Академический Документы

Профессиональный Документы

Культура Документы

Wika PM0202

Загружено:

kuraimundОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Wika PM0202

Загружено:

kuraimundАвторское право:

Доступные форматы

Mechanical

Pressure Measurement

Bourdon Tube Pressure Gauges

Stainless Steel Series

Type 232.50 - Dry Case

Type 233.50 - Liquid-filled Case

WIKA Datasheet 23X.50

Applications

With liquid-filled case for applications with high dynamic

pressure pulsations (add restrictor) or vibration

Suitable for corrosive environments and gaseous or liquid

media that will not obstruct the pressure system

Process industry: chemical/petrochemical, power

stations, mining, on and offshore, environmental

technology, mechanical engineering and plant

construction

Product Features

Excellent load-cycle stability and shock resistance

All stainless steel construction

Positive pressure ranges to 20,000 psi (1600 bar)

Bourdon Tube Pressure Gauge Model 232.50, 6

Specifications

-40F to +140F (-40C to +60C) - silicone-filled

Design Medium: +392F (+200C) maximum - dry

ASME B40.100 & EN 837-1 +212F (+100C) maximum - liquid-filled

Sizes Temperature error

2, 4 & 6 (63, 100 and 160 mm) Additional error when temperature changes from reference

temperature of 68F (20C) 0.4% of span for every 18F

Accuracy class (10K) rising or falling.

2: 2/1/2% of span (ASME B40.100 Grade A)

4 & 6: 1.0% of span (ASME B40.100 Grade 1A) Weather protection

Weather tight (NEMA 4X / IP65)

Ranges

Vacuum / Compound to 200 psi (16 bar) Pressure connection

Pressure from 0/15 psi (1 bar) to 0/15,000 psi (1,000 bar) Material: 316L stainless steel

- 2, 4 Lower mount (LM) or lower back mount (LBM)

Pressure from 0/10 (0.6 bar) to 0/20,000 psi (1,600 bar) - 6 Center back mount (CBM) for 2 size

or other equivalent units of pressure or vacuum NPT or NPT (other connections available)

Working pressure Bourdon tube

2: Steady: scale value Material: 316 stainless steel

Fluctuating: 2/3 full-scale value > 1,000 psi (100 bar): C-shape

Short time: full-scale value < 1,500 psi (100 bar): helical

4 & 6: Steady: full-scale value Movement

Fluctuating: 0.9x full-scale value Stainless steel

Short time: 1.3x full-scale value

Dial

Operating temperature White aluminum with black lettering; 2 with stop pin

Ambient: -40F to +140F (-40C to +60C) - dry

-4F to +140F (-20C to +60C) - glycerine-filled Pointer

WIKA Datasheet 23X.50 05/2016 Page 1 of 2

Case Optional extras

304 Stainless steel Other pressure connections

2- with pressure relief/fill plug on top of case Restrictors for applications with high dynamic

4 and 6- with blow out plug on back of case and pressure pulsations

fill plug on top of case Monel wetted parts (Type 26X.50), not available in 6 LBM

For pressure ranges < 300 psi, case has compensating Front flange, SS (CBM and LBM only)

valve/fill plug to vent case pressure Rear flange, SS

316 SS case material

Bezel ring U-clamp mounting, SS (not available on 4)

Stainless steel, bayonet-type Silicone or Halocarbon case filling

Non-adjustable pointer

Window Red drag pointer or mark pointer

Polycarbonate (2) and Safety Glass (4 & 6) Safety glass window

with Buna-N gasket Custom dial layout

Other pressure scales available: bar, kPa, MPa, kg/cm

Case fill and dual scales

Glycerine 99.7% - Type 233.50 Integral alarm contacts or transmitters

For size 4 1/2 please see date sheet 23X.40 4.5

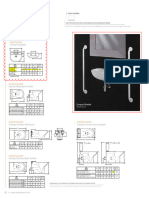

Dimensions

Size

A B C D4 E G H J L M N S T W Weight

2 mm 63 54 33 62 9.5 57 Note1 3.6 3 85 75 5 14 0.35 lb. dry

in 2.48 2.13 1.30 2.44 0.37 2.24 0.14 0.12 3.35 2.95 0.20 1/4 0.55 0.44 lb. filled

