Академический Документы

Профессиональный Документы

Культура Документы

HexPly M21 Global DataSheet

Загружено:

Guillermo MartínezАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

HexPly M21 Global DataSheet

Загружено:

Guillermo MartínezАвторское право:

Доступные форматы

HexPly M21

180C (350F) curing epoxy matrix

Product Data Sheet

Description

HexPly 21 is a high performance, very tough epoxy matrix for use in primary aerospace structures. It exhibits

excellent damage tolerance, especially at high energy impacts.

HexPly M21 is a toughened epoxy resin system supplied with unidirectional or woven carbon or glass fibers.

HexPly M21 was developed as a controlled flow system to operate in environments up at 121C (250F).

Benefits and Features

Excellent toughness, in particular at high energy impact.

High residual compression strength after impact.

Effective translation of fibre properties, especially with intermediate modulus carbon fiber.

Good hot-wet properties up to 150C (302F).

Low exotherm behavior allowing simple cures of thick structures up to 48mm (1.89).

Good tack life.

HexPly M21 is best suited to press or autoclave cure to obtain optimum mechanical performance from the

cured composite.

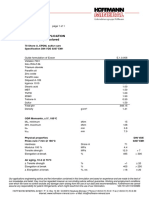

Resin Matrix Properties

Gel Time

Gel Time (minutes)

50

40

30

20

10

0

140 150 160 170 180 190 200 210 220

Copyright 2015 Hexcel Corporation All Rights Reserved. 1

HexPly M21

180C (350F) curing epoxy matrix

Product Data Sheet

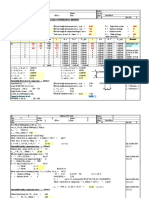

Cure Cycle Viscosity Profiles

All experiments were made on an ARES-RDA Rheometer and correspond to the recommended cure cycles overleaf.

Typical Autoclave Cure Monolithic Par <15mm (0.6) thick

1C/min (2F/min) heat-up rate 3C/min (5F/min) heat-up rate

1.E+05 200 1.E+05 200

180 180

1.E+04 1.E+04

160 160

Temperature

Temperature

Viscosity

140

Viscosity

1.E+03 140 1.E+03

120 120

1.E+02 100 1.E+02 100

80 80

1.E+01 1.E+01

60 60

1.E+00 40 1.E+00 40

0 25 50 75 100 125 150 0 25 50 75

Time (minutes) Time (minutes)

Pa-s Pa-s

Typical Autoclave Cure Monolithic Par 15 - 48mm (0.6-1.89) thick

1C/min (2F/min) heat-up rate 3C/min (5F/min) heat-up rate

1.E+05 200

1.E+05 200

180

1.E+04 180

160 1.E+04

160

Temperature

Temperature

140

Viscosity

140

Viscosity

1.E+03 1.E+03

120 120

1.E+02 1.E+02 100

100

80

80 1.E+01

1.E+01 60

60

1.E+00 40

1.E+00 40 0 25 50 75 100 125

0 25 50 75 100 125 150 175

Time (minutes)

Time (minutes)

Pa-s C

Pa-s

Typical Autoclave Cure Sandwich Parts

1C/min (2F/min) heat-up rate 3C/min (5F/min) heat-up rate

1.E+05 200 1.E+05 200

180 180

1.E+04 1.E+04

160 160

Temperature

Temperature

Viscosity

Viscosity

1.E+03 140 1.E+03 140

120 120

1.E+02 100 1.E+02 100

80 80

1.E+01 1.E+01

60 60

1.E+00 40 1.E+00 40

0 25 50 75 100 125 150 175 200 0 25 50 75 100 125

Time (minutes) Time (minutes)

Pa-s Pa-s

Prepreg Lay-up

To achieve the best laminate quality, the 1st ply should be vacuum debulked to the mould at room temperature.

Vacuum debulking of subsequent plies may be necessary to ensure removal of air trapped during the lay-up

process. The frequency of debulking depends on part size and complexity.

Copyright 2015 Hexcel Corporation All Rights Reserved. 2

HexPly M21

180C (350F) curing epoxy matrix

Product Data Sheet

Prepreg Curing Conditions

Defined heat-up rates will vary depending on the autoclave dimensions, the mass of tooling used and the size of

the component to be manufactured.

