Академический Документы

Профессиональный Документы

Культура Документы

Zap Screwlok® Data Sheet

Загружено:

LeomariniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Zap Screwlok® Data Sheet

Загружено:

LeomariniАвторское право:

Доступные форматы

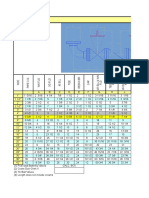

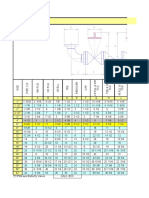

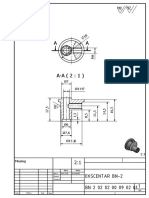

Sizes #3 - #11 Sizes #14 - #18

C

ZAP SCREWLOK DATA SHEET

C

A

A

Dimensions & Data END VIEW + +

(AFTER ASSEMBLY)

[inch-pound units] B B

X X

PRODUCT CODE COUPLER LENGTH NUMBER AVERAGE MIN.IMPACT

SCREW WRENCH

REBAR WEIGHT L A B C X SCREWS TORQUE RATING

ZAP SCREWLOK TYPE 2 / EPOXY SIZE TYPE 2 EPOXY (LB) (IN) (IN) (IN) (IN) (IN) PER BAR (FT-LB) (FT-LB)

13 5 7

3 03ZBA 03ZEA 1.0 5 16 8 16 1 18 2

4 04ZBA 04ZEA 2.2 7 1 116 11

16 1

2 1 38 3

1 3 5

60 250

5 05ZBA 05ZEA 3.4 9 1 8 4 8 1 58 4

L 6 06ZBA 06ZEA 4.7 11 1 316 15

16 11

16 1 34 5

1 1 13

7 07ZBA 07ZEA 7.6 13 1 4 1 16 16 2 116 5

1 5 1 7 1

105 500

8 08ZBA 08ZEA 10.9 15 4 1 16 1 16 8 2 4 6

9 09ZBA 09ZEA 17.6 16 34 1 58 1 14 1 116 2 58 6

1 11 7 1 3

10 10ZBA 10ZEA 21.4 19 8 1 16 1 16 1 8 2 4 7 215 750

11 11ZBA 11ZEA 25.4 21 12 1 1316 1 12 1 14 2 1516 8

14 14ZBA 14ZEA 37.2 18 2 516 1 34 1 12 3 34 10

1 1 1 13

350 1000

18 18ZBA 18ZEA 74.0 29 2 2 2 2 4 1 16 4 38 21

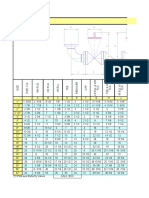

PRODUCT CODE COUPLER LENGTH NUMBER AVERAGE MIN.IMPACT

SCREW WRENCH

REBAR WEIGHT L A B C X SCREWS TORQUE RATING

ZAP SCREWLOK SL SIZE SL (LB) (IN) (IN) (IN) (IN) (IN) PER BAR (FT-LB) (FT-LB)

4 04SZBA 1.5 5 1 116 11

16 1

2 1 38 2

5 05SZBA 2.6 7 1 18 3

4 5

8 1 58 3 60 250

6 06SZBA 3.8 9 1 316 15

16 11

16 1 34 4

L

7 07SZBA 6.2 10 34 1 14 1 116 13

16 2 116 4

105 500

8 08SZBA 9.3 13 1 516 1 116 7

8 2 14 5

9 09SZBA 14.3 13 78 1 58 1 14 1 116 2 58 4

10 10SZBA 18.2 16 12 1 1116 1 716 1 18 2 34 5 215 750

1 13 1 1 15

11 11SZBA 22.3 19 8 1 16 1 2 1 4 2 16 6

14 14SZBA 32.0 15 38 2 516 1 34 1 12 3 34 8

1 1 1 13 3

350 1000

18 18SZBA 58.4 23 2 2 2 2 4 1 16 4 8 16

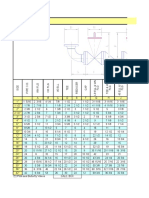

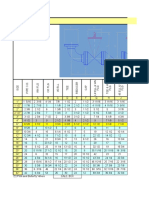

PRODUCT CODE COUPLER LENGTH NUMBER AVERAGE MIN.IMPACT

SCREW WRENCH

REBAR WEIGHT L A B C X SCREWS TORQUE RATING

ZAP SCREWLOK TRANSITION SIZE TRANSITION (LB) (IN) (IN) (IN) (IN) (IN) PER BAR (FT-LB) (FT-LB)

