Академический Документы

Профессиональный Документы

Культура Документы

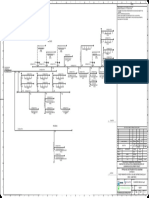

C-01-823956-009 PPF Erection CheckList Cali Final Rev0

Загружено:

gonzaliuxxxАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

C-01-823956-009 PPF Erection CheckList Cali Final Rev0

Загружено:

gonzaliuxxxАвторское право:

Доступные форматы

date of print: 23.11.

2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Table of Contents

ETERNIT

Pulping, Screening, Refining

Description Supplier Contract No. Equipment No. Page:

Plant: P1LI-PR

P1A33B Material Storage, Pulping, Coarse Screening and Refining

Discharge Pump Pulper ANDRITZ P1A33B04P1 2

Pulper ANDRITZ P1A33B04R1 4

Detrasher ANDRITZ P1A33B04R2 7

Pump Pulping System Water ANDRITZ P1A33B07P1 9

HD-Cleaner ANDRITZ P1A33B08S1 11

Coarse Screen ANDRITZ P1A33B22F1 14

HydraScreen ANDRITZ P1A33B22F2 16

MicraScreen ANDRITZ P1A33B23F2 19

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

Pump to Refiner Chest ANDRITZ P1A33B23P1 22

and agreement that it will neither copy, reproduce, disclose to third parties or use this

Agitator Intermediate Chest ANDRITZ P1A33B23R1 24

Pump Refiner ANDRITZ P1A33B24P1 26

Pump Storage Chest ANDRITZ P1A33B24P2 28

Refiner Gearbox Lubrication Unit ANDRITZ P1A33B24P3 30

Refiner ANDRITZ P1A33B24R1 32

Agitator Refiner Chest ANDRITZ P1A33B24R2 36

Agitator Storage Chest ANDRITZ P1A33B24R3 38

Plate Adjustment Refiner ANDRITZ P1A33B24X1 40

affiliates. CAE: ETERNIT : P1|LI-PR|LI-VT.56

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 1 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B04P1 Equipment Type: S3-125-400.3 Supplier: ANDRITZ

Equipment description: Discharge Pump Pulper

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves checked for tightness

5 No foreign matter in the impeller, turn by hand

6 Quality of oil, level in the bearing casing

7 Seal water connected

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

flow adjusted to ___________ l/min

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Stuffing box not too tight

9 Alignment of motor/drive coupling

(coupling protocol)

10 Motor size and speed, gear ratio

11 Sliding motor base

12 Safety covers and warning signs installed

13 Grouting

14 Repeat check of stuffing box (if applicable)

15 Cleaning and touch up paint

16 Check bearing temperatures after start-up

affiliates.

________ C / ________ C

17 Quality of oil, level in the oil level regulator

18 Alignment of belt if installed

19 Tension of belt if installed

20 Cleaning

21 Repeat check of belt tension

22 Repeat check of stuffing boxes

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 2 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B04P1 Equipment Type: S3-125-400.3 Supplier: ANDRITZ

Equipment description: Discharge Pump Pulper

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps

(with load at nominal Production)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 3 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B04R1 Equipment Type: FSR1-12 Supplier: ANDRITZ

Equipment description: Pulper

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Installation of the pulper visually checked

Plant: P1LI-PR

2 If vat supplied by customer critical dimensions,

stiffeners and design checked

3 Overflow pipe assembled/connected

4 Spray water pipes adjusted and flushed

(if applicable)

5 Flushing water connection of level

transmitter flushed

6 Foundation fasteners are tight

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

7 1.2m safety height to the top operating

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

edge checked (if applicable)

8 Coupling alignment protocols checked

(if applicable)

9 Belt alignment and tension checked

10 Fastening and arrangement of

gear box checked (if applicable)

11 Oil level (gear box) checked (if applicable)

12 Cooling water pipe (gear box) connected

(if applicable)

13 Safety covers and guards installed

affiliates.

