Академический Документы

Профессиональный Документы

Культура Документы

Gyprock 513 Party Wall 201407

Загружено:

eusufiqbalАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Gyprock 513 Party Wall 201407

Загружено:

eusufiqbalАвторское право:

Доступные форматы

GYPROCK PARTY WALL

INTERTENANCY WALL SYSTEMS

FOR CLASS 1 BUILDINGS

CONTENTS INTRODUCTION

Introduction The CSR Gyprock Party Wall System is designed to provide

2

a separating wall between dwellings that are side-by-side

Applications 3 such as town houses.

Advantages 3 CSR Gyprock Party Wall comprises a double frame wall with

a 25mm Shaft Liner Panel fire barrier between the frames.

Components 36 The basis of the fire performance is the central fire barrier,

Design Considerations 78 which provides the primary fire resistance, with the frame

lining on each side contributing to some extent. This allows

System Features 10 the wall linings to be installed as per normal decorative linings

Typical installation Sequence 11 and to incorporate penetrations.

System Selection The basis of the acoustic performance is a double cavity

12 13

system. This provides impact isolation, with connections

Installation of Linings 14 only at wall perimeters as allowed by the BCA definition of

discontinuous construction. Insulation in both cavities is used

Typical Construction Details 15 27

to meet various performance levels, including allowance for

Health, Safety & Warranty 28 certain penetrations and services that may occur.

Contact Information 28

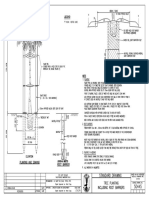

FIG 1: CSR GYPROCK PARTY WALL OVERVIEW

Gyprock Fyrchek in roof

Optional steel space fixed with laminating

track at top screws at 400mm max.

of wall centres

Gyprock Shaft

Liner Panel

H-studs

Gyprock Fyrchek at floor level

UNIT 1 fixed with laminating screws at

400mm max. centres

Steel track fastened back-to-back

to support shaft liner panel at all

horizontal joints

UNIT 1

H-studs

Timber or

steel party

wall frame

Steel track at base

and ends of wall UNIT 2

GYPROCK PARTY WALL SYSTEMS 2

APPLICATIONS Gyprock Fyrchek

CSR Gyprock Party Wall intertenancy systems are designed Features

as separating walls for Class 1 buildings. Systems are Suitable for wall and ceiling

available for steel and timber framed buildings with FRL systems where a fire rating is to

be achieved, or where acoustic

60/60/60 and sound ratings to meet BCA requirements. performance is required.

Composed of a specially

The systems have some elements that are common to the processed glass fibre reinforced

adjoining buildings, and are suitable for buildings with shared gypsum core encased in a heavy

duty pink liner board.

title on single allotments. Long edges are recessed for

flush jointing.

Systems for other classes of buildings, buildings with

separate titles and for FRL 90/90/90 are also available. Applications

Contact CSR Gyprock for information on construction for Fire rated walls and ceilings.

High performance acoustic rated walls and ceilings.

these systems.

ADVANTAGES Gyprock Fyrchek MR

Features

Steel and timber frame options.

A fire rated board with moisture

Systems for Rw + Ctr 50 and discontinuous construction. resistant properties.

Primarily intended for walls and

Linings installed as for non-rated systems. ceilings in wet areas and for

protected soffits and external

No setting joints of central fire barrier. eaves which must also achieve

fire resistance.

Services simply incorporated. Both the core and the liner board

are treated in manufacture to

Minimal use of sealants. withstand the effects of high

humidity and moisture.

Fibre cement options in wet areas.

Long edges are recessed for

Rapid installation. flush jointing.

No additional trades. Applications

Walls and ceilings in wet areas and for protected soffits and external

eaves which must also achieve fire resistance.

COMPONENTS Gyprock Aquachek

Features

Linings Specially processed

plasterboard.

Both the core and linerboard

facing are treated in manufacture

Gyprock Shaft Liner Panel to withstand the effects of

moisture and high humidity.

Features Manufactured to the

requirements specified in

Machine made sheet composed

American Society for Testing and

of a glass fibre reinforced

Materials C630.

gypsum core encased in a heavy

duty liner board. For use as a wall and ceiling

lining in wet areas and high

25mm thick with a mass of

moisture areas in residential and

approximately 19.8kg/m2

commercial applications.

Recessed edges allow flush

jointing to Recessed Edge

Plasterboard.

Applications

Gyprock Aquachek is a suitable substrate for ceramic tiles.

Usage areas include bathrooms, kitchens, laundries. garages and ceiling

applications such as walkways and verandahs.

Applications The Gyprock Aquachek Wet Area Lining System is suitable for walls in high,

Fire rated separating walls and service shafts. medium and low risk level wet areas as defined in AS3740.

GYPROCK PARTY WALL SYSTEMS 3

Gyprock Standard Plasterboard Gyprock Soundchek

Features

Features

Recessed long edges to assist

in producing smooth even and Designed to provide enhanced

continuous surface once jointed. acoustic resistance in wall and

ceiling systems.

Square edge and square edge/

recessed edge also available. A machine made sheet

composed of a high density

10mm and 13mm thickness. gypsum core encased in a heavy

Manufactured to the duty linerboard.

requirements specified in Long edges are recessed to

AS2588 : 1998 Gypsum assist in producing a smooth,

Plasterboard. even and continuous surface

once jointed.

13mm thickness.

Manufactured to the

Applications requirements specified in

Internal walls and ceilings. AS2588 : 1998 Gypsum

Plasterboard.

Gyprock Superchek Applications

Internal walls where a higher sound rating is required.

Features

10mm plasterboard with denser

core and heavy duty facing TABLE 1: GYPROCK PRODUCT WEIGHTS

material.

Resists double the force to Colour shading behind each product approximates the colour of the

impose a discernable surface product face liner sheets. For detailed sheet sizes and availability,

indentation compared to contact the CSR Gyprock Sales Centre in your region or refer to

standard plasterboard.

www.gyprock.com.au

Denser core for sound

resistance. Walls lined with

Superchek provide a clearly Thickness Mass

Gyprock Lining Products

noticeable, 15% reduction in mm kg/m2

perceived loudness compared to CSRG-2011

standard plasterboard. GECA 04-2011 Standard Plasterboard 10 6.5

PANEL BOARDS

Recessed Edge 13 8.5

Standard Plasterboard 10 6.5

Applications

Recessed Edge/Square Edge 13 8.5

High traffic areas such as hallways, stairways, playrooms and garages.

Standard Plasterboard

10 6.5

Square Edge

Supaceil 10 6.1*

CeminSeal Wallboard

Soundchek 13 13.0

Features 10 8.0

Aquachek

CeminSeal Wallboard Sheet 13 10.4

conforms to the requirements Impactchek 13 10.3

of AS2908.2 : 1992 Cellulose-

cement products Part 2: Flat Superchek 10 10.4

sheets. Type B, Category 3. EC08 Partition 13 9.3

Features an embedded micro EC08 Fire 13 10.5

waterblock technology that

prevents water penetrating into EC08 Impact 13 12.1

the sheet, repelling water and Flexible 6.5 4.25

providing a more stable sheet.

