN ENGINEERING

Jorgensen and Bohanon1 derived compressible-flow fan laws, which are

the basis for the variations listed in Table 12.1. The incompressible versions,

which were listed in earlier editions of this handbook, can be obtained by

setting the compressibility coefficient ratio equal to unity. Table 12.2 lists

Fan Law 1 on the basis of mass flow rate and fan work. Fan Laws 2 through

10 could also be listed on this basis but are omitted because mass flow rate

and fan work are not yet in general use.

Applications

The fan laws can be used to predict the performance of a fan, if certain

requirements are satisfied. The basic requirement is that the performance at

the corresponding points of rating for an homologous fan be known. Two or

more fans are said to be homologous when their air passages are

geometrically similar. Two or more homologous fans are said to be operating

at corresponding points of rating if the positions of the operating points,

relative to shutoff and free delivery, are the same.

The fan laws are listed in Table 12.1. Any of the ten variations can be

used to predict the performance of a fan (subscript a) when the performance

of another fan (subscript b) is known. These ten are simply mathematical

manipulations of one fundamental set of relationships. The different

variations have different groups of dependent and independent variables.

Density and compressibility coefficients are always shown as independent

variables, but velocity pressure and sound power level are always dependent

variables. Note that an entire set of dependent variables must be calculated

whenever a particular set of independent variables is changed. Also, note that

efficiency and point of rating are constant for all fan law applications.

Whenever the flow can be considered incompressible, the ratio of

compressibility coefficients can be taken to be unity, thereby simplifying

many calculations.

The choice of fan law variation to be used in any particular situation will

depend on the independent variables. For instance, if a new D and a new N

are specified, as is frequently so when drawing performance curves, then Fan

Law 1 should be used. This is illustrated in Example 12.1. If the performance

of a given fan is to be varied, then D will be constant and must be one of the

independent variables. Fan Law 1, 2, 3, or 4 may be used, depending on

whether N , pFT , Q , or Pi is specified. See Examples 12.2 and 12.3.

Fan Laws 1 and 5 lead to some very useful concepts, which are discussed

in the sections on equivalency, power formulae, specific speed, specific

diameter, and specific sound power level.

Different methods of rating fans could be developed using various

combinations of the ten fan law variations. Methods for rating a particular

size of fan can be developed from the first four variations because diameter is

an independent variable. However, methods for determining the size may call

for one of the last six variations. Some of the more common rating methods

are described in the chapter on selection.

1

See footnote previous page.

1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-3

Table 12.1 Fan Laws

For all fan laws: Ta = Tb and (point of rating)a = (point of rating)b

No. Dependent Independent Variables

D 3

N 1

1 K 1

1a Q a = Q b

D

a

b

N

a

b

1 K

pa

pb

D 2

N 2

1

K 1

1b pFTa = pFTb

D

a

b

N

a

b

a

b

K

pa

pb

D 5

N 3

1

K 1

1c Pia = Pib

D

a

b

N

a

b

a

b

K

pa

pb

D

2

N 2

1

1

pFVa = pFVb

D

N 1

a a a

1d

D N

b b b

+ 70 log 50 log + 20 log

LWa = LWb

D +

N

a a a

1e

b b b

D

2

p

12 1 2

K 1 2

2a Q a = Q b

D

a

b

p

FT a

FTb

a

b

K

pa

pb

D

1

p

12 1 2

K 12

2b N a = Nb

D

a

b

p

FT a

FTb

a

b

K

pa

pb

D

2

p

32 1 2

K 12

2c Pia = Pib

D

a

b

p

FT a

FTb

a

b

K

pa

pb

1 p 1

1

K 1

2d pFVa = pFVb

1

p

FT a

FTb

1 K

pa

pb

+ 20 log

D p 5 log

25 log

LWa = LWb

D +

p

a Ft a a

2e

b Ft b b

Note that an entire set of dependent variables must be calculated whenever a

particular set of independent variables is changed.

#1999 Howden Buffalo, Inc.

12-4 FAN ENGINEERING

Table 12.1 (cont.) Fan Laws

For all fan laws: Ta = Tb and (point of rating)a = (point of rating)b

No. Dependent Independent Variables

D

3

Q

1

1 K 1

3a N a = Nb

D

a

b

Q

a

b

1 K pa

pb

D

4

Q 2

1

K 1

3b pFTa = pFTb

D

a

b

Q

a

b

a

b

K pa

pb

D

4

Q 3

1

K 2

3c Pia = Pib

D

a

b

Q

a

b

a

b

K pa

pb

D

4

Q 2

1

K 2

3d pFVa = pFVb

D

a

b

Q

a

b

a

b

K pa

pb

D

80 log 50 log

Q

+ 20 log

LWa = LWb

D +

Q

a a a

3e

b b b

D 43

P 13

1 3

K 2 3

4a Q a = Q b

D

a

b

P

ia

ib

a

b

K pa

pb

D 4 3

P 23

13

K 1 3

4b pFTa = pFTb

D

a

b

P

ia

ib

a

b

K pa

pb

D 5 3

P 13

1 3

K 13

4c N a = Nb

D

a

b

P

ia

ib

a

b

K pa

pb

D 4 3

P 23

13

K 23

4d pFVa = pFVb

D

a

b

P

ia

ib

a

b

K pa

pb

D

13.3 log + 16.6 log

P

LWa = LWb

D P + 3.3 log

a ia a

4e

b ib b

Note that an entire set of dependent variables must be calculated whenever a

particular set of independent variables is changed.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-5

Table 12.1 (cont.) Fan Laws

For all fan laws: Ta = Tb and (point of rating)a = (point of rating)b

No. Dependent Independent Variables

Q

12

p 1 4

14

K 14

5a Da = Db

Q

a

b

p

FT a

FTb

a

b

K pa

pb

Q

1 2

p 34

3 4

K 14

5b N a = Nb

Q

a

b

p

FT a

FTb

a

b

K pa

pb

Q 1

p 1

1

K 1

5c Pia = Pib

Q

a

b

p

FT a

FTb 1 K pa

pb

1 p 1

1

K 1

5d pFVa = pFVb

1

p

FT a

FTb 1 K pa

pb

+ 10 log

Q p + 0 log

5e LWa = LWb

Q

a

b

p + 20 log FT a

FT b

a

Q N 1

13 1 3

K 13

6a Da = Db

Q

a

b N 1

a

b

K pa

pb

Q N

23 43 1

K 1 3

6b pFTa = pFTb

Q

a

b N

a

b

a

b

K pa

pb

Q N

53 43 1

K 23

6c Pia = Pib

Q

a

b N

a

b

a

b

K pa

pb

Q N

23 43 1

K 23

6d pFVa = pFVb

Q

a

b N

a

b

a

b

K pa

pb

Q N

+ 23.3 log + 26.6 log + 20 log

LWa = LWb

Q N

a a a

6e

b b b

Note that an entire set of dependent variables must be calculated whenever a

particular set of independent variables is changed.

1999 Howden Buffalo, Inc.

12-6 FAN ENGINEERING

Table 12.1 (cont.) Fan Laws

For all fan laws: Ta = Tb and (point of rating)a = (point of rating)b

No. Dependent Independent Variables

p

N

12 1

1 2

K 12

7a Da = Db

p

FT a

FTb N

a

b

a

b

K

pa

pb

p

N

32 2

3 2

K 12

7b N a = Nb

p

FT a

FTb N

a

b

a

b

K

pa

pb

p

N

52 2

3 2

K 32

7c Pia = Pib

p

FT a

FTb N

a

b

a

b

K

pa

pb

p 1

1

1 K 1

7d pFVa = pFVb

p

FT a

FTb 1 1 K

pa

pb

p 20 log N

+ 35 log

15 log

LWa = LWb

p N

FT a a a

7e

FT b b b

P Q

1 4 34

14

K 12

8a Da = Db

P

ia

ib Q

a

b

a

b

K

pa

pb

P Q

34 5 4

3 4

K 1 2

8b N a = Nb

P

ia

ib Q

a

b

a

b

K

pa

pb

P Q

1 1

1 K 1

8c pFTa = pFTb

P

ia

ib Q

a

b

1 K

pa

pb

P Q

1 1

1 1

pFVa = pFVb

P Q 1

1

ia a

8d

P Q

ib b

+ 20 log 10 log + 0 log

8e ` LWa = LWb

P Q

ia a a

ib b b

Note that an entire set of dependent variables must be calculated whenever a

particular set of independent variables is changed.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-7