4 mm 101 86 49.5 99 15.5 83 30 4.8 3 132 116 5 22 1.32 lb. dry

in 3.98 3.43 1.95 3.90 0.61 3.27 1.18 0.19 0.12 5.20 4.57 0.20 1/2 0.87 1.98 lb. filled

6 mm 161 118 49.5 159 15.5 83 50 5.8 3 196 178 5 22 2.42 lb. dry

in 6.34 4.65 1.95 6.26 0.61 3.27 1.97 0.23 0.12 7.72 7.01 0.20 1/2 0.87 4.40 lb. filled

Center back mount (CBM)

Plus 0.63 ( 16 mm) for pressure ranges > 1,500 psi

Weight without optional accessories

4

D (+) 1mm for panel cutout

Page 2 of 2 WIKA Datasheet 23X.50 05/2016

Ordering information

Pressure gauge model / Nominal size / Scale range / Size of connection / Optional extras required

Specifications and dimensions given in this leaflet represent the state of engineering at the time of printing.

Modifications may take place and materials specified may be replaced by others without prior notice. WIKA Instrument Corporation

1000 Wiegand Boulevard

Lawrenceville, GA 30045

Tel (770) 513-8200 Toll-free 1-888-WIKA-USA

Fax (770) 338-5118

E-Mail info@wika.com

www.wika.com

Вам также может понравиться

- AWWA M23-2002 PVC Pipe Design and Installation, 176p PDFДокумент176 страницAWWA M23-2002 PVC Pipe Design and Installation, 176p PDFEagle3232100% (11)

- Fire Safety and Evacuation Plan TemplateДокумент19 страницFire Safety and Evacuation Plan Templatekuraimund100% (1)

- Declaration Page Sample Homeowners 12Документ1 страницаDeclaration Page Sample Homeowners 12Keller Brown JnrОценок пока нет

- The List InditexДокумент126 страницThe List InditexRezoanul Haque100% (2)

- Dosage Calculations, CH 10 ProblemsДокумент1 страницаDosage Calculations, CH 10 ProblemsJacqueline GreerОценок пока нет

- 23X 53Документ2 страницы23X 53fabianrico2Оценок пока нет

- Gauge PressureДокумент5 страницGauge PressureMuhammad IhsanОценок пока нет

- Bourdon Tube Pressure Gauges Industrial Stainless Steel Gauge Type 232.54 - Dry Case Type 233.54 - Liquid-Filled CaseДокумент2 страницыBourdon Tube Pressure Gauges Industrial Stainless Steel Gauge Type 232.54 - Dry Case Type 233.54 - Liquid-Filled CasehoamnОценок пока нет

- S1.4.5.) Datasheet PRESSURE GAUGEДокумент3 страницыS1.4.5.) Datasheet PRESSURE GAUGEEkoОценок пока нет

- Bourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CaseДокумент3 страницыBourdon Tube Pressure Gauge Stainless Steel Case Type 212.53 - Dry Case Type 213.53 - Liquid-Filled CasecarlosОценок пока нет

- Pressure GaugeДокумент2 страницыPressure GaugeVishnu PatilОценок пока нет

- Bourdon Tube Pressure Gauge Stainless Steel Construction Model 21X.53Документ3 страницыBourdon Tube Pressure Gauge Stainless Steel Construction Model 21X.53Dennis MendozaОценок пока нет

- Bourdon Tube Pressure Gauges Stainless Steel Series Type 232.53 - Dry Case Type 233.53 - Liquid-Filled CaseДокумент8 страницBourdon Tube Pressure Gauges Stainless Steel Series Type 232.53 - Dry Case Type 233.53 - Liquid-Filled Caseasghar khanОценок пока нет

