Академический Документы

Профессиональный Документы

Культура Документы

Hiking Superior Industrial Co., Limited: Certificate of Detailed Quality

Загружено:

Carlos Cordova0 оценок0% нашли этот документ полезным (0 голосов)

25 просмотров1 страницаReporT

Оригинальное название

Gráfico1

Авторское право

© © All Rights Reserved

Доступные форматы

PDF, TXT или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документReporT

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

25 просмотров1 страницаHiking Superior Industrial Co., Limited: Certificate of Detailed Quality

Загружено:

Carlos CordovaReporT

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF, TXT или читайте онлайн в Scribd

Вы находитесь на странице: 1из 1

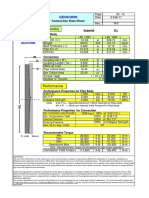

HIKING SUPERIOR INDUSTRIAL CO.

, LIMITED

CERTIFICATE OF DETAILED QUALITY

HAS BEEN FOUND TO CONFORM TO THE QUALITY SYSTEM STANDARD : ISO 9001

CONTRACT NO. : 2017HKS--008Y DATE OF TEST : 2017. 04. 08 QR8. 2--17

STEEL WIRE ROPE SURFACE STATE EG DIA OF CORE WIRE 0. 57 (mm)

PRODUCTS

DIA OF SURROUNDING

CONSTRUCTION 6x19+IWRC DIA 5/16 0. 50 (mm)

STRANDS

T/S 1870 N / mm2 LAY RHRL T/S 1870 N / mm2

GRADE OF QUALITY OF

COMMONLY CHECK OUT TEST CERTIFICATE OF STEEL WIRE

APLICATIONS FACIES

LENGTH 2000M*5 NT. WT 2353KG MAX MIN

DATE OF TENSILE STRENGTH

PACKAGING WOODEN REEL 2017. 03 2190 1890

MANUFACTURE ( N/mm2)

REEL NO. NUMBER OF BENDS 17 14

NUMBER OF TORSIONS 37 24

MINIMUM

39. 1 KN RATIO OF KNOTTING

BREAKING LOAD

TENSION

WEIGHT OF ZINC

COATINGS (g/m2)

ACCORDING AS GB/T 20118--2006 GRADE OF

APPLICATIONS OR COMMONLY

TOUGHNESS

SPECIAL SEAL OF RPOOF--TEST DATE: 2017. 04. 08

ANNOTATE: 1. Be sure to wind or release steel wire ropes in ninght direction. 2. Proper protective grease coating wooden sleeper

under steel wire ropes and waterproof covers are necessary when storing the ropes out of doors, To store used wire ropes be sure to clean

the rope and to coat it with fresh grease. 3. Be sure to prevent steel wire ropes from overload, over speed, impact and vibration. 4. Be sure

to check steel wire ropes regulalarly and replace old wire rope with new ones.

Reference Specifications: ASTM - A - 1023; API Spec 9A; EN 12385 - 4

Вам также может понравиться

- Nantong Tiema Metal Products ISO 9001 certificateДокумент6 страницNantong Tiema Metal Products ISO 9001 certificateAsdrubal Fredy GutierrezОценок пока нет

- Design Data Sheet: Insulating JointsДокумент1 страницаDesign Data Sheet: Insulating Jointsibra benaОценок пока нет

- Revised Offer THEJO ZA 600KLДокумент1 страницаRevised Offer THEJO ZA 600KLrajaОценок пока нет

- NASH ENGINEERING LIQUID RING PUMP SPECIFICATION SHEETДокумент1 страницаNASH ENGINEERING LIQUID RING PUMP SPECIFICATION SHEETGabriel VejarОценок пока нет

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Документ55 страницG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHОценок пока нет

- GEL-IN-CIL-IDT-V-DRG-003Документ25 страницGEL-IN-CIL-IDT-V-DRG-003rinkukachhelaОценок пока нет

- Pt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Документ2 страницыPt. Bukaka Teknik Utama: Welding Book Process Piping (Duplex)Solikhul HarisОценок пока нет

- Wire Rope Test CertificateДокумент2 страницыWire Rope Test CertificateDustin Xender50% (2)