Long edges are recessed to

13 10.5

Fyrchek

enable seamless jointing. 16 12.5

In accordance with the Building 13 10.7

Code of Australia, Part 3.7.1.2, Fyrchek MR

Cemintel fibre cement sheets 16 13.5

can be used wherever non- Perforated Sheet 13 10.0

combustible material is required

by the code. Shaft Liner Panel 25 19.8

Applications * 6.5kg/m2 available in Western Australia

Wet area such as bathrooms, laundries and semi-exposed ceilings and

soffits.

Thickness Mass

Impact resistant walls. Cemintel Fibre Cement Product

mm kg/m2

CeminSeal Wallboard 6 9.7

CeminSeal Wallboard 9 14.3

GYPROCK PARTY WALL SYSTEMS 4

Fasteners Insulation

Gyprock Plasterboard Laminating Screw: Bradford Gold R1.5 wall batts (75mm).

40mm x N10.for fixing 16mm Gyprock Fyrchek Bradford Gold R2.0 wall batts (75mm).

plasterboard to Shaft Liner Panels.

Bradford Gold R2.0 wall batts (90mm).

Order N Pack Qty

Bradford Gold R2.7 wall batts (90mm).

12215 1000

Bradford SoundScreen R1.6 batts (60mm).

Drill-point wafer-head screw: Bradford SoundScreen R2.0 batts (75mm).

10g x 16mm, for joining steel track back-to-back, for fixing Bradford Glasswool Partition batts 11kg/m3 (75mm).

Wall Clip to H-Stud, and for fixing wall clip to steel frame.

Bradford Glasswool Partition batts 14kg/m3 (75mm).

Order N Pack Qty

Bradford Glasswool Partition batts 11kg/m3 (110mm).

39367 1000

Cavity Seal. Bradford rockwool batts (eg; Soundscreen

40914 100

or Fibretex 350) lightly compressed into the cavity being

Drill-point wafer-head screw: sealed.

10g x 30mm for fixing Wall Clip to H-Stud through Gyprock

Fyrchek plasterboard. Steel H-Stud

Order N Pack Qty The Gyprock Party Wall System incorporates 25mm H-Studs

39368 1000 to support the Shaft Liner Panels at all vertical joints. It is

made from 0.55mm BMT G275 galvanised steel.

40915 100

Order N Length

Needle-point screw:

39156 3000mm

6g x 25mm for fixing Wall Clip to timber plate.

Order N Pack Qty

12234 1000 25mm

Nails:

2mm x 25mm hot-dip galvanised for fixing Wall Clip to

timber plate.

34mm

Order N Pack Qty

11332 2.5kg

12786 0.5kg

Track fasteners:

Must be steel e.g. Power actuated concrete nails, flat or

round head expansion anchors.

Sealants

Gyprock Wet Area Acrylic Sealant:

Order N Pack Qty

10902 450g tube

Gyprock Fire Mastic:

Order N Pack Qty

10924 600ml tube

GYPROCK PARTY WALL SYSTEMS 5

Steel Track Wall Clip

Steel track (Rondo NP140) is used in the following Aluminium Wall Clip: Used to support the 25mm

applications: H-Stud, and are critical in the fire performance of systems

Support of Shaft Liner Panels at the top and the bottom with a single 25mm Shaft Liner. They are manufactured

of the wall. from 1.6mm aluminium.

Support of Shaft Liner Panels at the ends of the wall. Order N Pack Qty

81408 1

Used back to back at all horizontal joints in Shaft Liner

Panels. Aluminium Strap: Used as an alternative to wall clips at

Order N Length wall ends (supply by others) minimum size 50x90x1.6mm

10465 3000mm

Gyprock Folding Track may be used as an alternative for

ease of installation.

Order N Length

74014 3000mm

Restraint tab

Fold line

50

28mm Galvanised

Slot for Track - Rondo Part NP140

screw fixing 0.55mm BMT 28mm

(where noted)

25

50

H Studs extend into

horizontal steel tracks

40mm

90mm

Continuous steel track

fixed back to back at all

horizontal joints Wall Clip 50mm

GYPROCK PARTY WALL SYSTEMS 6

DESIGN FIG 3: PARTY WALL SUPPORT ARRANGEMENTS

CONSIDERATIONS

Gyprock Party Wall is

not suitable for

Building Design Gyprock

unsupported areas

CSR Gyprock Party Wall systems consist of vertically Party Wall

spanning elements extending from the ground slab or footing

up to the roof. It may not be possible to start the Party

Wall systems over a void or above cavity masonry while Light weight floor

maintaining both fire and acoustic ratings. Consideration of

roof framing is also important to avoid penetrating the fire

barrier with trusses, ties, hip beams, etc. Gyprock

Party Wall

Details are provided to allow the adjoining houses to be off-

set in height, with the higher level walls treated as fire rated

external walls. CSR Party Wall systems are ideally suited to

buildings with aligned facades, A detail for an off-set brick

veneer facade is provided.

The maximum height for the Shaft Liner Panel fire barrier is Gyprock Party Wall

12m, with a maximum individual floor/ceiling height of 3m. is only suitable for

areas where the fire

barrier is continuous

from foundation

level to roof level

FIG 2: MAXIMUM PANEL AND WALL HEIGHT DETAILS

Structural Design

All walls must be designed for the applied loads. Timber

framing shall be in accordance with AS1684 or AS1720.1

and steel framing shall be designed to AS/NZS 4600 or AS

3.0m max. 3623. H-Studs must be restrained at top and bottom to

panel height

frames on each side of the barrier with wall clips spaced at

3m maximum centres. Wall clips must be placed a maximum

600mm below the top of a H-Stud. The building designer

must ensure load-bearing walls have been designed

6.0m max.

assuming no contribution to axial strength from the wall

linings.

Gyprock Party Wall Systems may be exposed to wind during

construction for up to three months during construction,

for wind zones N1 and N2. For higher wind loads or longer

3.0m max. exposure, the H-Studs must be adequately propped until the

panel height

building is enclosed.

Fire Resistance

The Gyprock Party Wall systems in this manual have been

assessed by Exova Warrington Fire in accordance with

the general principles of AS1530.4. They are suitable for

the stated FRL when designed in accordance with the

building and structural considerations above, and installed

in accordance with the details in this manual.

The systems are designed for one side to collapse in a fire,

leaving the central barrier and the opposing wall in place. In

areas such as the roof space and between floor and ceiling

where there are no stud linings, 16mm Fyrchek plasterboard

is laminated to the Shaft Liner to maintain the rating.

The aluminium clips used in single Shaft Liner systems are

intended to melt on the fire side only, allowing collapse

without damage to the remaining system.

