Академический Документы

Профессиональный Документы

Культура Документы

A New Paradigm For Mixing Rs232 Rs485 Ethrnet

Загружено:

Juan Gil RocaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

A New Paradigm For Mixing Rs232 Rs485 Ethrnet

Загружено:

Juan Gil RocaАвторское право:

Доступные форматы

Robust DataComm Pte Ltd

USA & Singapore

www.robustdc.com

Making Industrial Data Flow Like Water ... Safely, Silently, & Sanely

A New Paradigm for Mixing

RS-232, RS-485 & TCP/IP Ethernet

in Multi-Vendor Automation Projects

RobustDC Application Note #28

Quick Index:

! The Growing Ethernet TCP/IP Challenge:

! The Old Integration Paradigm - MODBUS/RTU over RS-232 or RS-485

! The New Integration Paradigm - MODBUS/TCP over Ethernet TCP/IP

! Example System Integrated with MODBUS/TCP over Ethernet TCP/IP

! Summary

The Growing Ethernet TCP/IP Challenge:

The use of robust Ethernet technologies - such as fiber optics, redundant media, and fast-switching/ATM

hubs - is making Ethernet an increasingly popular industrial network back-bone. Either as part of the initial

construction or as a later upgrade, end users are increasingly investing in a plant-wide Ethernet utility

which includes access points in every area on site - possibly even to remote sites or neighboring countries!

System integrators are seeing more and more quotations which include only Ethernet via sub-sea fiber op-

tic cable to offshore platforms or Ethernet via high-speed leased lines to remote sites. Because this utility

investment already exists, small-to-medium sized integrators are increasingly being disadvantaged when

quoting if they must include the cost of running additional copper or fiber optic or leased lines to support

their Modbus or asynchronous serial communications. We all know that the ability to integrate fully with

the big boys is critical to the success of small-to-medium sized integrators and equipment makers. There-

fore, the growing interest in Ethernet and TCP/IP is a trend to be monitored carefully.

So how can small companies add Ethernet TCP/IP support to their automation products without huge

R&D budgets and long delays? Fortunately, there is a new paradigm developing which allows any device

with MODBUS/RTU to instantly become a fully TCP/IP enabled device.

The Old Integration Paradigm - MODBUS/RTU over RS-232 or RS-485

Youve all heard of the MODBUS/RTU protocol. While MODBUS is a trademark of Schneider Automation, it is

regarded as a public protocol and has become the de-facto standard in multi-vendor integration.

MODBUS is a simple, flexible, publicly-published protocol which allows devices to exchange discrete and

analog data. All end users know that specifying MODBUS/RTU as the required interface between sub-

systems is the only sure way to achieve multi-vendor integration with the largest purchasing options and at

the lowest cost. All small equipment makers know that they must offer MODBUS/RTU ports with RS-232 and/or

RS-485 to have the easiest time selling their equipment to system integrators for use in these larger projects.

All system integrators know that MODBUS/RTU is a safe interface to commit to, as they can be sure of finding

enough equipment on the market to both realize the required designs - and handle the inevitable

change orders which come along.

AN-028 - New Multi-Vendor Paradigm with TCP/IP RobustDC 2001 Page 1 of 4

Robust DataComm Pte Ltd

USA & Singapore

Making Industrial Data Flow Like Water ... Safely, Silently, & Sanely www.robustdc.com

Yet MODBUS/RTU suffers increasing from the limitations of RS-232/485 serial lines:

1. Serial lines are relatively slow - 9600 to 115,000 baud means only 0.010Mbps to 0.115Mbps. Compare

that to todays common control network speeds of 5 to 16Mbps - or even the new Ethernet speeds of

100Mbps and 1000Mbps!

2. While it is easy to link 2 or 3 devices by RS-232 and 20-30 devices by RS-485 - how do you link 500 de-

vices with RS-232 and/or RS-485? The only solution is a complex hierarchy of masters and slaves in a

deeply nested tree structure - these solutions are never pretty or easy to maintain!

3. Serial links with MODBUS/RTU are inherently single-master designs. That means, only one device can

talk to a group of slave devices - so only that 1 master device can know what the current real-time

data is. How can designers share this data with multiple operator workstations, control systems, data-

base systems, customized process optimizing workstations, and all the other potential users of the data?

