Академический Документы

Профессиональный Документы

Культура Документы

Tabla de Fuerzas Medidor de Tensión de Fajas PDF

Загружено:

Luis CaballeroОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tabla de Fuerzas Medidor de Tensión de Fajas PDF

Загружено:

Luis CaballeroАвторское право:

Доступные форматы

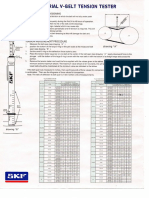

INDUSTRIAL V-BELT TENSION TESTER

G E N E R A L RULES OF T E N S I O N I N G

1. Ideal tensin is the lowest tensin at which the belt will not slip under peak

load conditions

2. Check the belt tensin frequently during the first 24 to 48 hours of operation.

3. Over tensioning will shorten the life of the belt and the bearings.

4. Keep belts free from foreign material which may cause slip.

5. Make V-belt drive inspections periodically and re-tension as required. This will

prevent slippage and optimize belt life.

6. S K F does not recommend belt dressing as this will damage the belt and

promote premature failures.

TENSION M E A S U R E M E N T PROCEDURE

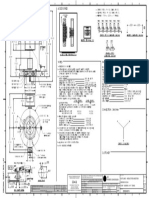

1. Measure the belt span (see drawing " A " )

Deilection 2. position the bottom of the large 0 ring on the pen scale at the measured belt drawing " A "

Forc span (see drawing " B " )

Scale

3. Set the small 0 ring on the deflection forc scale to zero.

4. Place the tensin tester squarely on one belt at the center of the belt span (see drawing " A " )apply downward forc to the

Small plunger until the bottom of the large 0 ring is even with the next belt or with the bottom of a straight edge laid across the

"O" Ring

pulleys.

5. Remove the tensin tester and read the forc applied with the vales given in the tables. The forc should be between the

minmum and the mximum shown. The mximum valu shown is for new belts, this will allow for anticipated tensin loss.

Used belts should be maintained at the mnimum valu as indicated n the tables.

If the belt span was measured in inches, then use the pounds of forc vales for comparison. If the belt span was measured

in centimeters. Then use the kilograms of forc vales for comparison.

Note: The ratio of deflection to belt span is 1:64 in either units of measurements.

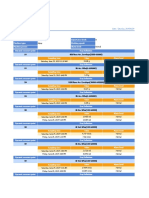

PULLEY DIAMETER IN INCHES PULLEY DIAMETER IN MILLIMETERS

DEFLECTION FORCE IN LBS DEFLECTION FORCE IN NG

Belt deflection forc LBS Belt deflection forc KG

Smallsst Pul ley Dia meter Smallest Pulley Diameter

Belt Type RPM Range Un-Cogged Belts Cogged Belts Belt Type RPM Range Un-Cogged Belts Cogged Belts

