Академический Документы

Профессиональный Документы

Культура Документы

Balancing Valve PDF

Загружено:

mazumdar_satyajitОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Balancing Valve PDF

Загружено:

mazumdar_satyajitАвторское право:

Доступные форматы

9001 GR

SO

OU

AN I

P

TE

LD

C

R

N

H

OL O

OGY W

BALANCING VALVE

FEATURES

Precise Double Regulation Tamperproof setting with lockshield

EPDM sealing disc to ensure positive shut-off With Pressure Test Cocks

Facilitates system design Saves energy Easy installation & setting

Facilitates systematic commissioning of the plant for optimal operation

BALANCING

CONTROL AND SHUT-OFF

FLANGED

VALVE WITH BUILT-IN

FLOW MEASURING

FACILITY

CHANGING THE WAY YOU THINK ABOUT VALVES

( C A S T I R O N F L A N G E D V A L V E S )

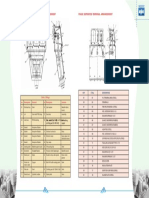

CONSTRUCTION AND TECHNICAL I N F O R M AT I O N

BODY & BONNET : Study construction in Cast Iron as per IS 210 Gr. 260/BS TECHNICAL DATA : Standard valves are designed for

1452/ASTM A48/GG25, other metallurgy on request. Maximum operating pressure of 16 bar (230 psi) for

0 0

liquid temperature not exceeding 120 C (250 F) with

SEAT : Erosion resistant stainless steel of Gr. AISI 410 discs with EPDM seal for tight

pH values 4 to 9.5. Higher pressure & temperature

shut-off. Discs are also available in EN3 material with epoxy coating for normal water

valves can be offered on request.

applications.

DIMENSIONS

STEM SEALING : Special double seal of EPDM as back seat graphite asbestos (All dimensions in mm )

gland packing.

SPINDLE (STEM) : Non-rising Spindle (Stem) of Stainless Steel Gr. SS 410. The

movement of stem can be locked to make tamper proof.

HANDWHEEL : Cast iron / steel hand wheel for easy operation.

DOUBLE REGULATION : Double regulation by precise and concealed limitation of

stroke, Indicator scale from "O" (fully shut) to fully open, shows handle turns.

Additional "Micro Meter Scale" allows fine setting upto 1/10 of a hand wheel turn.

After setting the valve as per balancing requirement, the spindle is locked by lock

screw thus limiting the maximum opening of valve to preregulated position while still

allowing to use as shut-off valve.

MEASUREMENT OF PRESSURE DROP & FLOW RATE : The valves are delivered

with two body taps and one set of pressure test quarter turn cocks. Pressure drop

across the valve can be measured with specially designed ADVANCE Portable

Mercury Manometer or digital deferential pressure meter, having instant couplings

with the pressure test cocks. Pressure test cocks are opened by 1/4 turn using 6mm MATERIAL SPECIFICATION :

square double end spanner. Flow can be regulated by turning the wheel. Flow Hand wheel - CI 220 / M.S. Seat Seal - EPDM.

through the valve can be calculated by measuring differential pressure across the Body/Bonnet Gasket-CAF. Lower Disc - SS-410.

valve, noting set hand Wheel turns, using the published "K" factor of the valve for Body/Bonnet Bolts - Bonnet - CI 260

different hand wheel turns. A 307 Gr. B. (GG 25).

Gland Packing - Graphited Body - CI 260

Flow characteristic are available in form of Graph as well as in the computerized

Asbestos. (GG 25).

format.

Stem seal - EPDM Lock Screw.

The setting thus obtained can be locked by screwing in the lock screw and locking Stem - SS 410. Counter Nut.

Upper Disc - SS 410. Body Plugs.

Design & Printing by : MIND 011-22053519

the lock nut which is protected by the locks shield on the hand wheel.

