Академический Документы

Профессиональный Документы

Культура Документы

Maanas, Multi Purpose Building S-1

Загружено:

Lon OdiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Maanas, Multi Purpose Building S-1

Загружено:

Lon OdiАвторское право:

Доступные форматы

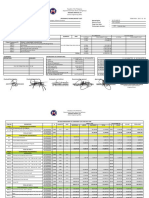

1 2 3 4 5 6 GENERAL NOTES:

3.0 FOUNDATION

1.0 STANDARDS AND REFERENCE 4.2.4 UNLESS OTHER WISE INDICATED, SPLICING OF REINFORCEMENT SHALL BE IN

ACCORDANCE WITH ACI-318M, EXCEPT THAT THE MINIMUM LAP SPLICES HALL BE

30.00 - THE FOLLOWING SHALL GOVERN THE DESIGN, FABRICATION AND

3.1 ASSUMED SOIL BEARING CAPACITY SHALL BE 96 KPa (2,000 PSF)

40 BAR DIAMETER BUT NOT LESS THAN 600mm.

CONSTRUCTION OF THE PROJECT.

3.1.1 IN CASE THE ACTUAL SOIL BEARING CAPACITY IS FOUND LESS THE ASSUMED.

96 kPa; NOTIFY THE DESIGNER, BUREAU OF DESIGN FOR PROPER REVISION 4.2.5 DEVELOPMENT LENGTH (Ld) OF REINFORCING BARS SHALL BE AS FOLLOWS:

1.1 NATIONAL STRUCTURAL CODE OF THE PHILIPPINES

5.00 5.00 10.00 5.00 5.00 (N.S.C.P.). VOL.1, 6th EDITION. OF FOUNDATION.

SIZE OF REBARS

10mm

DEVELOPMENT LENGTH

170mm

3.1.2 NO FOOTING SHALL REST ON FILL. 12mm 220mm

2.0 DESIGN CRITERIA 16mm 270mm

3.1.3 BOTTOM OF FOOTING SHALL BE ATLEAST 1.00m. BELOW NATURAL GRADE LINE. 20mm 380mm

2.1 LOADINGS 25mm 600mm

3.1.4 SOIL BEARING CAPACITY SHALL BE INCREASED BY 33 WHEN IN COMBINATION

A. DEAD LOAD WITH SEISMIC OR WIND LOAD. 4.3 STRUCTURAL STEEL

STEEL --76.93kNm 3

3.2 ALL COLUMN FOOTINGS & TIE BEAMS SHALL REST ON 100 mm THK. WELL COMPACTED 4.3.1 ALL STRUCTURAL STEEL SHALL HAVE A MINIMUM YIELD STRESS, Fy = 248MPa (36,000psi)

B. LIVE LOAD

ROOF --0.75kPa GRAVELBASECOURSE.

4.3.2 ALL STRUCTURAL STEEL SHALL BE FABRICATED AND ERECTED IN ACCORDANCE WITH

3.3 BACK FILL SHALL BE PLACED IN LAYER AND EACH LAYER SHALL BE 200 mm THK. AND THE AISC SPECIFICATIONS AND CODE OF STANDARD PRACTICE AS AMMENDED TO DATE.

C. WIND LOAD (NSCP 2010)

SHALL BE COMPACTED TO 95 MAXIMUM DRY DENSITY.

BASIC WIND VELOCITY, V = 150KPH

4.3.3 ALL BOLTS SHALL CONFORM TO ASTMA-307 UNLESS OTHER WISE INDICATED.

P = qh(GCpf)-(GCpi)(DESIGNWINDPRESSURE)

3.4 WHERE LOOSE SOFT MATERIAL IS ENCOUNTERED A TDEPTH OF EMBEDMENT IN DICATED.

WHERE: qh = VELOCITY PRESSURE, kPa

EXCAVATE TO FIRM LAYER AND REPLACE LOOSE MATERIALS UNDER NEATH THE FOOTING 4.3.4 SHOP AND FIELD WELDING SHALL BE IN ACCORDANCE WITH A WSD1.1 AND PERFORMED

GCpf = EXTERNAL PRESSURE COEFFICIENT

WITH IN THE FOOTING AREA PLUS 12 DEPTH OF SOFT MATERIAL ON ALL SIDES WITH BY QUALIFIED WELDERS.