Inches Millimelers

Used Belt New Belt Used Belt New Belt Used Belt New Belt Used Belt New Belt

1000-2500 1.2 1.7 1.3 2.0 100D-2500 0.5 0.8 0.6 0.9

1.5-2.5 40-60

2501-4000 1.4 2.1 1.6 2.4 2501-4000 0.6 1.0 0.7 1.1

Z,ZX Z, ZX

1000-2500 2.0 2.2 3.4 1000-2500 0.9 1.3 L.O 1.5

2.5-Over 60 over

2501-4000 2 0 2.2 3.4 2501-4000 0.9 1.3 1.0 1.5

1000-2500 3.7 4.1 6.1 1000-2500 1.7 2.5 1.9 2.3

3.0-3.6 75-90

'2501-4000 2.8 4.2 3.4 5.0 2501-4000 1.3 T.B 1 < 2.3

1000-2500 4.5 5.0 7.4 1000-2500 2.0 3.1 2.3 3.4

A, AX 3.8-4.6 A,AX 91-120

i - 4.3 6.4 1.7 26 2.0 2.9

1000-2500 5 '- 5.7 8.4 2.4 i.E 2.6 3.8

50-over 121-175

2501-4000 4.7 5.1 7.6 - 2 ; 3.4

860-2500 4.9 7.2 860-2500 2.2 3.3

3.4-4.2 85-105

2501-4000 4.2 6.2 2501-4000 1.9 2.8

860-2500 7.1 10.5 860-2500 2.4 3.6 3.0 4.8

8. BX 4,4-5.6 B, BX 106-140

2501-4000 45 6.1 9.1 2501-4000 2.0 '3.0 2.8 4.1

860-2500 6.3 8.5 12.6 860-250C 2.9 4.3 3.9 57

5.8-over 141-220

2501-4000 60 7.3 10.9 2501-4000 2.7 i :: 3.3 4.9

500-1740 11.5 17.0 14.7 21.8 500-1740 5.2 7.7 6.7 9.9

7.Q-S.0 175-230

1741-3000 4 13.8 ' 9 17.5 1741-3000 4.3 - 3 5.4 7.9

c, ex c, ex

500-1740 14 1 21.0 15.9 23.5 -' -i

7 6.4 'i 5 7.2 107

9.5-over 231400

12.5 18.5 14.6 21.6 ^4--3c:o 5.7 ; - 6.6 9.8

12.0-16.0

200-850 24.9 37.0 -

305-400

200-850 11.3 16 8

-

851-1500 21.2 31.3 851-1500 9.6 14.2

D D

200-850 30.4 45.2 200-850 13.8 20.5

18.0-over 401-510

851-1500 25.6 38.0 851-1500 11,6 11

1000-2500 3.8 4.1 6.1 1000-2500 1.7 2.7 1.9 2.8

1.5-2.5 56-79

2501-4000 3.0 3.4 49 2501-4000 1.3 : 2 1 5 2.2

1000-2500 4.3 4.9 7.4 1000-2500 2.0 3.7 2.2 3.4

SPZ.XPZ 2.5.-3 SPZ.XPZ 80-95

2501-4000 4.7 4.7 7.2 2501-4000 2.1 i 3 2.1 3.3

1000-2500 5.4 5.6 8.5 1000-2500 2.4 : 2.6 3.9

3-over 95 over

2501-4000 4.8 5.3 8.1 25C'-C30 2.2 : 4 2.4 3.7

i=: 6.5 7.4 11.2 2.9 4.4 3.4 5.1

3.8-4.1 71-105

5.9 6.7 10.0 2.7 4.0 3.1 4.6

1000-2500 7.8 11.7 9.0 13.5 3.6 5.3 4.1 6.1

SPA.XPA 4.1-5.5 SPA.XPA 106-140

2501-4000 7.1 10.6 8.1 12.1 2501-4000 3.2 4 8 3.7 5.5

1000-2500 9.8 14.9 11.2 17.1 1000-2500 4.5 6 8 5.1 7.8

5.5-over

2501-4000 14,8 10 1 15.3 over 2501-4000 4.5 6.7 4.6 6.9

860-2500 11.0 16.4 12.6 18.9 860-2500 5.0 7.5 5.7 8.6

3.4-4.2 107-158

2501-4000 10.6 15.9 12.1 18.2 2501-4000 4.8 7 2 5.5 8.3

860-2500 14.2 21.1 16.2 24.3 - %25X 6.4 y6 7.3 11.0

SPB.XPB 4.4-5.6 SPB,XPB 160-250

iy.--i-.:: 12.6 18 9 15.0 22.5 25014000 5.7 S 6 6.8 10.2

25.2 18.0 27.0 860-2500 7.7 11.4 8.2 12.2

5.8-over 250 over

- 14.4 21.6 16.4 24.7 25-;---C: 6.5 9.8 7.4 11.2

500-1740 22.8 34.1 26.1 39.1 500-1740 10.4 15.5 11.6 17.7

7.0-9.0 200-355

23.0 34.6 26.3 39.7 1741-3000 10.5 15 11.9 18.0

SPC.XPC SPC.XPC

500-1740 2b I) 38.8 29.7 44.5 500-1740 11.8 17.6 13.5 20.2

9.5-over 356 over

1741-3000 30.1 45.0 34.4 51.7 1741-3000 13.7 20 ! 15.6 23.5

1000-2500 3.3 4.9 1000-2500 1.5 2.2

2.2-2.4 55-60

2501-4000 2.9 4.3 2501-4000 1.3 2.0

1000-2500 5.1 4.2 6.2 1000-2500 1.6 2.3 1.9 2.8

3V.3VX 2.65-3.65 3V.3VX 61-90

2501-4000 4.4 3.8 5.6 25014000 1.4 2.0 1.7 2.5

1000-2500 4.9 7.3 5.3 79 1000-2500 2.2 3.3 2.4 3.6

4,2-0,., 91-175

4.4 66 4.9 7.3 25014000 2.0 i 2.2 3.3

9.4 15.2 1000-2500 4.6 6.9

4.4-6.7 110-170