Table 12.1 (cont.) Fan Laws

For all fan laws: Ta = Tb and (point of rating)a = (point of rating)b

No. Dependent Independent Variables

P

12

p 3 4

14

K 1 4

9a Da = Db

P

ia

ib p

FT a

FTb

a

b

K

pa

pb

P

1 2

p 54

3 4

K 34

9b N a = Nb

P

ia

ib p

FT a

FTb

a

b

K pa

pb

P 1

p 1

1 K 1

9c Q a = Q b

P

ia

ib p

FT a

FTb

1 K pa

pb

1 p 1

1 K 1

9d pFVa = pFVb

1

p

FT a

FTb

1 K

pa

pb

P

+ 10 log + 10 log

p

+ 0 log

LWa = LWb

P p

ia FT a a

9e

ib FTb b

P

15

N 3 5

1 5

K 15

10a Da = Db

P

ia

ib

N

a

b

a

b

K pa

pb

P

35

N 4 5

3 5

K 2 5

10b Q a = Q b

P

ia

ib

N

a

b

a

b

K pa

pb

P

25

N 45

35

K 3 5

10c pFTa = pFTb

P

ia

ib

N

a

b

a

b

K pa

pb

P

25

N 45

35

K 25

10d pFVa = pFVb

P

ia

ib

N

a

b

a

b

K pa

pb

P

+ 14 log + 8 log

N

+ 6 log

10e LWa = LWb

P N

ia a a

ib b b

Note that an entire set of dependent variables must be calculated whenever a

particular set of independent variables is changed.

1999 Howden Buffalo, Inc.

12-8 FAN ENGINEERING

Table 12.2 Fan Law 1 Based on m and y F

For all fan laws: Ta = Tb and (point of rating)a = (point of rating)b

No. Dependent Independent Variables

D

3

N 1

1

K 1

1a m a = m b

D

a

b

N

a

b

a

b

K

pa

pb

D

2

N 2

1 1

yF a = yF b

D

N 1 1

a a

1b

b b

D

5

N 3

1

K 1

1c Pia = Pib

D

a

b

N

a

b

a

b

K

pa

pb

D

+ 70 log 50 log

N

+ 20 log

LWa = LWb

D +

N

a a a

1e

b b b

Note that Fan Laws 2 through 10 could also be listed on the basis of mass flow rate m and

fan work or fan specific energy y F .

Example 12.1 Use of Fan Law 1 Incompressible Flow

Given a 36.5-in. diameter fan delivering 10000 cfm at 1.85 in. wg, 0.075

lbm/ft3, 600 rpm, and 3.4 hp, find the corresponding performance of an

homologous fan of 73.0-in. diameter at 0.070 lbm/ft, and 1200 rpm.

Use Fan Law 1 because the known quantities (independent variables) are D ,

N , and . Assume incompressible flow.

Q a

73.0

3

1200

1

1 1

Q b

=

36.5

600

1

1

= 16.00,

pFTa

=

73.0 1200 0.070 1 = 14.93, and

2 2 1

pFTb 36.5 600 0.075 1

Pia

=

73.0 1200 0.070 1 = 238.93.

5 3 1

Pib 36.5 600 0.075 1

Q = 10000 16.00 = 160 000 cfm,

a

pFTa = 185

. 14.93 = 27.62 in. wg, and

Pia = 3.4 238.93 = 812.4 hp.

Note that the same factors could be applied to other ratings of the 36.5-in. fan,

so that sufficient points could be determined for the 73.0-in. fan to facilitate

drawing constant speed curves.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-9

Example 12.2 Use of Fan Law 3 Incompressible Flow

Given a fan delivering 10000 cfm at 1.85 in. wg, 0.075 lbm/ft3, 600 rpm, and

3.4 hp, find the corresponding performance of the same fan at 12000 cfm and

0.075 lbm/ft3.

Use Fan Law 3 because the independent variables are D and (which are to

be held constant), and Q . Assume incompressible flow.

1 12000 1 1 = 720 rpm,

N = 600

3 1 1 1

a

1 10000 1 1

1 12000 1 1 = 2.66 in. wg, and

.

4 2 1 1

p = 185

FTa

1 10000 1 1

1 12000 1 1 = 5.9 hp.

P = 3.4

4 3 1 2

ia

1 10000 1 1

Note that the fan must operate at the same point of rating, which will happen

only if the system has a characteristic that requires 2.66 in. wg at 12000 cfm

and 0.075 lbm/ft3.

Example 12.3 Use of Fan Law 4 Incompressible Flow

Given a fan delivering 10000 cfm at 1.85 in. wg, 0.075 lbm/ft3, 600 rpm, and

3.4 hp, find the corresponding performance of the same fan at 5.0 hp and

0.060 lbm/ft3.

Use Fan Law 4 because the independent variables are D (which is to be held

constant), Pi , and . Assume incompressible flow.

1 5.0 0.060

43 13 1 3

1 2 3

Q a = 10000

1 3.4 0.075

1 = 12250 cfm, and

4 3 23 13 1 3

1 5.0 0.060 1

pFT A = 1.85 = 2.22 in. wg,

1 3.4 0.075 1

5 3 13 1 3 13

1 5.0 0.060 1

N A = 600 = 735 rpm.

1 3.4 0.075 1

Note that the fan must operate at the same point of rating, which will happen

only if the system has a characteristic that requires 2.22 in. wg at 12250 cfm

and 0.060 lbm/ft3.

1999 Howden Buffalo, Inc.

12-10 FAN ENGINEERING

Compressibility

The effects of compressibility are accounted for in the fan laws by the

inclusion of a compressibility coefficient K p for each of the two fans. This

coefficient is a function of the polytropic1 exponent n , the absolute total

pressure pT1 at the inlet, and the absolute total pressure pT 2 at the outlet:

n p

n 1

"#

n

n 1 p

T2

1

##

Kp = ! T1

$. (12.1)

pT 2

1

pT 1

The polytropic exponent can be evaluated using the isentropic exponent

and the polytropic efficiency p :

n p

= . (12.2)

n 1 1

The polytropic efficiency can usually be considered equal to the fan total

efficiency T without serious error:

p

p 1

"#

p

p

1

T2

1

##

Kp = ! T1

$. (12.3)

pT 2

1

pT 1

Equation 12.3 can be solved for both K p and p using an appropriate

iteration procedure.

Figure 12.1 is a graphical representation of Equation 12.3 using = 14

. .

2

Jorgensen and Bohanon have shown that the evaluation of K p can often

be facilitated by the use of a pressure-rise coefficient x , a temperature-rise

coefficient z , and

1 6

z ln 1 + x

Kp =

1 6

x ln 1 + z

. (12.4)

1

The assumption of a polytropic process between end states that are defined by total pressures

is, of course, only an approximation of the real process through a fan. Nevertheless, the

effects of compressibility are predicted quite well by this "total polytropic" assumption.

2

See footnote page 12-1.

1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-11

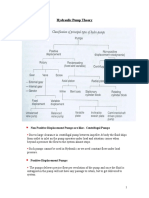

Figure l2.1 Compressibility Coefficient

Figure 12.2 is a graphical representation of Equation 12.4. The values of x

and z can be determined from Equations 12.6 and 12.7.

The fan laws for compressible flow include the ratio of the compressibility

coefficient for the predicted fan K pa to the compressibility coefficient for the

tested fan K pb raised to various powers. The evaluation of this ratio can also

often be facilitated by using the technique that Jorgensen and Bohanon1 have

developed. They showed that

K pa z x 1 .

=

z x 1

a b a b

(12.5)

K pb b a a b

The pressure-rise coefficient for the tested fan xb is a function of the fan

total pressure pFTb and the absolute total pressure pTb1 at the inlet and can be

evaluated from test data:

pFTb

xb = . (12.6)

pT 1b

The temperature-rise coefficient for the tested fan zb is a function of the

isentropic exponent b , the fan input power Pib , the fan flow rate Q b , and the

absolute total pressure pT 1b at the inlet and can be evaluated using test data:

1

See footnote page 12-1.

#1999 Howden Buffalo, Inc.

12-12 FAN ENGINEERING

Figure l2.2 Compressibility Coefficients

Adapted from the data of AMCA: Laboratory Method, of Testing Fans for Rating, AMCA

Standard 210-74, 1974, p. 39.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-13

b 1 CQ Pib

zb =

b Q b pT 1b

.