For all systems, penetrations may be made in Shaft Liner

GYPROCK PARTY WALL SYSTEMS 7

Panels in the roof space only, and must be fire sealed to suit Wallboard & Plasterboard Fixing

the system fire rating. Systems lined with Cemintel Wallboard

must include Bradford glasswool or rockwool insulation to Once erected, it is recommended that the central barrier of

each frame to achieve the stated fire resistance. Gyprock Shaft Liner Panels and Fyrchek plasterboard are

protected from rain. The use of suitable sheeting can prevent

Acoustic Performance the formation of mould, and avoid delays in allowing boards

The acoustic performance of wall systems is expressed in to dry before internal linings are applied. In any case, the

terms of Rw and Rw+Ctr. The systems have been assessed central barrier may be left exposed to weather for up to one

by PKA Acoustic Consulting, and the ratings refer to month if required.

expected laboratory performance. The site performance Walls may be built to achieve a particular Level of Finish as

of the systems may be affected by sound flanking, the defined in AS/NZS2589.1. The Level of Finish specified can

effectiveness of workmanship, and the inclusion of structural have requirements for frame alignment, jointing and back

elements and bridging items. The building designer must blocking methods, and sheet orientation.

pay special attention to airborne and structural flanking CeminSeal Wallboard and Gyprock plasterboard may be

paths to minimise the difference between laboratory and installed vertically or horizontally, although for some Levels

field performance. of Finish horizontal sheeting must be used. Walls lined

Wall clips are only to be installed at or within floor and ceiling with Gyprock plasterboard or CemintSeal Wallboard may

zones as shown in the details. Using additional clips within be finished with tiles. Refer to the appropriate installation

the storey height will reduce the acoustic performance manual.

of the wall, and the wall will not meet the requirement for

discontinuous construction. Services

For flanking sound control, it is required that each story ceiling

CSR Gyprock Party Wall systems allow penetrations for

consists of plasterboard 10mm or thicker, and that insulation

plumbing and electrical services to be installed without

extends 1200mm minimum on each side of the wall over the

the need for acoustic caulking, baffles or fire seals. The

ceiling. The insulation is to be glasswool or rockwool 75mm

penetrations may be made in the stud wall linings and back-

or thicker, such as Bradford R1.5 Gold batts. There must be

to-back services are permitted.

no penetration to the ceiling in rooms adjacent to the Party

Wall, unless they have effective acoustic treatment. Systems have been fire tested with services including PVC

(65mm max. diameter), copper plumbing, and electrical

It is assumed no rating is required between the two adjoining

services installed in both wall leaves with acceptable

roof spaces and that the spaces are not able to be occupied.

performance. Services may be installed through the stud

It is proposed that the detail is an alternative solution based

framing or, with a minimum 10mm clearance to the central

on BCA Part1 F5.5(e) + (f), to be confirmed by the certifier.

Shaft Liner barrier, may be fixed to the back of studs.

All systems achieve Rw > 45 and Rw + Ctr > 40 for services

Simply prepare neat cut holes with a 6mm maximum

in the adjoining unit.

clearance. No fire or acoustic sealant is required at junction

of shaft liner panel with H-Studs or between the track and

Substitution an even floor slab. No fire caulking is required in the outer

Plasterboard linings and barriers, and fibre cement linings, linings.

must be as specified in the system and be supplied by CSR. No penetrations are permitted through the central fire barrier,

No statement of performance will be provided by CSR when except within the roof space where they must be fire sealed.

other brand products are used.

Wet Area Systems

The stud linings on one side of a system may be substituted

with the linings from another system to create an asymmetric

system. This might occur, for example, where a wet area in

one unit is adjacent to a habitable area of an adjoining unit.

The fire and acoustic performance of the asymmetric system

shall be taken as the lower of the values of the two systems

that were combined.

Alternatively systems may be modified for use in wet areas

by substituting wet area board. For example, use 2 x 10mm

Gyprock Aquachek in lieu of 2 x 10mm Gyprock Standard

Plasterboard.

GYPROCK PARTY WALL SYSTEMS 8

FIG 4: TYPICAL APPLICATIONS CLASS 1 BUILDINGS

450mm parapet for

combustable roof

coverings

Separating wall continued up

to underside of non-combustible roof

Separating wall Fire rated Wall

continued down above lower roof

to ground

Dwelling 1 Dwelling 2

Dwelling 3 Dwelling 4 Dwelling 5

Suspended floor

Dwelling 9 Dwelling 10

Dwelling 7 Dwelling 8

Dwelling 6

Private garages may be under

or within class 1a dwelling

Gyprock Party Wall

GYPROCK PARTY WALL SYSTEMS 9

performance. No fire caulking is required in the outer linings.

SYSTEM FEATURES Simply prepare neat cut holes with a 6mm clearance.

For systems with FRL 60/60/60, penetrations such as No fire or acoustic sealant is required at junction of shaft

plumbing and electrical services can be installed without liner panel with H-Studs or between the track and an even

the need for acoustic caulking, baffles or complex details. floor slab.

The penetrations may be made in the stud wall linings and For all systems, penetrations may be made in Shaft Liner

back-to-back services are permitted. No penetrations are Panels in the roof space, and must be fire sealed to suit the

permitted through the central fire barrier outside the roof system fire rating.

space.

Systems have been fire tested with services including PVC

(65mm max. diameter), copper plumbing, and electrical

services installed in both wall leaves with acceptable

FIG 5: TYPICAL PENETRATION FEATURES

Services may

penetrate stud

wall lining without

fire caulking. Use

flexible sealant to

suit waterproofing

requirements

CeminSeal Wallboard or

Gyprock MR plasterboard

to wet areas

Services must have a 10mm

clearance to, and not be fixed

to, the fire barrier

Gyprock Shaft Liner Panel (no

penetration permitted through this

lining except in roof space)

GYPROCK PARTY WALL SYSTEMS 10

TYPICAL INSTALLATION SEQUENCE

FIG 6: GROUND FLOOR FIRE BARRIER INSTALLED FIG 8: FIRST FLOOR FIRE BARRIER INSTALLED

Gyprock

Optional steel Fyrchek in roof

track at top space fixed

Gyprock Fyrchek at of wall

Steel track fastened floor level fixed with with laminating

back-to-back to support shaft laminating screws at screws at

liner panel at all horizontal 400mm max. centres 400mm max.

joints centres

UNIT 1

Gyprock

Shaft Liner

Panel

UNIT 1

H-studs

Gyprock

Shaft Liner

Panel

UNIT 1 UNIT 2

H-studs

Timber or steel

party wall frame

Steel track at base

and ends of wall

UNIT 1

UNIT 2

UNIT 2

FIG 7: UNIT 2 FRAME AND FLOOR INSTALLED FIG 9: UNIT 2 FIRST FLOOR FRAMING INSTALLED

UNIT 1

UNIT 1

UNIT 2

Timber or steel

party wall frame

UNIT 2

UNIT 1

UNIT 1

UNIT 2 UNIT 2

GYPROCK PARTY WALL SYSTEMS 11

SYSTEM SELECTION

Timber Frame Internal Wall Systems Party Wall with 25mm Fire Barrier

SYSTEM SPECIFICATION TYPICAL LAYOUT (CSR 362a shown) ACOUSTIC

OPINION

PKA-018

Lining material as per system table. Discontinuous

Timber studs at 600mm maximum centres. Construction

Cavity insulation as per system table.