2501-4000 6.2 13.2 25014000 2.5 3.9

12.7 18 9 14.8 8.5 500-1740 5.8 8.6 6.7 10.0

5V.5VX 7.1-10.9 5V.5VX 171-275

1741-3001 11.2 16.7 13.7 22.1 1741-3001 5.1 7.6 6.2 9.1

11.8-over

500-1740 15.5 23.4 17.1 20.1

278-400

500-1740 7.0 io.fi! 7.8 11.6

1741-3001 14.6 21.8 16.8 25.5 1741-3001 6.6 3.9 7.6 11.3

200-850 33.0 49.3 200-850 15.0 22.4

12,5-17.0 315-430

851-1500 26.8 39.9 851-1500 12.2 18.1

8V 8V

200-850 39.6 59.2 200-850 18.0 2b 8

,8 ,- o v ,r 431-570

851-1500 35.3 52.7 851-1500 16.0 23 9

-

Вам также может понравиться

- SKF TMEA2manualДокумент378 страницSKF TMEA2manualLeon Montana100% (2)

- SK 19517Документ2 страницыSK 19517Carey C Jones100% (1)

- Tabla de Fuerzas Medidor de Tensión de FajasДокумент1 страницаTabla de Fuerzas Medidor de Tensión de Fajasmatrix1x100% (1)

- Rovalve PDFДокумент4 страницыRovalve PDFWilliam ValenciaОценок пока нет

- Semi-Topping Shaper CuttersДокумент4 страницыSemi-Topping Shaper CuttersalemarlonstosОценок пока нет

- Complete Catalogue Gear Couplings JaureДокумент48 страницComplete Catalogue Gear Couplings JaureJorge Franco Zapata0% (1)

- Manual Reductor LightninДокумент74 страницыManual Reductor LightninHernan100% (3)

- Tabla de Severidad Unidades SullairДокумент1 страницаTabla de Severidad Unidades Sullairlambjabibi100% (1)

- Dodge Txt8a - Dimensiones y PesoДокумент2 страницыDodge Txt8a - Dimensiones y PesomazzingerzОценок пока нет

- ROTALIGN Ultra System ManualДокумент30 страницROTALIGN Ultra System ManualFranco Taday100% (1)

- Falk V Class Type VP, Sizes 133 187 Shaft Drives Parts ManualДокумент4 страницыFalk V Class Type VP, Sizes 133 187 Shaft Drives Parts ManualNils Ericsson Sánchez HuayanaОценок пока нет

- DG Pump Catalague PDFДокумент20 страницDG Pump Catalague PDFJonas ArifinОценок пока нет

- SKF Industrial V Belt Tension Tester PDFДокумент3 страницыSKF Industrial V Belt Tension Tester PDFVeeresh nayakОценок пока нет

- 4.1.5 Newton's Laws of MotionДокумент30 страниц4.1.5 Newton's Laws of MotionjleodennisОценок пока нет

- Manual de Overhaul Io-520Документ133 страницыManual de Overhaul Io-520Alfredo Ergueta CorilaОценок пока нет

- Catalogo General Chumaceras Dodge SAF XTДокумент8 страницCatalogo General Chumaceras Dodge SAF XTingrivera13Оценок пока нет

- Fenner Belt Tension Pen Data Sheet PDFДокумент2 страницыFenner Belt Tension Pen Data Sheet PDFSadi KutkutОценок пока нет

- VIBXPERT II Balancing Manual en 052012Документ46 страницVIBXPERT II Balancing Manual en 052012luismariogallego50% (2)

- Involute Splines: According To DIN 5482Документ2 страницыInvolute Splines: According To DIN 5482ehtisham khanОценок пока нет

- Runout: GD&T Symbol: Relative To Datum MMC or LMC Applicable: Drawing CalloutДокумент6 страницRunout: GD&T Symbol: Relative To Datum MMC or LMC Applicable: Drawing CalloutanishОценок пока нет

- Eaton Vickers PVH Variable Axial Piston Pump: Industrial Applications Mobile ApplicationsДокумент9 страницEaton Vickers PVH Variable Axial Piston Pump: Industrial Applications Mobile ApplicationsPedro LandazuriОценок пока нет

- 2400 Service PresentationДокумент24 страницы2400 Service PresentationJuan Gabriel Pari ChipanaОценок пока нет

