Академический Документы

Профессиональный Документы

Культура Документы

Understanding Advanced Drilling Techniques

Загружено:

Anonymous H9n5g3aaCEОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Understanding Advanced Drilling Techniques

Загружено:

Anonymous H9n5g3aaCEАвторское право:

Доступные форматы

www.senergyworld.

com/training

Understanding advanced

drilling techniques

Aims

The course is ideal for industry professionals who wish to expand

their knowledge of the following Advanced Drilling Techniques

(ADT):

Coil Tubing Drilling (CTD)

Managed Pressure Drilling (MPD)

Underbalanced Drilling (UBD)

Through Tubing Drilling (TTRD)

This independent course explains how these technologies can help

overcome drilling issues and maximise potential economic returns

in depleted and brown fields. Participants gain a unique insight into

advanced drilling techniques through the practical integration of

theory and actual drilling data, reinforced by the extensive use of

real case studies from throughout the world.

Who Should Attend?

Benefits Well engineers, reservoir engineers, production and completion

The participants will gain an appreciation of: engineers, and other industry professionals eager to enhance their

practical understanding of advanced drilling techniques.

advanced drilling techniques

Duration - 3 days

where they are applicable

how to select the right technique for:

Course Instructor

well design

Joy Oyovwevotu is the Principal Drilling Engineer for the Advanced

HSE issues Drilling Techniques (ADT) department within Senergy. He has over

20 years operator and service company experience during which

completion philosophies

time he has held various senior drilling engineering positions

downhole equipment issues spanning well planning, design and execution both on and offshore.

surface equipment design Joy has planned and executed numerous ADT projects where he

has been responsible for a number of world and industry firsts

economics

in expanding the technical and technology envelope for drilling

and completing ADT wells. The workflows used in these projects

- from candidate selection and feasibility through to planning and

execution - provide the framework for this introductory course.

Topics

Coil Tubing Drilling Engineering and Modelling

advantages and limitations tubing forces

string design and selection tubing wear

fatigue wellhead load

candidate selection drilling fluid design

Coil Tubing Drilling Equipment hydraulics and cuttings transport

surface equipment cementing

downhole equipment Drill String

platform modifications drill string design

Fluid Design drill string components

fluid design and properties BHA selection

fluid selection criteria Surface Equipment

hydraulics and hole cleaning fluid handling

UBD / MPD pipe handling

advantages and limitations derrick issues

differences and similarities rig/platform modifications

Reservoir Issues Well Control

formation damage and skin BOP requirements

wellbore stability early kick detection systems

Fluid Selection kick tolerance considerations

UBD / MPD single phase fluids well kill options

UBD / MPD multiphase fluids Sidetracking

Hydraulics and hole cleaning fundamentals and options

Down Hole Equipment whipstock design

BHA systems Completions

completion challenges completion philosophy

deployment systems technology enablers

Surface Equipment HSE Issues

gas systems risk identification and management

well control equipment generic and application-specific safety issues

surface separation equipment environmental considerations

corrosion issues Case Studies

Thru-Tubing Rotary Drilling subsea TTRD

advantages and limitations onshore CT UBD

Tubing wear / completion damage platform based CT MPD

drill pipe selection platform TTRD

drill pipe fatigue

Candidate Selection

well planning www.senergyworld.com/training

reservoir target selection

Contact Beth Reid, Training Administrator

current well status E: technical.training@senergyworld.com

well planning

Senergy Training Centre 102 West Port

Edinburgh EH3 9DN United Kingdom

T: +44 1330 825188

F: +44 1330 825206

United Kingdom Norway Middle East India Africa Asia Pacific Americas

Oil & Gas Survey & GeoEngineering Alternative Energy Software Training SENTRA-33263-0812

Вам также может понравиться

- Drilling Program OverviewДокумент12 страницDrilling Program OverviewMas KuncritОценок пока нет

- Minor II Mid Review - FinalДокумент10 страницMinor II Mid Review - FinalArsh Attri100% (1)

- AC-0049 Well Design RulesДокумент5 страницAC-0049 Well Design RulesairlinemembershipОценок пока нет

- Dan 3Документ14 страницDan 3Adanenche Daniel EdohОценок пока нет

- Pore Pressure, Fracture Gradient & Leak Off Test GuideДокумент33 страницыPore Pressure, Fracture Gradient & Leak Off Test GuidePipinRioSianturi100% (1)

