Академический Документы

Профессиональный Документы

Культура Документы

Int IV - 2017 - Óxido de Etileno

Загружено:

Miguela Chavez MartinezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Int IV - 2017 - Óxido de Etileno

Загружено:

Miguela Chavez MartinezАвторское право:

Доступные форматы

OXIDATION OF ETHYLENE TO ETHYLENE OXIDE

Uses

Ethylene oxide is one of the most important raw materials used in large-scale

chemical production. Most ethylene oxide is used for synthesis of ethylene glycols,

including diethylene glycol and triethylene glycol that accounts for up to 75% of

global consumption. Other important products include ethylene glycol ethers,

ethanolamines and ethoxylates. Among glycols, ethylene glycol is used

as antifreeze, in the production of polyester and polyethylene terephthalate (PET

raw material for plastic bottles), liquid coolants and solvents.

Process tehnology

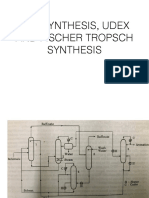

Figure 17.1 Flow sheet of production of ethylene oxide

C2 H4 + 0.5 O2 CH2OCH2

Ethylene to air ratio: 3 10 %

Side reaction products:

C2 H4 + 3 O2 2 CO2 + 2 H2O

C2 H4 + C2 H4 1-Butadiene

Catalyst: Silver oxide on alumina

Operating temperature and pressure: 250 300C and 120 300 psi

Supressing agent for side reactions: Ethylene dichloride

Reaction is exothermic

Air and ethylene are separate compressed and along with recycle stream are

sent to the shell and tube reactor.

The reactor is fed on the shell side with Dowtherm fluid that serves to maintain

the reaction temperature. A dowtherm fluid is a heat transfer fluid , which is a

mixture of two very stable compounds, biphenyl and diphenyl oxide. The fluid is

dyed clear to light yellow to aid in leak detection.

The hot dowtherm fluid from the reactor is sent to a waste heat recovery boiler to

generate steam.

The vapour stream is cooled using a integrated heat exchanger using the

unreacted vapour stream generated from an absorber.

The vapour stream is then sent to the heat integrated exchanger and is then sent

back to the reactor and a fraction of that is purged to eliminate the accumulation of

inerts such as Nitrogen and Argon.

The product vapors are compressed and sent to a water absorber which absorbs

ethylene oxide from the feed vapors. Eventually, the ethylene oxide rich water

stream is sent to a stripper which desorbs the ethylene oxide + water as vapour

and generates the regenerated water as bottom product. The regenerated water

reaches the absorber through a heat integrated exchanger.

The ethylene oxide + water vapour mixture is compressed (to about 4 - 5 atms)

and then sent to a stripper to generate light ends + H2O as a top product and the

bottom product is then sent to another fractionators to produce ethylene oxide as

top product. The heavy ends are obtained as bottom product.

Вам также может понравиться

- Ethanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesОт EverandEthanol Fuel Learn to Make and Use Ethanol to Power Your VehiclesОценок пока нет

- CT-308 Ethylene Oxide Production 2023Документ6 страницCT-308 Ethylene Oxide Production 2023Divyansh NagarОценок пока нет

- 07.-Quimicos Basados en EtilenoДокумент34 страницы07.-Quimicos Basados en EtilenoNo pos wuafОценок пока нет

- Catalytic Hydration Method To Produce Ethanol From EthyleneДокумент2 страницыCatalytic Hydration Method To Produce Ethanol From Ethylenejan100% (1)

- Styrene: Ethyly Benzene and StyreneДокумент7 страницStyrene: Ethyly Benzene and Styreneم.احمد سالمОценок пока нет

- Background: C H H O L)Документ1 страницаBackground: C H H O L)Lucy EvrettОценок пока нет

- Johann Joachim Becher Ethanol Iupac Organic Compound AlkenesДокумент4 страницыJohann Joachim Becher Ethanol Iupac Organic Compound AlkenesLeo TolstoyОценок пока нет