- Ficha TecnicaДокумент2 страницыFicha Tecnicaluis.trigosОценок пока нет

- Item 2 Indicador de PresiónДокумент2 страницыItem 2 Indicador de PresiónElvis CansinoОценок пока нет

- Bourdon Tube Pressure GaugesДокумент2 страницыBourdon Tube Pressure Gaugessashikiran83Оценок пока нет

- Wika Xsel Process Gauge Models 232.34 and 233.34 DatasheetДокумент4 страницыWika Xsel Process Gauge Models 232.34 and 233.34 DatasheetandhucaosОценок пока нет

- YCA.23X.34 Bourdon GageДокумент2 страницыYCA.23X.34 Bourdon Gagejanvierhotben3983Оценок пока нет

- Bourdon Tube Pressure Gauge Type 113.13 - ABS Case With Liquid Filling Standard SeriesДокумент2 страницыBourdon Tube Pressure Gauge Type 113.13 - ABS Case With Liquid Filling Standard Serieswarehouse cikalongОценок пока нет

- Datasheet Pressure Gauge 8009sДокумент13 страницDatasheet Pressure Gauge 8009smpicaОценок пока нет

- 43X X6Документ4 страницы43X X6reliableplacementОценок пока нет

- Data Sheet of WikiДокумент2 страницыData Sheet of Wikibcec startОценок пока нет

- Econ Pressure Gauges Bourdon Tube Type All of Stainless Steel Fig. 366Документ1 страницаEcon Pressure Gauges Bourdon Tube Type All of Stainless Steel Fig. 366ChristianОценок пока нет

- Bourdon Tube Pressure Gauges Stainless Steel Series Type 232.50 - Dry Case Type 233.50 - Liquid-Filled CaseДокумент2 страницыBourdon Tube Pressure Gauges Stainless Steel Series Type 232.50 - Dry Case Type 233.50 - Liquid-Filled CaseSachin GuptaОценок пока нет

- BR Oil and Gas Applications en Us 17430Документ5 страницBR Oil and Gas Applications en Us 17430bidokОценок пока нет

- Ds pm0215 en CoДокумент7 страницDs pm0215 en CoMsach RoysОценок пока нет

- Bourdon Tube Pressure Gauges: Solid-Front Turret Style Test Gauge Accuracy + 0.25% of SpanДокумент2 страницыBourdon Tube Pressure Gauges: Solid-Front Turret Style Test Gauge Accuracy + 0.25% of Spanhugo171630Оценок пока нет

- Man Sse Nae 8Документ8 страницMan Sse Nae 8Jorge Gustavo GoyecheaОценок пока нет

- Wika 213.4Документ2 страницыWika 213.4Cristian RamirezОценок пока нет

- BR Water Applications en Us 17436Документ7 страницBR Water Applications en Us 17436Ryan JayОценок пока нет

- 23x 50Документ2 страницы23x 50RioPrawiraОценок пока нет

- Wika F73.100 DS TM7301 en Co 2146Документ15 страницWika F73.100 DS TM7301 en Co 2146NCОценок пока нет

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterДокумент4 страницыSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAA Differential Pressure TransmitterMohammad HosseinОценок пока нет

- ManometreДокумент6 страницManometreAbdo KouОценок пока нет

- Wika Type 111.11Документ2 страницыWika Type 111.11warehouse cikalongОценок пока нет

- Wika 213.53 Pressure Gauge Catalog PageДокумент4 страницыWika 213.53 Pressure Gauge Catalog PageM MОценок пока нет

- Bourdon Tube Pressure Gauges Stainless Steel, Safety Pattern Version, High Overpressure Safety Model 232.36/233.36, Without/with Liquid FillingДокумент2 страницыBourdon Tube Pressure Gauges Stainless Steel, Safety Pattern Version, High Overpressure Safety Model 232.36/233.36, Without/with Liquid FillingRichard EVОценок пока нет

- Bourdon Tube Pressure Gauges Stainless Steel Series Model 232.50/233.50, Without/with Liquid FillingДокумент2 страницыBourdon Tube Pressure Gauges Stainless Steel Series Model 232.50/233.50, Without/with Liquid Fillingkholik arenОценок пока нет