14 Warning signs installed

15 Inspection openings working and closed

16 Sealing water pipe flushed and connected

17 Bearings and grease filling of the pulping

element checked

18 Check if rotor and screen plate screws are

tight and secured with loctite

19 Distance between rotor and screen

plate checked

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 4 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B04R1 Equipment Type: FSR1-12 Supplier: ANDRITZ

Equipment description: Pulper

No.: Inspections: Value/Done Signature date Remark

20 Pulper vat is clean and empty

21 Valves (hand- pneumatic) checked

Plant: P1LI-PR

22 Rotation test (oil pump) finished (if applicable)

23 Rotation test (main motor) finished,

for vibrations checked

24 Check bearing temperature under

continuous operation

25 Check sealing water flow

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 5 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B04R1 Equipment Type: FSR1-12 Supplier: ANDRITZ

Equipment description: Pulper

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Power cable connected (continuous power)

Plant: P1LI-PR

2 Function of temperature switches

(gear box) checked (if applicable)

3 Function of oil pressure switch

(gear box) checked (if applicable)

4 Function of difference pressure switch

(gear box) checked (if applicable)

5 Function of oil flow switch

(gear box) checked (if applicable)

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

6 Level transmitter checked

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

7 Protection earthing connected

8 Safety check carried out: o yes o no

9 Position and function of the emergency

stop switches checked

10 FC settings have to be checked if according to

the FC specification. The specification has to

be signed by all parties (AAG, FC supplier,

customer) and to be attached to this checklist

11 Motor power and speed

12 Cables sealed, protection earthing connected.

affiliates.

13 Instruments installed and checked.

14 Check interlockings (low level, high level)

15 Check motor load

16 Function of sealing water flow switch checked

17 Motor current: ________ Amps

(with load at nominal Production)

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 6 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B04R2 Equipment Type: FibreGuard FG01H Supplier: ANDRITZ

Equipment description: Detrasher

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Installation of the detrasher visually checked

Plant: P1LI-PR

2 Connected pipes sufficiently supported

3 Foundation fasteners are tight

4 Belt alignment and tension checked

5 Safety covers and guards installed

6 Warning signs installed

7 Sealing water pipe flushed and connected

8 Bearings and grease filling checked

9 Check if rotor and screen plate screws are

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

tight and secured with loctite

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

10 Distance between rotor and screen

plate checked

11 Gap adjustment indicator set to zero

12 Detrasher is clean and empty

13 Valves (hand- pneumatic) checked

14 Rotation test (main motor) finished,

for vibrations checked

15 Check bearing temperature under

continuous operation

16 Check sealing water flow

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 7 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B04R2 Equipment Type: FibreGuard FG01H Supplier: ANDRITZ

Equipment description: Detrasher

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Power cable connected and long enough for

Plant: P1LI-PR

movement (continuous power)

2 Pressure transmitter checked

3 Protection earthing connected

4 Safety check carried out: o yes o no

5 Position and function of the emergency

stop switches checked

6 Motor power and speed checked

7 Cables sealed, protection earthing connected.

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

8 Check interlockings (power high)

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

9 Check motor load

10 Function of sealing water flow switch checked

11 Motor current: ________ Amps

(with load at nominal Production)

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 8 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B07P1 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump Pulping System Water

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves checked for tightness

5 No foreign matter in the impeller, turn by hand

6 Quality of oil, level in the bearing casing

7 Seal water connected

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

flow adjusted to ___________ l/min

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Stuffing box not too tight

9 Alignment of motor/drive coupling

(coupling protocol)

10 Motor size and speed, gear ratio

11 Sliding motor base

12 Safety covers and warning signs installed

13 Grouting

14 Repeat check of stuffing box (if applicable)

15 Cleaning and touch up paint

16 Check bearing temperatures after start-up

affiliates.

________ C / ________ C

17 Quality of oil, level in the oil level regulator

18 Alignment of belt if installed

19 Tension of belt if installed

20 Cleaning

21 Repeat check of belt tension

22 Repeat check of stuffing boxes

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 9 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B07P1 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump Pulping System Water

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps

(with load at nominal Production)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 10 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B08S1 Equipment Type: RB300HD3 Supplier: ANDRITZ

Equipment description: HD-Cleaner

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Cleaners are correctly assembled and

Plant: P1LI-PR

connections are tightened

2 Pipes are correctly installed and supported

3 Any impurities generated during installation

(welding remains, slag, building mortar etc.)

are flushed away

4 Accept and reject valves for each AhlCleaner

bank as well as the accept and reject valves

in the pipeline are completely open

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

5 Discharge side valve of the feed pump for the

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

AhlCleaner bank is closed, i.e. the pump

will start against a closed valve

6 The valves on the suction side of feed

pumps are opened.