- PD TopicДокумент6 страницPD TopicAnonymous Flh0GZОценок пока нет

- Lecture - 17 - Ethylene Oxide and EthanolaminesДокумент5 страницLecture - 17 - Ethylene Oxide and EthanolaminesZahhzamzahОценок пока нет

- Manufacturing Ethylene GlycolДокумент12 страницManufacturing Ethylene GlycolShobana MikeОценок пока нет

- Petrochemical IndustryДокумент30 страницPetrochemical Industrybuhayche14Оценок пока нет

- Design of An Ethylene Oxide Production ProcessДокумент13 страницDesign of An Ethylene Oxide Production ProcessGie100% (4)

- Production of Ethylene GlycolДокумент2 страницыProduction of Ethylene GlycolAhmed Ali0% (2)

- Ethylene Production by Naphtha Cracking TechnologyДокумент6 страницEthylene Production by Naphtha Cracking TechnologyHina IbrahimОценок пока нет

- Production of StyreneДокумент14 страницProduction of StyreneAinggararuban GaneshanОценок пока нет

- Project 4 Ethylene OxideДокумент12 страницProject 4 Ethylene OxideNhan Nguyen Van100% (4)

- Production: Industrial RoutesДокумент6 страницProduction: Industrial RoutesCaballeroGiovanniОценок пока нет

- Ethylene OxideДокумент6 страницEthylene OxideRabiya SaeedОценок пока нет

- Acetaldehyde Methods 2520of 2520 ProductionДокумент6 страницAcetaldehyde Methods 2520of 2520 Productionapi-3714811100% (3)

- Major Engineering ProblemsДокумент5 страницMajor Engineering ProblemsaathiraОценок пока нет

- Plant DesignДокумент42 страницыPlant Designmuhammad ilyasОценок пока нет

- 5 Petrochemical ProductsДокумент13 страниц5 Petrochemical ProductsAli aliraqiОценок пока нет

- OXIDATIONДокумент36 страницOXIDATIONMansab AliОценок пока нет

- ALCOHOLS (Class)Документ9 страницALCOHOLS (Class)adritaОценок пока нет

- Petrochemical 2Документ60 страницPetrochemical 2AnilKumarОценок пока нет

- More Carbon Than The Reacting OlefinДокумент9 страницMore Carbon Than The Reacting OlefinAli aliraqiОценок пока нет

- 1.0 Task Specification: For Each Unit Operation and Overall PlantДокумент22 страницы1.0 Task Specification: For Each Unit Operation and Overall PlantS Kiong TingОценок пока нет

- Chemicals Based On PropyleneДокумент21 страницаChemicals Based On PropyleneAli aliraqiОценок пока нет

- Ethylene 2520oxide Methods 2520of 2520productionДокумент25 страницEthylene 2520oxide Methods 2520of 2520productionmartin_2104Оценок пока нет

- Ethyleneglycol - Methods 2520of 2520production (Quality Specifications)Документ5 страницEthyleneglycol - Methods 2520of 2520production (Quality Specifications)jorgchanОценок пока нет

- Ethylene BalanceДокумент29 страницEthylene BalanceCraigUnderwood100% (2)

- Yr 12 Notes (Other Half)Документ83 страницыYr 12 Notes (Other Half)Catherine LiОценок пока нет

- Project 6 - Ethylene Oxide PDFДокумент13 страницProject 6 - Ethylene Oxide PDFStephanie Hawkins100% (1)

- Lecture 18 Ethylene GlycolДокумент6 страницLecture 18 Ethylene GlycolJayraj DaymaОценок пока нет

- TVK Ethylene Plant OverviewДокумент32 страницыTVK Ethylene Plant Overviewstavros7100% (2)

- QuenchingДокумент10 страницQuenchingRehanОценок пока нет

- Petrochemical IndustryДокумент42 страницыPetrochemical IndustryFaraydwn Farsat HakimОценок пока нет

