Академический Документы

Профессиональный Документы

Культура Документы

Dome 3 PDF

Загружено:

Dinesh Chougule0 оценок0% нашли этот документ полезным (0 голосов)

117 просмотров2 страницыОригинальное название

DOME 3.pdf

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

117 просмотров2 страницыDome 3 PDF

Загружено:

Dinesh ChouguleАвторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

Dome Valve II Dome Valve II Dome Valve II

inflatable seat valve advanced features the problem solver

A pioneering and innovative departure principle of operation special performance advantages

from the traditional valve seat approach

to achieving sealing efficiency and ac-

The dome component closes beneath the seat (seal) when the seal simplicity zero-contact proximity

The Dome Valve is used in a wide variety of applications in

is relaxed (not inflated), allowing a controlled gap between the seat almost every process. The unique closing and sealing action of

ceptable valve seat life.

switch for inflatable

(seal) and the closing member (dome). Material is allowed to pass seal operation one piece precision the Dome Valve enables continuous reliable operation where

through or enter the controlled gap if, due to its characteristics, it is high torque, double molded inflatable seat conventional valves fail to perform. Here is why:

pulled into the gap by the action of the dome component moving acting actuator

to its closed position. In the closed position, high pressure air or abrasive materials

other gas enters the space between the back of the seal face and Slurries, bulk powders, granules, lumps or dust-laden gases

the insert ring to cause the seal face to expand onto and around cause seat erosion and ineffective closure. The inflatable seal

the periphery of the dome component. Material particles are en- provides continuous wear compensation.

trapped by the seal against the dome surface, irrespective of parti- single gasket assembly

cle size or shape. Before opening the valve, the seat is relaxed, and pressure differential

the controlled gap is reestablished before the dome component Pressure differential also causes accelerated seat wear in con-

moves to its open position. The seal is a loose component clamped ventional seat valves. The inflatable seal provides continuous

into place by a spigot piece and external fasteners holding the top wear compensation.

plate assembly to the body. The seal is easily removed for inspec-

tion.

high temperature

Thermal expansion prevents consistent valve seat action. The

inflatable seats inflatable seal provides compensation throughout the tem-

Inflatable flexible seats entrap particles that are normally the cause

of seat erosion. Particles are induced to move across valve seats durability perature range of 0 to 350C. Temperatures above this range

may be accepted using special valve configurations.

relaxed seat under the influence of pressure differentials on either side of the

dome component closing member. Entrapping particles within a flexible face during

the period of valve closure prevents particle movement and consid-

close and seal

The action of the rotating dome within the valve housing al-

erably reduces valve seat wear. Inflatable seats allow automatic

lows displacement of material so that a choke-filled Dome

wear compensation.

Valve will close and seal through most packed materials.

air supply Particle entrapment prevents seal/seat

erosion, solving the cause of valve wear. hard seats

The conventional hard material approach to valve seat life relies on

seal and protection

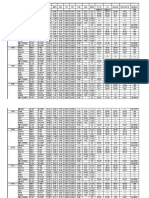

1 TOP PLATE BOLTS simple fastener assembly Seal protection and dome scraper ring remove particles adher-

crushing particles between the faces. This approach does not at- In M & F connection

2 TOP PLATE ing to the dome surface that affect seal performance.

tempt to entrap particles, but causes the particles remaining to U.S. Patent No. 5642751

become very small to reduce their erosion effect on the valve seat. 3 INSERT RING

However small the particles are, each particle contributes to con- 4 INFLATABLE SEAL double shaft seals abrasion / temperature / pressure

tinuing erosion. Particle movement and initial erosion allows accel- Dome Valve can achieve operating reliability in severe appli-

5 SPIGOT PIECE

erated subsequent erosion since the hard seats cannot compensate cations combining abrasive materials, high temperature and

6 GASKET stainless steel high pressure differential.

for wear.

