Академический Документы

Профессиональный Документы

Культура Документы

6-004 General Site Rules and HSE Induction

Загружено:

Johnn Doe Srdjan JocicАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

6-004 General Site Rules and HSE Induction

Загружено:

Johnn Doe Srdjan JocicАвторское право:

Доступные форматы

SAFE OPERATING PROCEDURES

06 GENERAL STANDARDS

GENERAL SITE RULES AND HSE

INDUCTION NO. 6.004

FUNCTION NAME POSITION SIGNATURE DATE

Preparation Jurie van der Watt Group HSE Manager

Country General

Approval Richard Davies

Manager

RECORD OF AMENDMENTS

Clause(s) Effective

No Pages re-issued Revision details

amended Date

0 N/A N/A New procedure 01/04/08

New

Revision# 1 2 3 4 5 6 7 8 9

Document

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 1 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

1. PURPOSE

To provide a set of rules to inform all employees of the basic safety

requirements.

2. SCOPE

This procedure is applicable to all Capital Drilling.

3. REFERENCE DOCUMENTS

Induction and SHE training record

SOP 6-001 - Emergency Preparedness and Response

SOP 6-002 - Parking procedure

SOP 6-003 - Supervisors HSE responsibilities

SOP 6-006 - Transport of employees

4. DEFINITIONS

None

5. PROCEDURE

5.1. PERSONAL REQUIREMENTS

No person is allowed to work or operate on any site unless he has been

medically examined and completed the applicable induction.

All people entering or leaving the site are liable to be searched, being

employees or visitors.

No person shall come to work, nor operate any machine or drive any motor

vehicle while under the influence of alcohol/drugs or any narcotic substances.

Breathe analyzing and drug tests shall be performed at random.

All employees shall carry their ID card and pit license on them while at work.

Safety equipment shall be worn as indicated by safety signs.

5.2. HAUL ROADS AND PIT TRAFFIC RULES

All traffic, road and pit signs shall be complied with: -

Drive/operate according to road conditions.

Slow down at crossings, sharp bends, curves and blind spots.

UNDER NO CIRCUMSTANCES IS IT ALLOWED TO REVERSE ON A

RAMP.

The speed limits is as follows: -

Haul road 50 km/h or as specified

Ramps 20 km/h or as specified

Office/Workshop yard 20 km/h or as specified

Towing of equipment 40 km/h or as specified

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 2 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

Vehicle following distances on haul roads and ramps shall be not less than 50

meters.

Safety belts shall be worn by equipment operators or as specified.

All rubber tire earthmoving equipment shall have stop blocks while at service

or during any repair work.

A pre-use checklist shall be filled in for all equipment before operating it.

It is not allowed to operate any equipment with an A hazard, as identified

during pre-use inspections.

All light motor vehicles shall have a luminous buggy whip, reverse hooter, and

beacon light, fire extinguisher and first aid pouch when entering the mining

area.

All machinery will have at least one fire extinguisher fitted and a reverse

hooter.

All vehicles within pit area will operate with lights on, whip pole and flag fitted

and a strobe light on.

Drivers of light motor vehicles must also do daily pre-use checks.

No vehicle will overtake any other vehicle in extreme dusty conditions or on

slippery road surface conditions.

No person shall be required or permitted to drive/operate/test any

machine or vehicle unless he has been trained, tested and passed by an

authorized person for that type of equipment.

Trainees may operate a machine only if he is instructed to do so and provided

he be under direct supervision of qualified operator or instructor.

No equipment may be moved from the workshop area without the permission

of the Maintenance Manager or service/repair supervisor.

All machines being serviced or on brake down in the mining area shall be

demarcated with road marking cones. After the demarcation is done, hardhat

and reflective vest can be removed in such area.

Operators/drivers shall be made aware of beacons, survey pegs or makers

and shall not upset or cause any damage to them.

A safety berm shall be constructed at all high walls, working benches and

tipping areas. The dimensions of the safety berm, is as follows:

The berm height shall be not less than the diameter of the largest machine

tire in use on site

The berm shall be not less than 800mm in width.

The berm shall be not less than meter away from the high wall where

possible.

If, for sound practical reasons, the construction of a safety berm is not

possible, then tipping shall take place not less than 5 meters away from the

high/low wall and the material shall be pushed over by a dozer.

No person is allowed to cross any safety berms.

No person is allowed to park closer than 5 meters from the top or bottom of a

high wall/bench

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 3 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

5.3. PARKING PROCEDURE

REFER TO THE PARKING PROCEDURE - REF NO SOP 6-002. THIS MUST

ALSO BE DISCUSSED DURING THE INDUCTION.

5.4. ILLUMINATION AND LIGHTS ON EQUIPMENT

All lighting plants shall be kept clean.

All lighting plants must have one extinguisher fitted.

Lights on vehicles must be switched on when in the mining area.