DIRECTION OF FLOW : Direction of the flow is marked on the valve body by an DIMENSIONS (All) :

arrow. Nominal DN mm 080 100 125 150 200 250 300

Size (Inch) (3) (4) (5) (6) (8) (10) (12)

FLANGED CONNECTION : Flanges are drilled to IS 6392 (PN 16) or to Purchaser's L mm 310 350 400 480 600 730 850

OD mm 200 220 250 285 340 405 460

specifications.

H mm 290 410 450 490 590 760 820

APPLICATIONS : As double regulating, balancing and shut-off valve in hydronic OC mm 175 225 225 300 400 480 480

Stroke mm 32 40 49 57 69 80 96

system, In process industry for balancing flow . With special alloys, these valves can

Handwheel

be used in Process Plants too for double regulation & flow measurement functions. 8 10 12.25 14.25 11.50 10 12

Turns

Weight kg. 22.5 38 55 76 119 220 315

Manufactured & Marketed by OVERSEAS OFFICES ( TEL / FAX) : BAHRAIN : +973 17 292 009 / +973 17 877 366, BRAZIL : +55 11 4447 4511/

+55 11 4447 4164 , FRANCE : +33 02 35208060 / +33 02 35550440, HOUSTON (U.S.A.) : +1 713 9391871/ +1

713 9379455, KINGDOM OF SAUDI ARABIA : +966 502255264 / +966 3 8960 600, KUWAIT : +965 4332796 /

965 4332762 MANCHESTER (U.K.) : +44 161 9625200/ +44 161 9629989, OMAN : +968 24492517 - 18 - 19

ADVANCE VALVES PVT. LTD. ADVANCE VALVES GLOBAL / +968 24492516 QATAR : +974 435 0151 / +974 435 0140, SOUTH AFRICA : +27 11 6232008 / 2003, U.A.E.

ADVANCE VALVE COMPANY (ABU DHABI) : +971 50 5500377 / +971 2 6732200 /+971 2 6732177, 6730259, 6730464, KOREA : +82 2

Corporate Office : 142 - A&B, NSEZ, Phase - 2, Noida - 201 305, INDIA 7859934 / +82 2 21799933, MALAYSIA : +603 56362211, 78472575 / 56381233 , 78472675.

Phone : +91 (0) 120 4796900 Fax No. : +91 (0) 120 2462376 OFFICES IN INDIA (TEL / EMAIL ) : EAST : (Kolkata) : +91 33 22341906 Email : kolkata@modsales.co.in

WEST (Mumbai) : +91-22-21676720 Email: info@modsales.co.in (Pune) : +91-9890187707, Email:

E-mail : (National) : communications@advancevalves.com,

pune@modsales.co.in NORTH (Delhi) : +91 11 23214101 / 02, / +91 9871244377 Email:

(International) : global@advancevalves.com,

skgvalves@gmail.com (Delhi) : +91-9899328340, +91 11 41539849 Email: skbros@gmail.com SOUTH

Website : www.advancevalves.com (Chennai) : 044-32909761 Email: p2v2engg@yahoo.com Bangalore : + 91 80 4054 2001 Email:

Works : D-8, Site B, Surajpur Industrial Area, Greater Noida- 201305, INDIA sales@orienttraders.net (Secunderabad) :+91-40-27714608, +91-939108288 (Secunderabad) : +91-

Works : Bharwain Road, Gagret, Dist. Una, Himachal Pradesh, INDIA 40-27807754, 09490751208. E-mail : sridhar.kusuma@advancevalves.com

Вам также может понравиться

- Imi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"Документ2 страницыImi PBM Ansi Double Block & Bleed Valves: AN/TN SERIES 5, Sizes 1/2" - 12"SAM AZОценок пока нет

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsОт EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsРейтинг: 5 из 5 звезд5/5 (1)

- Circuit Setter: Calibrated Balance Valves With Flanged ConnectionsДокумент2 страницыCircuit Setter: Calibrated Balance Valves With Flanged ConnectionsJulio MorenoОценок пока нет

- KSB Sicca HP Cast Gate Valve PDFДокумент4 страницыKSB Sicca HP Cast Gate Valve PDFJamalОценок пока нет