- Develop Your Kuji In Ability in Body and MindДокумент7 страницDevelop Your Kuji In Ability in Body and MindLenjivac100% (3)

- DRILLING TECHNOLOGY MODULEДокумент2 страницыDRILLING TECHNOLOGY MODULErckongc6631Оценок пока нет

- Mitigation of Production ProblemsДокумент16 страницMitigation of Production ProblemsShubham GuptaОценок пока нет

- EOR Methods GuideДокумент109 страницEOR Methods GuideKarwan DilmanyОценок пока нет

- M SC Petroleum Engineer 2Документ3 страницыM SC Petroleum Engineer 2anouari2014Оценок пока нет

- Horizontal WellsДокумент28 страницHorizontal Wellsjibada123Оценок пока нет

- Key Issues in Multilateral Technolog 1668247705Документ55 страницKey Issues in Multilateral Technolog 1668247705Dhani de EngineurОценок пока нет

- Managed Pressure Drilling & Underbalanced Operations: Platinum SponsorsДокумент4 страницыManaged Pressure Drilling & Underbalanced Operations: Platinum SponsorsSyed IrtazaОценок пока нет

- Mud Losses PDFДокумент67 страницMud Losses PDFMohamed KouchacheОценок пока нет

- Casing SeatДокумент16 страницCasing SeatAОценок пока нет

- Wellbore Stability Analysis with PSI SoftwareДокумент2 страницыWellbore Stability Analysis with PSI SoftwareNagaLangit69Оценок пока нет

- Formation Evaluation Homework 1Документ6 страницFormation Evaluation Homework 1Noman RazaОценок пока нет

- Wax RemediationДокумент3 страницыWax RemediationDonna GrayОценок пока нет

- 1 - Introduction To Advanced Drilling EngineeringДокумент40 страниц1 - Introduction To Advanced Drilling EngineeringAli AbdullahОценок пока нет

- Introduction To Thermal RecoveryДокумент49 страницIntroduction To Thermal RecoveryShely RiveraОценок пока нет

- A Guide To Understanding Rotary Steerable Technology: Baker Hughes INTEQДокумент8 страницA Guide To Understanding Rotary Steerable Technology: Baker Hughes INTEQdiegoilОценок пока нет

- Underbalanced Drilling Techniques for Enhanced Oil RecoveryДокумент13 страницUnderbalanced Drilling Techniques for Enhanced Oil RecoveryZiad AouichatОценок пока нет

- Software AДокумент35 страницSoftware Amelkady2020Оценок пока нет

- Air Compressors 1170cfm T4Документ2 страницыAir Compressors 1170cfm T4death666darkОценок пока нет

- GOS Lithology and Drilling Problems PanelДокумент1 страницаGOS Lithology and Drilling Problems PanelMohamed Mokhtar100% (1)

- Drilling Formulas Calculation Sheet Verson 1.4Документ190 страницDrilling Formulas Calculation Sheet Verson 1.4Adedire FisayoОценок пока нет

- What Is Dissolved Gas AnalysisДокумент5 страницWhat Is Dissolved Gas AnalysisselvamuthukumarОценок пока нет

- WELLFLO Oil and Gas Well Design Software - Well Engineering SoftwareДокумент2 страницыWELLFLO Oil and Gas Well Design Software - Well Engineering SoftwareagrajitОценок пока нет

- 1 Reservoir DeliverabilityДокумент76 страниц1 Reservoir DeliverabilityEric FamacyОценок пока нет

- Drilling CostДокумент1 страницаDrilling CostAmit Kumar SinghОценок пока нет

- SPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyДокумент14 страницSPE 128115 Combining Selective Stimulation With Tailored Perforating Improves Injection Profile in A Carbonate Reservoir: A Case StudyErika Daniela ReyesОценок пока нет

- 1001 385v2-STIMPRO ISДокумент2 страницы1001 385v2-STIMPRO ISRodolfo PerezОценок пока нет

- OKW 61 (De Comp.) TimelineДокумент6 страницOKW 61 (De Comp.) TimelineVibhu GuptaОценок пока нет

- Well Test AnalysisДокумент6 страницWell Test AnalysisnrnakОценок пока нет

- Extended Reach Drilling1 PDFДокумент18 страницExtended Reach Drilling1 PDFMayra Betancourt Dominguez100% (1)

- Geomechanics: Wellbore Stability, Casing Drilling, Conclusions and Way ForwardДокумент7 страницGeomechanics: Wellbore Stability, Casing Drilling, Conclusions and Way ForwardAnca SesermanОценок пока нет