GCpi = INTERNAL PRESSURE COEFFICIENT

SELECT GRANULAR BACKFILL. COMPACT SELECT GRANULAR BACK FILL TO 95 OF

4.3.5 UNLESS OTHER WISE INDICATED, WELDING ELECTRODES SHALL BE E60.

2.2 DESIGN STRESSES MAXIMUM DRY DENSITY.

3.0 MATERIALS 4.3.6 NO STEEL SHALL BE FABRICATED OR ERECTED UNTIL SHOP DRAWING HAVE BEEN

A. CONCRETE

APPROVED BY THE STRUCTURAL ENGINEER.

COMPRESSIVE STRENGTH @ 28 DAYS fc = 20.7 MPa (3,000psi)

A B. REINFORCING BARS

A. FOR BARS 16mm AND GREATER fy = 275 MPa (40,000psi)

4.1 CONCRETE

4.1.1 CONCRETE COVER OVER REINFORCING BARS SHALL BE AS FOLLOWS:

4.3.7 WELDS (CONFORM WITH AMERICAN WELDING STANDARDS) USIN GE60xx ELECTRODES.

4.3.8 ANCHOR BOLTS (CONFORM WITH ASTMA-307) ft = 96.60 MPa. fv = 69 MPa.

a. FOOTINGS, FOOTING - TIE BEAMS (CAST AGAINST EARTH) 75mm

C1F1 C1F1 C1F1 C1F1 C1F1 C1F1 C. STRUCTURAL STEEL, ASTM-A36

b. BEAMS AND COLUMNS (TO STIRRUPS AND TIES) 40mm

FOR TRUSSES, BRACING, & STRUTS fy = 205 MPa (30,000psi)

4.2 REINFORCING BARS

D. PURLINS

COLD FORMED LIGHT CAGE SHAPES fy = 248 MPa( 36,000psi) 4.2.1 ALL REINFORCING BARS SHALL BE CLEAN OF RUST, GREASE OR OTHER MATERIALS

THAT WILL IMPAIR BOND.

E. WELDS - USED E-60xx ELECTRODE

4.2.2 ALL REINFORCING BARS SHALL BE ACCURATELY AND SECURELY PLACED BEFORE

POURING CONCRETE OR APPLYING MORTAR OR GROUT.

D. STRUCTURAL BOLTS. ASTM-A307

a. ft = 96.60 MPa (14,000psi) b. fv = 69 MPa (10,000psi)

4.2.3 LAPPED SPLICES SHALL BE STAGGERED WHERE POSSIBLE.

4 - 20mm VERT. BARS

W/ 10mm TIES @ 0.20m. 200mm B.I. PIPE

SEE PEDESTAL SCHED. 40 FILLED

COLUMN JOINT DETAIL W/ CONCRETE UP

4 - 20mm x 400mm TO GIRT

1 @ 50mm, 3 @ 100mm ANCHOR BOLTS

17.00

EXISTING REST @ 250mm, O.C. 10mm W/ STD.NUTS AND

12.7mm THK. BASE

0.60 WASHERS

PAVEMENT EXISTING FFL.

PLATE FULL WELD

0.50

0.20 NAT. GRND. LINE CEMENTITOUS GROUT

(SELF LEVELING)

0.90 0.40 0.32

0.60

0.80

0.30 EXISTING FFL.

0.20 NAT. GRND. LINE

0.10m. GRAVEL BED

C1F1

C1F1 C1F1 C1F1 C1F1 C1F1 C1F1

B

4-16mm

1.20

VERTICAL BARS

PEDESTAL PIPE

4-12mm VERTICAL BARS

0.35 4 COLUMN JOINT DETAIL

S-1 SCALE 1:20 M.

1 FOUNDATION PLAN 10 - 16mm TEMP.

S-1 SCALE 1:100 M. 1.20 0.35 REBARS SPACED

EQUALLY

12.7mm THK. BASE PLATE BOTHWAYS

0.04 AND STIFFENER 200mm B.I. PIPE

SCHED. 40 FILLED

12.7mmTHK.BASEPLATE W/ CONCRETE UP

FULLWELD TO GIRT

4 - 20mm x 400mm

ANCHOR BOLTS 0.35 PLAN

0.15 W/ STD.NUTS AND

WASHERS 4 - 20mm

W/ 10mm

VERT. BARS

TIES @ 0.20m. 3 COLUMN & FOOTING DETAIL

0.075 S-1 SCALE 1:30 M.

0.35

2 BRACE PLATE DETAIL PLAN

S-1 SCALE 1:10 M.