20-40mm separation between frame and Gyprock Shaft

Liner Panel.

25mm Gyprock Shaft Liner Panel between steel H-Studs

at 600mm maximum centres.

20-40mm separation between frame and Gyprock Shaft

Liner Panel.

Cavity insulation as per system table.

Timber studs at 600mm maximum centres.

Lining material as per system table.

STUD DEPTH mm 70 90

FRL SYSTEM

WALL LININGS CAVITY INFILL

Report/Opinion N Rw / Rw+Ctr

Both sides (Refer to Section A)

CSR 360

(a) 75 Gold Batts 2.0 60/47 61/49

60/60/60 BOTH SIDES (b) 90 Gold Batts 2.7 61/48 62/50

1 x 10mm Gyprock

EWFA 45743 Superchek. (c) 88 Soundscreen 2.5 61/48 62/50

WALL THICKNESS mm 225 265

CSR 361

(a) 75 Gold Batts 2.0 61/49 62/50

60/60/60 BOTH SIDES (b) 90 Gold Batts 2.7 62/50 63/51

2 x 10mm Gyprock

EWFA 45743 Standard Plasterboard. (c) 88 Soundscreen 2.5 62/50 63/51

WALL THICKNESS mm 245 285

CSR 362

(a) 75 Gold Batts 2.0 61/49 62/50

60/60/60 BOTH SIDES (b) 90 Gold Batts 2.7 62/50 63/51

1 x 13mm Gyprock

EWFA 45743 Soundchek. (c) 88 Soundscreen 2.5 62/50 63/51

WALL THICKNESS mm 231 271

CSR 363

(a) 75 Gold Batts 2.0 62/50 63/51

BOTH SIDES (ANY ORDER)

60/60/60 1 x 6mm CeminSeal (b) 90 Gold Batts 2.0 62/50 63/51

Wallboard.

EWFA 45743 1 x 10mm Gyprock (c) 88 Soundscreen 2.5 63/51 64/52

Aquachek plasterboard.

WALL THICKNESS mm 237 277

CSR 364

(a) 75 Gold Batts 1.5 61/49 62/50

BOTH SIDES (ANY ORDER)

60/60/60 1 x 10mm Gyprock (b) 90 Gold Batts 2.0 62/50 63/51

Superchek plasterboard.

EWFA 45743 1 x 10mm Gyprock (c) 88 Soundscreen 2.5 63/51 64/52

Standard Plasterboard.

WALL THICKNESS mm 245 285

GYPROCK PARTY WALL SYSTEMS 12

Steel Frame Internal Wall Systems Party Wall 25mm Fire Barrier

SYSTEM SPECIFICATION TYPICAL LAYOUT (CSR 100a shown) ACOUSTIC

OPINION

Lining material as per system table. PKA-052

Steel studs at 600mm maximum centres.

Discontinuous

Cavity insulation as per system table.

Construction

20-40mm separation between frame and Gyprock Shaft

Liner Panel.

25mm Gyprock Shaft Liner Panel between steel H-Studs

at 600mm maximum centres.

20-40mm separation between frame and Gyprock Shaft

Liner Panel.

Cavity insulation as per system table.

Steel studs at 600mm maximum centres.

Lining material as per system table.

STUD DEPTH mm 64 76

FRL SYSTEM

WALL LININGS

Report/Opinion N CAVITY INFILL (Both Sides) Rw / Rw+Ctr

(Refer to Section A)

CSR 100

(a) 75 GW Partition 14kg 60/48 61/49

60/60/60 BOTH SIDES (b) 110 GW Partition 11kg 62/50 62/50

2 x 10mm Gyprock (c) 88 RW Soundscreen R2.5 61/49 62/50

EWFA 45743 Standard Plasterboard.

MINIMUM WALL THICKNESS mm 257 289

CSR 101

(a) 75 GW Partition 14kg 62/50 62/51

60/60/60 BOTH SIDES (b) 110 GW Partition 11kg 63/52 63/52

2 x 13mm Gyprock

EWFA 45743

(c) 88 RW Soundscreen R2.5 63/51 63/52

Standard Plasterboard.

MINIMUM WALL THICKNESS mm 269 301

CSR 102

(a) 75 GW Partition 14kg 60/48 61/49

60/60/60 BOTH SIDES (b) 110 GW Partition 11kg 62/50 62/50

1 x 13mm Gyprock (c) 88 RW Soundscreen R2.5 61/49 62/50

EWFA 45743 Soundchek.

MINIMUM WALL THICKNESS mm 243 275

CSR 103

BOTH SIDES (a) 75 GW Partition 11kg 61/49 61/50

60/60/60 1 x 6mm CeminSeal (b) 75 GW Partition 14kg 62/50 62/51

Wallboard.

EWFA 45743

(c) 88 RW Soundscreen R2.5 63/51 63/52

1 x 10mm Gyprock

Aquachek.

MINIMUM WALL THICKNESS mm 249 281

GYPROCK PARTY WALL SYSTEMS 13

INSTALLATION OF LININGS

Internal lining systems must be installed in accordance with

the relevant installation manuals. The first layer of any double

layer system must be fixed using the all fastener method.

TABLE 2: WALL LINING FIXING METHODS

Lining Application Fixing Manual Notes

10mm Superchek General areas GYP547 (timber studs) Adhesive/Fastener fixing.

13mm Soundchek GYP544 (steel studs) or

Full fastener fixing

(screws or nails).

6mm CeminSeal Wallboard Wet areas and FC101 Tiled areas: All fastener fixing.

General areas Non-tiled areas: Adhesive/

Fastener or all fastener fixing.

10 13mm Aquachek Wet areas GYP547 (timber studs) Tiled areas: All fastener fixing.

GYP544 (steel studs) Non-tiled areas: Adhesive/

Fastener or all fastener fixing.