- Causes of Water Influx Relationship Between:: - A Well and Oil Reservoir. - Oil Reservoir and The AquiferДокумент26 страницCauses of Water Influx Relationship Between:: - A Well and Oil Reservoir. - Oil Reservoir and The AquiferAnonymous qaI31HОценок пока нет

- Stuck Pipe PDFДокумент16 страницStuck Pipe PDFcarlos801Оценок пока нет

- 200 Petroleum Company Interview Questions Part1Документ12 страниц200 Petroleum Company Interview Questions Part1Sifeddine SaâdОценок пока нет

- Kick Tolerance Calculations For Well Design and Drilling OperationsДокумент2 страницыKick Tolerance Calculations For Well Design and Drilling Operationsi oОценок пока нет

- Extended Reach Drilling PDFДокумент2 страницыExtended Reach Drilling PDFGina0% (1)

- Smart Well Drilling Completion HorizontalДокумент65 страницSmart Well Drilling Completion HorizontalPhong Huynh100% (1)

- Introduction To Formation EvaluationДокумент2 страницыIntroduction To Formation EvaluationVince EspacioОценок пока нет

- WT AssignmentДокумент27 страницWT Assignmentabdilrhman sulimanОценок пока нет

- ResChar-SEOДокумент82 страницыResChar-SEOGerardo Zambrano PerdomoОценок пока нет

- Spe 135704 MS PDFДокумент9 страницSpe 135704 MS PDFKd FaОценок пока нет

- Introduction To Coiled Tubing: Module 00 - Day OneДокумент7 страницIntroduction To Coiled Tubing: Module 00 - Day OneFauzan Rahman HaqОценок пока нет

- Impes Method 2Документ13 страницImpes Method 2David ReyesОценок пока нет

- Artificial Lift PC Pump DriveheadsДокумент4 страницыArtificial Lift PC Pump DriveheadsrichardОценок пока нет

- Briefing N°8 - Chaperon-Method-in-Coning-at-Horizontal-Oil-WellsДокумент4 страницыBriefing N°8 - Chaperon-Method-in-Coning-at-Horizontal-Oil-WellsANDREW LOJAОценок пока нет

- Aiyeru SegunДокумент83 страницыAiyeru SegunPeng TerОценок пока нет

- Directional Drilling DesignДокумент53 страницыDirectional Drilling DesignAfnan AhmadОценок пока нет

- MCQДокумент60 страницMCQkushal100% (1)

- S2 2015 336441 Chapter1Документ15 страницS2 2015 336441 Chapter1arispriyatmonoОценок пока нет

- TA MWD-LWD SpecificationДокумент17 страницTA MWD-LWD SpecificationgjzrОценок пока нет

- SPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingДокумент11 страницSPE-124295-PP New Integrated Approach For Updating Pore-Pressure Predictions During DrillingMarcelo Ayllón RiberaОценок пока нет

- Drilling Terms and AbbreviationsДокумент69 страницDrilling Terms and Abbreviationsnissefar007Оценок пока нет

- Optimization of Biodiesel Production Using Aspen PlusДокумент46 страницOptimization of Biodiesel Production Using Aspen PlusKhairatun NisaОценок пока нет

- User Programming PetroWorksДокумент207 страницUser Programming PetroWorksAlfian AminОценок пока нет

- SPE Casing Design For Dual Gradient WellsДокумент18 страницSPE Casing Design For Dual Gradient WellsAntonio HernándezОценок пока нет

- Nguyen, Don TuanДокумент70 страницNguyen, Don TuanAnonymous H9n5g3aaCEОценок пока нет

- Preliminary Study On Air Injection in Annuli To Manage Pressure During CementingДокумент22 страницыPreliminary Study On Air Injection in Annuli To Manage Pressure During CementingAnonymous H9n5g3aaCEОценок пока нет

- Eleonu Ositadinma TochiДокумент136 страницEleonu Ositadinma TochiAnonymous H9n5g3aaCEОценок пока нет

- Northeastern University Graduate Admissions RecomДокумент1 страницаNortheastern University Graduate Admissions RecomAnonymous H9n5g3aaCEОценок пока нет

- Managed Pressure Drilling (SPE MPD Seminar Abstracts)Документ6 страницManaged Pressure Drilling (SPE MPD Seminar Abstracts)Anonymous H9n5g3aaCEОценок пока нет