7 VALVE BODY quality shafts

flexible seats 8 DOME reliability

Flexible seats that do not inflate require the force of engagement 9 V-RING A heavy-duty valve designed to perform where other valves

on closing to entrap particles. However the flexible valve seat has 10 PIVOT SHAFT cannot. Rated for hundreds of thousands of cycles between

limited life because the worn surface of the flexible seat cannot DRIVE SHAFT inspections in approved applications.

11

continue to reengage the closing member and entrap particles. 12 SHAFT SEAL

Inflatable seats compensate for wear to the seat and provide

13 SEAL RETAINER applications in every process worldwide

longer sealing life.

14 BEARING

More than 100,000 Dome Valves are in operation in

inflated seat 15 ACTUATOR DRIVE ASSEMBLY almost every country of the world, providing long life and

dome component 16 ACTUATOR MOUNT operating reliability where conventional valves have failed.

17 ACTUATOR

18 PROXIMITY SWITCH

19 DOME-TO-SHAFT BOLT

reliability

U.S. Patent No. 4,137,935

Dome Valve II

Macawber China Ltd. Mactenn Systems Ltd.

standard configurations Suite 901, 145 PuJian Rd. Unit 6, Bull Lane Industrial Estate

Pudong, Shanghai, China 200127 Acton, Sudbury, Suffolk CO10 0BD, UK

Tel: +86 (021) 6875 1377 Tel: +44 (0) 1787 882 422

bulkhead Fax: +86 (021) 5831 2152 Fax: +44 (0) 1787 882 433

macawber@macawber.com.cn sales@mactenn.com

www.macawber.com.cn www.mactenn.com

Macawber Engineering Systems PDL Sistemas, Brazil

India Pvt. Ltd. Av. Pedro Lessa, 1.064/31 - Aparecida

130-131, Hindustan Kohinoor Complex, 11025-000, Santos, Sao Paulo , Brazil

LBS Rd., Vikhroli, Mumbai 400083 Tel/Fax: +55 13 3278 3380

response@macawberindia.com pdl@pdl.com.br

standard options

www.macawberindia.com www.pdl.com.br

Dome Valve II

size (in): 2, 4, 6, 8, 10, 12, 16

inflatable seat valves

design temp: 230F/110C, 536F/280C, 662F/350C

design pressure: 100 psig / 7 barg

flanges: ANSI 150 / PN 10 / PN 16

construction: Cast Iron A278 C40 / Stainless 304/316

the process engineering valve solution

non-standard options

inline

size options (in): up to 30

design temp: up to 1500F/815C * ISO 9001 REGISTERED

design pressure: up to 630 psig / 43 barg

Macawber Engineering Inc.

inflatable seat valves

advanced pneumatic conveying systems

controlled rate injection systems

1829 Clydesdale Street, Maryville, TN 37801, USA

Tel: 800.433.2213 Fax: 865.977.4131

www.macawber.com webinquiry@macawber.com

Your Local Distributor:

*Requires high temp batching valve

Вам также может понравиться

- TF100-53C 3900 Series QD CouplingsДокумент8 страницTF100-53C 3900 Series QD CouplingsAhmet SönmezОценок пока нет

- Single-Ball Safety Valve: Applications DescriptionДокумент1 страницаSingle-Ball Safety Valve: Applications DescriptionYves-donald MakoumbouОценок пока нет

- Diaphragm Valve D100Документ10 страницDiaphragm Valve D100Mohd Khairi Mohd Norzian0% (1)

- 2012 RF Insamcor LW Catalogue - EnglishДокумент7 страниц2012 RF Insamcor LW Catalogue - EnglishNay Win MaungОценок пока нет

- Keystone F129 F239Документ4 страницыKeystone F129 F239Mohd Khairi Mohd NorzianОценок пока нет

- Dow Corning 888Документ3 страницыDow Corning 888candyamОценок пока нет

- SKG - ValvulasДокумент8 страницSKG - ValvulasfrmalthusОценок пока нет

- Ash Conveying SystemsДокумент1 страницаAsh Conveying SystemsTrishul Nath PallayОценок пока нет