Republic of the Philippines PROJECT TITLE : SHEET CONTENTS: PREPARED: REVIEWED/SUBMITTED: RECOMMENDING APPROVAL: APPROVAL: SET NO. SHEET NO.

Region X FOUNDATION PLAN

DEPARTMENT OF PUBLIC WORKS AND HIGHWAYS BRACE PLATE DETAIL

CONSTRUCTION OF MULTI - PURPOSE PDS

Misamis Oriental First District Engineering Office COLUMN & FOOTING DETAIL

8

BUILDING PEDESTAL PIPE COLUMN JOINT DETAIL

RIZA B. MAANDIG REY NEIL S. DESABILLE RONALD T. GEMPISAO MARIVEL FRANCES L. ONG, A.E.R. S-1

OFFICE OF THE DISTRICT ENGINEER GENERAL NOTES

12

P-5, BRGY. 26, GINGOOG CITY OIC - Chief, Planning & Design Section Assistant District Engineer District Engineer

BRGY. KAUSWAGAN, BALINGOAN, MISAMIS ORIENTAL Engineering Assistant

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- ATPL Notes - Systems PDFДокумент37 страницATPL Notes - Systems PDFMoslem Grimaldi100% (1)

- U Type Retaining WallДокумент4 страницыU Type Retaining WallAshish G100% (1)

- Mathcad - 02. Analysis of Singly Reinforced Concrete Beam.Документ3 страницыMathcad - 02. Analysis of Singly Reinforced Concrete Beam.MrAlittle FingerОценок пока нет

- 40rr 2pДокумент12 страниц40rr 2pAlejandro Castillo100% (1)

- 1 CompletionDesignДокумент38 страниц1 CompletionDesignMikko Delos ReyesОценок пока нет

- Deck Slab Concreting - Aug 2011Документ11 страницDeck Slab Concreting - Aug 2011AlsonChinОценок пока нет

- UPVC DOORS & WINDOW NewДокумент14 страницUPVC DOORS & WINDOW NewRUSHALI SRIVASTAVAОценок пока нет

- CD 2023Документ14 страницCD 2023Lon OdiОценок пока нет

- MPB Truss Calculator V 1.7Документ12 страницMPB Truss Calculator V 1.7Lon OdiОценок пока нет

- Final Workflow Database Matrix For 2nd Sem - NEW 1Документ44 страницыFinal Workflow Database Matrix For 2nd Sem - NEW 1Lon OdiОценок пока нет

- Almera Brochure 1671423034Документ15 страницAlmera Brochure 1671423034Lon OdiОценок пока нет

- For QuoteДокумент3 страницыFor QuoteLon OdiОценок пока нет

- Dampias EA POWДокумент5 страницDampias EA POWLon OdiОценок пока нет

- Soluto Oct 2022 BrochureДокумент2 страницыSoluto Oct 2022 BrochureLon OdiОценок пока нет

- Cebu Pacific - Print ItineraryДокумент4 страницыCebu Pacific - Print ItineraryLon OdiОценок пока нет

- General Construction NotesДокумент1 страницаGeneral Construction NotesLon OdiОценок пока нет

- Flight Itinerary ReceiptДокумент7 страницFlight Itinerary ReceiptLon OdiОценок пока нет

- Gmail - FWD - Your Itinerary Receipt For Booking No. KBPFXLДокумент5 страницGmail - FWD - Your Itinerary Receipt For Booking No. KBPFXLLon OdiОценок пока нет

- Dimensions of Equal Angle BarsДокумент7 страницDimensions of Equal Angle BarsLon OdiОценок пока нет

- Construction of Multi-Purpose Building (27.6m X 17.7m), Excluding Electrical and Drainage/Plumbing WorksДокумент12 страницConstruction of Multi-Purpose Building (27.6m X 17.7m), Excluding Electrical and Drainage/Plumbing WorksLon OdiОценок пока нет

- MOFDEO RC Members REPORTДокумент61 страницаMOFDEO RC Members REPORTLon OdiОценок пока нет

- Two Way Slab Analysis: DL LLДокумент4 страницыTwo Way Slab Analysis: DL LLLon OdiОценок пока нет

- MOFDEO RC Members OUTPUTДокумент251 страницаMOFDEO RC Members OUTPUTLon OdiОценок пока нет