- Oxosynthesis, Udex and Fischer Tropsch SynthesisДокумент21 страницаOxosynthesis, Udex and Fischer Tropsch SynthesisNisha SubashОценок пока нет

- Ethylene Oxide Project QuestionДокумент1 страницаEthylene Oxide Project Questionkaryensam100% (1)

- LECTURE - 6: Ethylene Derivatives: Ethylene Oxide and Ethanol Amines 6.1 Ethylene OxideДокумент7 страницLECTURE - 6: Ethylene Derivatives: Ethylene Oxide and Ethanol Amines 6.1 Ethylene Oxideمحمود محمدОценок пока нет

- Ethylene Oxide-Ethylene Glycol - InfoДокумент10 страницEthylene Oxide-Ethylene Glycol - InfoAmeya SavnalОценок пока нет

- EthyleneДокумент4 страницыEthyleneashutosh kumarОценок пока нет

- CT-308 Phenol Production-2023Документ22 страницыCT-308 Phenol Production-2023Divyansh NagarОценок пока нет

- College of Science Departement of Chemistry Industrial Chemistry Two Group-4 PPT On Production of Ethylene Oxide Group Members 1Документ16 страницCollege of Science Departement of Chemistry Industrial Chemistry Two Group-4 PPT On Production of Ethylene Oxide Group Members 1Fikere'ab HabtamuОценок пока нет

- Hydrodealkylation SimulationДокумент8 страницHydrodealkylation SimulationLívia Lopes100% (2)

- CHE502 - Reaction Engineering 1 AssignmeДокумент22 страницыCHE502 - Reaction Engineering 1 AssignmeShilpa KodolikarОценок пока нет

- Production of Ethylene GlycolДокумент15 страницProduction of Ethylene Glycolindahazhr100% (6)

- Petrochemicals NoteДокумент12 страницPetrochemicals NoteSai Swaroop MandalОценок пока нет

- Lecture 18: Isopropanol and Acetone From Propylene: Module 3: PetrochemicalsДокумент2 страницыLecture 18: Isopropanol and Acetone From Propylene: Module 3: Petrochemicalsshamsullah hamdardОценок пока нет

- Flow Diagram of Isopropyl AlcoholДокумент2 страницыFlow Diagram of Isopropyl Alcoholshamsullah100% (1)

- Ethylene Glycol ProductionДокумент15 страницEthylene Glycol ProductionKUKUОценок пока нет

- Manufacture of Ethylene OxideДокумент83 страницыManufacture of Ethylene Oxidejoshua amarnath100% (3)

- Ethylene GlycolДокумент4 страницыEthylene GlycolAli AhsanОценок пока нет

- Advanced Pharmaceutical analysisОт EverandAdvanced Pharmaceutical analysisРейтинг: 4.5 из 5 звезд4.5/5 (2)

- Water Gas Shift Reaction: Research Developments and ApplicationsОт EverandWater Gas Shift Reaction: Research Developments and ApplicationsОценок пока нет

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОт EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesОценок пока нет

- Thermodynamic analysis of geothermal heat pumps for civil air-conditioningОт EverandThermodynamic analysis of geothermal heat pumps for civil air-conditioningРейтинг: 5 из 5 звезд5/5 (2)

- Hygiene Product CatalogueДокумент7 страницHygiene Product Catalogueolabi abdullahОценок пока нет

- Isolation Identification and Analysis of PhytoconstituentsДокумент30 страницIsolation Identification and Analysis of PhytoconstituentsMurugan MОценок пока нет

- New Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricДокумент24 страницыNew Solvent For Polyamide 66 and Its Use For Preparing Single-Polymer Composite Coated-FabricSSОценок пока нет

- Semi ProposalДокумент6 страницSemi ProposalDawit AbameОценок пока нет

- Carboset CA-600 - CST600 - CO - enДокумент3 страницыCarboset CA-600 - CST600 - CO - enNilsОценок пока нет

- Ferrite in Weld Metal PDFДокумент1 страницаFerrite in Weld Metal PDFhassan debianeОценок пока нет