5/4 05/04ZBA 3.0 8 1 18 3

4 5

8 1 58 3

6/4 06/04ZBA 60 250

4.3 10 1 316 15

16 11

16 1 34 4

6/5 06/05ZBA

7/5 07/05ZBA

6.8 12 1 14 1 116 13

16 2 116 4

7/6 07/06ZBA

8/5 08/05ZBA 105 500

8/6 08/06ZBA 9.9 14 18 1 516 1 18 7

8 2 14 5

8/7 08/07ZBA

9/6 09/06ZBA

L

9/7 09/07ZBA 16.2 15 916 1 58 1 14 1 116 2 58 5

9/8 09/08ZBA

10/7 10/07ZBA

10/8 10/08ZBA 20.1 17 1516 1 1116 1 716 1 18 2 34 6

215 750

10/9 10/09ZBA

11/7 11/07ZBA

11/8 11/08ZBA 20.1 17 1516 1 1316 1 12 1 14 2 1316 6

11/9 11/09ZBA

11/10 11/10ZBA 22.8 20 516 1 1316 1 12 1 14 2 1316 7

14/10 14/10ZBA

34.3 15 38 2 516 1 34 1 12 3 34 8

14/11 14/11ZBA

350 1000

18/11 18/11ZBA 9 1 1 13 3

53.2 18 16 2 2 2 4 1 16 4 8 12

18/14 18/14ZBA

Zap

Double Barrel Zap

Structural Connector

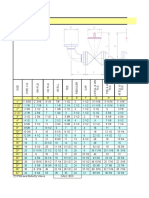

ZAP SCREWLOK DATA SHEET D

C

Dimensions & Data (page 2) END VIEW A

A

(AFTER ASSEMBLY)

+

[inch-pound units]

B S

PRODUCT CODE CONNECTOR LENGTH NUMBER AVERAGE MIN.IMPACT

SCREW WRENCH

REBAR WEIGHT L A B D W SCREWS RATING

ZAP STRUCTURAL CONNECTOR

TORQUE

SIZE Structural Conn (LB) (IN) (IN) (IN) (IN) (IN) PER BAR (FT-LB) (FT-LB)

4 04SZSC 0.9 3 18 1 116 1116 1 716 3

16 2

5 05SZSC 1.5 4 18 1 18 3

4 1 1116 1

4 3 60 250

6 06SZSC 2.3 5 38 3

1 16 15

16 1 78 1

4 4

L

7 07SZSC 3.6 6 38 1 14 1 116 2 18 5

16 4

W 105 500

8 08SZSC 5.5 7 78 1 516 1 116 2 516 3

8 5

9 09SZSC 7.6 8 1 58 1 14 2 1116 7

16 4

10 10SZSC 9.6 9 12 1 1116 1 716 2 78 1

2 5 215 750

11 11SZSC 12.1 11 18 1 1316 1 12 3 9

16 6

14 14SZSC 18.0 8 78 2 516 1 34 3 1316 11

16 7

350 1000

18 18SZSC 37.5 15 38 2 12 2 14 4 12 7

8 16

PRODUCT CODE COUPLER LENGTH NUMBER AVERAGE MIN.IMPACT

SCREW WRENCH

REBAR WEIGHT L A C S d SCREWS RATING

DOUBLE BARREL ZAP

TORQUE

SIZE Double Barrel (LB) (IN) (IN) (IN) (IN) (IN) PER BAR (FT-LB) (FT-LB)

3 03DBZA 1.3 2 18 1 18 3

8 15

16 3

8 2

4 04DBZA

1.3 2 18 1 116 1

2 15

16 1

2 2

4/3 04/03DBZA

5 05DBZA

2.3 3 1 18 5

8 15

16 5

8 3 60 250

L d 5/4 05/04DBZA

6 06DBZA

6/4 06/04DBZA 3.2 3 78 1 316 3

4 15

16 3

4 4

6/5 06/05DBZA

7 07DBZA

7/5 07/05DBZA 7.1 5 38 1 516 7

8 1 38 7

8 4

7/6 07/06DBZA 105 500

8 08DBZA

10.7 6 12 1 34 1 1 18 1 5

8/7 08/07DBZA

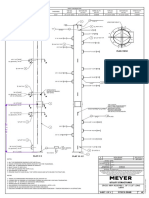

ZAP SCREWLOK Mechanical Splices and Connectors for Reinforcing Bars - Review...