(12.7)

The conversion constant CQ has a value of unity in SI units and 6354 in U.S.

customary units.

The procedure for evaluating the pressure-rise and temperature-rise

coefficients for the predicted fan varies, depending on which fan law is being

used.

For instance when using Fan Law 1, the temperature-rise coefficient za , is

D N p 1 .

=z

2 2 1 1

D N p 1

a a a T 1a b a

za b (12.8)

b b b T 1b b a

The pressure-rise coefficient xa . for the predicted condition can then be

evaluated using

1 6 1

ln 1 + xa = ln 1 + xb 6 lnln1111 ++ zz 66 1 1 and

a

b a

a b

b

(12.9)

xa = e 1 + xa 6 1.

ln 1

(12.10)

Finally, the ratio of compressibility factor K pa K pb can be evaluated:

K pa z x 1 .

=

z x 1

a b a b

(12.11)

K pb b a a b

The isentropic exponents a and b for the two conditions can be calculated

from information about the two gases. If the two conditions are the same, the

last two ratios cancel each other.

A similar procedure can be used with Fan Law 8 except that

P Q p 1 .

=z

1 1 1

P Q p 1

a a T 1a b a

za b (12.12)

b b T 1b b a

A slightly different procedure is required for Fan Laws 2, 5, 7, and 9. The

differences are

p p

=x

1 1

p p

FTa T 1a

xa b , (12.13)

FTb T 1b

#1999 Howden Buffalo, Inc.

12-14 FAN ENGINEERING

1 6 1

ln 1 + za = ln 1 + zb 6 lnln1111 ++ xx 66 1 1 , and

a

b a

a b

b

(12.14)

za = e 1 + za 6 1.

ln 1

(12.15)

Equation 12.3 can be used with Fan Laws 3, 4, 6, and 10. If the point of

rating is not known, an iteration procedure must be used.

Example 12.4 Use of Fan Law 1 Compressible Flow

Given a 36.5-in. diameter fan delivering 10000 cfm at 1.85 in. wg, 0.075

lbm/ft3, 600 rpm, 3.4 hp, 29.92-in. Hg inlet pressure, and 1.4 isentropic

exponent; find the corresponding performance of an homologous fan of 73.0

in. diameter at 0.070 lbm/ft3, 1200 rpm, 29.92 in. Hg, and 1.4 isentropic

exponent.

Use Fan Law 1 as in Example 12.1, but correct for compressibility.

pT 1b = 29.92 13.62 = 407.5 in. wg,

185

.

xb = = 0.004540,

407.5

. 1 6354 3.4

14

zb = = 0.001515,

. 10000 407.5

14

za = 0.001515 14.93 = 0.022619, (14.93 from Example 12.1),

1 6 1

ln 1 + xa = ln 1004540

. 6 11

ln 1022619

.

ln 1001515

.

6

6

= 0.066926,

xa = e 0.0066926 1 = 0.0692164,

K pa 0.022619 0.004540

= = 0.9793,

K pb 0.001515 0.0692164

Q = 160000 0.97931 = 163400 cfm,

pFTa = 27.62 0.97931 = 28.20 in. wg, and

Pia = 812.4 0.97931 = 829.6 hp.

The errors introduced in Example 12.1 by assuming incompressible flow are

about 2% each at this point of rating for Q , pFT , and Pi .

Example 12.5 Use of Fan Law 3 - Compressible Flow

Given a fan delivering 10000 cfm at 1.85 in. wg, 0.075 lbm/ft3, 600 rpm,

29.92 in. Hg inlet pressure, and 1.4 isentropic exponent; find the correspond-

ing performance of the same fan at 12000 cfm and 0.075 lbm/ft3.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-15

Use Fan Law 3 because the independent variables are D and (which are to

be held constant), and Q .

pT 1b = 29.92 13.62 = 407.5 in. wg,

185

.

xb = = 0.004540,

407.5

. 1 6354 3.4

14

zb = = 0.001515,

. 10000 407.5

14

0.001515 ln 1004540

. 1 6

K pb =

0.004540 ln 1001515

. 1 6

= 0.9985,

10000 185

. 0.9985

Tb = = 0.855,

6354 3.4

pFTa 2.66 from Example 12.2,

pT 2 a = 2.66 + 407.4 = 410.2,

410.2 0 .4

"#

. 0.855

14

407.5 1.4 0.855

1

#$

K pa =

0.4

! = 0.9978,

410.2

1

407.5

0.9978

N a = 720 = 719.5 rpm,

0.9985

0.9978

pFTa = 2.66 = 2.658 in. wg,

0.9985

0.9978

2

Pia = 5.9

0.9985

= 5.89 hp, and

12000 2.658 0.9978

Ta = = 0.850.

6354 589

.

Since Ta differs from the value used to compute K pa , recalculate:

pFTa = 2.658,

pT 2 a = 410.2, and

410.2 0 .4

"#

. 0.850

14

407.5 1.4 0.850

1

#$

K pa =

0.4

! = 0.9978.

410.2

1

407.5

This is nearly the same value that was obtained using 0.855 so:

N a = 719.5,

pFTa = 2.658,

Pia = 5.89, and

Ta = 0.850.

#1999 Howden Buffalo, Inc.

12-16 FAN ENGINEERING

The error introduced in Example 12.2 by assuming incompressible flow is

insignificant.

Equivalency

Sometimes the concept of equivalency can be used to facilitate

comparisons or calculations. Two equivalency concepts that are frequently

used in fan engineering are equivalent incompressible values and equivalent

total pressure.

Equivalent incompressible values can be defined as the values that a

particular fan, at a particular speed and a particular density, would have if the

fluid were incompressible rather than compressible. Fan Law 1 can be used

since diameter, speed, and density are independent variables and can be held

constant. It follows that

Q I = QK

p

pFTI = pFT K p , and

PiI = Pi K p (12.16)

Q I , pFTI , and PiI , are the incompressible values of flow rate, pressure, and

power. K pI = 10 . . Q , pFT , Pi , and K p are the corresponding compressible

values. Fan performance data can be reduced to equivalent incompressible

values for comparison purposes. This is one step toward the development of

dimensionless coefficients (discussed below).

Avoid the use of equivalent incompressible values for anything other than

comparisons, since the only real values for a fan are the compressible values.

(The fluid handled by a fan is always compressible.)

Equivalent total pressure pFTe is the total pressure developed by a

particular fan, at a particular speed and a particular reference air density e ,

which is equivalent to the required fan total pressure pFT at the required

density . From Fan Law 1b,

K .

pFTe = pFT

K

p

(12.17)

e pe

The reference density e will be standard air density if the reference data

are prepared for standard density. This concept is particularly useful when

making selections from published data that have been prepared for standard

air conditions. (See the chapter on fan selection for examples.) Often,

calculations can be simplified without excessive loss in accuracy by assuming

the compressibility ratio K p K pe to be unity.

1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-17

Power Formulae

The output power Po of a fan is the rate at which useful energy is

delivered to the gas stream. Based on the total polytropic assumption,

K

Qp

Po =

FT p

. (12.18)

CQ

This relationship of fan flow rate Q , fan total pressure pFT , and

compressibility coefficient K p is expressed in Fan Law 5c.

The power input to the impeller Pi can be calculated from the power

output and the polytropic efficiency p :

K

Qp

Pi =

FT p

. (12.19)

p CQ

The fan input power Ps is the sum of the power input to the impeller and

the mechanical losses of the drive train, if there is one:

Ps = Pi + Pm . (12.20)

The mechanical losses of the drive train Pm should be considered separately

because they cannot be predicted by fan laws. When fan law considerations

are not involved,

K

Qp

Ps =

FT p

(12.21)

T CQ

where the fan total efficiency T is the ratio of fan output power to fan input

power. If the kinetic energy leaving the fan is not useful, pFS and S can be

substituted for pFT and T .

The value of CQ is unity in SI units and 6354 in U.S. customary units.

Fan total head H F is proportional to pFT K p w , and weight flow rate w

, where w is the specific weight, so fan input power is

is Qw

F

wH

Ps = (12.22)

T Cw

where Cw is unity in SI units and 33000 in U.S. customary units.