- Polymer Chemistry and ApplicationsДокумент19 страницPolymer Chemistry and ApplicationsAnonymous H9n5g3aaCEОценок пока нет

- Drilling Books and Documents CollectionДокумент14 страницDrilling Books and Documents CollectionMohamed Abdrabo0% (1)

- Annudeep Dhiman, RHEOLOGICAL PROPERTIES & CORROSION CHARACTERISTICS OF PDFДокумент78 страницAnnudeep Dhiman, RHEOLOGICAL PROPERTIES & CORROSION CHARACTERISTICS OF PDFbharathpeОценок пока нет

- Greek Alphabet ChartsДокумент1 страницаGreek Alphabet ChartsRs JeqimsОценок пока нет

- Polymer Chemistry and ApplicationsДокумент19 страницPolymer Chemistry and ApplicationsAnonymous H9n5g3aaCEОценок пока нет

- Polymer An HP Starch UsedДокумент11 страницPolymer An HP Starch UsedAnonymous H9n5g3aaCEОценок пока нет

- Managed Pressure Drilling Techniques Explained in DetailДокумент3 страницыManaged Pressure Drilling Techniques Explained in DetailAnonymous H9n5g3aaCEОценок пока нет

- Well PlanningДокумент4 страницыWell PlanningSibte Hassan ButtОценок пока нет

- Polymer An HP Starch UsedДокумент11 страницPolymer An HP Starch UsedAnonymous H9n5g3aaCEОценок пока нет

- Viscometer Model 35 12speedДокумент2 страницыViscometer Model 35 12speedAnonymous H9n5g3aaCEОценок пока нет

- Drilling Fluid ComponentsДокумент27 страницDrilling Fluid ComponentsMahmoud Ahmed Ali AbdelrazikОценок пока нет

- Deepwater Managed Pressure Drilling and Casing While DrillingДокумент2 страницыDeepwater Managed Pressure Drilling and Casing While DrillingAnonymous H9n5g3aaCEОценок пока нет

- Managed Pressure Drilling (SPE MPD Seminar Abstracts) PDFДокумент6 страницManaged Pressure Drilling (SPE MPD Seminar Abstracts) PDFAnonymous H9n5g3aaCEОценок пока нет

- Well Design Issues PDFДокумент55 страницWell Design Issues PDFAnonymous H9n5g3aaCEОценок пока нет

- Deepwater Managed Pressure Drilling and Casing While Drilling PDFДокумент4 страницыDeepwater Managed Pressure Drilling and Casing While Drilling PDFAnonymous H9n5g3aaCEОценок пока нет

- Preliminary Study On Air Injection in Annuli To Manage Pressure During Cementing PDFДокумент6 страницPreliminary Study On Air Injection in Annuli To Manage Pressure During Cementing PDFAnonymous H9n5g3aaCEОценок пока нет

- Reelwell Drilling Method Pushes Limits for MPD, UBD & ERDДокумент8 страницReelwell Drilling Method Pushes Limits for MPD, UBD & ERDAnonymous H9n5g3aaCEОценок пока нет

- Email PhrasesДокумент23 страницыEmail PhrasesAnonymous H9n5g3aaCEОценок пока нет

- Email Phrases PDFДокумент4 страницыEmail Phrases PDFAnonymous H9n5g3aaCEОценок пока нет

- Email Phrases PDFДокумент4 страницыEmail Phrases PDFAnonymous H9n5g3aaCEОценок пока нет

- A Numerical Investigation of Wellbore Stability Problems Using AnДокумент97 страницA Numerical Investigation of Wellbore Stability Problems Using AnAnonymous H9n5g3aaCEОценок пока нет

- Master of Petroleum Well Engineering - Casing DesignДокумент92 страницыMaster of Petroleum Well Engineering - Casing DesignAnonymous H9n5g3aaCEОценок пока нет

- Chuong 5 - Casing Design - PPT Compatibility ModeДокумент65 страницChuong 5 - Casing Design - PPT Compatibility ModeAnonymous H9n5g3aaCEОценок пока нет

- Advanced Drilling Practices - Casing DesignДокумент92 страницыAdvanced Drilling Practices - Casing DesignAnonymous H9n5g3aaCEОценок пока нет

- Jakobson Linguistics and PoeticsДокумент8 страницJakobson Linguistics and PoeticsPhil KostovОценок пока нет

- Grammar Booster: Lesson 1Документ1 страницаGrammar Booster: Lesson 1Diana Carolina Figueroa MendezОценок пока нет

- BUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyДокумент34 страницыBUDDlab Volume2, BUDDcamp 2011: The City of Euphemia, Brescia / ItalyThe Bartlett Development Planning Unit - UCLОценок пока нет

- JEE Test Series ScheduleДокумент4 страницыJEE Test Series ScheduleB.K.Sivaraj rajОценок пока нет

- Lesson Plan V The ImperativeДокумент3 страницыLesson Plan V The ImperativeViviana Bursuc100% (1)

- Sprite Graphics For The Commodore 64Документ200 страницSprite Graphics For The Commodore 64scottmac67Оценок пока нет

- Indian Oil Corporation- Leading Indian State-Owned Oil and Gas CompanyДокумент10 страницIndian Oil Corporation- Leading Indian State-Owned Oil and Gas CompanyPrakhar ShuklaОценок пока нет

- Rhodium Catalyzed Hydroformylation - CH 07Документ14 страницRhodium Catalyzed Hydroformylation - CH 07maildesantiagoОценок пока нет

- Gpredict User Manual 1.2Документ64 страницыGpredict User Manual 1.2Will JacksonОценок пока нет

- Time Series Data Analysis For Forecasting - A Literature ReviewДокумент5 страницTime Series Data Analysis For Forecasting - A Literature ReviewIJMERОценок пока нет

- The Basics of Hacking and Pen TestingДокумент30 страницThe Basics of Hacking and Pen TestingAnonОценок пока нет

- Omega Fluid PDFДокумент2 страницыOmega Fluid PDFapatzinfedОценок пока нет

- Light Body ActivationsДокумент2 страницыLight Body ActivationsNaresh Muttavarapu100% (4)

- IS BIOCLIMATIC ARCHITECTURE A NEW STYLE OF DESIGNДокумент5 страницIS BIOCLIMATIC ARCHITECTURE A NEW STYLE OF DESIGNJorge DávilaОценок пока нет

- Pengenalan Icd-10 Struktur & IsiДокумент16 страницPengenalan Icd-10 Struktur & IsirsudpwslampungОценок пока нет

- Clinic Management System (24 PGS)Документ24 страницыClinic Management System (24 PGS)pranithОценок пока нет

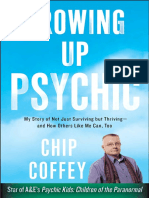

- Growing Up Psychic by Chip Coffey - ExcerptДокумент48 страницGrowing Up Psychic by Chip Coffey - ExcerptCrown Publishing Group100% (1)

- 10 1016@j Ultras 2016 09 002Документ11 страниц10 1016@j Ultras 2016 09 002Ismahene SmahenoОценок пока нет

- NMIMS MBA Midterm Decision Analysis and Modeling ExamДокумент2 страницыNMIMS MBA Midterm Decision Analysis and Modeling ExamSachi SurbhiОценок пока нет

- Significance of Vaiseshika's PragabhavaДокумент5 страницSignificance of Vaiseshika's Pragabhavavskanchi0% (1)

- CIPP ModelДокумент36 страницCIPP ModelIghfir Rijal TaufiqyОценок пока нет

- 7 JitДокумент36 страниц7 JitFatima AsadОценок пока нет

- Hum-Axis of Resistance A Study of Despair, Melancholy and Dis-Heartedness in Shahnaz Bashir's Novel The Half MotherДокумент8 страницHum-Axis of Resistance A Study of Despair, Melancholy and Dis-Heartedness in Shahnaz Bashir's Novel The Half MotherImpact JournalsОценок пока нет

- Finance Process Optimization - Mapping The Journey To High PerformanceДокумент3 страницыFinance Process Optimization - Mapping The Journey To High PerformanceStephen G. LynchОценок пока нет

- Users GuideДокумент34 страницыUsers GuideZaratustra NietzcheОценок пока нет

- Tutor Marked Assignment (TMA) SR Secondary 2018 19Документ98 страницTutor Marked Assignment (TMA) SR Secondary 2018 19kanna2750% (1)

- Math Curriculum Overview Grades 1 8Документ1 страницаMath Curriculum Overview Grades 1 8GuiselleОценок пока нет

- DCinv V6 Rev2 CleanДокумент38 страницDCinv V6 Rev2 Cleanyasirarafat91Оценок пока нет

- Key Note Units 3-4Документ4 страницыKey Note Units 3-4Javier BahenaОценок пока нет