- Circuit Setter: Calibrated Balance Valves With Flanged ConnectionsДокумент1 страницаCircuit Setter: Calibrated Balance Valves With Flanged Connectionsfernandoperdomo20-1Оценок пока нет

- LRV19Документ1 страницаLRV19Louis BörkОценок пока нет

- DemblaДокумент12 страницDemblaISHAN VERMAОценок пока нет

- Parker Subsea Ball Valves CatalogДокумент3 страницыParker Subsea Ball Valves Catalogfjb9ms2jgqОценок пока нет

- Bulletin 71.1:1301: Types 1301F and 1301G High-Pressure RegulatorsДокумент8 страницBulletin 71.1:1301: Types 1301F and 1301G High-Pressure RegulatorsinvidiuoОценок пока нет

- Hattersley Fig 980 CatalogueДокумент1 страницаHattersley Fig 980 CataloguerkssОценок пока нет

- Avk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300Документ2 страницыAvk Swing Check Valve, Resilient Seated Pn10/16 41/60-003: With Free Shaft End, DN50-300DanielSchwaskiОценок пока нет

- MS 01 54Документ6 страницMS 01 54fagundds2Оценок пока нет

- Dm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Документ1 страницаDm931 Da931 Vodrv Balancingvalves Cranefs Ds 160418Hasan V SОценок пока нет

- ValvesДокумент97 страницValvesvit200711Оценок пока нет

- Specification - 9110 - 201510 at Globe (Rev.03)Документ10 страницSpecification - 9110 - 201510 at Globe (Rev.03)Công PhạmОценок пока нет

- Top Entry Ball ValvesДокумент8 страницTop Entry Ball ValvesHuda LAОценок пока нет

- PK Valve Page-13-17Документ5 страницPK Valve Page-13-17ICASA IngenieríaОценок пока нет

- Class 150 Bronze Globe Valves: Union Bonnet - Integral Seat - Renewable Seat DiscДокумент1 страницаClass 150 Bronze Globe Valves: Union Bonnet - Integral Seat - Renewable Seat DiscSujitH Sekar GnanasekaranОценок пока нет

- Avk 555-301-302-V8-0713Документ2 страницыAvk 555-301-302-V8-0713mokbelОценок пока нет

- Brochure Pressure Reducing Valve RYUKOДокумент7 страницBrochure Pressure Reducing Valve RYUKOPandyОценок пока нет

- Rotary FittingsДокумент21 страницаRotary FittingscarmaОценок пока нет

- Hand Shut-Off Valves: Product Bulletin 80-01 K For Standard and Extended BonnetsДокумент20 страницHand Shut-Off Valves: Product Bulletin 80-01 K For Standard and Extended BonnetsАлександр ЩербаковОценок пока нет

- Dm941 Da941 Fodrv Balancingvalves Cranefs Ds 160418Документ1 страницаDm941 Da941 Fodrv Balancingvalves Cranefs Ds 160418mikebhassigОценок пока нет

- AFC Gate Valve & Indicator Post, ULFMДокумент8 страницAFC Gate Valve & Indicator Post, ULFMFight FireОценок пока нет

- Es Lfusg B M2Документ2 страницыEs Lfusg B M2WattsОценок пока нет

- Valvula ACI - WefloДокумент2 страницыValvula ACI - WefloWilly RiosОценок пока нет

- Flanged-Non-Retun-Valve DimensionsДокумент13 страницFlanged-Non-Retun-Valve DimensionsAhmed AbdoОценок пока нет

- 800D SeriesДокумент3 страницы800D Seriesvkeie0206Оценок пока нет

- Butterfly ValvesДокумент4 страницыButterfly ValvesrahulОценок пока нет

- 06-35-006 Avkcms en 427228Документ2 страницы06-35-006 Avkcms en 427228bre brilianОценок пока нет

- Alfacond Range: Plate CondensersДокумент2 страницыAlfacond Range: Plate Condensersandres mОценок пока нет

- Caleffi: Valvole Di BilanciamentoДокумент16 страницCaleffi: Valvole Di BilanciamentoThomas GregantiОценок пока нет