- Cono RC CedarapidsДокумент8 страницCono RC CedarapidsJesus DugarteОценок пока нет

- DVC 99straightwayДокумент2 страницыDVC 99straightwayMohamed ElmakkyОценок пока нет

- ASME Safety Relief Valves for Boilers & Pressure VesselsДокумент9 страницASME Safety Relief Valves for Boilers & Pressure VesselsscribpenumakaОценок пока нет

- BRO Diffusor Web-04-AUG-2015Документ2 страницыBRO Diffusor Web-04-AUG-2015Federico SilvaОценок пока нет

- Pick The Right ValveДокумент6 страницPick The Right ValveSiddharth KishanОценок пока нет

- XOMOXДокумент16 страницXOMOXjkpothabathula4581Оценок пока нет

- Eccentricity Enhance Valve PerformanceДокумент3 страницыEccentricity Enhance Valve PerformanceScipp ZengОценок пока нет

- Spin Valves - Dual Plate Wafer Check ValveДокумент4 страницыSpin Valves - Dual Plate Wafer Check ValvePablo HurtubiaОценок пока нет

- Quick Descent Roller Latch Head Assembly (App) PDFДокумент4 страницыQuick Descent Roller Latch Head Assembly (App) PDFAgostina MiniОценок пока нет

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37 - IsoДокумент18 страницKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37 - IsoktexОценок пока нет

- Bray / Mccannalok: 41R High Performance Valves For The SUGAR INDUSTRYДокумент4 страницыBray / Mccannalok: 41R High Performance Valves For The SUGAR INDUSTRYABDELОценок пока нет

- Pump-Through Flapper Safety Valve: Applications DescriptionДокумент1 страницаPump-Through Flapper Safety Valve: Applications DescriptionYves-donald MakoumbouОценок пока нет

- Keystone Figure 990 and 920 Resilient Seated Butterfly ValvesДокумент12 страницKeystone Figure 990 and 920 Resilient Seated Butterfly ValvesMohd Khairi Mohd NorzianОценок пока нет

- Figure 990-920 KeystoneДокумент12 страницFigure 990-920 KeystonesiskaОценок пока нет

- BMV Brochure 4 Page Web - 2019Документ4 страницыBMV Brochure 4 Page Web - 2019Velibor StokicОценок пока нет

- Velan Pressure Seal Valve CatalogДокумент4 страницыVelan Pressure Seal Valve CatalogulfatОценок пока нет

- Maintenance-free knife gate valveДокумент12 страницMaintenance-free knife gate valvecvfОценок пока нет

- Bypass Blow Valve: Reliable TightДокумент2 страницыBypass Blow Valve: Reliable TightAlejo ObregonОценок пока нет

- Hdfpump Brochure-Final WebДокумент7 страницHdfpump Brochure-Final WebPaulo BergamoОценок пока нет

- Rego Multiport A8574AGДокумент2 страницыRego Multiport A8574AGCristobal CherigoОценок пока нет

- ST 9 PDFДокумент1 страницаST 9 PDFjosemartinhmОценок пока нет

- Diaphragm-Type Process Metering Pump Technology OverviewДокумент16 страницDiaphragm-Type Process Metering Pump Technology OverviewTeuku Rizki Muda KeulanaОценок пока нет

- Keystone K-Lok: High Performance Butterfly Valves Series 36 and 37Документ16 страницKeystone K-Lok: High Performance Butterfly Valves Series 36 and 37el_apache10Оценок пока нет

- Axial Flow Nozzle Check Valves For Pumps and Compressors ProtectionДокумент3 страницыAxial Flow Nozzle Check Valves For Pumps and Compressors ProtectionEuclidesОценок пока нет