7 The dilution water tank for the AhlCleaner

is full of water

8 Deaeration valves (if any) are closed and the

instrumentation is correctly installed

9 Adjust the feed pressure with the discharge

side valve of the pump, which will open

affiliates.

gradually to its set value within 30-60 sec.

(to avoid cleaner pressure shock !!!)

10 Once stable conditions have been achieved

with water and the air has been removed from

the cleaner bank (which can be hastened by

opening the R 1/2" deaeration valves (if any)

in the top part of accept and feed pipe),

thick stock can be led into the circulation.

Once stock has entered the circulation, make

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 11 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B08S1 Equipment Type: RB300HD3 Supplier: ANDRITZ

Equipment description: HD-Cleaner

No.: Inspections: Value/Done Signature date Remark

sure that the pressures are correctly adjusted,

and make any necessary changes.

Plant: P1LI-PR

11 Make sure that all cleaners reject. This is done

by looking through the sight glasses, where a

reject flow can be seen as a steady turbulent

movement. In connection with a

misadjustment, the reject flow may cease.

Should this happen, increase accept pressure

while keeping the pressure loss unchanged.

Then readjust the reject pressure

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

12 Tune the AhlCleaner centrifugal cleaning plant

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

by taking consistency samples at every stage

13 Check the feed, accept and reject pressures,

check the consistencies (and ash content),

measure the reject amount

14 Pay attention to the sounds of the cleaner;

any unusual sounds are a sign of particles

circulating in the cleaner

15 Check the cleaner for leaks

16 Monitor the cleaners for any vibration,

which is a sign of plugged cleaners

affiliates.

17 Check local pneumatic pressure gauge cabinet

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 12 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B08S1 Equipment Type: RB300HD3 Supplier: ANDRITZ

Equipment description: HD-Cleaner

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Instruments installed and checked.

Plant: P1LI-PR

2 Check junk trap logic if existing

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 13 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B22F1 Equipment Type: ModuScreen F10W Supplier: ANDRITZ

Equipment description: Coarse Screen

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installation of the equipment visual checked

3 Installation of piping system checked

4 Installed according to flow sheet

5 Foundation bolts, flange bolts and

gaskets tightened (steel work)

6 Piping and valves checked for tightness

7 Screen and piping system flushed

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

(without basket)

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Basket type: ____________________

9 Rotor type: ____________________

10 No foreign matter inside the body,

free movement of the rotor

11 Bearings re-lubricated

12 Sealing water pipe flushed and connected

13 Seal water connected

flow adjusted to ___________ l/min

14 Mechanical seal checked

15 Alignment of belt

affiliates.

16 Tension of belt

17 Motor size and speed, gear ratio

18 Identification plate/test plate for pressure vessel

19 Rotation test (main motor) finished,

for vibrations checked

20 Repeat check of belt tension

21 Safety covers and warning signs installed

22 Cleaning and touch up paint

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 14 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B22F1 Equipment Type: ModuScreen F10W Supplier: ANDRITZ

Equipment description: Coarse Screen

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps (without load)

8 Motor current: ________ Amps

(with load at nominal Production)

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

9 Emergency stop tested

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

10 Safety check carried out: o yes o no

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 15 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B22F2 Equipment Type: HydraScreen 750 Supplier: ANDRITZ

Equipment description: HydraScreen

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves checked for tightness

5 Piping connections properly

aligned and supported

6 No foreign matters on the screens

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

7 All guards, covers are mounted

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Platform and staircase free from

foreign matters

9 Shower water supply __________ bar,

capacity __________ liter/minute

10 Cleaning and touch up paint

11 Safety guards installed

Micra Screen:

12 Feed Piping design

13 Discharge Chute piping design

affiliates.