- Exect SUMДокумент1 страницаExect SUMLon OdiОценок пока нет

- Structural Analysis & DesignДокумент2 страницыStructural Analysis & DesignLon OdiОценок пока нет

- Bill of Quantities: 1,327,636.37 75 CD Item No. Description Qty Unit Unit Price Amount (Pesos)Документ1 страницаBill of Quantities: 1,327,636.37 75 CD Item No. Description Qty Unit Unit Price Amount (Pesos)Lon OdiОценок пока нет

- Basic UI AutoCADДокумент1 страницаBasic UI AutoCADLon OdiОценок пока нет

- Resignation Labis Surveying OfficeДокумент1 страницаResignation Labis Surveying OfficeLon OdiОценок пока нет

- Experiment 13-Unconfined CompressionДокумент13 страницExperiment 13-Unconfined CompressionMuhammad LutfiОценок пока нет

- Miss Silka Cagayan Application FormДокумент2 страницыMiss Silka Cagayan Application FormLon OdiОценок пока нет

- Fracture GradientДокумент144 страницыFracture GradientPrasanti Plaban DashОценок пока нет

- Analysis and Design of Singly Reinforced BeamДокумент2 страницыAnalysis and Design of Singly Reinforced BeamLouise DiazОценок пока нет

- B31.3 Process Piping Course - 04 - PressureDesignofMetalsДокумент28 страницB31.3 Process Piping Course - 04 - PressureDesignofMetalslyesОценок пока нет

- Standard Notes CBE29-3 Construction in Civil Engineering 20150222Документ37 страницStandard Notes CBE29-3 Construction in Civil Engineering 20150222Genie LoОценок пока нет

- Lesson 1 - CE Laws, Contracts and EthicsДокумент23 страницыLesson 1 - CE Laws, Contracts and EthicsJohn Rodolfo BultronОценок пока нет

- Vernacular Terms in Philippine ContructionДокумент16 страницVernacular Terms in Philippine Contructionjoana quiambaoОценок пока нет

- Intze TankДокумент20 страницIntze Tankrascad111Оценок пока нет

- Inplant TrainingДокумент19 страницInplant TrainingKlien ParkerОценок пока нет

- Installation Mantainance ManualFan CoilYEKN YGKNДокумент19 страницInstallation Mantainance ManualFan CoilYEKN YGKNJavier SosaОценок пока нет

- Shaft Failure Journal PDFДокумент7 страницShaft Failure Journal PDFBahim BahimanОценок пока нет

- Description Dr. Fixit Pidifin 2KДокумент4 страницыDescription Dr. Fixit Pidifin 2KshashiОценок пока нет

- Assignment 1 ChitrakshiiДокумент15 страницAssignment 1 ChitrakshiichitrakshiОценок пока нет

- Modelling of A Windcatcher For Natural VentilationДокумент7 страницModelling of A Windcatcher For Natural Ventilationmohammad mejoОценок пока нет

- Design of Square Footing (With or Without Moment)Документ13 страницDesign of Square Footing (With or Without Moment)Ella Clent moralesОценок пока нет

- Design of Compression MembersДокумент22 страницыDesign of Compression MembersChee Fong MakeОценок пока нет

- Rural Road DesignДокумент142 страницыRural Road DesignELAYATHAMBY SURENDRAОценок пока нет

- AVK SVMC Pipe Joints BrochureДокумент25 страницAVK SVMC Pipe Joints BrochureImtiyaz KhanОценок пока нет

- Ce 55 Group 4 ReportДокумент41 страницаCe 55 Group 4 ReportCj GuerreroОценок пока нет

- Fresh and Mechanical Properties of Basalt Fiber Reinforced ConcreteДокумент7 страницFresh and Mechanical Properties of Basalt Fiber Reinforced ConcreteОлег ШибекоОценок пока нет

- Jiroga Weir SchemeДокумент10 страницJiroga Weir SchemeShashi PrakashОценок пока нет

- Assignment 7Документ4 страницыAssignment 7mahakОценок пока нет

- Saudi Aramco Oil Company: SECTION 07820 Skylights Part 01 - General 1.01 Section IncludesДокумент8 страницSaudi Aramco Oil Company: SECTION 07820 Skylights Part 01 - General 1.01 Section Includessaneela bibiОценок пока нет

- Specifications: Cold Rooms and Freezer RoomsДокумент1 страницаSpecifications: Cold Rooms and Freezer RoomsOsama merganiОценок пока нет