- 4G70mm N2XBY Type Test ReportДокумент1 страница4G70mm N2XBY Type Test ReportB JoldzicОценок пока нет

- Tech Specs-1000M3 LNG TankДокумент1 страницаTech Specs-1000M3 LNG Tankf09aiОценок пока нет

- Un Series - DatasheetДокумент3 страницыUn Series - DatasheetAamir SayeedОценок пока нет

- Report on Welding Procedure Specifications for Single V-Groove JointsДокумент15 страницReport on Welding Procedure Specifications for Single V-Groove JointsAvishek Gupta100% (1)

- 54 PNA enДокумент2 страницы54 PNA enArmin HajdarovićОценок пока нет

- Fire and Gas Detection System Cable ScheduleДокумент6 страницFire and Gas Detection System Cable ScheduleAnonymous v6ybIxZFОценок пока нет

- Er89-196 MHF 50Документ1 страницаEr89-196 MHF 50Gabriel VejarОценок пока нет

- Base Plate External Pipe Rack PK 12bДокумент2 страницыBase Plate External Pipe Rack PK 12bDass DassОценок пока нет

- 45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselДокумент4 страницы45 KL Oil Storage Tank V-102: Mechanical Data Sheet For VesselKrunalОценок пока нет

- Low SupportДокумент1 страницаLow SupportMDhana SekarОценок пока нет

- POLYTUNG-NICRBWC DatasheetДокумент1 страницаPOLYTUNG-NICRBWC Datasheetrajeevkv4Оценок пока нет

- 50-0RG2N-DD-021 Data Sheet For Ad-306001 (Bit)Документ3 страницы50-0RG2N-DD-021 Data Sheet For Ad-306001 (Bit)RajaramОценок пока нет

- PT. VARIA USAHA BETON Mini Pile SpecificationДокумент4 страницыPT. VARIA USAHA BETON Mini Pile Specificationsugi zhuangОценок пока нет

- NA2XSEBY 3x (35 300) MM 12 20kVДокумент4 страницыNA2XSEBY 3x (35 300) MM 12 20kVKontraktor Panel SceОценок пока нет

- Samples Spection Report GREE CABO 3X2,50mm 5,0m CegoДокумент1 страницаSamples Spection Report GREE CABO 3X2,50mm 5,0m CegoMoises NogueiraОценок пока нет

- WE HEREBY That The Following Tire Products Are Manufactured in Compliance With The Specifications of Norm INEN 2100Документ2 страницыWE HEREBY That The Following Tire Products Are Manufactured in Compliance With The Specifications of Norm INEN 2100Daniel BarbaОценок пока нет

- Technical Specification N3 Wind Conditions: Design NotesДокумент1 страницаTechnical Specification N3 Wind Conditions: Design NotesMinh HoОценок пока нет

- 1416 MC MDS V 104 - Rev.0Документ5 страниц1416 MC MDS V 104 - Rev.0KrunalОценок пока нет

- NiCu-7 solid wire for welding nickel-copper alloysДокумент1 страницаNiCu-7 solid wire for welding nickel-copper alloyssatnamОценок пока нет

- Mechanical Data Sheet For Nitrogen ReceiverДокумент8 страницMechanical Data Sheet For Nitrogen ReceiversudjonoОценок пока нет

- Wall Thickness: Piping SpecificationДокумент2 страницыWall Thickness: Piping SpecificationLynn AlgerОценок пока нет

- Nas 1714Документ2 страницыNas 1714YossiОценок пока нет

- Samples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Документ1 страницаSamples Spection Report Signify Fio Sólido Vermelho 0,50mm2 440610001241Moises NogueiraОценок пока нет

- BOQ Concrete Works (1) PricedДокумент2 страницыBOQ Concrete Works (1) PricedAbdullah AkmalОценок пока нет

- 33KV Rigid Bus SupportДокумент6 страниц33KV Rigid Bus SupportNNANYELU CHINWUBAОценок пока нет

- Flare Scrubber DSДокумент8 страницFlare Scrubber DSsudjonoОценок пока нет

- Shandong Tanglu Metal Material Co., LTDДокумент1 страницаShandong Tanglu Metal Material Co., LTDAndro RgcОценок пока нет