GYPROCK PARTY WALL SYSTEMS 14

TYPICAL CONSTRUCTION DETAILS

FIG 10: BASE DETAIL AT SLAB FIG 12: BASE DETAIL AT FRAMED FLOOR

Refer to System

Table for wall lining

and insulation

20-40mm gap

on each side

Timber or steel

20-40mm gap on stud wall framing

each side

25mm Gyprock Shaft

Steel or Timber Liner Panel between

studs steel H studs at

600mm centres

25mm Gyprock Shaft

Liner Panel with Timber or

steel H-studs at Refer to System steel subfloor Timber or steel

vertical panel joints Table for wall lining members subfloor members

and insulation

Steel track fixed to Continuous strip of

concrete slab at 16mm Gyprock

150mm max. from Fyrchek screw

Fire Mastic only ends and 600mm

required at gaps laminated to Gyprock

max. centres Shaft Liner Panel

between

Concrete or

masonry wall with

FRL equal to

Gyprock Party Wall

Concrete slab above. Dampcourse

and termite barrier

as required

FIG 11: ALTERNATE BASE DETAIL

Tip: For steel wall framing, clips

may be fixed to a short section

of inverted track.

20-40mm gap on

each side

Inverted Track

Steel or Timber

studs

25mm Gyprock Shaft

Liner Panel with Wall Clip

steel H-studs at Refer to System

vertical panel joints Table for wall lining

and insulation

Wall Clips fixed at

Fire Mastic only each H-Stud

required at gaps Base Track

Concrete slab

GYPROCK PARTY WALL SYSTEMS 15

FIG 13: DETAIL AT UPPER STOREY FRAMED FLOOR

20-40mm gap

on each side

16mm Gyprock Fyrchek screw

laminated to one side (can be

on either side of shaft liner

4mm min.

panel). Butt together neatly at

sheet joins

Continuous steel track fixed back to

200mm min. back at 600mm max. centres

Floor joists may be

perpendicular or Alternative

parallel to wall clip location

Floor joists may be perpendicular

or parallel to wall

600mm max. from clip to

joint in shaft liner panel

Optional

insulation Optional insulation

200mm min.

Additional nogging

at each clip

NOTE: No additional clips to

be placed within storey height

Refer to Party Wall System Table

for insulation and wall linings Wall Clips at each H-Stud

on both sides of wall

Gyprock Shaft Liner

Panel with H-Studs at Timber or

panel joints steel studs

FIG 14: DETAIL FOR STEEL COLUMN AND BEAM SUPPORT

20-40mm gap

on each side

16mm Gyprock Fyrchek screw

laminated to one side (can be

on either side of shaft liner

4mm min. panel). Butt together neatly at

sheet joins

Continuous steel track fixed back to

back at 600mm max. centres

200mm min.

Floor joists

Steel floor beam 600mm max.

Floor joists may be perpendicular

or parallel to wall

Optional insulation

Steel loadbearing Optional insulation

column within wall cavity

200mm min.

Refer to Party Wall System Table

for insulation and wall linings

Wall Clips at each H-Stud on both

sides of wall (fixed to additional

Gyprock Shaft Liner nogging where required

Panel with H-Studs at

panel joints Timber or steel studs

GYPROCK PARTY WALL SYSTEMS 16

FIG 15: DETAIL AT EXTERNAL TIMBER FRAME WALL

External cladding

Insulation

system fixed to studs

10mm Gyprock

Standard Plasterboard Required acoustic

insulation, minimum

R1.5 Bradford Gold

Refer to System Wall Clips at each H-Stud batts

Table for wall lining and ends, both sides

and insulation

Wall clips or straps

at wall end

Control joint opposite

Gyprock Shaft Liner

Panel

Rondo P140 track

vertically at outer ends of

wall (seal to cladding with

Timber or steel Gyprock Fire Mastic)

stud wall framing

Required acoustic

insulation, minimum

R1.5 Bradford Gold

10mm Gyprock batts

Standard Plasterboard

Sarking as

required

Insulation

FIG 16: DETAIL AT EXTERNAL STEEL FRAME WALL

External cladding

system fixed to studs

(thermal break may

be required)

10mm Gyprock

Standard

Refer to Party Wall Plasterboard

System Table for wall Required acoustic

linings and insulation Wall Clips at each insulation, minimum

H-Stud, both sides R1.5 Bradford Gold

batts

Wall clips or straps

at wall end

Rondo P140 track

vertically at outer ends of

Steel stud wall (seal to cladding with

wall framing Steel angle 35x35mm Gyprock Fire Mastic)

or additional stud for

plasterboard fixing

Required acoustic

insulation minimum

R1.5 Bradford Gold

batts

Sarking as

required

GYPROCK PARTY WALL SYSTEMS 17

FIG 17: PARTY WALL PROJECTION WITH LIGHT WEIGHT FACADE

Optional

insulation For frame projection limit

refer to project engineer

10mm Gyprock

Standard

Plasterboard External

Refer to System Wall Clips cladding

Table for wall lining at each H-Stud, system

and insulation both sides

Aluminium straps may be

used in lieu of clips

Rondo P140 track

vertically at outer ends of

wall (seal to cladding with

Timber or steel Gyprock Fire Mastic)

stud wall framing 10mm Gyprock

Standard

Plasterboard

Optional

insulation

FIG 18: PARTY WALL SECTION WITH LIGHT WEIGHT FACADE WITH ALUMINIUM STRAPS

Refer to system

table for wall linings

and insulation Rondo P140 track

vertically at outer ends of

wall (seal to cladding with

Gyprock Fire Mastic)

Timber or steel

stud wall framing

Aluminium straps may be

used in lieu of clips

(Typical strap layout)

GYPROCK PARTY WALL SYSTEMS 18

FIG 19: DETAIL AT EXTERNAL BRICK VENEER WALL

Required acoustic

insulation, minimum

R1.5 Bradford Gold

batts

Brick veneer

10mm Gyprock

Standard Plasterboard

Wall Clips Control joint opposite

at each H-Stud, Gyprock Shaft

Refer to System

both sides Liner Panel

Table for wall lining

and insulation

150mm min.

Rockwool cavity seal

Rondo P140 track

Timber or steel Required acoustic vertically at outer

stud wall insulation, minimum ends of wall

framing R1.5 Bradford Gold

batts

Aluminium straps

10mm Gyprock

Standard Plasterboard

Sarking.

1. For walls without

sarking, protect the

cavity seal with damp

course against the

brickwork

2. Cavity Seal may be

inside sarking

FIG 20: DETAIL AT RETURN IN BRICK VENEER WALL

Optional Brick veneer

insulation

10mm Gyprock

Standard Plasterboard

Required acoustic 150mm wide

insulation, minimum Rockwool cavity

R1.5 Bradford Gold seal

batts

Sarking.

1. For walls without

Wall Clips sarking, protect the

at each H-Stud, cavity seal with damp

Refer to System both sides course against the

Table for wall lining brickwork

and insulation 2. Cavity Seal may be

inside sarking

Rondo P140 track vertically

Timber or steel at outer ends of wall with

stud wall framing wall clips or wall straps

both sides

10mm Gyprock

Standard Plasterboard

GYPROCK PARTY WALL SYSTEMS 19

FIG 21: DETAIL AT CEILING AND ROOF

Nominal 10mm gap to top of Gyprock Shaft

Non-combustible roofing Liner Panel (track optional) Battens may be continuous over party

wall. Refer to BCA requirements

Roof battens Fill void between

battens with Rockwool Roof sarking.

cavity seal, 300mm For roofs without sarking,

Roof framing protect Rockwool with

min. width Wall Clips at damp course under tiles

each H-Stud

both sides of wall

16mm Gyprock Fyrchek laminated to

Gyprock Shaft Liner Panel with

laminating screws at 400mm x

400mm max. centres

600mm max.