- FP 700 EngineeringДокумент8 страницFP 700 EngineeringCarlos Alberto VargasОценок пока нет

- Norm Ex ValvesДокумент6 страницNorm Ex Valvesapi-3712612Оценок пока нет

- Sta-F: Balancing Valves September 1985Документ8 страницSta-F: Balancing Valves September 1985ThanhОценок пока нет

- Avk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300Документ2 страницыAvk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300kad-7Оценок пока нет

- Resilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionДокумент6 страницResilient Seated Gate Valve: Design Connection Face To Face Marking Tests Corrosion ProtectionMohamed RaafatОценок пока нет

- Fpe 1 2 Válvula TermostáticaДокумент6 страницFpe 1 2 Válvula TermostáticamarbbanОценок пока нет

- Quick Connect QC, QF, QM & QTM Series (MS-01-138) R5Документ12 страницQuick Connect QC, QF, QM & QTM Series (MS-01-138) R5herysyam1980Оценок пока нет

- 08.25 Victaulic® Knife Gate ValveДокумент8 страниц08.25 Victaulic® Knife Gate ValveMichał KisielewskiОценок пока нет

- Solenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Документ2 страницыSolenoid Valve 2/2 Way N.O. Direct Acting - Dampness-Proof IP 67Ramius HamdaniОценок пока нет

- HD 282 Butterfly Valves R02 17Документ4 страницыHD 282 Butterfly Valves R02 17Satish IndiaОценок пока нет

- Forged Gate, Globe & Check ValvesДокумент4 страницыForged Gate, Globe & Check ValvesRavi KantОценок пока нет

- Quick Sheet: API 602 Forged Steel Gate ValveДокумент3 страницыQuick Sheet: API 602 Forged Steel Gate ValveNaresh AОценок пока нет

- CVC Steel FullДокумент28 страницCVC Steel FullSergio Bacca SantiagoОценок пока нет

- FT - HighPress Check ValveДокумент1 страницаFT - HighPress Check ValveJamesОценок пока нет

- Avk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400Документ2 страницыAvk Gate Valve, Flanged, Bs STD, Pn25 21/60-004: BS 5163/EN558 Ser.3, Ductile Iron, Stainless Steel Stem, DN50-400brilian pungkyОценок пока нет

- LT Aquaseal Max Fabricated Steel Butterfly ValvesДокумент4 страницыLT Aquaseal Max Fabricated Steel Butterfly ValvesVictor Hugo Lopez GonzalezОценок пока нет

- Jamesbury 3000Документ4 страницыJamesbury 3000jacquesstrappe06Оценок пока нет

- Knife Gate Valve - AVKCMSДокумент2 страницыKnife Gate Valve - AVKCMSjuantamad02Оценок пока нет

- 45-BC AVK Gate Valve OSYДокумент2 страницы45-BC AVK Gate Valve OSYAnonymous X3PnFL6Оценок пока нет

- V4-CWD-A200: Double Door Check ValveДокумент1 страницаV4-CWD-A200: Double Door Check ValveArthur DeiparineОценок пока нет

- Specifications, Applications, Service Instructions & Parts: AW300H Butt Weld Angle ValveДокумент20 страницSpecifications, Applications, Service Instructions & Parts: AW300H Butt Weld Angle ValveGabriel Rincón RodríguezОценок пока нет

- Avk Control Valve, One Way Altitude, Pn10/16 859/2031-001: Reduced Bore, SS 304 Trim, WRAS Rubber, 300 M Blue EPДокумент4 страницыAvk Control Valve, One Way Altitude, Pn10/16 859/2031-001: Reduced Bore, SS 304 Trim, WRAS Rubber, 300 M Blue EPindra putraОценок пока нет

- Avk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400Документ2 страницыAvk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400umair186Оценок пока нет

- 1) Wouter Witzel EVTLSДокумент7 страниц1) Wouter Witzel EVTLSAizat RomainoОценок пока нет