All light must be in a good working order.

All lights must be kept clean of mud and other build up.

Use indicators to indicate intended direction of movement.

5.5. OVERTAKING

Exercise extreme caution when overtaking.

It is not permitted to overtake any vehicles on any ramps, bends or blind

corners.

Never overtake another vehicle where there is a possibility that a vehicle may

change direction.

A dump truck is not allowed to overtake another dump truck.

Dozers, drills, excavators, graders and water carts may be overtaken. Hooter

shall be sounded to inform the vehicle to be overtaken and ensure that the

operator of that equipment is aware of it.

Keep to the left of the road or as indicated by road signs.

5.6. HOUSEKEEPING

All vehicles/machines shall be kept clean and free of loose material inside the

cab.

Windows shall be kept clean for maximum visibility.

All workshops shall be free from material to prevent tripping/falling hazards.

All tools not in use shall be safely stored away.

Dustbins shall be emptied on regular basis.

Toilets, change rooms and eating-places shall be clean, hygienic and free

from waste, insects and rodents.

Occupants shall keep offices clean at all times.

Sufficient dustbins and skips shall be provided for paper and rubbish.

5.7. ENVIRONMENTAL ISSUES

No form of ground, air and water pollution shall be allowed.

Accidental oil and grease spillages shall be cleaned up immediately.

Oil catch up trays shall be used when open or loosing oil/hydraulic pipes.

No oil is allowed to enter water streams.

Symbolic safety signs shall indicate drinkable and non-drinkable water.

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 4 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

5.8. GENERAL

Report all injuries and accidents immediately.

NO INJURIES WILL BE ACCEPTED IF IT IS ONLY REPORTED THE NEXT

DAY.

Unsafe acts, unsafe conditions and near-miss incidents must be reported

immediately.

Only one passenger is allowed on the front seat of a LDV or other non-

earthmoving equipment.

The rule No Seat No Ride will apply and no passengers will be allowed to be

transported at the back of an LV (ute). Passengers are allowed to be

transported in a PC carrier.

No persons shall interfere with or abuse fire extinguishers or first-aid

equipment.

Playing or fooling around in the workplace is strictly prohibited.

No firearms are allowed on any site.

No hazardous substances (chemicals) will be brought on to a site without

authorization and a Material Safety Data Sheet.

No person, other than a competent person, shall work on any electrical

apparatus.

Be aware that some or most machines are left-handed driven and you may

not always be visible to the operator. Exercise special care near such

vehicles.

Do not park at the right-hand side of a left-handed driven machine.

Only authorized persons such as mechanics or service supervisors are

permitted to open radiator caps and tank/containers that are under pressure.

No unauthorized vehicle is permitted on a blasting pattern.

No person is allowed to tamper with any explosives or accessories.

No person is allowed to enter any explosives charged area unless the charger

or supervisor in charge gives permission to do so.

No cell phones, radios, cigarettes or lighters/matches are allowed in an

explosive charged area.

All employees working in the open pit mining area shall wear a or overall or

shirt blue over orange with reflective strips.

Every person is responsible for his own safety.

Hazard identification must be completed before tasks are performed. If not

sure how task can be done safely, contact the supervisor and consult the HSE

System Manual for safe working procedures.

Three-point contact (Two feet, 1 hand or 2 hands, one foot) shall be

maintained when climbing on/off any equipment.

No persons shall jump off any vehicle or equipment.

A hair net shall cover long hair.

Loose clothing and jewellery may not be worn near moving/rotating machine

parts.

A responsible company official shall at all times accompany visitors.

Hand protection shall be worn wherever there is a possibility on injuries to

hands or fingers.

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 5 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

Eye protection shall be worn where there is danger of foreign objects entering

the eyes e.g. hitting with a hammer, greasing, washing vehicles, drilling grade

control or blasting holes etc.

All employees must make themselves familiar with the information displayed

on the main notice board.

No items, material or any other company property may be removed from the

premises unless a written approval has been obtained from the applicable

head of department.

It is strictly prohibited to use a cell phone while operating any

machines/equipment or while performing work.

5.8. FIRE FIGHTING AND CONTROL

5.8.1. ANATOMY OF A FIRE

There are four elements needed to start a fire

Oxygen Fuel

Heat Chemical Reaction

To extinguish a fire, it is necessary to remove one or more of the above-

mentioned elements.