Blocking to support

ceiling lining

Required acoustic insulation

Wall Clips at each H-Stud minimum 75mm Bradford

both sides of wall R1.5 Gold batts

200mm min.

Required acoustic insulation 4mm minimum gap

minimum 75mm Bradford

R1.5 Gold batts

Refer to Party Wall

System Table for wall

lining and insulation

Gyprock Shaft

Liner Panel

20-40mm gap

each side of wall

FIG 22: INSTALLATION DETAIL FOR FYRCHEK LAMINATION

16mm Gyprock Fyrchek

75mm laminated to Shaft Liner

min. Panel

25mm Gyprock Shaft H-Stud

Liner Panel

400mm

100mm max.

max.

400mm

max.

100mm

max.

Setting of joints

is not required

GYPROCK PARTY WALL SYSTEMS 20

FIG 23: DETAIL AT ROOF/CEILING AND VALLEY GUTTER

Optional track along top of

Gyprock Shaft Liner Panel

25mm gap over Gyprock

Shaft Liner Panel Fill void at top of wall with

Rockwool cavity seal

Required acoustic insulation Required acoustic insulation

minimum 75mm Bradford minimum 75mm Bradford

R1.5 Gold batts R1.5 Gold batts

Timber packing Blocking 45mm thick

to suit between trusses

Wall Clips at each H-Stud

Extended bottom chord to on both sides of wall

trusses (refer to truss

supplier)

Refer to Party Wall

Gyprock Shaft System Table for wall

Liner Panel lining and insulation

FIG 24: DETAIL AT STEPPED ROOF

External cladding Sarking

system and battens

16mm Gyprock

Fyrchek MR Refer

to system CSR 900

for details

Flashing and sarking

to building designers

details Fill void at top of

Roofing wall with Rockwool

cavity seal

100mm

min. 300mm

max.

Note: FRL of external wall

Sarking

has load limitations. Refer

to CSR 900 for details.

Wall Clips at each H-Stud, 16mm Gyprock

both sides of wall. Fyrchek

Gyprock Shaft

Liner Panel

200mm min. Refer to Party Wall

System Table for

wall lining and

insulation

GYPROCK PARTY WALL SYSTEMS 21

FIG 25: DETAIL AT ROOF/CEILING

Fill void between

battens with Rockwool

cavity seal, 300mm

Nominal 10mm gap to top of Gyprock min. width

Roof battens Shaft Liner Panel (track optional)

Non-combustible roofing

Roof sarking.

For roofs without sarking,

protect Rockwool with

damp course under tiles

Roof framing

Wall Clips at

each H-Stud

both sides of wall

16mm Gyprock Fyrchek laminated to

Gyprock Shaft Liner Panel with

600mm laminating screws at 400mm x

max. 400mm max. centres

Required acoustic insulation

200mm min. minimum 75mm Bradford

Wall Clips at each H-Stud

both sides of wall R1.5 Gold batts

Required acoustic insulation

minimum 75mm Bradford 4mm minimum gap

R1.5 Gold batts

Refer to Party Wall

System Table for wall

lining and insulation

Gyprock Shaft

Liner Panel

20-40mm gap

each side of wall

GYPROCK PARTY WALL SYSTEMS 22

FIG 26: DETAIL AT ROOF/CEILING AND PARAPET

Optional track along top of

Gyprock Shaft Liner Panel Fill void at top of wall with

Rockwool cavity seal

Parapet capping

Wall Clips

at all H-Studs,

both sides of wall

Required acoustic Required acoustic

insulation minimum insulation minimum

Bradford R1.5 Gold batts Bradford R1.5 Gold batts

45mm min. thick

ledger with joist

200mm hanger

min.

Wall Clips at each H-Stud,

both sides of wall. 16mm Gyprock Fyrchek laminated to

Gyprock Shaft Liner Panel with

laminating screws at 400mm x

400mm max. centres

Loadbearing timber

wall frame both sides

Refer to Party Wall

System Table for

wall lining and

insulation

Gyprock Shaft

Liner Panel

GYPROCK PARTY WALL SYSTEMS 23

FIG 27: DETAIL FOR OFFSET ROOF

Track optional Fill void between battens with

Rockwool cavity seal

Capping and flashing to

project specifications

Roof battens

Roof sarking

Roof framing

Wall Clips at each H-Stud

both sides of wall 16mm Gyprock Fyrchek laminated to

Gyprock Shaft Liner Panel, fixed with

laminating screws at 400 x 400mm max.

centres

600mm max.

from clips

Non-combustible roofing Blocking to support

ceiling lining

Required acoustic insulation

Wall Clips at each H-Stud minimum 75mm Bradford

R1.5 Gold batts

4mm minimum

gap

20-40mm gap Refer to System

each side of wall Specification for wall

lining and insulation

1 x 25mm Gyprock Shaft Liner

Panel in H-stud framing

Required acoustic insulation

minimum 75mm Bradford

R1.5 Gold batts Wall Clips at each H-Stud

fixed to noggings

200mm min.

GYPROCK PARTY WALL SYSTEMS 24

FIG 28: EAVES DETAIL (SIDE ELEVATION)

Leave 10mm gap between top of fire barrier P140 track continuous

and underside of battens and fill all gaps and fixed to next

H-stud

with Rockwool cavity seal

Gyprock Shaft Liner Panel within framing

formed with P140 steel track

H studs at 600mm max. cts for eaves

over 600mm high or over 1200mm wide

Wall clips each side of fire barrier fixed Rafter or

to P140 track and ends of rafters truss

Non-combustible roofing

Non-combustible anti-ponding

board with sarking over

(sarking not shown for clarity

Screw fix through Party Wall

fascia and track Framing each

side of fire

P140 track Screw fix all barrier

connections

Soffit bearer Wall clip each side of

Eaves lining party wall fixed to

P140 track and studs

Bradford Rockwool Cavity

Seal, full height of

cladding and fill gap

above cladding Gyprock Party Wall

System

Sarking

FIG 29: EAVES DETAIL (OUTSIDE END ELEVATION)

Non-combustible Completely fill all gaps between roofing

anti-ponding board and top of fire barrier with Rockwool

Non-combustible with sarking over cavity seal to 150mm min. each side

roofing material

Wall clips each side of fire

Fascia barrier fixed to P140 track and Fascia

board ends of rafters P140 track board

Rafter

Soffit bearer

CeminSeal Eaves P140 track to outer end

Lining Sheet of Gyprock Shaft Liner

Panel

GYPROCK PARTY WALL SYSTEMS 25

FIG 30: DETAIL FOR JUNCTION OF GYPROCK PARTY FIG 33: DETAIL FOR JUNCTION OF GYPROCK PARTY

WALL AND NON FIRE-RATED WALL WALL AND NON FIRE-RATED WALL

TIMBER STUD PLAN VIEW STEEL STUD PLAN VIEW

Refer to Party Wall Wall Clips at each H-Stud, Refer to Party Wall Wall Clips at each H-Stud,

System Table for wall both sides of wall System Table for wall both sides of wall

lining and insulation lining and insulation

Insulation in

Timber stud wall this zone to Steel angle for Steel stud

framing be rockwool fixing wall framing

or glasswool plasterboard

only

Non fire-rated wall 600mm min.

