Академический Документы

Профессиональный Документы

Культура Документы

Vishay - Mounting Through Hole Capacitors

Загружено:

Benjamin DoverАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Vishay - Mounting Through Hole Capacitors

Загружено:

Benjamin DoverАвторское право:

Доступные форматы

VISHAY SPRAGUE

Leaded Tantalum Capacitors Technical Note

Mounting for Through-hole Components

General tor be performed by our factories under controlled condi-

tions.

All through-hole or leaded styles fall into two general

classes. The first is provided with leads extending from Molded series have only one site of solder, the internal

opposite ends of the body, generally along the principle axis cathode connection. The rate of heat transfer through the

of the body (axial leads). The second is provided with plastic is lower than through the metal can of our hermetic

parallel leads extending from one side or face of the body styles. However the opportunity for temperature transfer or

(radial leads). With both type, mounting points are conduction along the negative lead-wire to re-melt

normally provided by the leads themselves. this solder is very similar. There is little internal void

within molded cased capacitors, so re-melted solder tends

Axial leads may be used for point-to-point wiring, to remain in its original location and solidify when heat is

but usually, the wires are bent at 90 from the capacitor axis removed. Short circuiting is very unlikely, but reliability of

for insertion through printed circuit (PC) boards. Axial the internal connection may be compromised by leaching of

capacitors supplied on reels for machine insertion will silver from the paint into the molten solder. The latter effect

withstand the mechanical stresses of bending and inserting. degrades the cathode connection in hermetic parts as well.

The Vishay axial series may be supplied on reels to feed

such machines. Radial leads are intended to plug directly

into holes of PC boards. Auto-insertion machines will Lead Forming

insert compatible radial capacitor designs, and most Vishay

capacitors may be supplied in appropriate reeled forms. While we will provide some general guidelines for bending

leads, more specific details are outlined in J-STD-001. The

With either axial or radial types, attention should be paid to positive or anode lead bend must be a minimum of 0.050"

treatment of the capacitors during mounting and afterward from the case or from the external weld connection. If the

under service conditions. Difficulty during mounting usually part has a hermetic (glass-to-metal) seal, do not bend, cut,

arises from lead damage or from overheating. The hand or disturb the tube between the weld and the glass seal. The

soldering technique or more often, wave-soldering cathode lead bend must be a minimum of 0.050" from the

machines can cause overheating. The internal cathode case.

connection on most solid tantalum through-hole series is

made between solder and a silver-pigmented paint. If too

much heat is applied, this solder may reflow and degrade Solder Heat Test

the silver-solder interface or cause a direct short circuit.

All through-hole capacitors will pass the Resistance

Vishays hermetically-sealed series has an internal space to Soldering Heat Test of MIL-STD-202, Method 210,

into which molten cathode solder may run, depriving the Condition B. This test dips each lead-wire into

cathode connection and possibly flowing across molten solder at + 260 C for 10 s while the capacitor

the terminals to short circuit the capacitor from the inside. body is held vertically above the solder. Vishay capacitors

It is also possible to remelt or reflow the solder which will pass this test when the depth of immersion brings the

bonds the rim of the glass-metal seal, causing loss capacitor body (or closest external solder joint, if it is closer

TECH NOTE

of hermeticity and possibly a short circuit. Finally, solder as in some hermetic styles) to a minimum distance of

at the exit point of the positive wire may be re-melted with- 0.100" from the solder surface. This demonstration of

similar effect. This solder however, is a high-temperature resistance to solder heat is in accordance with what is

alloy, and it is much less likely to be melted. Redipping of believed to be the industry standard. More severe treatment

leadwires is practiced by some users, introducing another must be considered reflective of an improper soldering

hazard of re-melting this solder. Vishay recommends process.

that redipping or hot solder dipping of any tantalum capaci-

Document Number: 40108 For technical questions, contact: tantalum@vishay.com www.vishay.com

Revision: 27-Nov-07 11

Technical Note

Vishay Sprague

Mounting for Through-hole Components

Solder Profile

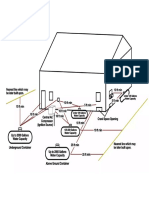

Shown below is a recommended solder wave profile for both axial and radial through-hole solid tantalum capacitors.