Again, we end up with complex, fragile hierarchies of master/slave groups shuffling data bucket-

brigade style up the ladder to all the potential users. Besides the complexity involved, lower levels of

the hierarchy (even expensive DCS systems!) find themselves wasting valuable time shuffling data

solely for the benefit of higher levels of the hierarchy.

The New Integration Paradigm - MODBUS/TCP over Ethernet TCP/IP

Fortunately there is a new integration paradigm coming to the rescue of small-to-medium sized compa-

nies. MODBUS has quietly made the move to the world of mega-bits-per-second in the form of the

MODBUs/TCP standard. While still a trademark & property of Schneider Automation, it is also publicly pub-

lished and just as simple and flexible as the original Modbus/RTU standard. Modbus/TCP promises to

become the de-facto standard for multi-vendor integration over TCP/IP networks.

Technically, MODBUS/TCP has been around a while - yet most people have neither heard of it nor been

introduced to the absolute simplicity and brilliance of its use for multi-vendor TCP/IP networks. Modbus/TCP

was introduced to support Modicon Quantum PLC with direct Ethernet adapters. Yet it is not an exotic,

complex new protocol - merely MODBUS/RTU ADDR CMD CNT DATA CRC16

MODBUS/RTU in a TCP/IP wrapper! So

the real beauty of MODBUS/TCP is in

MODBUS/TCP Header ADDR CMD CNT DATA (TCP uses a CRC32)

how fast it can be implemented. Any

company with the following three (3) Figure 1) MODBUS/RTU to MODBUS/TCP Conversion

resources can implement MODBUS/TCP in a few days: source code for an existing MODBUS/RTU serial driver,

a TCP socket library, and one competent programmer. So presto, vendors can now have a

MODBUS/TCP driver almost instantly, plus all their application programs which already support the data ac-

cess paradigm of MODBUS/RTU can also support MODBUS/TCP just as easily.

So why call MODBUS/TCP the TCP/IP Rescue Package? Why do we need rescue from TCP/IP anyway?

The problem is that TCP is a transport protocol - not an user application protocol. Saying 2 devices speak

TCP/IP promises as much compatibility as saying they both have RS-232 ports! All TCP/IP does is allow

blocks of binary data to be moved between computers - it does not help you interpret what that data

AN-028 - New Multi-Vendor Paradigm with TCP/IP RobustDC 2001 Page 2 of 4

Robust DataComm Pte Ltd

USA & Singapore

www.robustdc.com

Making Industrial Data Flow Like Water ... Safely, Silently, & Sanely

means! It is 100% analogous to the postal system. I can received a letter posted from Japan or Pakistan

and addressed perfectly to me - both you and I fully support the snail-mail postal system protocol! Yet

the postal system cannot help me read the letter inside if it is written in Japanese or Arabic, can it! In the

same manner as the postal system, TCP/IP safely moves blocks of data between 2 different systems. TCP/IP

handles blocks of any size, whether 10 or 100 or even 1,000,000 bytes, but TCP/IP can promise absolutely

nothing about what that data means or how to interpret it. There still has to be agreed upon rules to inter-

pret that data - a user application protocol like MODBUS/TCP. (For details of the MODBUS/TCP specification

see http://www.modicon.com/openmbus and for information on multi-vendor availability see

http://www.robustdc.com/mbus_tcp.htm)

Example System Integrated with MODBUS/TCP over TCP/IP

Figure 2 shows a simple multi-

vendor system integrated with

MODBUS/TCP. It also introduces

the idea of a protocol bridge

(PB) to integrate older RS-232

and RS-485 MODBUS/RTU and

MODBUS/ASCII devices into a

new TCP/IP network. These

devices are already available

from a number of companies -

search the Web for Modbus

TCP to find some of them. This

example shows 3 work-stations

Figure 2) TCP/IP Integrated System

from 2 different vendors and 5

field devices from 3 different vendors. The TCP/IP Ethernet acts as the mixing medium allowing them all

to talk freely between themselves. In this design, A, B, C, E, and F can all act as MODBUS masters, while D, E,

F, G, & H can act as MODBUS slaves.