- Cs Co.,L TD.: Mill Test CertificateДокумент1 страницаCs Co.,L TD.: Mill Test CertificateVishva NathanОценок пока нет

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaДокумент1 страницаSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitОценок пока нет

- Aramco Accumulator Vessel Data SheetДокумент3 страницыAramco Accumulator Vessel Data SheetAhmed MusallamОценок пока нет

- Reference List ACHE PDFДокумент8 страницReference List ACHE PDFMarakanaMaheshОценок пока нет

- Hascelik-Acsr 490-65Документ1 страницаHascelik-Acsr 490-65Maxence MenandezОценок пока нет

- Bharat Heavy Electricals Limited, Bhopal Traction Machines Engineering DivisionДокумент2 страницыBharat Heavy Electricals Limited, Bhopal Traction Machines Engineering DivisionJfsgksktsОценок пока нет

- L&T Hydrocarbon Modular Fabrication Fit Up ReportДокумент54 страницыL&T Hydrocarbon Modular Fabrication Fit Up ReportPrathamesh OmtechОценок пока нет

- Supplier:Neel Metal Products Ltd. (Faridabad) : Process FmeaДокумент1 страницаSupplier:Neel Metal Products Ltd. (Faridabad) : Process FmearohitОценок пока нет

- WPS PQR Smaw + Fcaw D1.1Документ8 страницWPS PQR Smaw + Fcaw D1.1Yhuto W. Putra100% (3)

- LT AB Cable GTPsДокумент3 страницыLT AB Cable GTPsnishant sainiОценок пока нет

- Vanillin Crude B Column Mechanical DatasheetДокумент3 страницыVanillin Crude B Column Mechanical DatasheetDarshan PanchalОценок пока нет

- BR HRRL Tank 00000 71127 DWG Rsfps 078 - Rev.1 - Code R With CommentsДокумент15 страницBR HRRL Tank 00000 71127 DWG Rsfps 078 - Rev.1 - Code R With CommentsNeilNJohnОценок пока нет

- Mill Certificate: 2 2 2 3 3 3 4 N/mm2 N/mm2 % x10 x10 x10 x10 x10 x10 x10Документ1 страницаMill Certificate: 2 2 2 3 3 3 4 N/mm2 N/mm2 % x10 x10 x10 x10 x10 x10 x10Binh Hung OngОценок пока нет

- IOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01Документ1 страницаIOCL-EKC-STATIONARY CASCADE-DIA 559 X 06 CYLINDER X 3000 LTR-SHEET 1 OF 5-REV.01subudhiprasannaОценок пока нет

- TZX-Series Diodo ZenerДокумент7 страницTZX-Series Diodo ZenerPedro RodriguezОценок пока нет

- KGSB 170074 Af 06 - A0 PDFДокумент1 страницаKGSB 170074 Af 06 - A0 PDFLallamaОценок пока нет

- Metal One Corp. Connection Data SheetДокумент1 страницаMetal One Corp. Connection Data SheetBalkis FatihaОценок пока нет

- DS-01 - LR BendsДокумент1 страницаDS-01 - LR BendsMecon LtdОценок пока нет

- Seacon Catalog - Hummer ConnectorДокумент8 страницSeacon Catalog - Hummer ConnectorBruno SallesОценок пока нет

- Roxul Comfortboard 80: Insulated SheathingДокумент1 страницаRoxul Comfortboard 80: Insulated SheathingMark RauОценок пока нет

- Christofer Seguel Campos P8-36Документ1 страницаChristofer Seguel Campos P8-36bareau.informationОценок пока нет

- Terminal BlocksДокумент6 страницTerminal Blockshasanah1108aОценок пока нет

- Token Ring Technology ReportОт EverandToken Ring Technology ReportОценок пока нет

- sl-20140 PPCДокумент52 страницыsl-20140 PPCcarlosj_echeverriaОценок пока нет

- Wires and Cables PDFДокумент14 страницWires and Cables PDFRomel Panis88% (8)