Min. R1.5 Glasswool or

Non fire-rated wall R1.6 Rockwool to 600mm

min. from Party Wall

FIG 31: ALTERNATIVE DETAIL FOR JUNCTION OF

GYPROCK PARTY WALL AND NON FIRE-RATED WALL

STEEL STUD PLAN VIEW

Refer to Party Wall Wall Clips at each H-Stud,

System Table for wall both sides of wall

lining and insulation

Plasterboard Steel stud

continuous wall framing

though

FIG 32: DETAIL AT CORNER PLAN VIEW

Gyprock Shaft

Liner Panel

Refer to System

Table for wall lining

and insulation

Refer to System Wall Clips at each

Table for wall lining Timber or steel

H-Stud, both sides Wall Clip at first

and insulation stud wall framing

floor height

GYPROCK PARTY WALL SYSTEMS 26

FIG 34: ROOF VOID DETAIL WITH HORIZONTAL SHEETING (FRONT ELEVATION)

16mm Gyprock Fyrchek

laminated to Gyprock

Shaft Liner Panel with

Wall clips at laminating screws at

600mm max. 400mm x 400mm max.

centres, both centres

sides of wall

Gyprock Shaft Liner Panel

installed vertically

600mm max.

Gyprock Shaft Liner Panel

installed horizontally Back to back H-Studs

installed horizontally Truss

chord

100mm max.

Gyprock Shaft Trimmer placed in

Liner Panel trusses each side Wall clips at all Truss

installed of wall to allow H-Stud, both bottom

vertically fixing of wall clips sides of wall chord

Wall clips at all Wall

H-Stud, both framing 200mm min.

sides of wall

FIG 35: ROOF VOID DETAIL WITH HORIZONTAL

SHEETING (SIDE ELEVATION)

Wall clips at 600mm

max. centres, both Rockwool cavity

sides of wall seal between

battens

Gyprock Shaft Liner 600mm max.

Panel panel installed

horizontally 16mm Gyprock

Fyrchek laminated to

Gyprock Shaft Liner

Back to back H-Studs Panel with laminating

installed horizontally screws at 400mm x

400mm max. centres

Trimmer placed in

trusses each side 100mm max.

of wall to allow

fixing of wall clips

Gyprock Shaft Liner

Wall clips at all Panel installed

H-Stud, both vertically

sides of wall

GYPROCK PARTY WALL SYSTEMS 27

Health & Safety Contact Details

Information on any known health risks of our products and CSR Gyprock Website

how to handle them safely is on their package and/or the www.gyprock.com.au

documentation accompanying them. CSR Gyprock Sales Support

Additional information is listed in the Material Safety Telephone: 13 17 44

Data Sheet. To obtain a copy, telephone 1800 807 668. Facsimile: 1800 646 364

CSR DesignLINK Technical Support Service

Warranty Telephone: 1800 621 117

Facsimile: 1800 069 904

Gyprock products are manufactured for life, with all CSR

Email: designlink@csr.com.au

products designed to achieve optimal performance when

part of a CSR integrated system. New South Wales and ACT

376 Victoria Street,

Gyprock continues to lead the market with premium quality

Wetherill Park NSW 2164

products which are the preferred choice of plastering

professionals. Queensland

768 Boundary Road,

Gyprock plasterboard products are manufactured to the Coopers Plains QLD 4108

Australian Standard AS2588, providing confidence in

Victoria

quality of product and support. For details on our product

warranty, please visit www.gyprock.com.au, or contact us on 277 Whitehall Street,

1300 306 556. Yarraville VIC 3013

South Australia

Lot 100 Sharp Court,

Mawson Lakes SA 5095

ACTU

UF

Western Australia

MAN

RE

19 Sheffield Road,

D

Welshpool WA 6106

FO

R LIFE Tasmania

11 Farley St,

Derwent Park TAS 7009

Northern Territory

Cnr Stuart Hwy & Angliss St,

Berrimah NT 0828

GYP513 July 2014

CSR Gyprock, CSR Building Products A.B.N. 55 008 631 356.

CSR Limited 2013. Except as provided by the Copyright Act 1968, no part of this publication maybe

reproduced in any form or by any means without the prior written permission of CSR Limited.

The following are trade marks of CSR Limited and are under license. CSR, Gyprock, Soundchek,

Aquachek, Superchek, Fyrchek, CeminSeal, Bradford, DesignLINK.

GYP513.BMS1048.0714

Вам также может понравиться

- ChemSet - Reo - 502 - Plus - + - ChemSet - Anchor - Studs - HDG - Gr5.8 - M16-21 - 09 - 2022 FootpathДокумент7 страницChemSet - Reo - 502 - Plus - + - ChemSet - Anchor - Studs - HDG - Gr5.8 - M16-21 - 09 - 2022 FootpatheusufiqbalОценок пока нет

- Stainless Wire Balustrade BCA Construction RegulationsДокумент3 страницыStainless Wire Balustrade BCA Construction RegulationseusufiqbalОценок пока нет

- Burj Khalifa 22 PDFДокумент1 страницаBurj Khalifa 22 PDFDenilson Cuya RiveraОценок пока нет

- DCP 106 Amendment No 1 DocumentДокумент58 страницDCP 106 Amendment No 1 DocumenteusufiqbalОценок пока нет

- TEX207 Aquacomb OSD Brochure v4.1 4PP WEBДокумент4 страницыTEX207 Aquacomb OSD Brochure v4.1 4PP WEBeusufiqbalОценок пока нет

- Root BarrierДокумент1 страницаRoot BarriereusufiqbalОценок пока нет

- Stainless Steel Grade Composition ChartДокумент8 страницStainless Steel Grade Composition Chart23OtterОценок пока нет

- Eltrak Component Selection GuideДокумент1 страницаEltrak Component Selection GuideeusufiqbalОценок пока нет

- Stainless Steel Grade Composition ChartДокумент6 страницStainless Steel Grade Composition Charteusufiqbal100% (1)

- Firestop PDSДокумент2 страницыFirestop PDSeusufiqbal100% (1)