- Vibration Pen Plus PDFДокумент4 страницыVibration Pen Plus PDFPablo Hidalgo RíosОценок пока нет

- Maryland Metrics - Thread Data ChartsДокумент3 страницыMaryland Metrics - Thread Data ChartsLal KishanОценок пока нет

- Catalogo Rotulas IKOДокумент14 страницCatalogo Rotulas IKOpedroОценок пока нет

- FlenderДокумент384 страницыFlenderAnis Kurniawati100% (1)

- Shaft AlignmentДокумент4 страницыShaft AlignmentmokarahОценок пока нет

- Standard Torque Values - Metric SystemДокумент1 страницаStandard Torque Values - Metric SystemHassan Sleem100% (1)

- Belt Tension RequiredДокумент2 страницыBelt Tension RequiredJinto A J100% (3)

- Mining Industry Gear Units for Conveyor BeltsДокумент5 страницMining Industry Gear Units for Conveyor BeltsZahir KhiraОценок пока нет

- 378 200 Falk Quadrive Model A, Sizes 5107 5315 Shaft Mounted Gears Owners ManualДокумент52 страницы378 200 Falk Quadrive Model A, Sizes 5107 5315 Shaft Mounted Gears Owners ManualRemmaq MoreliaОценок пока нет

- Digital Tachometer ManualДокумент12 страницDigital Tachometer ManualBaneMarkovicОценок пока нет

- FL SmidthДокумент4 страницыFL SmidthTanmay MajhiОценок пока нет

- Safe Seal ScanpumpДокумент4 страницыSafe Seal ScanpumpHector MaldonadoОценок пока нет

- 25713-220-V2A-MPY0-00089 Manual Giw Español PDFДокумент271 страница25713-220-V2A-MPY0-00089 Manual Giw Español PDFFERNANDA ARLETTIS TORRESОценок пока нет

- Laser Rotary Device ManualДокумент10 страницLaser Rotary Device Manualvajaterp2010Оценок пока нет

- Pulley Alignment ProceduДокумент9 страницPulley Alignment ProceduJosh Watts100% (2)

- Metric Thread - Extended Thread Size RangeДокумент20 страницMetric Thread - Extended Thread Size Rangerickscribd33100% (1)

- TV Mas en 3Документ23 страницыTV Mas en 3Rendra ArdyantoОценок пока нет

- 13 Ways To Kill A Mechanical Seal FINALДокумент16 страниц13 Ways To Kill A Mechanical Seal FINALRanjit Koshy AlexanderОценок пока нет

- Alignment Using LaserДокумент14 страницAlignment Using LaserJessie DomingoОценок пока нет

- Eaton AirflexДокумент12 страницEaton AirflexagusОценок пока нет

- Gear Box InspДокумент19 страницGear Box InspdombipinОценок пока нет

- Guomao GroupДокумент15 страницGuomao GroupArnaldo Macchi Millan100% (1)

- Vibrating Screen QAP-17Документ8 страницVibrating Screen QAP-17Mohammad AdilОценок пока нет

- PhospateДокумент2 страницыPhospateMuhammad RidwanОценок пока нет

- Manual TMEA 2-EN PDFДокумент35 страницManual TMEA 2-EN PDFfacundo100% (1)

- Seal Types & Gland Design: Major ClassificationsДокумент6 страницSeal Types & Gland Design: Major ClassificationsvinothОценок пока нет

- Installation Procedure - RFN 7012Документ3 страницыInstallation Procedure - RFN 7012Barry ChungОценок пока нет

- SKF Belt Tensioning PDFДокумент27 страницSKF Belt Tensioning PDFAdrian CantaragiuОценок пока нет

- Example Alignment Report PDFДокумент11 страницExample Alignment Report PDFdg_cd7340Оценок пока нет

- Rim Face V Bs Dial On MovableДокумент1 страницаRim Face V Bs Dial On MovablereiОценок пока нет

- Fenner Taper Lock Bush CatalogueДокумент3 страницыFenner Taper Lock Bush CatalogueKeshav ChhawchhariaОценок пока нет

- 2013 SKF Training Handbook: Reliability Maintenance InstituteДокумент134 страницы2013 SKF Training Handbook: Reliability Maintenance InstituteBalázs HernádiОценок пока нет

- Alignment Protocol: Siemens LTDДокумент6 страницAlignment Protocol: Siemens LTDhalder_kalyan9216100% (2)