- Tritec: 150 / 300 / 600 / 900 / 1500 / 2500lb RangeДокумент8 страницTritec: 150 / 300 / 600 / 900 / 1500 / 2500lb RangeretrogradesОценок пока нет

- Nord Lock Wedge Lock Washer Provides Maximum Reliability Under ExtremesДокумент2 страницыNord Lock Wedge Lock Washer Provides Maximum Reliability Under ExtremesVijay BhureОценок пока нет

- Mueller Co Series 2361 RWGV FormДокумент1 страницаMueller Co Series 2361 RWGV FormLarry Wayne Sumpter, JrОценок пока нет

- EagleBurgmann DGSДокумент8 страницEagleBurgmann DGSdfОценок пока нет

- 8639GBДокумент34 страницы8639GBWai Ee YapОценок пока нет

- Valve Body ServiceДокумент2 страницыValve Body ServiceABHISHEK SINGHОценок пока нет

- Caged Control Plug Valves: Dependability in Critical ApplicationsДокумент2 страницыCaged Control Plug Valves: Dependability in Critical ApplicationsAhmed KhairiОценок пока нет

- Data Sheets Series 200 400 500 700 800 Pilot Operated Relief Valves Anderson Greenwood en en 5198016Документ64 страницыData Sheets Series 200 400 500 700 800 Pilot Operated Relief Valves Anderson Greenwood en en 5198016Bouzaida MaherОценок пока нет

- Manual Pinch Valve BrochureДокумент8 страницManual Pinch Valve BrochureCarlos Manuel AcostaОценок пока нет

- Valmet Uhle Box CoverДокумент1 страницаValmet Uhle Box Coverjavier bravo zarorОценок пока нет

- BTV 2000Документ12 страницBTV 2000Felipe Gamboa GálvezОценок пока нет

- Plug-In Seals: Double Mechanical Seal in One Easy-To-Install UnitДокумент2 страницыPlug-In Seals: Double Mechanical Seal in One Easy-To-Install UnitAndrey GyrychОценок пока нет

- How It Works Switching ValvesДокумент3 страницыHow It Works Switching Valvesdaus nasОценок пока нет

- Tufline SPV WeldEnd 329723 12-04Документ16 страницTufline SPV WeldEnd 329723 12-04Marcio NegraoОценок пока нет

- Liquid Ring Vacuum Pump Guide for Maximized EfficiencyДокумент12 страницLiquid Ring Vacuum Pump Guide for Maximized EfficiencyTrần Phước TrungОценок пока нет

- Mueller Fire HydrantДокумент6 страницMueller Fire Hydrantfarshan296015Оценок пока нет

- Welded Bevel Seal (AFP-1-401D)Документ2 страницыWelded Bevel Seal (AFP-1-401D)Im ChinithОценок пока нет

- SolFly Druckscheibenfilter - en X240Документ2 страницыSolFly Druckscheibenfilter - en X240munhОценок пока нет

- Cooper - Flange UnitsДокумент4 страницыCooper - Flange UnitsJose ChambiОценок пока нет

- Plug ValveДокумент1 страницаPlug ValveVinicio VillarruelОценок пока нет

- BFV WeightДокумент8 страницBFV WeightBhargav PatelОценок пока нет

- Api 6DДокумент12 страницApi 6Dcarlosalex200050% (2)

- Data Sheets Series 200 400 500 700 800 Pilot Operated Relief Valves Anderson Greenwood en en 5198016Документ64 страницыData Sheets Series 200 400 500 700 800 Pilot Operated Relief Valves Anderson Greenwood en en 5198016Santosh Iim LucknowОценок пока нет

- Acoples Kop-Flex Serie ElastomericaДокумент14 страницAcoples Kop-Flex Serie Elastomericamarcelo castilloОценок пока нет

- Basic Mechanical Sealing FundamentalДокумент90 страницBasic Mechanical Sealing FundamentalJoko LelonoОценок пока нет