1999 Howden Buffalo, Inc.

12-18 FAN ENGINEERING

Example 12.6 Output Power and Efficiency

Given a fan handling 163400 cfm, 28.20 in. wg, 829.6-hp power input to the

impeller, 29.92 in. Hg inlet pressure, 1.4 isentropic exponent, 0.070 lbm/ft3,

and 1200 rpm; find the output power and the total efficiency.

pT1 = 29.92 13.62 = 407.5 in. wg,

28.20

x= = 0.06920,

407.5

. 1 6354 829.6

14

z= = 0.02262,

14

. 163400 407.5

0.02262 ln 106920

.

Kp = = 0.9778,

0.06920 ln 102262

.

0.9778

Po = 163400 28.20 = 709.1, and

6354

709.1

T = = 0.855.

829.6

This is a supplement to Example 12.4.

Specific Speed and Specific Size

Specific speed N s for a given fan at a given rating is the speed at which

an homologous fan would have to operate to produce a fan flow rate of unity

( Q s = 1) and a fan total pressure of unity ( pFTs = 1), at unit density ( s = 1)

and the same point of rating. From Fan Law 5b,

NQ 1 2 3 4

Ns = 34 14

. (12.23)

pFT K p

The unit of specific speed will be the same as that of fan speed N . The value

of specific speed will depend on the system of units used for fan flow rate Q ,

fan air density , and fan total pressure pFT . (Compressibility coefficient

K p is frequently omitted.)

Specific size Ds is the size of the homologous fan referred to above.

From Fan Law 5a,

14

DpFT

Ds = 1 4 1 2

. (12.24)

Q K p1 4

1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-19

Figure l2.3

Specific Speeds and Specific Sizes for Various Fans

#1999 Howden Buffalo, Inc.

12-20 FAN ENGINEERING

The unit of specific size will be the same as that of fan size D . Its value also

depends on the system of units used. Another version of specific speed N se is

based on equivalent total pressure pFTe :

NQ 1 4

N se = 34 14

. (12.25)

pFTe K p

This amounts to dividing Equation 12.22 by 3e 4 , so that for standard air

N se = 6.978 N s in U.S. units or N se = 0.8722 N s in SI units. Similarly,

14

DpFTe

Dse = . (12.26)

Q 1 2 K

14

p

This is obtained by multiplying Equation 12.23 by 1e 4 , so that for standard

air Dse = 0.5233Ds in U.S. units or Dse = 10467

. Ds in SI units.

Similar, but dimensionless, quantities are speed coefficient and diameter

coefficient, which are discussed under dimensionless coefficients.

Figure 12.3 illustrates the relationships among specific speed, specific

size, and efficiency for various types of fans. These relationships are useful in

both design and selection of all types of turbomachinery. Since for any design

of fan there is only one value of specific speed at the point of maximum

efficiency, that value serves to identify the particular design. The same is true

for specific size. If either specific speed or specific size can be established

from the requirements of an application, only those designs with correspond-

ing identifying values need be considered as possible selections.

Sound Power Level and Specific Sound Power Level

The fan laws for sound are given in Table 12.1. Additional fan law

variations could be written with sound power level LW as an independent

variable, but for simplicity, sound power level is always listed as a dependent

variable in this table. Compressibility has been omitted from the sound laws

because compressibility effects are insignificant compared to the uncertainties

in sound measurement. The relationships embodied in the sound laws have

been verified by Madison and Graham1 in the Buffalo Forge Company

laboratory. However, more recent evidence suggests that the coefficient on

fan speed shown as 50 in Fan Law 1e can range from 60 to 70 depending on

fan design.

The overall sound power level of a fan can be predicted from the overall

sound power level of an homologous fan at the same point of rating. For

reliable predictions, both fans must have good bearings and must be in good

balance.

1

R. D. Madison and J. B Graham, "Fan Noise Variation with Changing Fan Operation,

Trans. ASHRAE, vol. 64, 1958, pp. 319-340.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-21

The sound spectrum for a fan may or may not be predictable by fan laws

from the spectrum for an homologous fan at the same point of rating. Simi-

larity requires that corresponding frequencies (e.g. blade-passing frequencies

and harmonics) be equal. Spectra will be similar only when fan speeds are

equal. Various methods of estimating spectra are discussed in the chapter on

fan noise.

Specific sound power level LWs is the sound power level of an homolo-

gous fan when producing a fan flow rate of unity ( Q = 1) at a fan total pres-

s

sure of unity ( pFTs = 1) and the same point of rating. From Fan Law 5e,

( )

LWs = Lw 10 log Q pFT .

2

(12.27)

The unit of specific sound power level is the same as that for sound power

level LW . The value of specific sound power level will depend on the system

of units used for fan flow rate Q and fan total pressure pFT . A similar, but

dimensionless, quantity is sound power level coefficient, which is discussed

under dimensionless coefficients.

Similarity and Deviations

The fan laws are based on similarity of flow for the two fans whose per-

formances are being compared. There must be geometric, kinematic, and dy-

namic similarity. Geometric similarity requires that corresponding linear di-

mensions be proportional and corresponding angles be equal, for the various

flow passages of the two fans. The constant of proportionality is the ratio of

any corresponding dimensions (for example, the ratio of impeller diameters).

Theoretically, thicknesses of parts, roughnesses of surfaces, clearances be-

tween parts, etc. should all be proportional. Fortunately, some variations can

be tolerated without invalidating the fan laws. However, the effects of any

compromise in geometric similarity should be thoroughly investigated, as dis-

cussed in the section on size effects.

Kinematic similarity requires that corresponding magnitudes be propor-

tional and corresponding angles be equal, for the various fluid velocities in the

two fans. The constant of proportionality is the ratio of corresponding periph-

eral speeds of the impeller. The condition of kinematic similarity leads to the

conclusions of Fan Law la: that fan flow rate, being proportional to velocity

times area, is, therefore, proportional to peripheral speed times diameter

squared, which itself is proportional to rotational speed times diameter cubed.

Dynamic similarity requires that corresponding magnitudes be propor-

tional and corresponding angles be equal, for the various fluid forces in the

two fans. The constant of proportionality is the ratio of the inertia forces of

two similarly located fluid particles. The inertia force of a fluid on a unit area

is proportional to mass density and velocity squared. One of the conditions of

dynamic similarity leads to the conclusions of Fan Law lb: that pressure force

per unit area being proportional to inertia force per unit area is, therefore,

1999 Howden Buffalo, Inc.

12-22 FAN ENGINEERING

proportional to mass density times velocity squared. This leads to fan pres-

sure being proportional to mass density times velocity squared or to mass

density times diameter squared times rotational speed squared.

The other forces in the fluid are those due to elasticity, viscosity, gravity,

and surface tension. The ratio of the inertia force to these forces leads to the

Mach, Reynolds, Froude, and Weber numbers, respectively. The concept of

dynamic similarity requires that, at corresponding points in the two fans,

Mach, Reynolds, Froude, and Weber numbers be equal. However, surface

tension and gravity forces are not significant in fans, so in practical applica-

tions Weber and Froude numbers can be ignored.

Viscosity can have a significant effect on fan law relationships, so Rey-

nolds number should be considered, as discussed in the section on Reynolds

number effect. Elasticity can also have a significant effect as discussed in the

Mach number section.

Size Effects

According to Fan Law 1, the performance of a full-scale fan can be

predicted from the test results for a model of different scale. It is not always

practicable to model every feature of the design. However, the resulting

imperfections in geometric similitude may impair the accuracy of the predic-

tions. For example, the relative thicknesses of the parts may differ for struc-

tural or economic reasons. Fortunately, such differences can be ignored in all

but extreme cases. The relative clearances between parts can also easily

differ. Such differences, however, can be critical and should be eliminated by

careful design and quality control. If not, sufficient tests will have to be made

to determine the effect of each variation. The relative roughnesses of the

various surfaces may differ, too, simply because the same materials are used

for the construction of both the larger and the smaller fan. Ideally, sufficient

tests should be made to determine roughness effects also, but this may not

always be practicable. Unless the surface is hydraulically smooth for both the

larger and the smaller fans, predictions of efficiency for larger fans will

generally be conservative because the effect of decreased relative roughness is

to reduce frictional losses. The pressure coefficients for larger fans will

generally increase because of this reduction. (On the other hand, the work of

Varley1 shows that increased roughness can increase pressure coefficients in

pumps. In his tests, the increased pumping action apparently more than

compensated for the increased losses.)