- hck5d 1Документ8 страницhck5d 1abrahan enoc pacheco hernandezОценок пока нет

- AVK-S 45-00 - NRS-ANSI FL Flat FaceДокумент2 страницыAVK-S 45-00 - NRS-ANSI FL Flat FaceAhmed Said IbrahimОценок пока нет

- Screw Pumps Series SPF: Application Shaft SealingДокумент16 страницScrew Pumps Series SPF: Application Shaft Sealingmsh16000Оценок пока нет

- Ventilation: Installation ConsiderationsДокумент2 страницыVentilation: Installation Considerationsmazumdar_satyajitОценок пока нет

- PPT6Документ1 страницаPPT6mazumdar_satyajitОценок пока нет

- Ventilation: Thumb Rule For Calculation of Air Flow From An Louvered OpeningДокумент1 страницаVentilation: Thumb Rule For Calculation of Air Flow From An Louvered Openingmazumdar_satyajitОценок пока нет

- 14 Q KG/HR) 0.3 GM/HR 14 0.01998 X (Fuel Rate in G/HR) X (%fuel Sulphur by WT.)Документ2 страницы14 Q KG/HR) 0.3 GM/HR 14 0.01998 X (Fuel Rate in G/HR) X (%fuel Sulphur by WT.)mazumdar_satyajitОценок пока нет

- CH Design-R1 PDFДокумент12 страницCH Design-R1 PDFmazumdar_satyajitОценок пока нет

- Phase Segregated Terminal Arrangement Phase Seperated Terminal ArrangementДокумент1 страницаPhase Segregated Terminal Arrangement Phase Seperated Terminal Arrangementmazumdar_satyajitОценок пока нет

- General Technical Versions: Motor Terminal BoxesДокумент1 страницаGeneral Technical Versions: Motor Terminal Boxesmazumdar_satyajitОценок пока нет

- Fault Level CalculationДокумент43 страницыFault Level Calculationmazumdar_satyajitОценок пока нет

- Phase Segregated Terminal Box: Atex / Iecex Gas & Dust CertifiedДокумент2 страницыPhase Segregated Terminal Box: Atex / Iecex Gas & Dust Certifiedmazumdar_satyajitОценок пока нет

- China Nonroad EmissionsДокумент6 страницChina Nonroad Emissionsmazumdar_satyajitОценок пока нет

- Exhaust System Back Pressure CalculationДокумент1 страницаExhaust System Back Pressure Calculationmazumdar_satyajitОценок пока нет

- Genon 15 06 10Документ6 страницGenon 15 06 10mazumdar_satyajitОценок пока нет

- Additional Cost Break Up Details For Chimney: Base Plate ODДокумент1 страницаAdditional Cost Break Up Details For Chimney: Base Plate ODmazumdar_satyajitОценок пока нет

- Dear Priyankara, Pls Find Attached The Pictures Acoustic Works For Your Perusal: We Will Be Supplying Below Need To Be Installed at SiteДокумент11 страницDear Priyankara, Pls Find Attached The Pictures Acoustic Works For Your Perusal: We Will Be Supplying Below Need To Be Installed at Sitemazumdar_satyajitОценок пока нет

- Design of Tower Supporting Structure: Electronics City ProjectДокумент7 страницDesign of Tower Supporting Structure: Electronics City Projectmazumdar_satyajitОценок пока нет

- KeiДокумент7 страницKeimazumdar_satyajitОценок пока нет

- FC CalcДокумент1 страницаFC Calcmazumdar_satyajitОценок пока нет

- Chimney Calculations 14-7-2003Документ4 страницыChimney Calculations 14-7-2003surinder yadavОценок пока нет

- Exhaust Pipe Dia & Back Pressure Calculations - TCS TrivandrumДокумент6 страницExhaust Pipe Dia & Back Pressure Calculations - TCS Trivandrummazumdar_satyajitОценок пока нет

- Technical Data Sheet For R B Slabs-1Документ1 страницаTechnical Data Sheet For R B Slabs-1mazumdar_satyajitОценок пока нет

- Chimney Flow Rate CalculatorДокумент4 страницыChimney Flow Rate Calculatormazumdar_satyajitОценок пока нет