LEADED SOLDER WAVE PROFILE

MAX. PEAK TEMPERATURE FOR LEAD (Pb)-FREE SOLDERING: 260 C

265

TIME AT PEAK ~ 4 s

BOTTOM SIDE

245

TEMPERATURE PROFILE

225 260 C MAX.

TEMPERATURE (C)

205

185 TOP SIDE

TEMPERATURE PROFILE

165

150 C

145

125

105

85

65

45

25

0 1 2 3 4 5 6

TIME (MINUTES)

TECH NOTE

www.vishay.com For technical questions, contact: tantalum@vishay.com Document Number: 40108

12 Revision: 27-Nov-07

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Sutherland S Handbook For Bicycle Mechanics 6th EditionДокумент593 страницыSutherland S Handbook For Bicycle Mechanics 6th Editionstarengineer3473100% (7)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Tendernotice 5 PDFДокумент148 страницTendernotice 5 PDFAbhijit BhandarkarОценок пока нет

- Bogen Amplifier - Gs-SeriesДокумент20 страницBogen Amplifier - Gs-SeriesBenjamin DoverОценок пока нет

- TV Rptrs RPTR 135Документ11 страницTV Rptrs RPTR 135Benjamin DoverОценок пока нет

- TV Rptrs RPTR 121 1Документ12 страницTV Rptrs RPTR 121 1Benjamin DoverОценок пока нет

- Battleship IOWA EventДокумент1 страницаBattleship IOWA EventBenjamin DoverОценок пока нет

- Merci Train Box CarsДокумент2 страницыMerci Train Box CarsBenjamin DoverОценок пока нет

- TV Rptrs RPTR 118Документ10 страницTV Rptrs RPTR 118Benjamin DoverОценок пока нет

- TV Rptrs RPTR 122Документ10 страницTV Rptrs RPTR 122Benjamin DoverОценок пока нет

- ZyXEL - NAS326 - 6Документ6 страницZyXEL - NAS326 - 6Benjamin DoverОценок пока нет

- ZyXEL - NAS326 - V5.21 - Ed4Документ341 страницаZyXEL - NAS326 - V5.21 - Ed4Benjamin DoverОценок пока нет

- Radio Shack Pro-2040Документ44 страницыRadio Shack Pro-2040Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-106-2Документ13 страницBoulder Amateur TV Repeater's Newsletter-106-2Benjamin DoverОценок пока нет

- TV Rptrs RPTR 120revДокумент12 страницTV Rptrs RPTR 120revBenjamin DoverОценок пока нет

- Nature Power 110 Watt Solar Panel KitДокумент10 страницNature Power 110 Watt Solar Panel KitBenjamin DoverОценок пока нет

- Camera Lens Sizes, Mounts & AdaptersДокумент11 страницCamera Lens Sizes, Mounts & AdaptersBenjamin DoverОценок пока нет

- HR9670 Amateur Radio Emergency Preparedness ActДокумент14 страницHR9670 Amateur Radio Emergency Preparedness ActBenjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-109Документ9 страницBoulder Amateur TV Repeater's Newsletter-109Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-111revДокумент9 страницBoulder Amateur TV Repeater's Newsletter-111revBenjamin DoverОценок пока нет

- Rca Remote Rcr412s - OmДокумент21 страницаRca Remote Rcr412s - OmBenjamin DoverОценок пока нет

- Hoshizaki IM-500SAA Icemaker Service ManualДокумент39 страницHoshizaki IM-500SAA Icemaker Service ManualBenjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-108Документ9 страницBoulder Amateur TV Repeater's Newsletter-108Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-110Документ11 страницBoulder Amateur TV Repeater's Newsletter-110Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-112Документ13 страницBoulder Amateur TV Repeater's Newsletter-112Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-98Документ11 страницBoulder Amateur TV Repeater's Newsletter-98Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-105Документ10 страницBoulder Amateur TV Repeater's Newsletter-105Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-107Документ11 страницBoulder Amateur TV Repeater's Newsletter-107Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-104Документ14 страницBoulder Amateur TV Repeater's Newsletter-104Benjamin DoverОценок пока нет

- TV Rptrs RPTR 113Документ11 страницTV Rptrs RPTR 113Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-99Документ11 страницBoulder Amateur TV Repeater's Newsletter-99Benjamin DoverОценок пока нет