Reynolds Number Effect

The Reynolds numbers for the various flow passages of a fan will differ

because of their differing passage dimensions and fluid velocities. It is

.

1

E. A. Varley. "Effects of Impeller Design and Surface Roughness on the Performance of

Centrifugal Pumps," Proceedings of the Institution of Mechanical Engineers, London, vol.

175, no. 21, 1961, pp. 955-989.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-23

convenient and customary to define a single Reynolds number Re1 for a fan,

based on the impeller diameter at the tip D , the peripheral velocity at the tip

ND , and the mass density and viscosity, of the fluid at the inlet:

ND 2

Re = . (12.28)

Although this number is rather arbitrary, it can be used to help establish

whether two fans are dynamically similar. One of the conditions of dynamic

similitude is that Reynolds numbers be equal at all corresponding points in the

two fans. When N or D changes, or will have to be changed in order

to compensate; for some types of turbomachinery, this can be accomplished

by a judicious selection of fluid. With fans, however, it is not generally

practicable. Any resulting imperfections in dynamic similitude may impair

the accuracy of fan law predictions, as discussed below.

Variations in Re can be produced by changing N or D , or both. By

varying N separately, any size effects that might accompany a change of D

can be eliminated. Tests of this kind by Phelan, et al1 suggest that there is a

threshold value of Re for every fan design below which occur gradually

increasing deviations from fan law behavior. The indicated threshold value of

Re is: 2.0 106 for airfoil-bladed centrifugal fans, 1.0 106 for backwardly

inclined-bladed centrifugal fans, and 0.8 106 for forwardly curved-bladed

centrifugal fans. For radial-bladed centrifugal fans, no significant deviations

were observed at Reynolds numbers as low as 0.4 106. However, pressure

coefficient did gradually deteriorate with decreasing Re. Power coefficient

also generally decreased, but not as rapidly, and even increased for some

points of rating.

Kittredge2 has derived a general formula for estimating the efficiency of a

prototype from tests of a geometrically similar model. He also lists many

other investigators' formulae, most of which are simplifications of the

following:

11 6 = s + 11 s6 f 1Re 6 .

n

1

i =1

f Re

h h

n

(12.29)

h h i

i =1

This and most of the simplified formulae are based on the premise that a

1 6

certain fraction s of the hydraulic losses 1 h h is due to shock losses

that follow the fan laws and are independent of Reynolds number.

1

J, J. Phelan, S. H. Russell, and W. C. Zeluff, "A Study of the Influence of Reynolds Number

on the Performance of Centrifugal Fans," ASME Paper, No. 78- WA/PTC-1, 1978.

2

C. P. Kittredge, "Estimating the Efficiency of Prototype Pumps from Model Tests," ASME

Paper No 67-WA/FE-6, 1967.

1999 Howden Buffalo, Inc.

12-24 FAN ENGINEERING

The remainder is due to friction losses that are functions of the local Reynolds

numbers Rei and have to be summed 6. If the friction factors for the various

flow passages are similar to those for ducts, their values depend on the flow

regime. The tests by Phelan, et al. seem to support this. For radial-bladed

centrifugal fans, performance was independent of Re, which suggests that

flow was in the wholly rough zone regardless of speed. This is consistent

with the fact that there are few, if any, points where the flow is not highly

turbulent for this simple design. The more sophisticated designs show

improvements with Re increasing up to the threshold value. This suggests

that flow was in the transitional region at least until a speed was reached at

which most of the passages became hydraulically rough. All this demontrates

the difficulty of using any formulation to predict efficiency improvements.

The best technique for establishing performance at different Re is to test

sufficient points over the range to permit interpolation.

Mach Number Effects

The Mach numbers for the various flow passages of a fan will differ

because of their differing fluid velocities. It is convenient to define a single

Mach number Ma for a fan, based on the peripheral velocity of the impeller

tip and on the speed of sound c for the fluid at the inlet:

ND

Ma = . (12.30)

c

Although this number is rather arbitrary, it can be used to help establish

whether two fans are dynamically similar.

One of the conditions of dynamic similitude is that Mach numbers be

equal at all corresponding points in the two fans. It is highly unlikely that two

fans will have the same Mach numbers unless they develop the same

equivalent pressures. Any resulting imperfections in dynamic similitude may

impair the accuracy of fan law predictions, as discussed below.

Aside from compressibility effects, variations in Ma produce no fan law

deviations unless one of the corresponding values approaches unity. When

the local Mach number at any point does approach unity, critical conditions

develop, as discussed in the fluid-flow chapter. Because the flow rate

becomes limited, such a condition is usually described as choking. However,

critical conditions are not likely to occur unless the fan requirements approach

those of a compressor or a passage is highly obstructed.

Dimensionless Coefficients

Table 12.3 lists a number of dimensionless coefficients that are useful in

fan engineering and inspecting this table will show that all these coefficients

are related to the fan laws. Either SI or U.S. customary units can be used.

For SI units, the formulae can be used directly without prefixes, but when

U.S. units are used, the results must be adjusted by the U.S. factor. Most of

the coefficients are interrelated, and their relationships are also listed.

1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-25

Some authors in the field of engineering prefer to use coefficients with

more physical significance. For instance, they like the pressure coefficient to

reflect the ratio of pressure produced to the pressure corresponding to the

peripheral speed at the impeller tip. This leads to a value of the pressure

coefficient that differs, by a factor of 2 2 , from the value calculated using

the listed formula. The various physical factors are listed for convenience in

comparing data of the two different types.

All the coefficients except are based on the compressible-flow fan

laws, as indicated by the inclusion of compressibility factor K p . Often, K p

can be assumed to be equal to unity resulting in considerably simpler

calculations. However, it is important to include K p whenever these

coefficients are used to examine the effects of small changes.

The conversion factor gc would ordinarily be included in the formulae

whenever pFT , pFV , or Pi appear. It has been omitted because its value is

unity in SI. The U.S. factor takes gc and all other conversions into account

for the following units.

Symbol SI U.S. Symbol SI U.S.

Q m3/s cfm kg/m3 lbm/ft3

pFT Pa in. wg N rps rpm

pFV Pa in. wg D m ft

Pi W hp Kp - -

LW dB dB gc m-kg/N-s2 ft-lbm/lb-s2

Flow Coefficients

Flow coefficient , also called the capacity coefficient, is based on the

relationships in Fan Law la. Perhaps more than any of the other coefficients,

can be modified to suit the purposes of the individual fan designer or

author. Multiplying by the factor 4 2 yields the ratio of the actual flow rate

to a reference flow rate that corresponds to the product of the peripheral

velocity at the tip and the circular area based on the tip diameter. The value

of the reference flow rate is not important in itself, so the 4 2 factor can be

omitted. However, certain geometric ratios have a great influence on flow

rate, so variations in these ratios should be taken into account when

correlating data. These ratios can be incorporated in a modified flow

coefficient, or they can be stated separately.

1999 Howden Buffalo, Inc.

12-26 FAN ENGINEERING

Table l2.3 Dimensionless Coefficients

Name Symbol SI Formula

Flow Coefficient

QK 3

p ND

Pressure Coefficient (total) pFT K p N 2 D 2

Pressure Coefficient (velocity) V pFV N 2 D 2

Pressure Coefficient (static) S 3p FT K p pFV 8 pFT K p

Power Coefficient Pi K p N D53

Efficiency (total) T K P

Qp FT p i

Efficiency (static) S 3

T pFT K p pFV 8 N D

2 2

NQ 1 2` 3 4 pFT K p

34 14

Speed Coefficient

DpFT 1 4 Q 1 2 K p

14 14

Diameter Coefficient

Throttling Coefficient Q 2 K p pFT D 4

Sound-Power-Level Coefficient LW 10 log Qp 3

2 2 N 5 D7

FT 8

Table 12.3 (cont.) Dimensionless Coefficients

Symbol U.S. Factor Interrelation2 Physical Factor1

- 1 3 4 2 = 0.4053

6.015 105 1 2 2 2 2 = 0.2026

V 6.015 105 2 D 4 2 A22 2 2 = 0.2026

S 6.015 105 V 2 2 = 0.2026

3822

. 109 8 4 = 0.08213

T 6354 -

S S -

2.160 104 1 2 3 4 2 = 2.1078

14 12

27.85 1 4 1 2 1 2 2 3 4 = 1.0539

6.015 105 2 2 2 = 0.8106

-116 dB LW 10log 1 6 2

10 log 16 6 =-18 dB7

1

The physical factor for each coefficient is explained in the text for that

coefficient.