Oxygen Smother CO2, DCP

Heat Cooling Water, CO2

Fuel Remove Water, CO2,

DCP

Chemical reaction Break DCP, CO2

There are four classes of fire: -

Class A Combustible fixed material Wood, Paper, and Grass

Class B Combustible liquid material Diesel, Petrol, and Oil

Class C Combustible electrical material Electrical motors, Cables,

Plugs

Class D Combustible metals Magnesium

Types of extinguishing agents for different classes of fires :

Class A Water, Sand, CO2, DCP

Class B CO2, DCP (NO WATER)

Class C DCP, CO2, (NO WATER)

Class D Sand, Foam type fire extinguisher

At GGM we use DCP and CO2 type fire extinguishers

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 6 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

5.8.2 FIRE FIGHTING RULES (THESE FOLLOWING ARE GENERAL RULES.

THIS IS NOT AN EVACUATION PROCEDURE)

When fire is observed, raise the alarm immediately.

Determine what type of fire it is.

Get nearest fire extinguisher and make sure it is fit for use.

Determine the wind direction and ensure that you are upwind of the fire.

Stand approximately 3 meters from the fire and break the seal on the fire

extinguisher.

Take the discharge hose in one hand and point it in the direction of the base

of the fire.

Press down firmly on the handle with the other hand.

Walk slowly to the fire while the agent in the extinguisher is released.

Make figure 8 movements with the nozzle while aiming to the base of the fire

to see if the fire flares up again.

When the fire is out, retreat backwards and watch for re-ignition.

Never turn your back on a fire.

Replace empty fire extinguisher with full ones as soon as possible at the Fire

Department.

5.1.1. GENERAL FIRE RULES

Know where the nearest fire extinguisher is located.

Never play with a fire extinguisher.

No stacking is allowed in front of fire extinguisher or refuses bins.

Good house keeping prevents fires.

Adhere to safety signs prohibiting smoking or open flames.

Under NO, circumstances are open fires allowed except with the permission

of the HSE Manager

Flammable liquids such as paint and solvents shall be stored in separate

storage facilities specially designated for the purpose.

Heaters may not be used to dry clothing.

Heaters must be turned of when vacating a room.

Regular inspections on electrical cords and equipment to prevent electrical

fires and shocks are to be performed by a competent person.

Regular inspections on fire extinguishers will ensure that it will work in an

event of a fire.

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 7 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

6. RESPONSIBILITY

HOD, area responsible person, HSE Representative, HSE Officer will conduct

monthly inspections on compliance to this element.

Deviations must be reported to the area responsible person who must rectify

as soon as possible.

7. RECORDS

The HOD must fill in monthly walk about inspection report.

The part time safety rep must use their logbook.

The HSE Officer must use his deviation sheet to fill in all deviations found.

8. DISCIPLINARY ACTION

Disciplinary action will be taken against an employee found to be in breach of

this Standard.

Document: 04_CDTZN_ OHSE_ Capital Drilling_Operational Control_09_General Standards

Prepared By Jurie van der Watt Reviewed By Richard Davies Approved By: B. Rudd

Issue Date: 01-Jan-09 Print Date: 15-Aug-17 Review Date: 01-Jan-10

Version No: 03 Page No: Page 8 of 8

THIS DOCUMENT IS UNCONTROLLED IN HARD COPY

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Somes SSNДокумент8 страницSomes SSNremedios y recetas caseras amparo50% (2)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Bliss Installation BookletДокумент66 страницBliss Installation BookletbigjohnnyОценок пока нет

- Heavy-Construction Competency ModelДокумент21 страницаHeavy-Construction Competency ModelnuzunetОценок пока нет

- 02 PA TransaxleДокумент29 страниц02 PA TransaxleJoaquimAndreLemos86% (7)

- 8-028 Working at HeightsДокумент7 страниц8-028 Working at HeightsJohnn Doe Srdjan JocicОценок пока нет

- Piling Works Mos RevisedДокумент4 страницыPiling Works Mos RevisedPrince Car-chang50% (2)

- Torts Bar QuestionsДокумент19 страницTorts Bar QuestionsSheilah Mae PadallaОценок пока нет

- Valle Verde 3 Village SecurityДокумент3 страницыValle Verde 3 Village SecurityHarleyОценок пока нет

- Construction of High Level Bridge Over Sutlej River Well FoundationДокумент32 страницыConstruction of High Level Bridge Over Sutlej River Well FoundationAvishkar Jain100% (1)

- Cadillac: Operator'S ManualДокумент63 страницыCadillac: Operator'S ManualRaj jainОценок пока нет

- Aggregate Tests For Hot Mix Asphalt: State of The PracticeДокумент22 страницыAggregate Tests For Hot Mix Asphalt: State of The PracticeProf. Prithvi Singh KandhalОценок пока нет

- Cable StructuresДокумент44 страницыCable StructuressindhuraОценок пока нет

- ĐÁP ÁN PRE TOEIC LISTENING UNIT 1 VÀ 2Документ74 страницыĐÁP ÁN PRE TOEIC LISTENING UNIT 1 VÀ 2Phan Tuấn VũОценок пока нет