14 Flush piping design

15 Vent piping design

16 Screen plate/s installed and fixed

17 Mechanical adjustment of the feed slice gap

18 Check feed slice cylinder plate

19 Adjustment of shower water pipe movement

20 All covers closed and sealed

21 Flushing of spray pipes

22 Flushing of feed pipe and head box

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 16 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B22F2 Equipment Type: HydraScreen 750 Supplier: ANDRITZ

Equipment description: HydraScreen

No.: Inspections: Value/Done Signature date Remark

Plant: P1LI-PR

Hydra Screen:

23 Vent piping design

24 Screen plate/s installed and fixed

25 All covers closed and sealed

26 Flushing of spray pipes

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 17 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B22F2 Equipment Type: HydraScreen 750 Supplier: ANDRITZ

Equipment description: HydraScreen

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

Micra Screen:

Plant: P1LI-PR

1 Function of valves (feed,flush valves)

2 Function of feed valve cylinder

3 Function of washing device

4 Feed slice cleaning cycle adjusted to:

5 Cleaning cycle adjusted to:

Hydra Screen:

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

6 Function of washing device

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

7 Adjustment of washing device

8 Cleaning cycle adjusted to:

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 18 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B23F2 Equipment Type: MS Single Supplier: ANDRITZ

Equipment description: MicraScreen

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves checked for tightness

5 Piping connections properly

aligned and supported

6 No foreign matters on the screens

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

7 All guards, covers are mounted

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Platform and staircase free from

foreign matters

9 Shower water supply __________ bar,

capacity __________ liter/minute

10 Cleaning and touch up paint

11 Safety guards installed

Micra Screen:

12 Feed Piping design

13 Discharge Chute piping design

affiliates.

14 Flush piping design

15 Vent piping design

16 Screen plate/s installed and fixed

17 Mechanical adjustment of the feed slice gap

18 Check feed slice cylinder plate

19 Adjustment of shower water pipe movement

20 All covers closed and sealed

21 Flushing of spray pipes

22 Flushing of feed pipe and head box

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 19 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B23F2 Equipment Type: MS Single Supplier: ANDRITZ

Equipment description: MicraScreen

No.: Inspections: Value/Done Signature date Remark

Plant: P1LI-PR

Hydra Screen:

23 Vent piping design

24 Screen plate/s installed and fixed

25 All covers closed and sealed

26 Flushing of spray pipes

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 20 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B23F2 Equipment Type: MS Single Supplier: ANDRITZ

Equipment description: MicraScreen

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

Micra Screen:

Plant: P1LI-PR

1 Function of valves (feed,flush valves)

2 Function of feed valve cylinder

3 Function of washing device

4 Feed slice cleaning cycle adjusted to:

5 Cleaning cycle adjusted to:

Hydra Screen:

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

6 Function of washing device

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

7 Adjustment of washing device

8 Cleaning cycle adjusted to:

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 21 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B23P1 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump to Refiner Chest

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves checked for tightness

5 No foreign matter in the impeller, turn by hand

6 Quality of oil, level in the bearing casing

7 Seal water connected

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

flow adjusted to ___________ l/min

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Stuffing box not too tight

9 Alignment of motor/drive coupling

(coupling protocol)

10 Motor size and speed, gear ratio

11 Sliding motor base

12 Safety covers and warning signs installed

13 Grouting

14 Repeat check of stuffing box (if applicable)

15 Cleaning and touch up paint

16 Check bearing temperatures after start-up

affiliates.

________ C / ________ C

17 Quality of oil, level in the oil level regulator

18 Alignment of belt if installed

19 Tension of belt if installed

20 Cleaning

21 Repeat check of belt tension

22 Repeat check of stuffing boxes

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 22 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B23P1 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump to Refiner Chest

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps

(with load at nominal Production)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 23 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B23R1 Equipment Type: TMX810 Supplier: ANDRITZ

Equipment description: Agitator Intermediate Chest

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves: refiner safety valve

5 No foreign matter inside the body,

free movement of the agitator

6 Bearings re-lubricated

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

7 Alignment of belt

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Tension of belt

9 Motor size and speed, gear ratio

10 Repeat check of belt tension

11 Identification plate / test plate for

pressure vessel

12 Safety covers and warning signs installed

13 Cleaning and touch up paint

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 24 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B23R1 Equipment Type: TMX810 Supplier: ANDRITZ

Equipment description: Agitator Intermediate Chest

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps (with load)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 25 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24P1 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump Refiner

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves checked for tightness

5 No foreign matter in the impeller, turn by hand

6 Quality of oil, level in the bearing casing

7 Seal water connected

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

flow adjusted to ___________ l/min

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Stuffing box not too tight

9 Alignment of motor/drive coupling

(coupling protocol)

10 Motor size and speed, gear ratio

11 Sliding motor base

12 Safety covers and warning signs installed

13 Grouting

14 Repeat check of stuffing box (if applicable)

15 Cleaning and touch up paint

16 Check bearing temperatures after start-up

affiliates.