ZAP SCREWLOK mechanical splices and connectors are compatible with reinforcing bars that comply with ASTM A615, ASTM A706, ASTM A996, or equal

and consist of smooth, shaped, steel sleeves with converging sides. A series of cone-pointed hex-head screws are arranged along the longitudinal axes in one

or two rows. In the case of butt splices, reinforcing bars are inserted from each end to a center stop. No special bar-end preparation is required, so ends can be

sheared, sawed, or flame-cut. Installation instructions are normally supplied with orders and are also available at www.barsplice.com.

During mechanical splice assembly, the screws are tightened and embed themselves into

the rebar surface whereupon the heads twist off at a prescribed tightening torque. Forces Single Row

from the screws cause rebar deformations to interlock within the coupling wedge. This DUAL #3 - #11

mechanical action, results in a full positive connection for transferring tension or compression

forces from bar-to-bar. Screws can be tightened using suitable impact wrenches. Linear BEFORE

alignment is preserved across the splice by using reinforcing bars with straight ends and AND

securing the continuation bar in the desired position at the time of assembly.

AFTER

When making splices between fixed points, a coupler sleeve without a center stop can be ASSEMBLY

slipped entirely onto one bar and subsequently repositioned over the two bar ends being spliced.

Mechanical butt splices and connectors are available for reinforcing bar sizes No. 3

Double Row

through 18 (10 through 57 mm) per BPIs Dimensions & Data charts. Transition splices

are used to connect rebars of different sizes. #14 - #18

Mechanical lap splices are available for bar sizes No. 3 through 8 (10 through 25 mm). BEFORE

Epoxy-coated steel reinforcing bars that comply with ASTM A775 can be spliced by means AND

of Epoxy-coated Zap Screwlok coupling sleeves without shielding or removing the epoxy AFTER

coating from the bar. Zinc-coated (galvanized) bars can be mechanically spliced by means of

galvanized Zap Screwlok coupling sleeves.

ASSEMBLY

ZAP SCREWLOK is an engineered mechanical splice system whose strength is independent of the concrete which surrounds it, thereby providing true

structural continuity. Applications include new construction, field repair of reinforcement, splicing of column steel, beam reinforcement, concrete piles and deck

steel, and splicing of older types of reinforcing bars. The Zap Screwlok system is used for rehab and retrofit projects, strengthening and up-grading concrete

elements, extending deck steel to widen bridges, highway patch and repair projects, splicing of bars across closure pours. Zap Screwlok Type 2 splices are

used for mechanically splicing reinforcement in members resisting earthquake induced forces. Benefits of Zap Screwlok include a field installed splice with

easy visual inspection, no specialized equipment, minimal clearance requirements, a positive rebar center-stop and no rebar end preparation.

While the information contained in this document is believed to be accurate at the time of publication, BPI reserves the right to make changes, design modifications,

corrections and other revisions as it sees fit, without notice. All products described herein are supplied in accordance with BPIs standard Terms and Conditions of Sale. This

document is of a promotional nature only. Aspects of structural design, evaluation of product fitness for use, suitability or similar attributes are the responsibility of others.

REV. L 10/20/2016

BarSplice Products, Inc., 4900 Webster Street, Dayton OH 45414, USA

lTel: (937) 275-8700 lFax: (937) 275-9566 lE-mail: bar@barsplice.com

Copyright 2013-2016, Barsplice Products, Inc., BPI. All rights reserved.