- LT Vs HTДокумент1 страницаLT Vs HTmazumdar_satyajitОценок пока нет

- Acoustic Installation ProcedureДокумент12 страницAcoustic Installation Proceduremazumdar_satyajitОценок пока нет

- Technical Data Sheet For R B Slabs-1Документ1 страницаTechnical Data Sheet For R B Slabs-1mazumdar_satyajitОценок пока нет

- Missouri Department of Transportation: Standard Inspection and Testing Plan (ITP)Документ32 страницыMissouri Department of Transportation: Standard Inspection and Testing Plan (ITP)mohamedamine.zemouriОценок пока нет

- Stelma & Cameron PDFДокумент35 страницStelma & Cameron PDFCatarinaОценок пока нет

- PE1 Introduction To MovementsДокумент4 страницыPE1 Introduction To MovementsDaniela AnsayОценок пока нет

- 3393 - Supervision of Concrete Construction Volume 2Документ271 страница3393 - Supervision of Concrete Construction Volume 2Oum ChhayNoy100% (11)

- HPB Brochure 0708Документ12 страницHPB Brochure 0708musaluddinОценок пока нет

- Megger-Mjolner-600 Ds enДокумент5 страницMegger-Mjolner-600 Ds enAmit Kumar KandiОценок пока нет

- Synchronous Motor AC DrivesДокумент40 страницSynchronous Motor AC DrivesHarshal Thakur100% (1)

- Language Focus. Past Simple or Past ContinuousДокумент3 страницыLanguage Focus. Past Simple or Past ContinuoustotydnrОценок пока нет

- Modul MarketingДокумент5 страницModul MarketingDeni IrvandaОценок пока нет

- A Practical Guide To HL7 Interface DevelopmentДокумент5 страницA Practical Guide To HL7 Interface DevelopmentmjohnstnОценок пока нет

- Assignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionДокумент6 страницAssignment-2: 1) Explain Classification With Logistic Regression and Sigmoid FunctionpraneshОценок пока нет

- Classical Electromagnetism 1st Edition Franklin Solutions ManualДокумент21 страницаClassical Electromagnetism 1st Edition Franklin Solutions ManualBrianYorktnqsw100% (15)

- Jurnal Ari Maulana Ullum Sasmi 1801038Документ12 страницJurnal Ari Maulana Ullum Sasmi 180103803. Ari Maulana Ullum Sasmi / TD 2.10Оценок пока нет

- Eng Essay For PresentationДокумент8 страницEng Essay For Presentationctn batrisyiaОценок пока нет

- A Comparison Study of Process Scheduling in Freebsd, Linux and Win2KДокумент12 страницA Comparison Study of Process Scheduling in Freebsd, Linux and Win2Kbenito agusОценок пока нет

- BITS Pilani: Scale Up and Post Approval ChangesДокумент56 страницBITS Pilani: Scale Up and Post Approval ChangesshrikantmsdОценок пока нет

- Introduction To Game Theory: Analysis of GamesДокумент13 страницIntroduction To Game Theory: Analysis of GamesAoiОценок пока нет

- Toyota Motor Manufacturing (TMM)Документ20 страницToyota Motor Manufacturing (TMM)Lekha ShahОценок пока нет

- Minimum Leak Path For TTJДокумент3 страницыMinimum Leak Path For TTJparikshitpadture100% (2)

- Engineers House Fire Fighting Course FP 01Документ54 страницыEngineers House Fire Fighting Course FP 01Muhammad ElbarbaryОценок пока нет

- MYP Unit Planner - MathДокумент5 страницMYP Unit Planner - MathMarija CvetkovicОценок пока нет

- Fame and FortuneДокумент8 страницFame and FortuneNguyễn Đình Tuấn ĐạtОценок пока нет

- Jaquar Sanitarywares PricelistДокумент8 страницJaquar Sanitarywares PricelistAnil KumarОценок пока нет

- Hydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationДокумент8 страницHydrogen Sulfide and Mercaptan Sulfur in Liquid Hydrocarbons by Potentiometric TitrationINOPETRO DO BRASILОценок пока нет