- Astm A121 PDFДокумент4 страницыAstm A121 PDFbanglvhОценок пока нет

- E50100d 160208 PWS RoctestДокумент2 страницыE50100d 160208 PWS RoctestJohel Kevin Berrocal TabrajОценок пока нет

- Astm A416-A416m-05Документ5 страницAstm A416-A416m-05NadhiraОценок пока нет

- Cable Tray ExcellentДокумент27 страницCable Tray Excellentraja kumarОценок пока нет

- Itm - Codigos SiemensДокумент234 страницыItm - Codigos SiemensSantiago FarfanОценок пока нет

- 13 7X 8 Forged Wire Stripper Data SheetДокумент2 страницы13 7X 8 Forged Wire Stripper Data SheetSonaina KhanОценок пока нет

- Analytic Performance Scoring Rubrics For Dustpan Making Criteria Performance IndicatorsДокумент4 страницыAnalytic Performance Scoring Rubrics For Dustpan Making Criteria Performance Indicatorsfull docsОценок пока нет

- LIT941 0618 Installation ManualДокумент8 страницLIT941 0618 Installation ManualBurhan SharafОценок пока нет

- Cutler Hammer CH340Документ10 страницCutler Hammer CH340Josue Crespo GonzalezОценок пока нет

- AAAC XLPE Overhead Conductor SpecificationДокумент1 страницаAAAC XLPE Overhead Conductor SpecificationMarioОценок пока нет

- 110V. Three Wire Motor Using Leviton Switch: CoverstarДокумент1 страница110V. Three Wire Motor Using Leviton Switch: CoverstarGjpuОценок пока нет

- Speedrite Electric Fencing ManualДокумент34 страницыSpeedrite Electric Fencing ManualismaelОценок пока нет

- Example Problem 18-1: SpringsДокумент5 страницExample Problem 18-1: SpringsVinaasha BalakrishnanОценок пока нет

- REMOTE SENSOR DC2We PDFДокумент11 страницREMOTE SENSOR DC2We PDFvipvashОценок пока нет

- BH - MaterialsДокумент10 страницBH - MaterialsFranc Anthony GalaoОценок пока нет

- Set Up RAMPS (Arduino, RepRap)Документ1 страницаSet Up RAMPS (Arduino, RepRap)DanielSpinozaОценок пока нет

- 49 Dstu en So 14343 2019 Zvaryuvaln Mater AliДокумент23 страницы49 Dstu en So 14343 2019 Zvaryuvaln Mater AliUDDOM CHHENGОценок пока нет

- Locatio Map A: Symbols DescriptionДокумент1 страницаLocatio Map A: Symbols DescriptionAlsean Soriano DetubioОценок пока нет

- MinarcMig Evo Operating Manual 1910020 1340 enДокумент26 страницMinarcMig Evo Operating Manual 1910020 1340 enAnanta SatpathyОценок пока нет

- BS en 10223-4-2012Документ16 страницBS en 10223-4-2012Federico De MartiniОценок пока нет

- Loading Methods in PLS-CADDДокумент17 страницLoading Methods in PLS-CADDSimonckloh100% (1)

- Conductor Ampacity Based On The 2017 National Electrical Code®Документ1 страницаConductor Ampacity Based On The 2017 National Electrical Code®Ira Jane LosañezОценок пока нет

- Shielding of Power CablesДокумент6 страницShielding of Power CablesYudo Heru PribadiОценок пока нет

- Morgan Advanced Materials Collector Brochure English ModifiedДокумент12 страницMorgan Advanced Materials Collector Brochure English Modifiedra suОценок пока нет

- 03 Jul 201511 Jun 2014fiana162779Документ6 страниц03 Jul 201511 Jun 2014fiana162779Saumya ShrivastavaОценок пока нет

- Poliuretano - Mallas WS85Документ32 страницыPoliuretano - Mallas WS85Oscar C SotomayorОценок пока нет

- CNC EDM Wire Cutting Machine User ManualДокумент45 страницCNC EDM Wire Cutting Machine User Manualdprdouglas100% (2)

- ResumeДокумент4 страницыResumewraheelОценок пока нет