________ C / ________ C

17 Quality of oil, level in the oil level regulator

18 Alignment of belt if installed

19 Tension of belt if installed

20 Cleaning

21 Repeat check of belt tension

22 Repeat check of stuffing boxes

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 26 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24P1 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump Refiner

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps

(with load at nominal Production)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 27 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24P2 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump Storage Chest

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves checked for tightness

5 No foreign matter in the impeller, turn by hand

6 Quality of oil, level in the bearing casing

7 Seal water connected

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

flow adjusted to ___________ l/min

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Stuffing box not too tight

9 Alignment of motor/drive coupling

(coupling protocol)

10 Motor size and speed, gear ratio

11 Sliding motor base

12 Safety covers and warning signs installed

13 Grouting

14 Repeat check of stuffing box (if applicable)

15 Cleaning and touch up paint

16 Check bearing temperatures after start-up

affiliates.

________ C / ________ C

17 Quality of oil, level in the oil level regulator

18 Alignment of belt if installed

19 Tension of belt if installed

20 Cleaning

21 Repeat check of belt tension

22 Repeat check of stuffing boxes

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 28 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24P2 Equipment Type: ACP100-250.4 Supplier: ANDRITZ

Equipment description: Pump Storage Chest

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps

(with load at nominal Production)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 29 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24P3 Equipment Type: Supplier: ANDRITZ

Equipment description: Refiner Gearbox Lubrication Unit

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Flange bolts and gaskets tightened

4 Flushing of piping

5 Filter change after flushing

6 Tank cleaned and inspected

7 Check leak tightness

8 Check if no forces are induced from piping to

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

panel (stress relieved)

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

9 Oil filling after flushing, oil type

____________________ (see lube oil list)

10 Safety covers and warning signs installed

11 Cleaning and touch up paint

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 30 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24P3 Equipment Type: Supplier: ANDRITZ

Equipment description: Refiner Gearbox Lubrication Unit

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Local switches installed

Plant: P1LI-PR

2 Alarm settings of flow- and pressure switches

3 (see alarm list)

4 Direction of rotation - oil pump

5 Cables sealed, protection earthing connected

6 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 31 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R1 Equipment Type: TwinFlo TF20 Supplier: ANDRITZ

Equipment description: Refiner

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Flange bolts and gaskets tightened

4 Refiner bolted to foundation acc. to Drawings

5 Piping and valves - lubeoil, hydraulic,

seal water, dilution water

6 Piping and valves correct mounted

7 No foreign material inside the refiner

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

8 Refiner plates installed,

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

model __________________

9 Function of seal

(mechanical, universal, stuffing box)

10 Repeated tension of pipe fittings

after first operation

11 Safety covers and warning signs installed

12 Cleaning and touch up paint

13 Identification plate

14 Leveling and alignment protocols

to be added as enclosure

affiliates.

15 Installation of piping system checked

16 Sealing water pipes flushed and connected

17 Cooling water pipes flushed and connected

18 Consistency transmitter checked

(rotation/direction)

19 Refiner and piping system flushed

20 Function of flow meters checked

21 Refiner opened and filling checked

22 Oil level refiner checked

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 32 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R1 Equipment Type: TwinFlo TF20 Supplier: ANDRITZ

Equipment description: Refiner

No.: Inspections: Value/Done Signature date Remark

23 Oil level gear box checked

24 Oil pump tested (direction, pressure)

Plant: P1LI-PR

25 Flow cooling water adjusted

26 Alignment of coupling checked (protocol)

27 Remove transportation lock

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 33 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R1 Equipment Type: TwinFlo TF20 Supplier: ANDRITZ

Equipment description: Refiner

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Function of valves for sealing water, fail

Plant: P1LI-PR

safe function

2 Check seal water supply pressure

3 Seal water adjustment, flow switch test

4 Check bearing vibration in idling

Position measurement system

5 Check safety switch

6 Adjust open position switch

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

Plate adjustment system

7 Motor power

8 Protection earthing for motor

9 Rotation direction test (load)

10 Emergency stop tested (hardwired)

11 Local control tested

Instrumentation

12 Check fail safe function of drain valves

13 Check inlet pressure measurement

affiliates.