- AN3000 SeriesДокумент2 страницыAN3000 SeriesdanishaslОценок пока нет

- 2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetДокумент4 страницы2462 Duragauge Pressure Gauge With PLUS! Performance Option: Data SheetAlfonso BlancoОценок пока нет

- DS PM11111 en Us 15142Документ3 страницыDS PM11111 en Us 15142Rafael JuncoОценок пока нет

- Manometer Air DryerДокумент4 страницыManometer Air DryerBerryОценок пока нет

- Mark 96 Series: Sanitary Pressure RegulatorsДокумент8 страницMark 96 Series: Sanitary Pressure Regulatorsalejandro carmona henaoОценок пока нет

- Wika Pressure Gauge 6 InchДокумент3 страницыWika Pressure Gauge 6 InchsanОценок пока нет

- Servo Motor SchematicДокумент8 страницServo Motor Schematicعلي كامل الاسديОценок пока нет

- Bourdon Tube Pressure Gauges Economical Stainless Steel Gauge Type 132.53 - Dry Case Type 133.53 - Liquid-Filled CaseДокумент2 страницыBourdon Tube Pressure Gauges Economical Stainless Steel Gauge Type 132.53 - Dry Case Type 133.53 - Liquid-Filled CaseSholhan AzizОценок пока нет

- Differential Pressure Recorder Data SheetДокумент8 страницDifferential Pressure Recorder Data SheetEdmund LimОценок пока нет

- Specification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterДокумент4 страницыSpecification Sheet: Deltapi N Series Pneumatic Transmitters Model NAD Differential Pressure TransmitterJane Umali CastilloОценок пока нет

- Bourdon Tube Pressure Gauge Model 111.12, Back Pressure EntryДокумент2 страницыBourdon Tube Pressure Gauge Model 111.12, Back Pressure Entrykholik arenОценок пока нет

- Differential Pressure Gauges Diaphragm Element Series Type 732.51 All-Welded ConstructionДокумент4 страницыDifferential Pressure Gauges Diaphragm Element Series Type 732.51 All-Welded Constructionsamira ameriОценок пока нет

- Differential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionДокумент4 страницыDifferential Pressure Gauge Stainless Steel Version, With Diaphragm Element Model 732.51, All Welded ConstructionPaulkumar RamaiahОценок пока нет

- Industrial Pressure Gauge Model: P52: Standard SpecificationДокумент2 страницыIndustrial Pressure Gauge Model: P52: Standard SpecificationPort VideoОценок пока нет

- Mc. Daniel - Pressure GaugeДокумент6 страницMc. Daniel - Pressure GaugeMuhammad FuadyОценок пока нет

- Stainless Steel Pressure Filters - BrochureДокумент20 страницStainless Steel Pressure Filters - Brochureviktor_gligorovОценок пока нет

- Bourdon Tube Pressure Gauge Model 332.34 LM-All Stainless Steel Wetted PartsДокумент2 страницыBourdon Tube Pressure Gauge Model 332.34 LM-All Stainless Steel Wetted PartsbehnamatgОценок пока нет

- G Style - Pneumatic DatasheetДокумент2 страницыG Style - Pneumatic DatasheetMehemmed MelikovОценок пока нет

- Bourdon Tube Pressure Gauges: Solid-Front Turret Style Thermoplastic Case Pressure GaugesДокумент2 страницыBourdon Tube Pressure Gauges: Solid-Front Turret Style Thermoplastic Case Pressure Gaugeslcfigueroa1987Оценок пока нет

- DS PM332 30 en Us 15970Документ2 страницыDS PM332 30 en Us 15970Sukddesh RagavanОценок пока нет

- Bourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Документ4 страницыBourdon Tube Pressure Gauge, Stainless Steel For The Process Industry, Safety Version, NS 63, 100 and 160 Models 232.30, 233.30Chau TranОценок пока нет

- Tds - Wika Pressure GaugeДокумент4 страницыTds - Wika Pressure GaugeSenthil Kumar100% (1)

- Bourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionДокумент3 страницыBourdon Tube Pressure Gauge Model 131.11, Stainless Steel VersionChau TranОценок пока нет

- Ball Float ValveДокумент2 страницыBall Float ValvekuraimundОценок пока нет

- VSR Series: Vane-Type Waterflow SwitchДокумент1 страницаVSR Series: Vane-Type Waterflow SwitchkuraimundОценок пока нет

- Installation Instructions Spool Type Elastomer Expansion JointsДокумент2 страницыInstallation Instructions Spool Type Elastomer Expansion JointsAmina TaissaОценок пока нет

- Din Flanges Spec SheetДокумент5 страницDin Flanges Spec SheetSara MahmoudОценок пока нет

- Installation ManualДокумент5 страницInstallation ManualUhudhu AhmedОценок пока нет

- RAK Compact Disable Wash BasinДокумент1 страницаRAK Compact Disable Wash BasinkuraimundОценок пока нет

- ROCA - Tilting Wall Bracket (816323000)Документ2 страницыROCA - Tilting Wall Bracket (816323000)kuraimundОценок пока нет

- ACPE Qualifications FeesДокумент1 страницаACPE Qualifications FeeskuraimundОценок пока нет

- RAKTherm Reinforced Piping SystemsДокумент13 страницRAKTherm Reinforced Piping SystemskuraimundОценок пока нет

- Compressed Air HSEДокумент50 страницCompressed Air HSEOdalis ToscanoОценок пока нет

- Review of The WaterMark Certification SchemeДокумент107 страницReview of The WaterMark Certification SchemekuraimundОценок пока нет

- Atex GuidelinesДокумент76 страницAtex GuidelinesAN.ADAMMSОценок пока нет

- Standard Sewer DetailsДокумент59 страницStandard Sewer DetailsPhanhai KakaОценок пока нет

- Medical Gas Pipeline SystemsДокумент218 страницMedical Gas Pipeline Systemsmedo2005100% (10)

- Crane FS Balancing Valve IOMДокумент2 страницыCrane FS Balancing Valve IOMkuraimundОценок пока нет

- Gas Safety and Measurement Amendment Regulations 2011 PDFДокумент33 страницыGas Safety and Measurement Amendment Regulations 2011 PDFkuraimundОценок пока нет

- E01 0Документ9 страницE01 0Zaher El HajjОценок пока нет

- HARRIS UK CatalogueДокумент56 страницHARRIS UK CataloguekuraimundОценок пока нет

- Omron LY2 Data SheetДокумент16 страницOmron LY2 Data SheetkuraimundОценок пока нет

- Basic Dimensions For NPT American National Taper Pipe ThreadsДокумент2 страницыBasic Dimensions For NPT American National Taper Pipe ThreadsAndi DumayОценок пока нет

- Oxygen, DissolvedДокумент6 страницOxygen, DissolvedkuraimundОценок пока нет

- Dyke Wall PDFДокумент1 страницаDyke Wall PDFkuraimundОценок пока нет

- Flowsheet Symbols and PenI Diagrams PDFДокумент30 страницFlowsheet Symbols and PenI Diagrams PDFRajeshОценок пока нет

- Inst Symbols P ID FunctionДокумент37 страницInst Symbols P ID FunctionkuraimundОценок пока нет

- Pop Cad Bmi StndrdsДокумент106 страницPop Cad Bmi StndrdskuraimundОценок пока нет

- The Comprehensive Guide To Swimming Pool OwnershipДокумент42 страницыThe Comprehensive Guide To Swimming Pool OwnershipAhmedОценок пока нет

- RMC Thermal Balancing ValvesДокумент2 страницыRMC Thermal Balancing ValveskuraimundОценок пока нет

- 45-59-025 Avkcms enДокумент2 страницы45-59-025 Avkcms enkuraimundОценок пока нет

- SCL NotesДокумент4 страницыSCL NotesmayaОценок пока нет

- Resume Rough DraftДокумент1 страницаResume Rough Draftapi-392972673Оценок пока нет