Typical Autoclave Cure Monolithic Part <15mm (0.6) thick (1)

1. Apply full vacuum (1 bar).

2. Apply 7 bar gauge autoclave pressure.

3. Reduce vacuum to a safety value of -0.2 bar when the autoclave pressure

reaches ~ 1 bar gauge

4. Set heat-up rate from room temperature to 180C 5C (356C 9F) to

achieve an actual component heat-up rate between 1-2C/minute (2-4F/

minute).

5. Hold at 180C 5C (356C 9F) for 120 minutes 5 minutes.

6. Cool component at an actual cooldown rate of 2-5C/minute (4-9F/minute).

7. Vent autoclave pressure when the component reaches 60C (140F) or below.

Typical Autoclave Cure Monolithic Part <15mm-48mm (0.6-1.89) thick (1)

1. Apply full vacuum (1 bar).

2. Apply 7 bar gauge autoclave pressure.

3. Reduce vacuum to a safety value of -0.2 bar when the autoclave pressure

reaches ~ 1 bar gauge

4. Set heat-up rate from room temperature to 150C 5C (302C 9F) to

achieve and actual component heat-up rate between 0.5-1C/minute (1-

2F/ minute).

5. Hold at 150C 5C (302C 9F) for 180 minutes 5 minutes.

6. Set heat-up rate from 150C 5C (302C 9F) to 180C 5C (356C 9F)

to achieve an actual heat-up rate between 0.5-1C/minute (1-2F/minute).

7. Hold at 180C 5C (356C 9F) for 120 minutes 5 minutes.

8. Cool component at an actual cooldown rate of 2-5C/minute (4-9F/minute).

9. Vent autoclave pressure when the component reaches 60C (140F) or below.

Typical Autoclave Cure Sandwich Structure - Honeycomb or Foam (1)

1. Apply -0.3 bar maximum vacuum.

2. Do not apply autoclave pressure.

3. Set heat-up rate from room temperature to 135C 5C (275C 9F) to

achieve an actual heat-up rate between 1-2C/minute (2-4F/minute).

4. Hold at 135C 5C (275C 9F) for 60 minutes 5 minutes

5. After 60 minutes at 135C (275C), apply 2-3 bar gauge autoclave pressure

(dependent on core density).

6. Remove vacuum when the autoclave pressure reaches ~1 bar gauge.

7. Set heat-up rate from 135C 5C (275C 9F) to 180C 5C (356C 9F)

to achieve an actual heat-up rate between 1-2C/minute (2-4F/minute).

8. Hold at 180C 5C (356C 9F) for 120 minutes 5 minutes.

9. Cool component at an actual cooldown rate of 2-5C/minute (4-9F/minute).

10. Vent autoclave pressure when the component reaches 60C (140F) or below.

(1) As the cure cycle tolerance are related to the material, the temperature profile of the whole part must be kept within these tolerances. Thermocouples have to

be applied to the component to guarantee that the temperature recording is representative of the actual experienced cure cycle of the component.

Copyright 2015 Hexcel Corporation All Rights Reserved. 3

HexPly M21

180C (350F) curing epoxy matrix

Product Data Sheet

Cured Unidirectional Prepreg Properties

Nomenclature: resin/resin content by weight (%)/fiber weight (gsm)/fiber type

M21/34%/UD194/ M21/34%/ UD194/ M21/34%/ UD194/

Physical Properties Units

IM7-12K AS7-12K IMA-12K

Fiber IM7 AS7 IMA

Weave/UD g/m UD UD UD

Fiber Mass 194 194 194

Nominal Prepreg Mass g/m 294 294 294

Theoretical Calculated mm 0.184 0.184 0.184

Cured Ply Thickness (inch) (0.0072) (0.0072) (0.0072)

Theoretical Calculated

% 59.2 58.9 59.2

Fiber Volume

g/cm3 1.28 1.28

Resin Density

(lbs/ft3) (79.9) (79.9)

g/cm3 1.78 1.79 1.79

Fiber Density

(lbs/ft3) (111.1) (111.1) (111.1)

Theoretical Calculated g/cm3 1.58 1.58 1.58

Laminate Density (lbs/ft3) (98.6) (98,6) (98,6)

Mechanical Temp M21/34%/UD194/ M21/34%/ UD194/ M21/34%/ UD194/

Units

Properties C (F) IM7-12K AS7-12K IMA-12K

Test Standards US Standards European Standards

Glass Transition

C (F) 195 (383) 195 (383)