- High Performance Turning CenterДокумент24 страницыHigh Performance Turning CenterTombongОценок пока нет

- Product Catalogue: Page Summary TableДокумент22 страницыProduct Catalogue: Page Summary TableJhon ConnorОценок пока нет

- Unidad Hidraulica MPДокумент77 страницUnidad Hidraulica MPGustavo Nina100% (2)

- TYPE 8B1/8B1T: Elastomer O-Ring SealsДокумент6 страницTYPE 8B1/8B1T: Elastomer O-Ring SealshukОценок пока нет

- Belt Tension Gauge InstructionsДокумент2 страницыBelt Tension Gauge InstructionsTodor HuklevОценок пока нет

- V-Belt Installation-Maintenance-StorageДокумент7 страницV-Belt Installation-Maintenance-StoragedzkamiraОценок пока нет

- Industrial belt tension tester guideДокумент3 страницыIndustrial belt tension tester guidedaniel castilloОценок пока нет

- Zebra XSLATE R12 Rugged Tablet: The Tablet That Transforms To Match Your Work Style. Rugged RedefinedДокумент4 страницыZebra XSLATE R12 Rugged Tablet: The Tablet That Transforms To Match Your Work Style. Rugged RedefinedLuis CaballeroОценок пока нет

- Processes: Chemical IndustrialДокумент16 страницProcesses: Chemical IndustrialLuis CaballeroОценок пока нет

- Low Frequency Machinery Monitoring - Measurement ConsiderationsДокумент18 страницLow Frequency Machinery Monitoring - Measurement Considerationsluciano GarciaОценок пока нет

- Zebra XSLATE B10 Rugged Tablet: Product SpecificationsДокумент2 страницыZebra XSLATE B10 Rugged Tablet: Product SpecificationsLuis CaballeroОценок пока нет

- AFP FilterPress Brochure PDFДокумент4 страницыAFP FilterPress Brochure PDFMilan SjausОценок пока нет

- L16-04 - 373 - Barth - Uni Kaiserslautern - GermanyДокумент11 страницL16-04 - 373 - Barth - Uni Kaiserslautern - GermanyLuis CaballeroОценок пока нет

- AHLSTAR End Suction Single Stage Centrifugal PumpsДокумент24 страницыAHLSTAR End Suction Single Stage Centrifugal PumpsLuis CaballeroОценок пока нет

- Circuit Note: IEPE-Compatible Interface For Wideband MEMS Accelerometer SensorsДокумент6 страницCircuit Note: IEPE-Compatible Interface For Wideband MEMS Accelerometer SensorsLuis CaballeroОценок пока нет

- 2001 01 26 Vanhala e PDFДокумент3 страницы2001 01 26 Vanhala e PDFLuis CaballeroОценок пока нет

- Essa® Certified Pressure Filters: Reason For The RedesignДокумент10 страницEssa® Certified Pressure Filters: Reason For The RedesignLuis CaballeroОценок пока нет

- Filtration Products: Todd Wisdom +1-801-871-7422 Todd Wisdom +1-801-871-7422Документ46 страницFiltration Products: Todd Wisdom +1-801-871-7422 Todd Wisdom +1-801-871-7422Luis CaballeroОценок пока нет

- Overall: - Severity Data Rejilla 2Документ1 страницаOverall: - Severity Data Rejilla 2Luis CaballeroОценок пока нет

- Concepts in Coal Refuse Dewatering - r1Документ17 страницConcepts in Coal Refuse Dewatering - r1Luis CaballeroОценок пока нет

- Installation, Operation & Maintenance Manual: Covers ModelsДокумент60 страницInstallation, Operation & Maintenance Manual: Covers ModelsLuis CaballeroОценок пока нет

- Essa® Certified Pressure Filters: Reason For The RedesignДокумент10 страницEssa® Certified Pressure Filters: Reason For The RedesignLuis CaballeroОценок пока нет

- Strike-Bar Crusher - Draft1Документ5 страницStrike-Bar Crusher - Draft1Luis CaballeroОценок пока нет

- Industrial Videoscope Super Image QualityДокумент16 страницIndustrial Videoscope Super Image QualityLuis CaballeroОценок пока нет

- ReadmeДокумент4 страницыReadmeRenato LuzОценок пока нет

- Valor PromedioДокумент2 страницыValor PromedioLuis CaballeroОценок пока нет

- 2DRE Technical CatalogueДокумент20 страниц2DRE Technical CatalogueLuis CaballeroОценок пока нет