Вам также может понравиться

- Drop Forged U-Bolt Type: Malleable Wire Rope ClipsДокумент19 страницDrop Forged U-Bolt Type: Malleable Wire Rope ClipsingcalderonОценок пока нет

- Chain Hoist Dimensional DrawingДокумент1 страницаChain Hoist Dimensional DrawingBaris YeltekinОценок пока нет

- Xcelite Catalog 5506Документ100 страницXcelite Catalog 5506Ruben MontelongoОценок пока нет

- Grafica de promedios y rangos muestra diametrosДокумент2 страницыGrafica de promedios y rangos muestra diametrosmERCYОценок пока нет

- Adjustablereamers: Apered Hank One Piece ConstructionДокумент1 страницаAdjustablereamers: Apered Hank One Piece ConstructionAndy ReynoldsОценок пока нет

- Residensi Sakura BrochureДокумент13 страницResidensi Sakura Brochureafifah solehahОценок пока нет

- Pumpworks 610-PWVДокумент6 страницPumpworks 610-PWVMagico NinoОценок пока нет

- BT - Battle Armour Record SheetДокумент1 страницаBT - Battle Armour Record SheetFabianoBorgОценок пока нет

- Star Number Star Number: Battle Armor Record FormДокумент1 страницаStar Number Star Number: Battle Armor Record FormCarlos GonzalezОценок пока нет

- Star Number Star Number: Battle Armor Record FormДокумент1 страницаStar Number Star Number: Battle Armor Record FormArt NicklesОценок пока нет

- Battle Armor Rs PDFДокумент1 страницаBattle Armor Rs PDFripecueОценок пока нет

- Form Tally SheetДокумент2 страницыForm Tally Sheetfina noer triastutyОценок пока нет

- 505 2010 Schedule-01-31-10 PDFДокумент1 страница505 2010 Schedule-01-31-10 PDFdaniel_esdorn2082Оценок пока нет

- Energy Monitoring and Control ToolsДокумент2 страницыEnergy Monitoring and Control ToolsLuka CvijovićОценок пока нет

- L-SD + PlenumДокумент1 страницаL-SD + Plenumarmando montenegroОценок пока нет

- Sieve Comparison PDFДокумент2 страницыSieve Comparison PDFFitria RamadhonaОценок пока нет

- Piping DataДокумент162 страницыPiping DataMirena ArenaОценок пока нет

- Overall 2004Документ2 страницыOverall 2004hyclubОценок пока нет

- Tabela de Fittings Do Steel Pipe VesselДокумент259 страницTabela de Fittings Do Steel Pipe VesselArtur TeixeiraОценок пока нет

- Volleyball Scoresheet UpdatedДокумент2 страницыVolleyball Scoresheet Updatedᜁᜇᜒᜃ᜔ ᜊ᜔ ᜀᜄᜎᜒᜀᜋ᜔Оценок пока нет

- Rabu 24 Februari 2021Документ9 страницRabu 24 Februari 2021EdoОценок пока нет

- Useful Piping & Structural DataДокумент172 страницыUseful Piping & Structural Datahailay83Оценок пока нет

- SS SUB 175 v01Документ1 страницаSS SUB 175 v01mcohen LCIОценок пока нет

- A4 Quest 03 PDFДокумент3 страницыA4 Quest 03 PDFsenhor_xОценок пока нет

- 150# RF Piping DimensionsДокумент255 страниц150# RF Piping DimensionsFred McGuinnessОценок пока нет

- Ecler Sam512 SMДокумент29 страницEcler Sam512 SMPedroОценок пока нет

- Taper Pipe Threads Parallel PipethreadsДокумент1 страницаTaper Pipe Threads Parallel PipethreadssheffieldmacОценок пока нет

- AISC 360-05 Fillet Weld Capacity TableДокумент1 страницаAISC 360-05 Fillet Weld Capacity TablejxsnyderОценок пока нет

- Useful Piping & Structural DataДокумент159 страницUseful Piping & Structural DatamsaremiОценок пока нет

- Steel Pipe VesselДокумент257 страницSteel Pipe VesselVICTOR SEGOVIAОценок пока нет

- Pipe Dimensions and Valve Sizing ChartДокумент257 страницPipe Dimensions and Valve Sizing ChartDennis SongcoОценок пока нет

- Steel Pipe VesselДокумент251 страницаSteel Pipe VesselCristián Querevalu pardoОценок пока нет

- Pipe Dimensions and Valve Sizing ChartДокумент254 страницыPipe Dimensions and Valve Sizing ChartBSL PanipatОценок пока нет