- Wax Depilation ManualДокумент17 страницWax Depilation ManualAmit Sharma100% (1)

- PACKET 1 - Exercises and ActivitiesДокумент7 страницPACKET 1 - Exercises and ActivitiesPrantsir Pernes100% (2)

- Chapter - 1 Mcdonald'S IntroductionДокумент38 страницChapter - 1 Mcdonald'S IntroductionNisha GehlotОценок пока нет

- Clipsal RCD Tester 486D PDFДокумент4 страницыClipsal RCD Tester 486D PDF322399mk7086Оценок пока нет

- BU2508DFДокумент3 страницыBU2508DFRaduОценок пока нет

- EMC Design GuideДокумент42 страницыEMC Design GuideDe Raghu Veer KОценок пока нет

- EarthmattersДокумент7 страницEarthmattersfeafvaevsОценок пока нет

- 56.vocal Warmup Log For Belt Your FaceДокумент5 страниц56.vocal Warmup Log For Belt Your FaceAlinutza AlinaОценок пока нет

- Stats Review CH 1-6Документ15 страницStats Review CH 1-6Megha BanerjeeОценок пока нет

- Vinegar Intake Reduces Body Weight Body Fat Mass and Serum Triglyceride Levels in Obese Japanese SubjectsДокумент8 страницVinegar Intake Reduces Body Weight Body Fat Mass and Serum Triglyceride Levels in Obese Japanese SubjectsZaphan ZaphanОценок пока нет

- Aircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management EngineerДокумент46 страницAircraft Noise Management: Graduation Project Defense For The Diploma of Air Traffic Management Engineerchouchou chamaОценок пока нет

- WB Food Processing IndustryДокумент13 страницWB Food Processing IndustryRakesh KumarОценок пока нет

- Lab Safety RulesДокумент2 страницыLab Safety RulesChristine ManuelОценок пока нет

- 08 163 4 JPL ScheickДокумент50 страниц08 163 4 JPL ScheickSaqib Ali KhanОценок пока нет

- CHEM F313: Instrumental Methods of Analysis: Flame Photometry & Atomic Absorption SpectrosДокумент26 страницCHEM F313: Instrumental Methods of Analysis: Flame Photometry & Atomic Absorption SpectrosHARSHVARDHAN KHATRIОценок пока нет

- O OP PE ER RA Attiin NG G Iin NS STTR RU UC Cttiio ON NS S: UF 755 G UF 455 GДокумент14 страницO OP PE ER RA Attiin NG G Iin NS STTR RU UC Cttiio ON NS S: UF 755 G UF 455 GHomeroPerezОценок пока нет

- Water Quantity Estimation PDFДокумент3 страницыWater Quantity Estimation PDFOladunni AfolabiОценок пока нет

- Good Laboratory Practice GLP Compliance Monitoring ProgrammeДокумент17 страницGood Laboratory Practice GLP Compliance Monitoring ProgrammeamgranadosvОценок пока нет

- EML Prosedur ManualДокумент1 019 страницEML Prosedur Manualzrohim bapetenkfk2023Оценок пока нет

- H.influenzae Modified 2012Документ12 страницH.influenzae Modified 2012MoonAIRОценок пока нет

- Ens TecДокумент28 страницEns TecBorja CanalsОценок пока нет

- Coatings and Waterproofing: KhalafДокумент19 страницCoatings and Waterproofing: KhalafmohamedОценок пока нет

- Air Pollution Emissions 2008-2018 From Australian Coal Mining: Implications For Public and Occupational HealthДокумент11 страницAir Pollution Emissions 2008-2018 From Australian Coal Mining: Implications For Public and Occupational HealthMaria Stephany CalisayaОценок пока нет

- 45relay Rm4ua PDFДокумент1 страница45relay Rm4ua PDFtamky SubstationОценок пока нет

- QUIZ7 Audit of LiabilitiesДокумент3 страницыQUIZ7 Audit of LiabilitiesCarmela GulapaОценок пока нет