Temperature

Method ASTM E1640 EN 6032 - DMA extrapolated onset E

Tension Strength MPa (ksi) 23 (73) 2860 (415) 2350 (341) 3050 (442)

Tension Modulus GPa (msi) 23 (73) 160 (23.2) 148 (21.5) 178 (25.8)

Method ASTM D3039 (1) EN 2561 B

Compression Strength MPa (ksi) 23 (73) 1790 (260) 1560 (226) 1500 (218)

Compression Modulus GPa (msi) 23 (73) 148 (21.4) 123 (17.8) 146 (21.2)

Method ASTM D695 (2) EN 2850 B

ILSS MPa (ksi) 23 (73) 110 (15.9) 114 (16.5) 97 (14.1)

Method ASTM 2344 EN 2563

In-plane Shear Strength MPa (ksi) 23 (73) - 109 (15.8) 94 (13.6)

In-plane Shear Modulus GPa (msi) 23 (73) 4.6 (0.67) 5.2 (0.75) 5.2 (0.75)

Method ASTM D3039 (3) EN 6031

Open Hole Tension MPa (ksi) 23 (73) 495 (72) 365 (53) 510 (74)

Method - (25/50/25) (gross section) ASTM 5766 (5) EN6035 (4)

Open Hole Compression MPa (ksi) 23 (73) 303 (44) 315 (46) 305 (44)

Method - (25/50/25) (gross section) ASTM D6484 EN 6063 (6)

CAI @ 30.5J MPa (ksi) 23 (73) 298 (43) - -

CAI @ 30.0J MPa (ksi) 23 (73) - 238 (34.5) 219 (31.8)

Method - (25/50/25) ASTM D7136-D137 EN6038

(1) Specimen dimensions: 12.7mm wide and 127mm free length (0.5 wide and 5 free length)

(2) Specimen dimensions: 80x12.7mm (3.1x0.5)

(3) Specimen dimensions: 12.7mm wide and 127mm free length (+45/-45)s (0.5 wide and 5 free length)

(4) Specimen dimensions: 280x32 mm (11x1.3)

(5) Specimen dimensions: 305x38mm and 6.35mm hole diameter (12x1.5 and 0.25 hole diameter)

(6) Specimen dimensions: 132x32mm and 32 mm free length (5.2x1.3 and 1.3 free length)

Copyright 2015 Hexcel Corporation All Rights Reserved. 4

HexPly M21

180C (350F) curing epoxy matrix

Product Data Sheet

Cured Woven Prepreg Properties

Nomenclature: resin/resin content by weight (%)/reinforcement reference/width (mm)

M21/40%/285T2/ M21/35%/370H5/

Physical Properties Units M21/37%/7581 M21/45%/120 M21/56%/1080

AS4C-6K AS4C-6K

Fiber AS4C AS4C E-Glass E-Glass E-Glass

Weave/UD g/m 2x2 twill 5HS 8HS 4HS PW

Fiber Mass 285 370 300 105 48

Prepreg Mass g/m 475 569 476 193 109

Theoretical Calculated mm 0.285 0.343 0.235 0.106 0.066

Cured Ply Thickness (inch) (0.0112) (0.013) (0.009) (0.004) (0.0026)

Theoretical Calculated

% 55.8 60.2 50.0 38.4 28.2

Fiber Volume

g/cm 1.28

Resin Density

(lbs/ft) (79.9)

g/cm 1.78 1.78 2.56 2.56 2.56

Fiber Density

(lbs/ft) (111.1) (111.1) (159.8) (159.8) (159.8)

Theoretical Calculated g/cm 1.56 1.59 1.92 1.77 1.64

Laminate Density (lbs/ft) (97.7) (99.1) (119.9) (110.5) (102.4)

Mechanical Temp M21/40%/285T2/ M21/35%/370H5/

Units M21/37%/7581 M21/45%/120

Properties C (F) AS4C-6K AS4C-6K

Glass Transition

C (F) 195 (383)

Temperature

Method EN 6032 - DMA extrapolated onset E

Tension Strength MPa (ksi) 23 (73) 885 (128) 880 (128) 444 (64) 320 (weft) (46)

Tension Modulus GPa (msi) 23 (73) 67.6 (9.8) 73.9 (10.7) 25.5 (3.7) 24.8 (weft) (3.6)

Method EN 2597 B EN 2747

Compression Strength MPa (ksi) 23 (73) 835 (121) 820 (119) 692 (weft) (100) 674 (weft) (98)