- Aqua C Broch 0509Документ8 страницAqua C Broch 0509eusufiqbalОценок пока нет

- Hyspan Span Guide 28pp Oct12 PDFДокумент28 страницHyspan Span Guide 28pp Oct12 PDF_Asylum_Оценок пока нет

- Plumbing NotesДокумент53 страницыPlumbing NotesArvee VillamorОценок пока нет

- SK3 Eg CДокумент1 страницаSK3 Eg CeusufiqbalОценок пока нет

- 2 Exemplary 3D Animation 2012 PDFДокумент1 страница2 Exemplary 3D Animation 2012 PDFMKPashaPashaОценок пока нет

- 1045 Medium Tensile Carbon Steel BarДокумент3 страницы1045 Medium Tensile Carbon Steel BareusufiqbalОценок пока нет

- Design Guide Fire ProtectionДокумент36 страницDesign Guide Fire ProtectionElan Bakar84% (19)

- Atlas 1045Документ4 страницыAtlas 1045teddy18Оценок пока нет

- CH 2Документ31 страницаCH 2eusufiqbalОценок пока нет

- Compression MembersДокумент3 страницыCompression MembersRahul7LMОценок пока нет

- Pressure Vessel FormulasДокумент0 страницPressure Vessel FormulasSaylittle PrayerОценок пока нет

- Design of Free Standing Walls Feb 1984Документ40 страницDesign of Free Standing Walls Feb 1984Dale Stewart100% (4)

- Guide To Standards-Workplace Health and SafetyДокумент46 страницGuide To Standards-Workplace Health and SafetyeusufiqbalОценок пока нет

- Steel Construction Cop 2004Документ59 страницSteel Construction Cop 2004eusufiqbalОценок пока нет

- SpeediBolt Range DCP SPB 001Документ24 страницыSpeediBolt Range DCP SPB 001eusufiqbalОценок пока нет

- Hollow Sections 2nd EdtДокумент240 страницHollow Sections 2nd Edtksuscribdacct100% (2)

- Wooden Pallet 1200 X 800 MMДокумент1 страницаWooden Pallet 1200 X 800 MMeusufiqbalОценок пока нет

- Hollow Sections 2nd EdtДокумент240 страницHollow Sections 2nd Edtksuscribdacct100% (2)

- Bond CreteДокумент3 страницыBond CreteeusufiqbalОценок пока нет

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Practical 2 GuideДокумент2 страницыPractical 2 GuideJeffrey PiggottОценок пока нет

- Hibernate Tutorial 12 Caching ObjectsДокумент8 страницHibernate Tutorial 12 Caching ObjectskantiprasadОценок пока нет

- Ford Focus 2007 Real-Time Data and Fault CodesДокумент3 страницыFord Focus 2007 Real-Time Data and Fault CodesAndrei CiobanasuОценок пока нет

- ISO 9001 Clause 7.5.2 Validation of Special ProcessesДокумент3 страницыISO 9001 Clause 7.5.2 Validation of Special Processeseconchan100% (1)

- Ote Fp-S Filter Press Eng Web PDFДокумент8 страницOte Fp-S Filter Press Eng Web PDFRegina Choque HuallpaОценок пока нет

- CT Basics and Applications For StudentДокумент230 страницCT Basics and Applications For Studentanon_969492799Оценок пока нет

- Extec C12Specs PDFДокумент21 страницаExtec C12Specs PDFRached Douahchua100% (1)

- QualityStage - Investigate Stage Intro - PR3 Systems BlogДокумент6 страницQualityStage - Investigate Stage Intro - PR3 Systems BlogMuraliKrishnaОценок пока нет

- Centre For Performing Arts: SynopsisДокумент19 страницCentre For Performing Arts: SynopsisSurvesh Messi100% (1)

- Catalog 201506 PDFДокумент75 страницCatalog 201506 PDFDairo OvalleОценок пока нет

- Green Marketing Sustainable DevelopmentДокумент12 страницGreen Marketing Sustainable DevelopmentHarshbab VaithunОценок пока нет

- RNAV Training For ATC 2007Документ156 страницRNAV Training For ATC 2007Kaow SomskoolОценок пока нет

- Auscrown Ring Burners July15Документ7 страницAuscrown Ring Burners July15Elbin Antonio EspinalОценок пока нет

- Insulating Firebrick (IFB)Документ2 страницыInsulating Firebrick (IFB)rickidenesОценок пока нет

- Fundamentals of Electric Vehicles Lecture on Vehicle DynamicsДокумент15 страницFundamentals of Electric Vehicles Lecture on Vehicle DynamicsaerovinuОценок пока нет

- Midterm Exam Physics General 1 Forces MotionДокумент3 страницыMidterm Exam Physics General 1 Forces MotionNam Anh Nguyễn HữuОценок пока нет

- Steam Tank Pressure & QualityДокумент5 страницSteam Tank Pressure & QualityAri Reza KОценок пока нет

- Lifting Plan DetailsДокумент2 страницыLifting Plan DetailssivaavissriОценок пока нет

- The Motherboard: The Main Circuit Board of a ComputerДокумент18 страницThe Motherboard: The Main Circuit Board of a ComputerRojan Jay Climacosa100% (1)

- Sennheiser Open-Aire HD-414 HeadphoneДокумент2 страницыSennheiser Open-Aire HD-414 HeadphonePilisi CsabaОценок пока нет

- 3 Re 445 DSL SPC PDFДокумент58 страниц3 Re 445 DSL SPC PDFThomasBaby KavoorazhikathuОценок пока нет

- PTSC MC-Piping Design Training-Basic Piping-LATESTДокумент31 страницаPTSC MC-Piping Design Training-Basic Piping-LATESTNguyen Anh Tung50% (2)

- En LV Power Supplies For High Altitude Applications Application NoteДокумент7 страницEn LV Power Supplies For High Altitude Applications Application Notejoe blowОценок пока нет

- D475a, D475asd 5e0Документ18 страницD475a, D475asd 5e0João MariaОценок пока нет

- Modelling Load Flow and Short Circuit ScenariosДокумент4 страницыModelling Load Flow and Short Circuit ScenariosCRISTIAN CAMILO MORALES SOLISОценок пока нет

- CV Indah Dita Oktaviani PDFДокумент1 страницаCV Indah Dita Oktaviani PDFLovely KittyОценок пока нет

- CFD and CAE Tools for Designing Propeller Turbine RunnersДокумент13 страницCFD and CAE Tools for Designing Propeller Turbine RunnersVanessa RuizОценок пока нет

- Managing Design Services for Construction ProjectsДокумент22 страницыManaging Design Services for Construction ProjectsAnwarОценок пока нет

- Factors To Consider in Foundation Design Chapter # 02Документ18 страницFactors To Consider in Foundation Design Chapter # 02Ali ShaheryarОценок пока нет

- PRACTICAL RESERVOIR MONITORING AND WATERFLOODINGДокумент51 страницаPRACTICAL RESERVOIR MONITORING AND WATERFLOODINGDuddi Dennisuk100% (3)