- Co2 Utilization Developments in Conversion ProcessesДокумент44 страницыCo2 Utilization Developments in Conversion ProcessesRungrawin Ngamkhum100% (1)

- Sample Data: AnionsДокумент1 страницаSample Data: AnionsAyman KamounОценок пока нет

- High-Temperature Behavior of Laser ElectrodispersiДокумент18 страницHigh-Temperature Behavior of Laser Electrodispersiateer6727Оценок пока нет

- Fabrication Guide PDFДокумент96 страницFabrication Guide PDFbookpp100% (2)

- Thermal Cracking of Recycled Hydrocarbon Gas-Mixtures With High Olefins Concentrations in The Feed: Operational Analysis of Industrial FurnacesДокумент7 страницThermal Cracking of Recycled Hydrocarbon Gas-Mixtures With High Olefins Concentrations in The Feed: Operational Analysis of Industrial FurnacesMehul SutariyaОценок пока нет

- 2881-2883 Diclofenac Sodium Delayed-Release TabletsДокумент3 страницы2881-2883 Diclofenac Sodium Delayed-Release Tabletsoktaviana catur nurlailaОценок пока нет

- Chapter 11 - Surfacing and Shape Welding PDFДокумент15 страницChapter 11 - Surfacing and Shape Welding PDFCarlos GarcíaОценок пока нет

- Usp 1663Документ12 страницUsp 1663anilsamuel0077418100% (1)

- Advantages and DisadvantagesДокумент4 страницыAdvantages and DisadvantagesvenothОценок пока нет

- Aldehydes and Ketones - Properties, Reactions, Identification and 2,4-DNP PDFДокумент9 страницAldehydes and Ketones - Properties, Reactions, Identification and 2,4-DNP PDFStephenОценок пока нет

- My Sore SandalДокумент14 страницMy Sore SandalHarshi AkhilОценок пока нет

- Quassia Undulata Seed OilДокумент4 страницыQuassia Undulata Seed OilPedro Gerardo Trejo FloresОценок пока нет

- Qualitative Analysis of CationsДокумент12 страницQualitative Analysis of CationsRegina Morales0% (1)

- Edgar Ahn PDFДокумент24 страницыEdgar Ahn PDFLim Chee SiangОценок пока нет

- Epa 9081 Cation-Exchange Capacity of Soils (Sodium Acetate)Документ4 страницыEpa 9081 Cation-Exchange Capacity of Soils (Sodium Acetate)ErickОценок пока нет

- Chemical Nomenclature: Experiment #3Документ27 страницChemical Nomenclature: Experiment #3Ayi PunsalanОценок пока нет

- 1 s2.0 S2665927121000496 MainДокумент18 страниц1 s2.0 S2665927121000496 MainAtlasLiuОценок пока нет

- Maincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsДокумент10 страницMaincote™ EC-11: Waterborne Elastomeric Acrylic Resin For Industrial Maintenance CoatingsLong An ĐỗОценок пока нет

- SICOMIN CatalogДокумент42 страницыSICOMIN CatalogcsakkellОценок пока нет

- Wanhua Interior Coating SolutionsДокумент28 страницWanhua Interior Coating SolutionsThanh Vu100% (1)

- Manual de Operacion y Mantenimiento Motores CaterpillarДокумент42 страницыManual de Operacion y Mantenimiento Motores CaterpillarpetercuriОценок пока нет

- 821180-Palmvita SHT WF (1116) MRD 1x15Kg Carton-C331Документ4 страницы821180-Palmvita SHT WF (1116) MRD 1x15Kg Carton-C331QA RCPIОценок пока нет

- SJI 2019 Chemistry 6092 P2 EOYДокумент19 страницSJI 2019 Chemistry 6092 P2 EOYbenjamincylien1Оценок пока нет

- SPM Kimia Jul12 PDFДокумент49 страницSPM Kimia Jul12 PDFSyazwani RadziОценок пока нет