2

Other interrelations could be established leading to additional dimensionless

coefficients. For example: might be called work input coefficient. Some

designers use the reciprocals of a coefficient. One example is 1 .

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-27

For radial-flow fans, particularly narrower types, some prefer to use a

reference flow rate that corresponds to the product of the peripheral velocity

at the tip and the circular area based on the inlet diameter. Multiplying by the

1 6 2

geometric ratio D1 D2 will take this into account. We could define a

1 6

modified flow coefficient D1 D2 or treat and D1 D2 as individual

2

1 6 2

dimensionless coefficients.

For cross-flow fans, the flow rate is nearly proportional to the width of the

blading b . Multiplying by the geometric ratio D b will take this into ac-

count. We could define a modified coefficient b as D b or treat and

D b as individual dimensionless coefficients.

For axial-flow fans, the flow area is clearly influenced by the hub ratio ,

2

which is equal to D2 D1 . Multiplying by 1 1 2 will take this into 7

account. Furthermore, some prefer to use the peripheral velocity at the mean

effective radius. Multiplying by 21 2 1 + 2 2 7

12

will take this into account.

The 21 2 is an additional physical factor, so it can be omitted. We could

define modified flow coefficients , m , and m , as 1 2 , 2 7

2 7 , and 421 721 + 7 9 respectively; or we could treat ,

1+ 2 12 2 2 12

1 21 7 , and 1 21 + 7 as individual dimensionless coefficients.

2 2 12

The interrelation of , , and states in dimensionless terms what Fan

Law 1a says in dimensional quantities.

Pressure Coefficients

Total pressure coefficient , velocity pressure coefficient V , and static

pressure coefficient S are based on the relationships in Fan Law 1b and on

fan total pressure, fan velocity pressure, and fan static pressure, respectively.

(Pressure coefficient is also called head coefficient.) Multiplying by a factor

2 2 yields the ratio of the actual fan pressure to the reference pressure that

corresponds to the peripheral velocity at the tip. The value of the reference

pressure is unimportant in itself, so the 2 2 factor can be omitted. How-

ever, as with flow coefficient, there is a preference for using the peripheral

velocity at the mean effective radius as the reference pressure for axial-flow

2 7

fans. Multiplying by 2 1 + 2 will take this into account. The 2 is a physi-

cal factor and so can be omitted. We could define a modified pressure

2 7

coefficient m , or treat and 1 1 + 2 as individual dimensionless coeffi-

cients.

The interrelation of , , and states in dimensionless terms what Fan

Law lb says in dimensional quantities. Identical interrelationships would

follow for V and S except for compressibility effects. The interrelation

.

#1999 Howden Buffalo, Inc.

12-28 FAN ENGINEERING

shown for V is dimensionless even though it contains the dimensional terms

D 4 and A2 . The interrelation listed for S follows from the relationship of

pFS with pFT and pFV .

Power Coefficient

Power coefficient , also called coefficient of performance, is based on

the power input to the impeller and the relationships in Fan Law 1c. All

bearing losses and other drive losses should be deducted from the fan input

power. Multiplying by the factor 8 4 yields the ratio of actual input power

(to the impeller) to the reference power that corresponds to the flow rate and

pressure used as references for and . The value of the reference power is

not important in itself, so the 8 4 factor can be omitted. However, if either

or is modified as outlined above, should also be modified. The

interrelation of with and also requires that efficiency be consid-

ered.

Efficiency

Efficiency is a dimensionless performance parameter and, therefore, is

included among the dimensionless coefficients. Fan total efficiency T is the

K , to the input power to the impel-

ratio of the output power of the fan Qp FT p

ler Pi . Fan Law 5c embodies this relationship, as does the interrelation of

with , , and . Refer to the sections on compressibility and power

formulae for additional comments on fan total efficiency and fan static

efficiency.

Speed Coefficient

Speed coefficient is based on the relationships in Fan Law 5b. This

coefficient is the ratio of the actual rotational speed to the rotational speed of

an homologous fan (operating at unity flow coefficient and unity pressure

coefficient) for the same point of rating. Naturally, if the flow and pressure

coefficients incorporate physical factors, the speed coefficient should also be

multiplied by the appropriate factor.

Speed coefficient is a non-dimensional specific speed. Specific speed has

units of rotational speed and is that speed at which an homologous fan would

have to operate to produce a unit flow rate and a unit pressure (at standard air

conditions) for the same point of rating. The ratio of specific speed N se to

speed coefficient is 0.871 in SI units and 150600 in U.S. customary units.

Many investigators have shown that the physical proportions of a fan and

its speed coefficient are related. Figure 12.3 illustrates that narrow radial-

flow fans have lower speed coefficients at peak efficiency than wider radial-

flow fans. It also shows that axial-flow fans with high hub ratios have lower

speed coefficients at peak efficiency than those with low hub ratios. The best

value of efficiency that can be obtained depends on the degree of sophistica-

.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-29

tion in the design. For instance, airfoil-shaped blades exhibit higher

efficiencies than simpler, backwardly curved blades. Figure 12.3 can be used

in the initial stages of selection or design to choose the general type of fan that

might be most suitable.

Speed coefficient can also be used as illustrated in the chapters on

centrifugal and axial-flow fans to establish the approximate dimensions of a

fan on the basis of previously established relationships between specific

physical proportions and speed coefficient.

Once a design has been tested, speed coefficient can be used as an aid to

selecting and rating when Q , pFT , , and N are given and D must be

established. (This procedure is described and illustrated in the chapter on fan

selection.) A curve of speed coefficient versus either flow coefficient or flow

rate must be drawn. Spotting the appropriate value of speed coefficient will

determine the point of rating.

Diameter Coefficient

Diameter coefficient is based on the relationships in Fan Law 5a. This

coefficient is the ratio of the actual diameter to the diameter of an homologous

fan (operating at unity flow coefficient and unity pressure coefficient) for the

same point of rating. Naturally, if the flow and pressure coefficients

incorporate physical factors, the diameter coefficient should also be multiplied

by the appropriate factor.

Diameter coefficient is a non-dimensional specific size or specific

diameter. Specific size has units of length and is that size of an homologous

fan that produces a unit flow rate and a unit pressure at standard air conditions

for the same point of rating. As noted above, this fan would have to operate at

specific speed. The ratio of specific size Dse to diameter coefficient is 1.0466

in SI units and 1/53.20 in U.S. customary units.

Many investigators have shown that the physical proportions of a fan and

its diameter coefficient are related. Figure 12.3 illustrates that narrow radial-

flow fans have higher diameter coefficients at peak efficiency than wider

radial-flow fans. It also shows that axial-flow fans with high hub ratios have

higher diameter coefficients at peak efficiency than those with low hub ratios.

Diameter coefficient could be used to establish approximate dimensions in

the same way as speed coefficient. It is not done in this handbook because,

once the correlations are made for speed coefficient, there is no need to do the

same for diameter coefficient.

It is possible to use diameter coefficient as an aid to selecting and rating

when Q , pFT , , and D are given and N must be established. However, it

is more common to use throttling coefficient or one of its variations.

Throttling Coefficient

Throttling coefficient is based on the relationships in Fan Law 3b. This

coefficient is the ratio of a reference velocity pressure to the fan total pressure.

1999 Howden Buffalo, Inc.

12-30 FAN ENGINEERING

Multiplying by the factor 2 3 2 makes the area for the reference velocity

pressure equal to the circular area corresponding to the tip diameter. The

value of the reference velocity pressure is not important in itself, so the 2 3 2

factor can be omitted. Sometimes this physical factor is adjusted so that the

reference velocity pressure becomes the fan velocity pressure, and the coeffi-

cient is simply called pFV pFT . The square root of throttling coefficient can

be referred to as equivalent or relative orifice coefficient. The fourth root of

throttling coefficient is the reciprocal of diameter coefficient. In previous

editions of this handbook, a quantity similar to 1 2 called unit capacity was

discussed.

Throttling coefficient is useful in comparing competing designs. Plots

with as abscissa and p as ordinate can be drawn on the same chart for all

designs. Comparison of p values at equal values will show which design

has superior efficiency for the various points of rating. This approach factors

out the effects of speed. That is, the various designs may have to operate at

different speeds to produce the required Q and pFT but the plot will still

show which is the more efficient.