- Asphalt NotesДокумент5 страницAsphalt NotesTufail KhanОценок пока нет

- STOCKMOVEMENT-TICKET PRICELISTДокумент3 страницыSTOCKMOVEMENT-TICKET PRICELISTJohnn Doe Srdjan JocicОценок пока нет

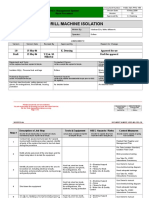

- WP Drill Machine IsolationДокумент4 страницыWP Drill Machine IsolationJohnn Doe Srdjan JocicОценок пока нет

- Safe Procedures for Accident & Incident RecordsДокумент18 страницSafe Procedures for Accident & Incident RecordsJohnn Doe Srdjan JocicОценок пока нет

- Safe Procedures for Accident & Incident RecordsДокумент18 страницSafe Procedures for Accident & Incident RecordsJohnn Doe Srdjan JocicОценок пока нет

- 6.0 Capital Drilling Consultation and CommunicationДокумент15 страниц6.0 Capital Drilling Consultation and CommunicationJohnn Doe Srdjan JocicОценок пока нет

- 1 - RDB SOP Working at HeightsДокумент7 страниц1 - RDB SOP Working at HeightsJohnn Doe Srdjan JocicОценок пока нет

- Drilling price basis and consumablesДокумент4 страницыDrilling price basis and consumablesJohnn Doe Srdjan JocicОценок пока нет

- Paragon InteractivePDF 2015 St5Документ13 страницParagon InteractivePDF 2015 St5Johnn Doe Srdjan JocicОценок пока нет

- FSF effluent stripping towerДокумент1 страницаFSF effluent stripping towerJohnn Doe Srdjan JocicОценок пока нет

- Depth Item Rate/per Meter (GHC) 0-50 50-100 100-150 150-200 200-250 250-300Документ4 страницыDepth Item Rate/per Meter (GHC) 0-50 50-100 100-150 150-200 200-250 250-300Johnn Doe Srdjan JocicОценок пока нет

- Visaform Lat PDFДокумент2 страницыVisaform Lat PDFJohnn Doe Srdjan JocicОценок пока нет

- HoA 1.1Документ19 страницHoA 1.1Johnn Doe Srdjan JocicОценок пока нет

- Power SteringДокумент98 страницPower SteringEdgar Rojas EspejoОценок пока нет

- Final Demo PlanДокумент5 страницFinal Demo PlanLester MendozaОценок пока нет

- Rules for Storage, Handling, and Transport of Coke, Coal and SulfurДокумент16 страницRules for Storage, Handling, and Transport of Coke, Coal and SulfurJohn ChenОценок пока нет

- Tata Hexa 2019 OMДокумент233 страницыTata Hexa 2019 OMM Venkateswara RaoОценок пока нет

- Airport technology chapter explores solutions to congestionДокумент50 страницAirport technology chapter explores solutions to congestionPriyaОценок пока нет

- PNR v. IAC, 217 SCRA 401Документ12 страницPNR v. IAC, 217 SCRA 401Ryuzaki HidekiОценок пока нет

- Chinh phục 80 đề tiếng anh vào 10 năm 2023 Bùi Văn Vinh PRACTICE TEST 7Документ5 страницChinh phục 80 đề tiếng anh vào 10 năm 2023 Bùi Văn Vinh PRACTICE TEST 7Bee House MaterialsОценок пока нет

- SAFETY ALERTДокумент2 страницыSAFETY ALERTGns Mohan KumarОценок пока нет

- MEASURMENT SHEET Format-Clearing Grubbing & Dismantling Existing StructureДокумент5 страницMEASURMENT SHEET Format-Clearing Grubbing & Dismantling Existing StructureMoumon DasОценок пока нет

- Thinking Cities - May 2017 Vol - 4Документ84 страницыThinking Cities - May 2017 Vol - 4J Mc GeeverОценок пока нет

- Revised Madison County Transit ScheduleДокумент3 страницыRevised Madison County Transit ScheduleKyle MennigОценок пока нет

- Guidance Notes HW WorksДокумент37 страницGuidance Notes HW WorksanjanaОценок пока нет

- Cool Pavement Report-ManalДокумент29 страницCool Pavement Report-ManalKavyaLetZSing music loverОценок пока нет

- Design Concepts For The Proposed General Santos City Walkable Government CenterДокумент46 страницDesign Concepts For The Proposed General Santos City Walkable Government CenterMyke AngОценок пока нет

- CD 122 Revision 1 Geometric Design of Grade Separated Junctions-WebДокумент96 страницCD 122 Revision 1 Geometric Design of Grade Separated Junctions-Web4630220100% (1)

- Unsafe Design TNHD - PaveДокумент17 страницUnsafe Design TNHD - Pavek.shanmuganathanОценок пока нет

- ADB Yuji Ono Research PaperДокумент17 страницADB Yuji Ono Research PaperHabeebMohammedFarooqОценок пока нет