Compression Modulus GPa (msi) 23 (73) 59.7 (8.6) 63.9 (9.3) - -

Method EN 2850 B

ILSS MPa (ksi) 23 (73) 70 (10.1) 70 (10.1) 75 (10.8) 60 (8.7)

Method EN 2563 EN 2377

In-plane Shear Strength MPa (ksi) 23 (73) 97 (14) 94 (14) 99 (14) -

In-plane Shear Modulus GPa (msi) 23 (73) 4.2 (0.61) 4.8 (0.70) 4.4 (0.64) -

Method EN 6031

Open Hole Tension MPa (ksi) 23 (73) 340 (49) 375 (54) - -

Method - (25/50/25) (gross section) EN6035 (1)

Open Hole Compression MPa (ksi) 23 (73) 330 (48) 345 (50) - -

Method - (25/50/25) (gross section) EN 6063 (2)

CAI @ 30.0J MPa (ksi) 23 (73) 276 (40) 270 (39) - -

Method - (25/50/25) EN6038

(1) Specimen dimensions: 280x32mm (11x1.3)

(2) Specimen dimensions: 132x32mm and 32mm free length (5.2x1.3 and 1.3 free length)

Results for UD and Woven prepregs after an autoclave cure at 180C (356F) for 120 minutes.

Data normalised to Vf = 59% (0.184mm (0.0072) ply) for UD

Data normalised to Vf=56% (0.285mm (0.0112) ply) for 285T2 and Vf=60.5% (0.343mm (0.013) ply) for 370H5, to Vf = 50% for 7581

No normalization for ILSS and IPS (shear properties)

Woven samples tested in the warp direction.

Nominal cured ply thickness quoted is based on zero bleed and is determined using the fiber weight, resin content and resin & fiber density. Data quoted is for

comparison only.

Copyright 2015 Hexcel Corporation All Rights Reserved. 5

HexPly M21

180C (350F) curing epoxy matrix

Product Data Sheet

Prepreg Storage Life

Tack Life: 10 to 15 days at 23C (73F) dependent on lay-up process (hand lay-up, ATL, AFP)

Out Life: 30 days at 23C (73F)

Shelf Life: 12 months at -18C (0F) (*from date of manufacture

Definitions:

Tack Life: The time, at room temperature, during which prepreg retains enough tack for easy component

lay-up.

Out Life: The maximum accumulated time allowed at room temperature between removal from the freezer

and cure.

Shelf Life: The maximum storage life for HexPly M21 prepreg, upon receipt by the customer, when stored

continuously, in a sealed moisture-proof bag, at -18 C (o F). To accurately establish the exact

expiry date, consult the box label.

HexPly M21 prepregs should be stored as received in a cool dry place or in a refrigerator. After removal from

refrigerator storage, prepreg should be allowed to reach room temperature before opening the polythene bag,

thus preventing condensation (A full reel in its packaging can take up to 48 hours).

Precautions for Use

The usual precautions when handling uncured synthetic resins and fibrous materials should be observe, and a

Safety Data Sheet is available for this product. The use of clean, disposable, inert gloves provides protection for

the operator and avoids contamination of material and components.

For more information

Hexcel is a leading worldwide supplier of composite materials to aerospace and industrial markets.

Our comprehensive range includes:

HexTow carbon fibers HexFlow RTM resins Acousti-Cap sound attenuating

HexForce reinforcements Redux adhesives honeycomb

HexPly prepregs HexTool tooling materials Engineered core

HexMC molding compounds HexWeb honeycombs Engineered products

For US quotes, orders and product information call toll-free 1-800-688-7734. For other worldwide sales office

FTA-002-AG16

telephone numbers and a full address list, please go to:

http://www.hexcel.com/contact/salesoffice

2016 Hexcel Corporation All rights reserved. Hexcel Corporation and its subsidiaries (Hexcel) believe that the technical data and other information

provided herein was materially accurate as of the date this document was issued. Hexcel reserves the right to update, revise or modify such technical data and

information at any time. Any performance values provided are considered representative but do not and should not constitute a substitute for your own testing of

the suitability of our products for your particular purpose. Hexcel makes no warranty or representation, express or implied, including but not limited to

the implied warranties of merchantability and fitness for a particular purpose, and disclaims any liability arising out of or related to, the use of or

reliance upon any of the technical data or information contained in this document.