Starting at the top, Workstations A and B use standard MMI software. Most commercially available

packages already support MODBUS/TCP - ask for their Modicon Ethernet Quantum PLC servers as many

supplier dont realize these are really MODBUS/TCP drivers! Remarkably, both A and B can act as masters to

all field devices D through H. Surprised? Even if devices D, G, & H only have 1 serial port each, both A and

B can act concurrently as MODBUS masters to them! (Honest, it works!) Workstation C is a special DOS-

based programming and monitoring station for field devices G & H. Since this vendor only supports

MODBUS/RTU over normal COM ports, the protocol bridge (PB) is used to integrate C into the MODBUS/TCP

system. Notice how the inherent multi-access nature of TCP/IP and MODBUS/TCP allows all three worksta-

tions to share being Master to all 5 field devices!

AN-028 - New Multi-Vendor Paradigm with TCP/IP RobustDC 2001 Page 3 of 4

Robust DataComm Pte Ltd

USA & Singapore

Making Industrial Data Flow Like Water ... Safely, Silently, & Sanely

www.robustdc.com

Now for the field devices: Field device D is an older device which only supports MODBUS/ASCII with an

RS-232 port. Not only does the protocol bridge (PB) convert the MODBUS/ASCII to MODBUS/TCP, but even

workstation C - which only supports MODBUS/RTU - can now access field device D. The PB allows this trans-

parently support even this RTU to ASCII conversion. Field devices E & F are newer products with direct

Ethernet and MODBUS/TCP support. Field devices G & H support MODBUS/RTU over RS-485.

But we are not finished yet. Direct MODBUS/TCP support means field devices E & F can be both MODBUS

master and MODBUS slave devices at the same time. Not only can they provide data requested by masters

A, B, & C, but they can use their own master functions to pull data directly from field devices D, G & H.

Remember, field device D only speaks MODBUS/ASCII, field device E & F only speak MODBUS/TCP, and field

devices G & H only speak MODBUS/RTU. The clever design of the new MODBUS/TCP protocol and the flexibility

of the old MODBUS/RTU and MODBUS/ASCII protocols allow compatibility and conversation between all three.

Summary

All local automation professionals should search out and become familiar with the latest Ethernet and

TCP/IP technologies. Then they will be ready to profit from application of these new technologies and the

more flexible multi-vendor systems they enable. We already know of several small local companies who

beat out the competition by proposing state-of-the-art Modbus TCP/IP solutions for the same money as

their competitors tried to sell old-fashioned serial solutions. Dont let these opportunities pass you by.

1. Buy a book on the subject of TCP/IP - titles like the Dummies Guide to TCP/IP readily exist at all good

book-shops. These will explain IP and UDP and TCP and FTP and all the other acronyms and jargon you

need to talk the talk and make the sale.

2. Review the MODBUS/TCP specification at www.modicon.com\openmbus

3. Ask your software application suppliers for MODBUS/TCP drivers and servers. If they dont have them yet,

press them to spend those few days to create them so you are ready when opportunity knocks. Its the

best few days you or they will ever spend!

4. Locate sources for Modbus protocol bridges through the Web and at upcoming trade shows. These

allow you to sell your existing Modbus/RTU solutions in new TCP/IP systems.

5. Make contact with local IT and networking suppliers to learn how to design and implement robust

Ethernet designs including redundant media and fiber optics support. DIN-rail mount and 24vdc supply

models are even available.

For More Information

Robust DataComm can truly make your data flow like water - safely, sanely, and silently.

Robust DataComm Robust DataComm Pte Ltd

26471 Portola Pkway, Suite 1E-242 18 Kaki Bukit Road 3 #02-08

Foothill Ranch, CA 92610-1743 U.S.A. Entrepreneur Business Center Singapore 415978

US Sales: (972)248-7466 Fax: (972)248-9533 Tel: (65)6487-5624 Fax: (65)6288-3306

email : info@robustdc.com web : http//www.robustdc.com

Copyright 1993-2001 Robust DataComm, USA and Singapore, All Rights Reserved.