- GE Power Conversion: KVAF - 8339P30 - 4P - TEAACДокумент1 страницаGE Power Conversion: KVAF - 8339P30 - 4P - TEAACLuis CaballeroОценок пока нет

- Tofd & Pe ReportДокумент1 страницаTofd & Pe ReportLuong Ho VuОценок пока нет

- Suction-Specific Speed:: Questions and Answers About Pumping's Least Understood MeasureДокумент5 страницSuction-Specific Speed:: Questions and Answers About Pumping's Least Understood MeasureLuis Joel Ramos RamosОценок пока нет

- OEM Viscosity Compensated Flowmeter Model VKA Specs & DetailsДокумент2 страницыOEM Viscosity Compensated Flowmeter Model VKA Specs & Details王敏Оценок пока нет

- Assignment #3Документ2 страницыAssignment #3Choa Pei ShuangОценок пока нет

- Service & Maintenance Manual for 260MRT Aerial LiftДокумент110 страницService & Maintenance Manual for 260MRT Aerial LiftКосОценок пока нет

- Stability Analysis of Columns With Variable Cross-Sections 1st Two Pages Placed LastДокумент12 страницStability Analysis of Columns With Variable Cross-Sections 1st Two Pages Placed LastIntishar RahmanОценок пока нет

- Simple Stress: Simple Stresses Are Expressed As The Ratio of The Applied Force Divided by The Resisting Area orДокумент36 страницSimple Stress: Simple Stresses Are Expressed As The Ratio of The Applied Force Divided by The Resisting Area orEric UrrizaОценок пока нет

- 1190 1Документ88 страниц1190 1TONОценок пока нет

- Wagner Brake Supplemental Catalog 4-2-02Документ72 страницыWagner Brake Supplemental Catalog 4-2-02Edinson Camba NucetteОценок пока нет

- Simple Machines TestДокумент7 страницSimple Machines TestAlyanna CrisologoОценок пока нет

- Ape City March 2013Документ60 страницApe City March 2013DEEPAKОценок пока нет

- Kirloskar SP 3HH Leaflet (A)Документ2 страницыKirloskar SP 3HH Leaflet (A)Imran_firdousiОценок пока нет

- P730 Brochure ENДокумент2 страницыP730 Brochure ENVictor GalarzaОценок пока нет

- Carbon-Carbon CompositesДокумент12 страницCarbon-Carbon CompositesSONU KUMARОценок пока нет

- Archimedes and BuoyancyДокумент2 страницыArchimedes and Buoyancyromaehab201912Оценок пока нет

- TAPPI TIP-0402-27 Continuous Dig Insp Rev 2005Документ11 страницTAPPI TIP-0402-27 Continuous Dig Insp Rev 2005a_parrat100% (2)

- A Mechanical Engineer S Handbook by ONGC PDFДокумент303 страницыA Mechanical Engineer S Handbook by ONGC PDFshujad77Оценок пока нет

- Volvo 242 244 245 Owners Manual 1976Документ105 страницVolvo 242 244 245 Owners Manual 1976Leif AndersonОценок пока нет

- Owner'S Manual & Competition Handbook Competition HandbookДокумент164 страницыOwner'S Manual & Competition Handbook Competition HandbookAgape SniperОценок пока нет

- Rolled Alloy ElectrodesДокумент12 страницRolled Alloy ElectrodesradenmuhaiminОценок пока нет

- Mechanical, Physical and Wear Properties of PP-SCF CompositesДокумент11 страницMechanical, Physical and Wear Properties of PP-SCF CompositesHarriJunaediОценок пока нет

- Aprilia Parts CatalogДокумент126 страницAprilia Parts CatalogyokoОценок пока нет

- General Online QuestДокумент80 страницGeneral Online QuestPankaj PooniaОценок пока нет

- Technical Description MPPUДокумент10 страницTechnical Description MPPUNinaОценок пока нет

- Gunsmithing and Tool Making Bible by Harold HoffmanДокумент294 страницыGunsmithing and Tool Making Bible by Harold HoffmanS Lucian Stefan100% (2)

- Fixed Free Fixed Free Plate PDFДокумент7 страницFixed Free Fixed Free Plate PDFbeenaОценок пока нет

- Geankoplis 2.6-4 2.7-4Документ7 страницGeankoplis 2.6-4 2.7-4BenePicarОценок пока нет