6

Вам также может понравиться

- Ansi Aiaa S-081b Space Systems - CopvДокумент54 страницыAnsi Aiaa S-081b Space Systems - CopvGuillermo MartínezОценок пока нет

- Me PADSДокумент2 страницыMe PADSJoshua Ndalo100% (1)

- ECSS E HB 32 22A Insert Design HandbookДокумент488 страницECSS E HB 32 22A Insert Design HandbookGuillermo Martínez100% (1)

- Nasa - Standard Materials and Processes PDFДокумент56 страницNasa - Standard Materials and Processes PDFGuillermo MartínezОценок пока нет

- ECSS E HB 32 22A Insert Design HandbookДокумент488 страницECSS E HB 32 22A Insert Design HandbookGuillermo Martínez100% (1)

- ECSS E HB 31 01 - Part6A Thermal Control SurfacesДокумент342 страницыECSS E HB 31 01 - Part6A Thermal Control SurfacesGuillermo MartínezОценок пока нет

- SMMS7 - Mini7 Product Line-Up OverviewДокумент46 страницSMMS7 - Mini7 Product Line-Up OverviewTín Nguyễn ThànhОценок пока нет

- Carbon Crmo Alloyed Stainless E309 E308 E309 E308 E308 E308 - E308LДокумент2 страницыCarbon Crmo Alloyed Stainless E309 E308 E309 E308 E308 E308 - E308LInaamОценок пока нет

- Sheathing, Light-Colored, DIN VDE 0207 EM1, 70 Shore A, EPDM, Sulfur Cure (E - 1 - 0 - 006)Документ1 страницаSheathing, Light-Colored, DIN VDE 0207 EM1, 70 Shore A, EPDM, Sulfur Cure (E - 1 - 0 - 006)andresmsantoshОценок пока нет

- Experiment No 09Документ10 страницExperiment No 09Fahad MehmoodОценок пока нет

- Operating and Installation ConditionsДокумент1 страницаOperating and Installation ConditionsJames GeorgeОценок пока нет

- Commercial Quality SteelДокумент2 страницыCommercial Quality Steeljamal nasirОценок пока нет

- T - Thermanit MTS 4 - Se - en - 5Документ1 страницаT - Thermanit MTS 4 - Se - en - 5bhanu.kiranОценок пока нет

- Solid State Pressure Sensor: FeaturesДокумент2 страницыSolid State Pressure Sensor: FeaturesCarlosDíazPeñaОценок пока нет

- FMEN-210A: Schottky Barrier DiodeДокумент7 страницFMEN-210A: Schottky Barrier DiodeFRANK NIELE DE OLIVEIRAОценок пока нет

- Mws Gen Aae Spe IntroductionДокумент6 страницMws Gen Aae Spe IntroductionautarkawОценок пока нет

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGДокумент2 страницыKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGBiaizidi Abbou SamirОценок пока нет

- Weldplast S6: Type of Welding MachineДокумент1 страницаWeldplast S6: Type of Welding MachineRICARDO NUÑEZ ALARCONОценок пока нет

- Electrical General - Answers - TempДокумент10 страницElectrical General - Answers - TempMohamed LabibОценок пока нет

- KSH International Enamelled Copper Conductors/Strips BrochureДокумент2 страницыKSH International Enamelled Copper Conductors/Strips Brochurekshintl100% (1)

- T Thermanit GEW 316L-17 Se en 5Документ1 страницаT Thermanit GEW 316L-17 Se en 5PubcrawlОценок пока нет

- Ncut Antiextrusion Ring For Metric Ing: MaterialДокумент4 страницыNcut Antiextrusion Ring For Metric Ing: MaterialArun JaisonОценок пока нет

- User Guide, S1 TITAN Weld AdapterДокумент2 страницыUser Guide, S1 TITAN Weld AdapterWoodrow FoxОценок пока нет

- Elmwood Temperatursicherung Eng TdsДокумент6 страницElmwood Temperatursicherung Eng TdsSebastianSimonОценок пока нет

- Ncut Antiextrusion Ring For Standard Ing: MaterialДокумент6 страницNcut Antiextrusion Ring For Standard Ing: MaterialArun JaisonОценок пока нет

- Astm A1Документ1 страницаAstm A1shahid khanОценок пока нет

- Erapol E90A: Technical DatasheetДокумент2 страницыErapol E90A: Technical Datasheetmgamal1080Оценок пока нет