AN-028 - New Multi-Vendor Paradigm with TCP/IP RobustDC 2001 Page 4 of 4

Вам также может понравиться

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Single Rail Power Supply Platform Atx12vo Design GuideДокумент74 страницыSingle Rail Power Supply Platform Atx12vo Design GuideJuan Gil RocaОценок пока нет

- Switching Power Supply Design: A Concise Practical Handbook: February 2022Документ5 страницSwitching Power Supply Design: A Concise Practical Handbook: February 2022Juan Gil RocaОценок пока нет

- An5419 Getting Started With stm32h723733 stm32h725735 and stm32h730 Value Line Hardware Development StmicroelectronicsДокумент50 страницAn5419 Getting Started With stm32h723733 stm32h725735 and stm32h730 Value Line Hardware Development StmicroelectronicsJuan Gil RocaОценок пока нет

- KMZ10A Magnetic Field SensorДокумент9 страницKMZ10A Magnetic Field SensorJuan Gil RocaОценок пока нет

- Vfc110 High Frequency Voltage To Frequency ConverteДокумент10 страницVfc110 High Frequency Voltage To Frequency ConverteJuan Gil RocaОценок пока нет

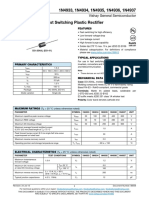

- 1N4933, 1N4934, 1N4935, 1N4936, 1N4937: Vishay General SemiconductorДокумент4 страницы1N4933, 1N4934, 1N4935, 1N4936, 1N4937: Vishay General SemiconductorJuan Gil RocaОценок пока нет

- ICL8069 Is A 1.2V Temperature-Compensated Voltage Reference.Документ4 страницыICL8069 Is A 1.2V Temperature-Compensated Voltage Reference.Juan Gil RocaОценок пока нет

- DS1847 Dual Temperature-Controlled NV Variable Resistor I2C PDFДокумент17 страницDS1847 Dual Temperature-Controlled NV Variable Resistor I2C PDFJuan Gil RocaОценок пока нет

- ICL8013 Four Quadrant Analog MultiplierДокумент8 страницICL8013 Four Quadrant Analog MultiplierJuan Gil RocaОценок пока нет

- HEF4052 Dual 4-Channel Analogue Multiplexer Demultiplexer PDFДокумент10 страницHEF4052 Dual 4-Channel Analogue Multiplexer Demultiplexer PDFJuan Gil RocaОценок пока нет

- DS1809 010 64-Position Linear Taper Two Nonvolatile Wiper Storage Options 10K OHMSДокумент9 страницDS1809 010 64-Position Linear Taper Two Nonvolatile Wiper Storage Options 10K OHMSJuan Gil RocaОценок пока нет

- Icl7660 Max1044Документ12 страницIcl7660 Max1044api-3850377Оценок пока нет

- BB Opa2652 Dual, 700mhz, Voltage-Feedback Operational AmplifierДокумент15 страницBB Opa2652 Dual, 700mhz, Voltage-Feedback Operational AmplifierJuan Gil RocaОценок пока нет

- DS3695 Multipoint RS485 RS422 Transceivers RepeatersДокумент17 страницDS3695 Multipoint RS485 RS422 Transceivers RepeatersJuan Gil Roca100% (1)

- PGA2505 Digitally-Controlled, Analog Microphone PreamplifierДокумент20 страницPGA2505 Digitally-Controlled, Analog Microphone PreamplifierJuan Gil RocaОценок пока нет

- FAN7371 High Current High Side DriverДокумент11 страницFAN7371 High Current High Side DriverJuan Gil RocaОценок пока нет

- MCP6N16 Zero Drift Instrumentation AmpДокумент58 страницMCP6N16 Zero Drift Instrumentation AmpJuan Gil RocaОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Ethernet Connection I219 DatasheetДокумент278 страницEthernet Connection I219 DatasheetsyafaatremliОценок пока нет

- Nexus 7kДокумент84 страницыNexus 7kCCNA classОценок пока нет

- Ccna3 Vlan TrunkДокумент5 страницCcna3 Vlan TrunkYoki WahyudiОценок пока нет

- 06 ZXCTN 9008 (V2.08.31) Packet Transport Product Hardware Introduction 46P - DiminuidoДокумент46 страниц06 ZXCTN 9008 (V2.08.31) Packet Transport Product Hardware Introduction 46P - DiminuidoDaniel Dantas100% (1)