- Boulder Amateur TV Repeater's Newsletter-101Документ12 страницBoulder Amateur TV Repeater's Newsletter-101Benjamin DoverОценок пока нет

- Propane Tank Location GuideДокумент1 страницаPropane Tank Location GuideBenjamin DoverОценок пока нет

- MIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)Документ20 страницMIL-W-8604 - A (Welding, Fusion Aluminum Alloys Process and Performance Of)ccorp0089Оценок пока нет

- CSL STDДокумент45 страницCSL STDPuratchi VelanОценок пока нет

- Gate Valve Data SheetДокумент4 страницыGate Valve Data SheetMohammad Ali ArianОценок пока нет

- Clay Bonded Graphite CrucibleДокумент4 страницыClay Bonded Graphite Cruciblevasu_nifft9352Оценок пока нет

- Section-Vi SCC Annexures: Tender - PART-IIДокумент345 страницSection-Vi SCC Annexures: Tender - PART-IIAbinash NayakОценок пока нет

- Bucket Elevator Installation Manual 473793 Revised 2016Документ77 страницBucket Elevator Installation Manual 473793 Revised 2016YhaneОценок пока нет

- Anchoring of Monolithic Refractories - UkДокумент9 страницAnchoring of Monolithic Refractories - Ukantoniorossini100% (1)

- Soldering and Disoldering Techniques-1Документ32 страницыSoldering and Disoldering Techniques-1noelmartin006Оценок пока нет

- Jig Boring, Jig Grinding and BroachingДокумент14 страницJig Boring, Jig Grinding and Broachingjineesha p jОценок пока нет

- 11 - Bending StampingДокумент14 страниц11 - Bending StampingsdhgwdОценок пока нет

- Manual DenverДокумент12 страницManual DenverVictor Alexander Aredo ChingaОценок пока нет

- Imo-202en 01-12Документ8 страницImo-202en 01-12HASBUL AZIZI BIN MAHMUNОценок пока нет

- Brosur FuselinkДокумент3 страницыBrosur FuselinkGabriella TambuwunОценок пока нет

- Experimental Investigation of MRR Using EDMДокумент6 страницExperimental Investigation of MRR Using EDMANKITОценок пока нет

- 8 Redox Reactions: SolutionsДокумент39 страниц8 Redox Reactions: SolutionsAdarsh ChauhanОценок пока нет

- Manufacturing Technology II-Unit I-Lecture 2Документ25 страницManufacturing Technology II-Unit I-Lecture 2Jayanth VuppalaОценок пока нет

- QAP Rev. 0 - MECONДокумент5 страницQAP Rev. 0 - MECONSachin KumarОценок пока нет

- Five Star Engg WorksДокумент7 страницFive Star Engg WorksSudhanshu GuptaОценок пока нет

- BrecoДокумент43 страницыBrecopangregisterlang99Оценок пока нет

- DEP 30.10.02.11 - Gen Feb 19Документ69 страницDEP 30.10.02.11 - Gen Feb 19JacquesBritsОценок пока нет

- Abbott Products CatalogДокумент40 страницAbbott Products CatalogSanam Rumianfar100% (1)

- (Davies, Michael Scott, P.J.B.) Guide To The UseДокумент645 страниц(Davies, Michael Scott, P.J.B.) Guide To The UseامينОценок пока нет

- ZTT-540 Application GuideДокумент8 страницZTT-540 Application GuidesejlОценок пока нет

- Mp63i40 ...Документ2 страницыMp63i40 ...Ckaal74100% (1)

- Military Standard: Printed Wiring For Electronic EquipmentДокумент53 страницыMilitary Standard: Printed Wiring For Electronic EquipmentJeff95TAОценок пока нет

- Overview of Process Piping - ASME313Документ110 страницOverview of Process Piping - ASME313Ese Ichekor100% (4)

- PVC Spacers SubmittalДокумент51 страницаPVC Spacers SubmittalAhmad ElghazolyОценок пока нет

- Technical Interview Questions For Fresher Mechanical Design EngineersДокумент12 страницTechnical Interview Questions For Fresher Mechanical Design EngineersRavisatya DasamОценок пока нет