- Plate ColumnsДокумент3 страницыPlate ColumnsK SrikanthОценок пока нет

- Technical Information For Typical Stretch CeilingsДокумент2 страницыTechnical Information For Typical Stretch Ceilingseromax1Оценок пока нет

- 1050 Data Sheet: Chemical CompositionДокумент1 страница1050 Data Sheet: Chemical CompositionMiguel Angel Rocca HuaytaОценок пока нет

- Material Comparison 11x17 - September 2020Документ1 страницаMaterial Comparison 11x17 - September 2020asdОценок пока нет

- Service Bulletin No Issue Date: Column "A" Column "B" Column "C"Документ2 страницыService Bulletin No Issue Date: Column "A" Column "B" Column "C"Carlos AdameОценок пока нет

- Chap 10 Marlin 2002Документ42 страницыChap 10 Marlin 2002sabto04296Оценок пока нет

- 09 Christensen NCHRP09-59updateДокумент41 страница09 Christensen NCHRP09-59updates pradhanОценок пока нет

- Not Alloyed: Case-Hardening Steels C16EДокумент1 страницаNot Alloyed: Case-Hardening Steels C16Esafat parОценок пока нет

- c70260 Cuni2si0.4 UsДокумент2 страницыc70260 Cuni2si0.4 UsBeyzanur TepecikОценок пока нет

- KV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGДокумент2 страницыKV45 R45S R45PB - C45E Nr.1.1191 C45R Nr.1.1201 ENGNarimane BentyОценок пока нет

- Ncut Antiextrusion Ring For Standard Ing: MaterialДокумент6 страницNcut Antiextrusion Ring For Standard Ing: MaterialRPINILLA (EICO S.A.)Оценок пока нет

- FFH FasterДокумент1 страницаFFH FasterviniciusОценок пока нет

- 6591TF 2000 Hybrid Web PDFДокумент1 страница6591TF 2000 Hybrid Web PDFGustavo MosqueraОценок пока нет

- Pipeliner® NR®-208-XP: (Applies Only To U.S. Products)Документ2 страницыPipeliner® NR®-208-XP: (Applies Only To U.S. Products)Pablo PazОценок пока нет

- Denison A - T6DDSДокумент3 страницыDenison A - T6DDSMohamed ElmakkyОценок пока нет

- Ss 03044Документ2 страницыSs 03044hyarub9Оценок пока нет

- Q1 Lot Number: 14997588: Certificate of ConformanceДокумент3 страницыQ1 Lot Number: 14997588: Certificate of ConformanceOscar BasantesОценок пока нет

- Chemical Composition Raw Material Grade: Metso Outotec India Private LimitedДокумент3 страницыChemical Composition Raw Material Grade: Metso Outotec India Private LimitedHImanshuОценок пока нет

- Through-Hardening Low Alloy Steel Bar 4340: Colour Code: Jade (Band) - MarigoldДокумент3 страницыThrough-Hardening Low Alloy Steel Bar 4340: Colour Code: Jade (Band) - Marigoldl_aguilar_mОценок пока нет

- Class Examples TableДокумент9 страницClass Examples TableChristian VelasquezОценок пока нет

- Espec Walk in Temperature ChamberДокумент20 страницEspec Walk in Temperature Chamberck_peyОценок пока нет

- Section 1-1: NotesДокумент1 страницаSection 1-1: Notestuyen nguyenОценок пока нет

- High Vibration of Centrifugal Compressors at Hot RestartДокумент23 страницыHigh Vibration of Centrifugal Compressors at Hot RestartAZZAF ChannelОценок пока нет

- Uddeholm C Si MN CR Mo V W Ni Co P S: Vanadis 6Документ1 страницаUddeholm C Si MN CR Mo V W Ni Co P S: Vanadis 6AndiniPermanaОценок пока нет

- Kim Hotstart Heater - 6-71Документ2 страницыKim Hotstart Heater - 6-71Nicolas Arturo Oyarzun ParraoОценок пока нет

- Swissi Safety 3Документ26 страницSwissi Safety 3skydominzeskyОценок пока нет

- StoTherm Insulation System - 80mmДокумент5 страницStoTherm Insulation System - 80mmMurat TopbaştekinОценок пока нет

- Let-Through Energies 415V-220VДокумент3 страницыLet-Through Energies 415V-220VNavneet SinghОценок пока нет