- San Beda University: Integrated Basic Education DepartmentДокумент3 страницыSan Beda University: Integrated Basic Education DepartmentEmil SamaniegoОценок пока нет

- Ipcrf Core Values 2019 - FinalДокумент23 страницыIpcrf Core Values 2019 - FinalFrendelyn p. Gador100% (4)

- TA-Modulator EN LowДокумент16 страницTA-Modulator EN Lowkap4enijОценок пока нет

- TGA Interpretation of Data, Sources of ErrorДокумент28 страницTGA Interpretation of Data, Sources of ErrorUsman GhaniОценок пока нет

- Uenr0997 12 00 - Manuals Service Modules - Testing & AdjustingДокумент90 страницUenr0997 12 00 - Manuals Service Modules - Testing & Adjustingmostafa aliОценок пока нет

- Art of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionОт EverandArt of Commenting: How to Influence Environmental Decisionmaking With Effective Comments, The, 2d EditionРейтинг: 3 из 5 звезд3/5 (1)

- Waste: One Woman’s Fight Against America’s Dirty SecretОт EverandWaste: One Woman’s Fight Against America’s Dirty SecretРейтинг: 5 из 5 звезд5/5 (1)

- Articulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceОт EverandArticulating Design Decisions: Communicate with Stakeholders, Keep Your Sanity, and Deliver the Best User ExperienceРейтинг: 4 из 5 звезд4/5 (19)

- Electrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tОт EverandElectrical Engineering 101: Everything You Should Have Learned in School...but Probably Didn'tРейтинг: 4.5 из 5 звезд4.5/5 (27)

- The Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneОт EverandThe Age of Agile: How Smart Companies Are Transforming the Way Work Gets DoneРейтинг: 4.5 из 5 звезд4.5/5 (5)

- The Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОт EverandThe Design Thinking Playbook: Mindful Digital Transformation of Teams, Products, Services, Businesses and EcosystemsОценок пока нет

- Artificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureОт EverandArtificial Intelligence Revolution: How AI Will Change our Society, Economy, and CultureРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Laws of UX: Using Psychology to Design Better Products & ServicesОт EverandLaws of UX: Using Psychology to Design Better Products & ServicesРейтинг: 5 из 5 звезд5/5 (9)

- UX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesОт EverandUX: Simple and Effective Methods for Designing UX Great Products Using UX Programming TheoriesОценок пока нет

- 507 Mechanical Movements: Mechanisms and DevicesОт Everand507 Mechanical Movements: Mechanisms and DevicesРейтинг: 4 из 5 звезд4/5 (28)

- Design for How People Think: Using Brain Science to Build Better ProductsОт EverandDesign for How People Think: Using Brain Science to Build Better ProductsРейтинг: 4 из 5 звезд4/5 (8)

- Analog Design and Simulation Using OrCAD Capture and PSpiceОт EverandAnalog Design and Simulation Using OrCAD Capture and PSpiceОценок пока нет

- Exposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontОт EverandExposure: Poisoned Water, Corporate Greed, and One Lawyer's Twenty-Year Battle Against DuPontРейтинг: 4.5 из 5 звезд4.5/5 (18)

- Design Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessОт EverandDesign Thinking and Innovation Metrics: Powerful Tools to Manage Creativity, OKRs, Product, and Business SuccessОценок пока нет

- CATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchОт EverandCATIA V5-6R2015 Basics - Part I : Getting Started and Sketcher WorkbenchРейтинг: 4 из 5 звезд4/5 (10)

- Designing for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionОт EverandDesigning for Behavior Change: Applying Psychology and Behavioral Economics 2nd EditionОценок пока нет

- Delft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsОт EverandDelft Design Guide -Revised edition: Perspectives- Models - Approaches - MethodsОценок пока нет

- The Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsОт EverandThe Jobs To Be Done Playbook: Align Your Markets, Organization, and Strategy Around Customer NeedsРейтинг: 5 из 5 звезд5/5 (1)