- DSMTS-0108.1 WC10Ni5Cr AggSintДокумент3 страницыDSMTS-0108.1 WC10Ni5Cr AggSintpawoe3064Оценок пока нет

- FA-2 English PaperДокумент2 страницыFA-2 English PaperDinesh ChouguleОценок пока нет

- FA-2 English PaperДокумент2 страницыFA-2 English PaperDinesh ChouguleОценок пока нет

- 5Документ1 страница5Dinesh ChouguleОценок пока нет

- Aptitude Test Instructions and InformationДокумент1 страницаAptitude Test Instructions and InformationDinesh ChouguleОценок пока нет

- Astm A106 PDFДокумент13 страницAstm A106 PDFDanny Milton Silva VasquezОценок пока нет

- WBCAL13675270000077683Документ1 страницаWBCAL13675270000077683Dinesh ChouguleОценок пока нет

- Eclerx Services KPO and roles profileДокумент12 страницEclerx Services KPO and roles profileDinesh ChouguleОценок пока нет

- Eletric ActuДокумент1 страницаEletric ActuDinesh ChouguleОценок пока нет

- Fire Box DN 100Документ1 страницаFire Box DN 100Dinesh ChouguleОценок пока нет

- 2Документ1 страница2Dinesh ChouguleОценок пока нет

- Letter of Ack. (Alfa Laval)Документ1 страницаLetter of Ack. (Alfa Laval)Dinesh ChouguleОценок пока нет

- 1Документ1 страница1Dinesh ChouguleОценок пока нет

- Sample Test QuestionsДокумент14 страницSample Test QuestionsDinesh ChouguleОценок пока нет

- EIL - Specification Sheet123Документ1 страницаEIL - Specification Sheet123Dinesh ChouguleОценок пока нет

- EIL - Specification SheetДокумент1 страницаEIL - Specification SheetDinesh ChouguleОценок пока нет

- Jamesbury 4000Документ12 страницJamesbury 4000Dinesh ChouguleОценок пока нет

- Sample EO PolicyДокумент31 страницаSample EO PolicyDinesh ChouguleОценок пока нет

- Cryogenic test record for check valveДокумент3 страницыCryogenic test record for check valveDinesh ChouguleОценок пока нет

- G 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesДокумент2 страницыG 3/8, G 1/2 - 5/2, 3/2 Pilot Operated High Flow ValvesDinesh ChouguleОценок пока нет

- Lifting Lug CapacityДокумент1 страницаLifting Lug CapacityDinesh ChouguleОценок пока нет

- M Tork New CatalogueДокумент16 страницM Tork New CatalogueDinesh ChouguleОценок пока нет

- General Purpose Butterfly ValvesДокумент2 страницыGeneral Purpose Butterfly Valvesphe zenОценок пока нет

- 15 FB / # 800 (3PC) Ball ValvesДокумент10 страниц15 FB / # 800 (3PC) Ball ValvesDinesh ChouguleОценок пока нет

- Filler Material Selection GuideДокумент32 страницыFiller Material Selection GuidemaknileОценок пока нет

- Gandhi Special Tubes LTD.: Product ProfileДокумент6 страницGandhi Special Tubes LTD.: Product ProfileDinesh ChouguleОценок пока нет

- Support Lug CalculationsДокумент26 страницSupport Lug CalculationsDinesh ChouguleОценок пока нет

- Lug Design R4Документ4 страницыLug Design R4Esapermana RiyanОценок пока нет

- DVG CatalogДокумент7 страницDVG CatalogDinesh ChouguleОценок пока нет

- 5 HPHT API 6x - FowlerДокумент13 страниц5 HPHT API 6x - Fowlerchau nguyenОценок пока нет

- Wind MachinesДокумент34 страницыWind Machinesjeswin johnsonОценок пока нет

- Physics 05-01 Fluids and DensityДокумент2 страницыPhysics 05-01 Fluids and DensityRocelin E. MolabolaОценок пока нет