- 07 10 2019 Lamifil Aluminium Alloys For Electrical ApplicationsДокумент1 страница07 10 2019 Lamifil Aluminium Alloys For Electrical ApplicationscantigiОценок пока нет

- ALUMINIUM ALLOYS For Electrical ApplicationsДокумент1 страницаALUMINIUM ALLOYS For Electrical Applicationstwo travellerОценок пока нет

- Certificados - Mtc-Po 23040-Req 14989Документ98 страницCertificados - Mtc-Po 23040-Req 14989MissionPetroleum InfoОценок пока нет

- KSB Pump Catalog Etaline SytДокумент26 страницKSB Pump Catalog Etaline SytCem KalaycıОценок пока нет

- The Navier Solution For The Ssss PlateДокумент4 страницыThe Navier Solution For The Ssss PlateSagarОценок пока нет

- 16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGДокумент2 страницы16MnCr5 1.7131 16MnCrS5 1.7139 RM16 ENGJerzy RistujczinОценок пока нет

- ALUMERO - Alloys EN AW 6060 AlMgSi0 - WebДокумент1 страницаALUMERO - Alloys EN AW 6060 AlMgSi0 - WebemilasanovskiОценок пока нет

- 97 Kurva Kesetimbangan Etanol-Air Pada Tekanan 1 AtmДокумент10 страниц97 Kurva Kesetimbangan Etanol-Air Pada Tekanan 1 AtmIra WatyОценок пока нет

- SA/AS1548 - 7 - 460R: XlerplateДокумент3 страницыSA/AS1548 - 7 - 460R: XlerplatenavОценок пока нет

- Carbon Crmo Alloyed Stainless E309 E308 E309 E308 E308 E347 E347Документ2 страницыCarbon Crmo Alloyed Stainless E309 E308 E309 E308 E308 E347 E347Willian Tavares de CarvalhoОценок пока нет

- ECSS Q ST 40 12C (31july2008)Документ11 страницECSS Q ST 40 12C (31july2008)jsadachiОценок пока нет

- Eurocomposites - Edge Closure - Ec568-106eДокумент1 страницаEurocomposites - Edge Closure - Ec568-106eGuillermo MartínezОценок пока нет

- ECSS E ST 70C (31july2008)Документ128 страницECSS E ST 70C (31july2008)jsadachi100% (1)

- Welding Symbols (ISO 2553)Документ32 страницыWelding Symbols (ISO 2553)Guillermo Martínez0% (1)

- Hexcel - Dry Fiber B DSF 282Документ1 страницаHexcel - Dry Fiber B DSF 282Guillermo MartínezОценок пока нет

- Click Bond Procedures PDFДокумент15 страницClick Bond Procedures PDFGuillermo MartínezОценок пока нет

- ECSS E HB 32 20 - Part6A Fracture and MaterialДокумент428 страницECSS E HB 32 20 - Part6A Fracture and MaterialGuillermo MartínezОценок пока нет

- CH4 1 Welding Joint SymbolsДокумент32 страницыCH4 1 Welding Joint SymbolsGuillermo MartínezОценок пока нет

- ECSS E HB 31 01 - Part7A InsulationsДокумент324 страницыECSS E HB 31 01 - Part7A InsulationsGuillermo MartínezОценок пока нет

- ECSS HB 32 24A Buckling of StructuresДокумент463 страницыECSS HB 32 24A Buckling of StructuresGuillermo MartínezОценок пока нет

- Ecss Q ST 70 14c1 CorrosionДокумент35 страницEcss Q ST 70 14c1 CorrosionGuillermo MartínezОценок пока нет

- ECSS E HB 31 01 - Part14A Cryogenic CoolingДокумент545 страницECSS E HB 31 01 - Part14A Cryogenic CoolingGuillermo MartínezОценок пока нет

- ECSS E HB 31 01 - Part13A Fluid LoopsДокумент489 страницECSS E HB 31 01 - Part13A Fluid LoopsGuillermo MartínezОценок пока нет

- ECSS E 10 03A (15feb2002) PDFДокумент160 страницECSS E 10 03A (15feb2002) PDFMarcoОценок пока нет

- ECSS E HB 31 01 - Part1A View FactorsДокумент126 страницECSS E HB 31 01 - Part1A View FactorsGuillermo MartínezОценок пока нет

- Tutorial 6Документ3 страницыTutorial 6Lai Qing YaoОценок пока нет

- Purification of Dilactide by Melt CrystallizationДокумент4 страницыPurification of Dilactide by Melt CrystallizationRaj SolankiОценок пока нет

- Thompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsДокумент49 страницThompson, Damon - Create A Servitor - How To Create A Servitor and Use The Power of Thought FormsMike Cedersköld100% (5)

- Steve Jobs TalkДокумент3 страницыSteve Jobs TalkDave CОценок пока нет

- Region: South Central State: Andhra PradeshДокумент118 страницRegion: South Central State: Andhra PradeshpaulinОценок пока нет

- Vertical Cutoff WallsДокумент18 страницVertical Cutoff WallsMark LaiОценок пока нет

- Assignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementДокумент3 страницыAssignment 4 Job Order Costing - ACTG321 - Cost Accounting and Cost ManagementGenithon PanisalesОценок пока нет

- CNC - Rdmacror: Public Static Extern Short Ushort Short Short ShortДокумент3 страницыCNC - Rdmacror: Public Static Extern Short Ushort Short Short ShortKession HouОценок пока нет

- Deloitte - Introduction To TS&A - CloudДокумент2 страницыDeloitte - Introduction To TS&A - Cloudsatyam100% (1)

- Report On Monitoring and Evaluation-Ilagan CityДокумент5 страницReport On Monitoring and Evaluation-Ilagan CityRonnie Francisco TejanoОценок пока нет

- OMM 618 Final PaperДокумент14 страницOMM 618 Final PaperTerri Mumma100% (1)

- Learning Module - Joints, Taps and SplicesДокумент9 страницLearning Module - Joints, Taps and SplicesCarlo Cartagenas100% (1)

- Family Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolДокумент11 страницFamily Factors: Its Effect On The Academic Performance of The Grade 6 Pupils of East Bayugan Central Elementary SchoolGrace Joy AsorОценок пока нет

- Genie PDFДокумент277 страницGenie PDFOscar ItzolОценок пока нет

- Math ExamДокумент21 страницаMath ExamedgemarkОценок пока нет

- Context in TranslationДокумент23 страницыContext in TranslationRaluca FloreaОценок пока нет

- Piping Class Spec. - 1C22 (Lurgi)Документ9 страницPiping Class Spec. - 1C22 (Lurgi)otezgidenОценок пока нет

- EvolutionCombatMedic 2022Документ17 страницEvolutionCombatMedic 2022smith.kevin1420344100% (1)

- Multi-Media Approach To Teaching-LearningДокумент8 страницMulti-Media Approach To Teaching-LearningswethashakiОценок пока нет

- State Farm Claims: PO Box 52250 Phoenix AZ 85072-2250Документ2 страницыState Farm Claims: PO Box 52250 Phoenix AZ 85072-2250georgia ann polley-yatesОценок пока нет

- Medical Equipment Quality Assurance For Healthcare FacilitiesДокумент5 страницMedical Equipment Quality Assurance For Healthcare FacilitiesJorge LopezОценок пока нет

- Influence of Freezing and Pasteurization of The Physical Condition of The Plastik (PE, PP and HDPE) As Selar Fish Packaging (Selaroides Leptolepis) in Sendang Biru, Malang, East Java. IndonesiaДокумент7 страницInfluence of Freezing and Pasteurization of The Physical Condition of The Plastik (PE, PP and HDPE) As Selar Fish Packaging (Selaroides Leptolepis) in Sendang Biru, Malang, East Java. IndonesiaInternational Network For Natural SciencesОценок пока нет

- School Clinic Action PlanДокумент2 страницыSchool Clinic Action PlanAlera Kim100% (7)

- ProjectДокумент22 страницыProjectSayan MondalОценок пока нет

- Technology 6 B Matrixed Approach ToДокумент12 страницTechnology 6 B Matrixed Approach ToNevin SunnyОценок пока нет

- Ducati WiringДокумент7 страницDucati WiringRyan LeisОценок пока нет

- King Saud UniversityДокумент10 страницKing Saud UniversitypganoelОценок пока нет

- Frequently Asked Questions: Lecture 7 To 9 Hydraulic PumpsДокумент5 страницFrequently Asked Questions: Lecture 7 To 9 Hydraulic PumpsJatadhara GSОценок пока нет

- H.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeДокумент108 страницH.mohamed Ibrahim Hussain A Study On Technology Updatiing and Its Impact Towards Employee Performance in Orcade Health Care PVT LTD ErodeeswariОценок пока нет