- FRP Pipe Supports, Anchors and GuidesДокумент8 страницFRP Pipe Supports, Anchors and Guidesgerardo herrera valenzuelaОценок пока нет

- Angle CockesДокумент4 страницыAngle CockescoolmaleankurОценок пока нет

- Useful Piping & Structural DataДокумент159 страницUseful Piping & Structural DataNejat AbabayОценок пока нет

- Steel Pipe VesselДокумент259 страницSteel Pipe VesselJuragan TanjungОценок пока нет

- Piping Spec Book 1Документ259 страницPiping Spec Book 1interx00Оценок пока нет

- Pipe Beam SizesДокумент262 страницыPipe Beam SizesjoehodohОценок пока нет

- SS SUB 181 v01Документ1 страницаSS SUB 181 v01mcohen LCIОценок пока нет

- Silence SteamДокумент181 страницаSilence SteamrowgerОценок пока нет

- Thermoplastic Flanges: Technical Information Weights & DimensionsДокумент11 страницThermoplastic Flanges: Technical Information Weights & DimensionsANDERSON NERESОценок пока нет

- Bridas Slip On Grandes b16.47Документ1 страницаBridas Slip On Grandes b16.47Nilton Inca TitoОценок пока нет

- 150# and 300# RF piping dimensions chartДокумент154 страницы150# and 300# RF piping dimensions charteduinОценок пока нет

- C 3 ShaferДокумент1 страницаC 3 ShaferSebastin DrignyОценок пока нет

- Explosionproof Meter Housing Threaded Cover VentanaДокумент2 страницыExplosionproof Meter Housing Threaded Cover VentanaJorge Calcaneo MartinezОценок пока нет

- Cross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4Документ4 страницыCross Arm Assembly, 38'-3 1/8" Long Xarm: Sheet 1 of 4raulОценок пока нет

- Torque APIДокумент1 страницаTorque APIStefan do Nascimento da SilvaОценок пока нет

- Manual Rus-20190408084940Документ32 страницыManual Rus-20190408084940comf002376Оценок пока нет

- Bleed RingДокумент3 страницыBleed RingXxavierОценок пока нет

- Flange APIДокумент29 страницFlange APIputujuliandikaОценок пока нет

- Overall Series 2002Документ1 страницаOverall Series 2002hyclubОценок пока нет

- Key Number Community 1 Cahto Tribe of The Laytonville Rancheria 2 Sherwood Valley Rancheria of Pomo Indians 3 Round Valley Indian TribesДокумент1 страницаKey Number Community 1 Cahto Tribe of The Laytonville Rancheria 2 Sherwood Valley Rancheria of Pomo Indians 3 Round Valley Indian TribesmongoОценок пока нет

- Assy Paper Shrader Parts ListДокумент9 страницAssy Paper Shrader Parts Listxinke laoОценок пока нет

- BN 2 02 02 09 02 01 Ekscentar BN-2Документ1 страницаBN 2 02 02 09 02 01 Ekscentar BN-2Jovana891Оценок пока нет

- National Pipe Thread Chart OPT PДокумент1 страницаNational Pipe Thread Chart OPT PVasantha KumarОценок пока нет

- National Pipe Thread Chart OPT PДокумент1 страницаNational Pipe Thread Chart OPT PAbhi PrajapatiОценок пока нет

- 11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolДокумент1 страница11.4 Welding Information Welding Information: Elements of A Typical Weld SymbolLeomarini100% (1)

- FBC 01 Materials DensityДокумент5 страницFBC 01 Materials DensityLeomariniОценок пока нет

- NCEES Sample Course DescriptionsДокумент1 страницаNCEES Sample Course DescriptionsLeomariniОценок пока нет

- AT&T TitlesДокумент8 страницAT&T TitlesLeomariniОценок пока нет

- AT&T Titles PDFДокумент8 страницAT&T Titles PDFLeomariniОценок пока нет

- Tavarez Infante Residence TittlesДокумент4 страницыTavarez Infante Residence TittlesLeomariniОценок пока нет

- BASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESДокумент41 страницаBASIC DIFFERENCES BETWEEN COUPLINGS, CLUTCHES AND BRAKESKadiyam VijayОценок пока нет

- Find this flexible cable product and technical specification onlineДокумент3 страницыFind this flexible cable product and technical specification onlineRicardo Mendes100% (1)