14 Check outlet pressure measurements

15 Check outlet temperature measurements

16 Check outlet flow measurements

17 Check feed consistency measurement

18 Check production and specific energy calc.

19 Safety related systems (pressure and

temperature switches) checked

20 Refiner drive

21 Motor power

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 34 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R1 Equipment Type: TwinFlo TF20 Supplier: ANDRITZ

Equipment description: Refiner

No.: Inspections: Value/Done Signature date Remark

22 Protection earthing for motor, gearbox

and machine

Plant: P1LI-PR

23 Rotation direction test (uncoupled)

24 Motor idle power (coupled)

25 Refiner idle power (with water)

26 Emergency stop tested (hardwired)

27 Coast down time checked

and adjusted (coupled)

28 Failsafe function (motor stops

when auxillary voltage trips)

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 35 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R2 Equipment Type: TMX810 Supplier: ANDRITZ

Equipment description: Agitator Refiner Chest

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves: refiner safety valve

5 No foreign matter inside the body,

free movement of the agitator

6 Bearings re-lubricated

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

7 Alignment of belt

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Tension of belt

9 Motor size and speed, gear ratio

10 Repeat check of belt tension

11 Identification plate / test plate for

pressure vessel

12 Safety covers and warning signs installed

13 Cleaning and touch up paint

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 36 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R2 Equipment Type: TMX810 Supplier: ANDRITZ

Equipment description: Agitator Refiner Chest

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps (with load)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 37 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R3 Equipment Type: TMX1010 Supplier: ANDRITZ

Equipment description: Agitator Storage Chest

No.: Inspections: Value/Done Signature date Remark

Mechanical checkout

1 Take notice of instructions in the

Plant: P1LI-PR

ANDRITZ AG manual/documentation

2 Installed according to flow sheet

3 Foundation bolts, flange bolts and

gaskets tightened (steel work)

4 Piping and valves: refiner safety valve

5 No foreign matter inside the body,

free movement of the agitator

6 Bearings re-lubricated

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

7 Alignment of belt

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

8 Tension of belt

9 Motor size and speed, gear ratio

10 Repeat check of belt tension

11 Identification plate / test plate for

pressure vessel

12 Safety covers and warning signs installed

13 Cleaning and touch up paint

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 38 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,

Project Description: Refining

P1 / ETERNIT_CALI

CUSTOMER: ETERNIT

Doc. no. ANDRITZ Doc. no. customer status: Final

Project No. CUSTOMER: 506965210

Equipment No.: P1A33B24R3 Equipment Type: TMX1010 Supplier: ANDRITZ

Equipment description: Agitator Storage Chest

No.: Inspections: Value/Done Signature date Remark

Electrical & Automation checkout

1 Motor power and speed

Plant: P1LI-PR

2 Cables sealed, protection earthing connected.

3 Direction of motor rotation checked

4 Local switches (if applicable)

5 Zero speed switch adjusted and tested

6 Flow switch adjusted and tested

7 Motor current: ________ Amps (with load)

8 Safety check carried out: o yes o no

document for any purpose other than those expressly agreed to by ANDRITZ AG or one of its

This document constitutes confidential and proprietary information of ANDRITZ AG and/or its

affiliates. Any party accepting receipt of this drawing does so on the express understanding

and agreement that it will neither copy, reproduce, disclose to third parties or use this

affiliates.

Remarks:

CAE: ETERNIT : P1|LI-PR|LI-VT.56

Signature Customer: Signature Andritz AG: Signature Erection Company /

Supplier / Consultant:

date: date: date:

Rev. Rev.Date Created Checked Description of Revision Crea.Date: 23.11.2016

Created: Wurglits

Checked: Kaiser / 23.11.2016

Page: / Of: 39 / 40

date of print: 23.11.2016 Project ANDRITZ: FIBRE CEMENT LINE End of Erection, Commissioning,

Project no. ANDRITZ: C-01-823956-009 Start-up Equipment Check List

Pulping, Screening,