Throttling coefficient can be plotted as ordinate with as abscissa on

dimensionless performance curves or with Q as abscissa on conventional

performance curves. Fan selection is facilitated when Q , pFT , , and D are

given and N must be established. An example is given in the chapter on fan

selection.

Sound Power Level Coefficient

Sound power level coefficient is based on the relationships in Fan Law

5e. This coefficient is the sound power level that an homologous fan would

produce when operating at unity flow coefficient and unity pressure coeffi-

cient for the same point of rating. Naturally, if the flow and pressure coeffi-

cients incorporate physical factors, the sound power level coefficient should

also be multiplied by the appropriate factor.

Sound power level coefficient is related to specific sound power level in

the same way that speed coefficient is related to specific speed. Specific

sound power level LWs is equal to LW 10 log Q pFT and is the sound power

level that an homologous fan would produce, when operating at unity flow

rate and unity pressure, for the same point of rating.

Both and LWs , are levels, so their values depend on the reference level

used to establish the sound power level LW . This is universally taken to be

10-12 watts. The value of should be the same regardless of the system of

units employed. In Table 12.3, the U.S. factor, when applied to U.S. units,

gives them the same value as SI units. However, the value of LWs will depend

on the system of units used, which, therefore, should be clearly identified.

When is plotted against , or LWs against Q , a minimum value will

occur at or very near the point of best efficiency.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-31

Compressibility factor K p has been omitted from the formulae for and

LWs because the effect K p is insignificant compared to the inaccuracy of

sound power level measurements. In fact, the fan law relationships involving

sound are not universally accepted. The application of sound power level

should be limited to the overall sound produced by the fan, and other rules

should be applied when predicting the spectrum. See the chapter on fan noise

for rules regarding centrifugal and axial fans.

Dimensionless Performance Curves

Dimensionless performance curves can be drawn using various co-

ordinates. One combination, as illustrated in Figure 12.4, is very similar to a

conventional constant speed, size, and density plot. Flow coefficient is used

as abscissa; and pressure, power, efficiency, speed, diameter, and throttling

coefficient are plotted as ordinates. It is tempting to say that such a set of

curves fully reveals the performance of an homologous series of fans. This is

true only up to that point where fan law deviations become significant.

Within these limitations, dimensionless plots can be used to represent the

performance of any fan in an homologous series, including fans with a control

such as VIV, IBD, or variable pitch. The first of these is illustrated in Figure

12.5.

Any fan requirement can be plotted as a point on Figure 12.4 or Figure

12.5, if the fan size and speed are known, simply by calculating and

from the appropriate Q and pFT . If the point falls within the range of the fan

design, the other variables, such as power and efficiency, can be determined.

If the point falls outside the range of the fan design, another speed or size

must be investigated.

Figure l2.4 Dimensionless Performance Curves

#1999 Howden Buffalo, Inc.

12-32 FAN ENGINEERING

Figure l2.5 Dimensionless VIV Curves

Mass-Flow-Rate/Specific-Energy Approach

It was noted in the opening paragraph of this chapter that fan mass flow

rate and fan specific energy can be used as performance variables. Table 12.2

shows Fan Law 1 based on these variables. The rest of this chapter, however,

deals only with volume flow rate and fan pressure as performance variables.

This is because it is customary to use the fan-volume-flow-rate/fan-pressure

approach in the U.S. Nevertheless, the alternative approach is valid. The

following remarks may be helpful in using this approach.

The alternative to Equation 12.18 is

m y F

Po = . (12.31)

Cm

The alternative to Equation 12.19 is

m y F

Pi = , (12.32)

i Cm

where i is the impeller efficiency.

#1999 Howden Buffalo, Inc.

CHAPTER 12 FAN LAWS 12-33

The alternative to Equation 12.21 is

m y F

Ps = , (12.33)

Cm

where the fan efficiency is the ratio of the fan output power to the fan input

power.

The value of Cm is unity in S.I. units and 33000 when power is in hp,

specific energy is in ft-lb/lbm, and mass flow rate is in lbm/min.

The alternatives to Equations 12.23, 12.24, and 12.27 are, respectively,

Nm 1 2

N sa = , (12.34)

yF 1 2

34

Dy F 1 2

14

Dsa = , and (12.35)

m 1 2

3

LWsa = LW 10 log m y F .

2

8 (12.36)

These are dimensional equations and will yield numerical results different

from the originals. For U.S. customary units, N sa = 5193 . N s , Dsa = 01926 . Ds ,

and LWsa = LWs + 14 dB . The reason for the differences is that the reference

quantities taken to be unity are m s , y Fs , and s rather than Q s , pFTs , and s .

That is, N sa and Dsa are the speed and size of the homologous fan required to

produce unity m s and unity y Fs with unity s . All this seems to suggest that

we would be much better off using dimensionless quantities.

The alternatives to the formulae given in Table 12.3 are listed in Table

12.4.

Almost all the discussions relating to Table 12.3 are also applicable to

Table 12.4. Although the physical factors are identical, the U.S. factors are

different, as shown in the table. The U.S. factors are based on mass flow rates

in lbm/min and specific energy in ft-lb/lbm; otherwise, the units are the same

as for Table 12.3. The pressure coefficient should probably be called the

specific-energy coefficient; otherwise, all the other names used in Table 12.3

apply.

As noted in the chapter on fan testing, the mass-flow-rate/specific-energy

approach is given as an alternative to the volume-flow-rate/pressure approach

in ASME PTC 11 and ISO 5801.

1999 Howden Buffalo, Inc.

12-34 FAN ENGINEERING

Table l2.4 Dimensionless Coefficients

Symbol SI Formula1 U.S. Factor2

m ND 3 -

yF N 2 D2 1158

. 105

Pi N 3 D5 3822

. 109

F Pi

my 33000

Nm 1 2 y F 1 2 6278

34

Dy F m 18.45

14 12 12

Dy F 1 2 m 1 2 1158 105

14

.

3

F 2 N 5 D 7

LW 10 log my 8 101 dB

1

SI based on m in kg/s, y F in J/kg, Pi in W, in kg/m3, N in rpm, and D in m.

2

U.S. Factors based on m in lbm/s, y F in ft-lb/lbm, Pi in hp, in lbm/ft3, N in rpm, and

D in ft.

Thrust and the Fan Laws

The preceeding discussions deal with the more or less conventional fan

performance parameters. Thrust is an aspect of fan performance that is

particularly applicable to jet fans which are axial flow fans that are used to

add momentum to the air in a tunnel or other space. The thrust T of a fan can

be predicted from the thrust of an homologous fan. Fan law 1 utilizes fan size

D, fan speed N, and fan air density as independent variables. Using these

independent variables and fan thrust as the dependent variables, we can write:

4 2 1

D N

Ta = Tb a a a . Fan Law 1f

Db N b b

Other variations could be written, but this is the most useful.

A dimentionless thrust coefficient can also be derived:

= T N 2 D 4 (12.31)

This is based on SI units. The use of U.S. units requires a factor of

2 7

1.158 105. Multiplying by 1 1 2 , where is the hub ratio, yields a

dimensionless group that corresponds to the annulus area. Multiplying by the

physical factor 2 3 yields a number that relates pressure to the peripheral

velocity. Both the AMCA and ISO jet fan test codes define thrust coefficient

on the basis of annulus area and peripheral velocity.

#1999 Howden Buffalo, Inc.