- DS-0035 3W PM2L-3LLx-SD v1.6Документ13 страницDS-0035 3W PM2L-3LLx-SD v1.6Pavan KumarОценок пока нет

- Curtain Wall EngineeringДокумент12 страницCurtain Wall EngineeringKayBee Datiles100% (2)

- Ficha Tecnica - Lana Mineral ThermafiberДокумент2 страницыFicha Tecnica - Lana Mineral ThermafiberJeshua Diego BarrientosОценок пока нет

- EKG Class4 Questions OnlyДокумент6 страницEKG Class4 Questions OnlyVyas SrinivasanОценок пока нет

- AP CRDA Basic Cost Of Materials 2016-2017Документ57 страницAP CRDA Basic Cost Of Materials 2016-2017Hari Krishna AaryanОценок пока нет

- LHF 400 LHFДокумент14 страницLHF 400 LHFValiBardaОценок пока нет

- Traction CONTROLДокумент18 страницTraction CONTROLkiransideasОценок пока нет

- Bead and MeshДокумент7 страницBead and Meshmuradali01Оценок пока нет

- CNC Bits Buying Guide: C08 C15 SS17 SF17 SB17Документ9 страницCNC Bits Buying Guide: C08 C15 SS17 SF17 SB17Sandro AlcantaraОценок пока нет

- URA Elect SR 2005 03Документ55 страницURA Elect SR 2005 03Zhu Qi WangОценок пока нет

- مهم٢Документ127 страницمهم٢سجى وليدОценок пока нет

- Scope of Work (Plumbing)Документ1 страницаScope of Work (Plumbing)Mochammad Waris S100% (1)

- Materials Selection Assignment. LiveДокумент10 страницMaterials Selection Assignment. Liverichward5Оценок пока нет

- Solid Waste Management A Case Study of Jaipur City IJERTCONV4IS23003Документ4 страницыSolid Waste Management A Case Study of Jaipur City IJERTCONV4IS23003manjuОценок пока нет

- SMT Vacuum PlusДокумент2 страницыSMT Vacuum PlusEerik-Hannes MatsinaОценок пока нет

- Continuity Testing Procedure-Nota Utk PelajarДокумент8 страницContinuity Testing Procedure-Nota Utk PelajarFairos ZakariahОценок пока нет

- Abb Price List 2012Документ75 страницAbb Price List 2012Sharafat Ali75% (4)

- Bombas de Lodo Blackmer MODELS: MLX4B, MLXW4B, MRLX4B, MRLXW4BДокумент4 страницыBombas de Lodo Blackmer MODELS: MLX4B, MLXW4B, MRLX4B, MRLXW4Bnardo_ingОценок пока нет

- Shear Properties of Composite Materials by The V-Notched Beam MethodДокумент13 страницShear Properties of Composite Materials by The V-Notched Beam MethodrsugarmanОценок пока нет

- Lec 7 (Design of Pumping Station)Документ17 страницLec 7 (Design of Pumping Station)hawkswimmer66100% (1)

- Plasma Ignition Technology For New and RetrofitДокумент17 страницPlasma Ignition Technology For New and Retrofitramesh baluОценок пока нет

- ARSENIC DISPOSAL PRACTICES IN THE METALLURGICAL INDUSTRY by P.A. RIVEROS PDFДокумент26 страницARSENIC DISPOSAL PRACTICES IN THE METALLURGICAL INDUSTRY by P.A. RIVEROS PDFFerudun AkyolОценок пока нет

- Clearway 3 DatasheetДокумент2 страницыClearway 3 Datasheetahmetgezer34Оценок пока нет

- Power CablesДокумент167 страницPower CablessubramanyaОценок пока нет

- Lanmark FTP Patch 26AWGДокумент3 страницыLanmark FTP Patch 26AWGAnonymous SE7u3C1dОценок пока нет

- DAPUS SkripsiДокумент2 страницыDAPUS SkripsiIndrakoОценок пока нет

- R1600HДокумент20 страницR1600HTefi' NeolaОценок пока нет

- Diesel Engineering Handbook Cooling SystemsДокумент14 страницDiesel Engineering Handbook Cooling Systemsmartin.ruben100% (1)