- ZXA10 C300 Maintenance Manual PDFДокумент75 страницZXA10 C300 Maintenance Manual PDFKarl ClosОценок пока нет

- Cse 5 6 2020 21Документ99 страницCse 5 6 2020 21Akash KadiyanОценок пока нет

- Quantum Ethernet Modules UnityДокумент382 страницыQuantum Ethernet Modules UnityGilbert H. Quiroga G.100% (1)

- Issues - Protection & Control Journal - October 2008Документ92 страницыIssues - Protection & Control Journal - October 2008brockwell496Оценок пока нет

- Compact 155 Mbit/S Add-Drop Multiplexer: SiemensДокумент6 страницCompact 155 Mbit/S Add-Drop Multiplexer: SiemensAbhay KumarОценок пока нет

- Modbus RTU TCP/IP: HMI SettingДокумент2 страницыModbus RTU TCP/IP: HMI SettingGeorge GaitanakisОценок пока нет

- OmniSwitch 9000 FamilyДокумент20 страницOmniSwitch 9000 FamilyDuy HuynhОценок пока нет

- Introduction To PLCsДокумент42 страницыIntroduction To PLCsArun Kumar YadavОценок пока нет

- Cerberus PACE Public Address and Controlled Evacuation Planning ToolДокумент2 страницыCerberus PACE Public Address and Controlled Evacuation Planning ToolMarcelo Lima SouzaОценок пока нет

- Huawei s9700 Series Switches DatasheetДокумент42 страницыHuawei s9700 Series Switches DatasheetBahzadОценок пока нет

- 1756 ControlLogix and GuardLogix ControllersДокумент52 страницы1756 ControlLogix and GuardLogix ControllersAndres ManriqueОценок пока нет

- Obafemi Siwes ReportДокумент45 страницObafemi Siwes ReportRoseline OmoareОценок пока нет

- 134.4902.06 - DM4170 - DatasheetДокумент7 страниц134.4902.06 - DM4170 - DatasheetVinicius MollОценок пока нет

- Fengine S5800 Switch Datasheet-V30R203Документ5 страницFengine S5800 Switch Datasheet-V30R203Aganinggar EdoОценок пока нет

- CD164937 - Metro Grau - ChiclayoДокумент3 страницыCD164937 - Metro Grau - Chiclayosps_angelОценок пока нет

- AAE 3282 Avionics Subsystem Databus and Avionics ArchitectureДокумент128 страницAAE 3282 Avionics Subsystem Databus and Avionics ArchitectureLnsfv100% (1)

- R-30iB Plus (FAC Guide Profinet Configuration CP1604 IOC FW2.7) (CONTROLLER)Документ22 страницыR-30iB Plus (FAC Guide Profinet Configuration CP1604 IOC FW2.7) (CONTROLLER)padrote-jОценок пока нет

- Connexium SwitchДокумент2 страницыConnexium Switchaae_101Оценок пока нет

- Lista de Precios FurukawaДокумент6 страницLista de Precios FurukawaWilly YPОценок пока нет

- Signalling Project Pakistan Railways RehabilitationДокумент13 страницSignalling Project Pakistan Railways RehabilitationCh Ahmed NoumanОценок пока нет

- RTN 320 V100R008C00 Commissioning and Configuration Guide 03Документ340 страницRTN 320 V100R008C00 Commissioning and Configuration Guide 03Fajar BalidoОценок пока нет

- L90 Ge Protection RelayДокумент8 страницL90 Ge Protection RelayThành DanhОценок пока нет

- Avaya Cisco InteroperabilityДокумент137 страницAvaya Cisco Interoperabilityshyco007Оценок пока нет

- Optix Osn 2000 Technical Manual - System Description: PDF Created With Pdffactory Pro Trial VersionДокумент55 страницOptix Osn 2000 Technical Manual - System Description: PDF Created With Pdffactory Pro Trial VersionRod SbОценок пока нет

- FortiSwitch Secure Access SeriesДокумент16 страницFortiSwitch Secure Access SeriesSiva NanthamОценок пока нет

- Unit 11 Computer Networks-Assignment 1 - Ethan Johnson - 122334Документ16 страницUnit 11 Computer Networks-Assignment 1 - Ethan Johnson - 122334api-591240370Оценок пока нет