Вам также может понравиться

- TransitionState PDFДокумент49 страницTransitionState PDFImran ParvezОценок пока нет

- Set 1 PDFДокумент3 страницыSet 1 PDFOmer IkhlasОценок пока нет

- PDF P324 06A (For Class) Lec Mod2 04a Diffusivity Eq (Orientation) PDFДокумент18 страницPDF P324 06A (For Class) Lec Mod2 04a Diffusivity Eq (Orientation) PDFvitaxnОценок пока нет

- Chapter 1B: Website ExercisesДокумент7 страницChapter 1B: Website ExercisesAlex CheungОценок пока нет

- Centrifugal Pumps 8 B PDFДокумент14 страницCentrifugal Pumps 8 B PDFGeorge OparОценок пока нет

- Air Leakage 04Документ1 страницаAir Leakage 04karun agrawalОценок пока нет

- Two-Way ANOVA: Analysis for Quantitative Outcome and Two Categorical VariablesДокумент26 страницTwo-Way ANOVA: Analysis for Quantitative Outcome and Two Categorical VariablesDece JaneОценок пока нет

- Roark's Formulas for Stress and Strain Chapter 10 Torsion Analysis of Wide Flanged BeamДокумент2 страницыRoark's Formulas for Stress and Strain Chapter 10 Torsion Analysis of Wide Flanged BeamAntonioОценок пока нет

- Uniform Flow and Its Computations: S CR VДокумент18 страницUniform Flow and Its Computations: S CR VOmkesh TripathiОценок пока нет

- 电动力学-课件:Course07-Orthogonal Functions and Seperation of VariablesДокумент27 страниц电动力学-课件:Course07-Orthogonal Functions and Seperation of Variablesorderly2233Оценок пока нет

- DFA Book 09 GasДокумент19 страницDFA Book 09 GasLuis LazardeОценок пока нет

- Harmonic Oscillator, A, A, Fock Space, Identicle Particles, Bose/FermiДокумент15 страницHarmonic Oscillator, A, A, Fock Space, Identicle Particles, Bose/FermiJosé JiménezОценок пока нет

- Gas Well Deliverability II 2018Документ55 страницGas Well Deliverability II 2018Johny ImitazОценок пока нет

- Problem 1A.3: C R C RДокумент4 страницыProblem 1A.3: C R C RÁngel Trinidad RamirezОценок пока нет

- Composition Dependence of Tensile Yield Stress in Filled PolymersДокумент3 страницыComposition Dependence of Tensile Yield Stress in Filled PolymersalperenacarОценок пока нет

- Models - Mph.automotive MufflerДокумент14 страницModels - Mph.automotive MufflerSumedh WaradeОценок пока нет

- Vannesa SPE 1 PDFДокумент7 страницVannesa SPE 1 PDFVanessa Ayala FОценок пока нет

- COMSOL ApplicationLibraryManualДокумент390 страницCOMSOL ApplicationLibraryManualJessicaTorresRedondoОценок пока нет

- SPE 166340 Deconvolution of Well Test Data in Lean and Rich Gas Condensate, and Volatile Oil Wells Below Saturation PressureДокумент15 страницSPE 166340 Deconvolution of Well Test Data in Lean and Rich Gas Condensate, and Volatile Oil Wells Below Saturation PressurekhayalОценок пока нет

- 7. The trigonometric functionsДокумент46 страниц7. The trigonometric functionsjoeОценок пока нет

- Pruebasde PresionДокумент11 страницPruebasde Presionmarco antonioОценок пока нет

- Mechanical Behavior of 6101 Aluminum AlloyДокумент8 страницMechanical Behavior of 6101 Aluminum AlloyViníciusAquinoОценок пока нет

- Ds BurnДокумент63 страницыDs BurnmahsaОценок пока нет

- Gas Production II 2018Документ54 страницыGas Production II 2018Akib ImtihanОценок пока нет

- Research Article: On The Simplex Algorithm InitializingДокумент16 страницResearch Article: On The Simplex Algorithm InitializingIbrahim ShowОценок пока нет

- Drill Stem Test Simulation: by Nicolas A. Jeannequin Practical Numerical AnalysisДокумент13 страницDrill Stem Test Simulation: by Nicolas A. Jeannequin Practical Numerical Analysissanjeevk4u_867705149Оценок пока нет

- Introduction To Chemical Engineering CH 7Документ19 страницIntroduction To Chemical Engineering CH 7정미학 / 학생 / 자유전공학부Оценок пока нет

- Examination Paper For TPG4150 Reservoir Recovery TechniquesДокумент16 страницExamination Paper For TPG4150 Reservoir Recovery TechniquesAmir MОценок пока нет

- Shakirov2017 Article TheEquivalentCircuitOfATwo-winДокумент7 страницShakirov2017 Article TheEquivalentCircuitOfATwo-winbeimanalfredoОценок пока нет

- Week 3 Solutions Fall 2015Документ4 страницыWeek 3 Solutions Fall 2015mfpau23Оценок пока нет

- Clase 11 Fisica ModernaДокумент2 страницыClase 11 Fisica ModernanoelОценок пока нет

- SPE36919 A Novel Graphical Method For Determining Dewpoint Pressures of Gas CondensatesДокумент3 страницыSPE36919 A Novel Graphical Method For Determining Dewpoint Pressures of Gas CondensatesWaleed Barakat MariaОценок пока нет

- Unit CircleДокумент7 страницUnit CircleAileen OrbinaОценок пока нет

- Chen 2002Документ10 страницChen 2002WICKEY WULANDARIОценок пока нет

- BJT Transistor OperationДокумент33 страницыBJT Transistor OperationSuraj PatirОценок пока нет

- Exam 2Документ9 страницExam 2Vannie BelloОценок пока нет

- Equations of state overviewДокумент35 страницEquations of state overviewrushdiОценок пока нет

- Chapter 8 Well ModelsДокумент19 страницChapter 8 Well Modelstamurt80Оценок пока нет

- The Breakdown Pressure Calculating Model For Open Hole Completion CBM Well Hydraulic FracturingДокумент8 страницThe Breakdown Pressure Calculating Model For Open Hole Completion CBM Well Hydraulic FracturingDevinaacsОценок пока нет

- Determinants Math 122 Calculus IIIДокумент5 страницDeterminants Math 122 Calculus IIIPrajwal BirwadkarОценок пока нет

- Projection and least squares problemsДокумент15 страницProjection and least squares problems이이이Оценок пока нет

- HW 6 SolutionsДокумент11 страницHW 6 Solutionskaren dejoОценок пока нет

- Wei 2011Документ12 страницWei 2011Franciani GoedertОценок пока нет

- Otto Cycle: Agenda 1. Air-Standard Otto, Diesel, Dual Cycle 2. Thermodynamic RelationsДокумент6 страницOtto Cycle: Agenda 1. Air-Standard Otto, Diesel, Dual Cycle 2. Thermodynamic RelationsscribebookОценок пока нет

- Propiedades Potencias Raices LogaritmosДокумент1 страницаPropiedades Potencias Raices Logaritmossofia caamañoОценок пока нет

- A5.Choke Performance - SolutionsДокумент3 страницыA5.Choke Performance - SolutionsVatsal ShahОценок пока нет

- Plücker Coordinates for Lines in SpaceДокумент11 страницPlücker Coordinates for Lines in SpaceGambitОценок пока нет

- Introduction To Compressible Fluid FlowsДокумент44 страницыIntroduction To Compressible Fluid FlowsShahzada ShujaОценок пока нет

- Step Growth PolymerizationДокумент6 страницStep Growth PolymerizationKrishna KumarОценок пока нет

- Parcial Mecánica de FluidosДокумент3 страницыParcial Mecánica de FluidosIñigoОценок пока нет

- Lec Notes 02 PDFДокумент6 страницLec Notes 02 PDFKrishna KumarОценок пока нет

- Multi-Effect Distillation Applied To An Industrial Case StudyДокумент11 страницMulti-Effect Distillation Applied To An Industrial Case StudyRay CharlesОценок пока нет

- Myhill-Nerode Theorem: Deepak D'SouzaДокумент37 страницMyhill-Nerode Theorem: Deepak D'SouzahacoОценок пока нет

- Tech Reservoir KravReservoirДокумент5 страницTech Reservoir KravReservoirkhansaОценок пока нет

- Errata For Signals and Systems: A MATLAB Integrated ApproachДокумент2 страницыErrata For Signals and Systems: A MATLAB Integrated ApproachAHLAD KUMARОценок пока нет

- Unit 2 Pressure and Its Measurement 10CV35Документ34 страницыUnit 2 Pressure and Its Measurement 10CV35p6a4nduОценок пока нет

- Grade 8 Module Adv. MathДокумент2 страницыGrade 8 Module Adv. Mathcharmaine cadalsoОценок пока нет

- Stress ConcentrationДокумент13 страницStress Concentrationmohammad abusarhanОценок пока нет

- Solution Manual for an Introduction to Equilibrium ThermodynamicsОт EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsОценок пока нет

- Compress Able FlowДокумент50 страницCompress Able FlowHector Pedraza RomeroОценок пока нет

- Compressible FlowДокумент16 страницCompressible FlowAkmal BhattiОценок пока нет