- Super Capacitors ConstructionДокумент7 страницSuper Capacitors ConstructionVivek BavdhaneОценок пока нет

- Fire Fighting System Case StudyДокумент8 страницFire Fighting System Case StudyBhakti WanaveОценок пока нет

- Indicator Valve Maintenance GuideДокумент15 страницIndicator Valve Maintenance GuideJonoAlexisDang-awanQuiban100% (1)

- Medonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsДокумент6 страницMedonic M-Series M32 Innovation Built On Total Quality: For Today'S Hematology LabsSubhanullah JalalОценок пока нет

- Engineering Technical Report of The v12 Engine and Related Assignments at Tipco IncДокумент36 страницEngineering Technical Report of The v12 Engine and Related Assignments at Tipco Incapi-244817040Оценок пока нет

- Sni+03 6868 2002Документ3 страницыSni+03 6868 2002abanghasanОценок пока нет

- Stresses, Loads, and Factors of Safety in Structural ElementsДокумент6 страницStresses, Loads, and Factors of Safety in Structural ElementsMark Louies Mago VillarosaОценок пока нет

- Classful IP Addressing (Cont.) : Address Prefix Address SuffixДокумент25 страницClassful IP Addressing (Cont.) : Address Prefix Address SuffixGetachew ShambelОценок пока нет

- Example of BVP ProblemsДокумент3 страницыExample of BVP ProblemsAbhishek KumarОценок пока нет

- Request Documents or InfoДокумент6 страницRequest Documents or InfoRashika RampalОценок пока нет

- Cl60 Rooftop Iom 0213 eДокумент94 страницыCl60 Rooftop Iom 0213 emikexiiОценок пока нет

- Ztree 2 StataДокумент3 страницыZtree 2 StataDaniel Felipe ParraОценок пока нет

- Year 11 IPT ProjectworkДокумент12 страницYear 11 IPT Projectworkoiu7hjjs50% (2)

- Class XII Computer Science: HOTS (High Order Thinking Skill)Документ14 страницClass XII Computer Science: HOTS (High Order Thinking Skill)JanakiОценок пока нет

- DELL XPS 11 VAZ90 LA-A161P Rev 1.0 (A00) 20130814Документ49 страницDELL XPS 11 VAZ90 LA-A161P Rev 1.0 (A00) 20130814Sonel SmithОценок пока нет

- User's Manual: Motherboard AMD Socket AM2Документ56 страницUser's Manual: Motherboard AMD Socket AM2vagnerrock007Оценок пока нет

- Clarifier Tank Structural PDFДокумент3 страницыClarifier Tank Structural PDFBenderlip CortezОценок пока нет

- InRoom Tech Data 31010 ApcДокумент92 страницыInRoom Tech Data 31010 ApcRolandoОценок пока нет

- Watershed & Four Water ConceptДокумент31 страницаWatershed & Four Water ConceptNarendra SinghОценок пока нет

- DemarcationДокумент4 страницыDemarcationpradz4Оценок пока нет

- Palm Tower 3 Coverage ReportДокумент61 страницаPalm Tower 3 Coverage ReportHassan DaudОценок пока нет

- HuskyДокумент10 страницHuskypreetimurali100% (1)

- Min. Requirements For Retaining Wall/Sloping BackfillДокумент6 страницMin. Requirements For Retaining Wall/Sloping Backfillfostbarr0% (1)

- CV Template ReceptionistДокумент2 страницыCV Template ReceptionistMuhammad Waqas LatifОценок пока нет

- Rtad Heat Recovery CatalogДокумент48 страницRtad Heat Recovery Catalogaidoudi walidОценок пока нет

- ZZZXДокумент14 страницZZZXJay R DenostaОценок пока нет

- 80305a PDFДокумент7 страниц80305a PDFlorisseОценок пока нет

- ISN SM 50 ManualДокумент8 страницISN SM 50 Manualsinggih bramantyoОценок пока нет