Академический Документы

Профессиональный Документы

Культура Документы

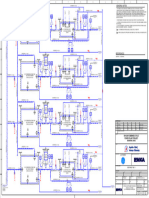

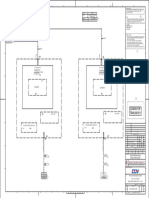

SD.20 Structural Concrete Standards Anchor Bolt Details

Загружено:

ajmainАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SD.20 Structural Concrete Standards Anchor Bolt Details

Загружено:

ajmainАвторское право:

Доступные форматы

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

ANCHOR BOLT MATERIALS : NOTES

59 PROJECTION THREAD LENGTH PROJECTION THREAD LENGTH PROJECTION THREAD LENGTH PROJECTION THREAD LENGTH 59

1. FOR CONCRETE GENERAL NOTES, LEGEND & ABBREVIATIONS SEE

ANCHOR BOLT MATERIALS SHALL CONFORM TO FOLLOWING STANDARD:

(SEE FDN DWG.) (SEE INSTRUCTION (SEE FDN DWG.) (SEE INSTRUCTION (SEE FDN DWG.) (SEE INSTRUCTION (SEE FDN DWG.) (SEE INSTRUCTION DRAWING No. EG001-CV-STD-11-GPWA0017-001.

- BOLTS: ASTM A36M OR F1554 THREADED STEEL RODS WITH UNC-2A THREADS

A BELOW) B02 BELOW) BELOW) B02 BELOW) A

- NUTS: ASTM A563M OR ASTM A563 GRADE A. HEAVY HEX WITH UNC-2B THREADS 2. FOR STEELWORK GENERAL NOTES, LEGEND & ABBREVIATIONS SEE

B02

- WASHERS: ASTM A36 PLATE DRAWING No. EG001-ST-STD-11-GPWA0001-001.

57 57

EG001-CV-STD-11-GPWA0024-001

TOC ELEV. TOC ELEV. TOC ELEV. TOC ELEV. - PLATES: ASTM A36 3. FOR MINIMUM SIZE (DIA) OF ANCHOR BOLTS TO BE USED SEE

TL

TL

TL

TL

(SEE FDN (SEE FDN (SEE FDN (SEE FDN STRUCTURAL DESIGN CRITERIA SPECIFICATION EG001-ST-BOD-11-0001.

P

DWG.) DWG.) DWG.) DWG.)

4. ANCHOR BOLT SPACING SHALL BE MINIMUM OF 8 x BOLT DIAMETER.

(MEASURED CENTRE TO CENTRE).

55 FABRICATION : 55

Ds 5. ANCHOR BOLT MINIMUM EDGE DISTANCE SHALL BE GREATER OF 75mm FROM FACE

SLEEVE, LOOSE

B02 B02 BOLT AND NUT FABRICATION SHALL COMPLY WITH THE MATERIALS SPECIFIED OF SLEEVE OR FACE OF BOLT AND SHALL ALSO BE AT LEAST :-

B SUPPLY B

ABOVE AND DIMENSIONS SPECIFIED IN THIS DRAWING. FIT OF NUTS ON THREADS OF FOR F1554 ANCHOR BOLTS 7.25 X BOLT DIAMETRE FROM BOLT CENTRE LINE

SEE NOTE 10 Ds B02

TO EDGE OF CONCRETE.FOR A36 ANCHOR BOLTS 6.0 X BOLT DIAMETRE.

S

B02 ANCHOR BOLTS SHALL BE VERIFIED BEFORE SHIPMENT.

53 53

L

6. ANCHOR BOLT TYPES A & B SHALL BE INSTALLED WITH ONE PLATE WASHER +

H

2 No. HEX NUTS. ANCHOR BOLTS WITH ONE NUT SHALL BE USED FOR

H

H

PROTECTION : MINOR FOUNDATIONS ONLY INCLUDING INDOOR INSTALLATION.

7. THE FOUNDATION GENERAL ARRANGEMENT DRAWINGS SHALL SPECIFY ANCHOR

GALVANISING IN ACCORDANCE WITH PROJECT SPECIFICATION EG001-MT-SPE-11-0009.

51 51

BOLT SIZE, TYPE, LENGTH, PROJECTION AND GROUT TYPE & THICKNESS.

THREAD WAX DIPPED, COVERED WITH LINEN OR PROTECTED WITH PLASTIC SLEEVE

8. CHEMICAL ANCHOR BOLTS SHALL ONLY BE USED FOR THE APPLICATIONS

C C

INDICATED IN THE TABLE AND NEVER IN CONDITIONS WHERE THE BOLT

MARKING :

TL

TL

TL

TL

0.5D min 0.5D min IS SUBJECT TO CONTINUOUS TENSION. CHEMICAL ANCHORS SHALL NOT

49 49

BE USED IN FIRE ZONE AREAS FOR EQUIPMENT CLASSED AS CRITICAL.

1

1

MATERIALS SHALL BE COLD STAMPED PRIOR TO ANY QUENCHING OR TEMPERING.

MARKING SHALL BE 3mm HIGH FOR 24mm DIA AND 4mm HIGH FOR 24mm DIA. 9. ANCHOR BOLTS SHALL BE DESIGN CHECKED FOR ULTIMATE LOADING IN

1

TACK WELD IN SHOP TACK WELD IN SHOP B02 TACK WELD IN SHOP TACK WELD IN SHOP

ACCORDANCE WITH ACI318, APPENDIX D.

3 No. PLACES 3 No. PLACES 3D 3 No. PLACES 3D 3 No. PLACES

10. SLEEVES TO BE SUPPLIED LOOSE AND SHALL BE PREMOULDED HIGH DENSITY

47 DESIGN CRITERIA : 47

.Sheet No.)

B02 POLYETHYLENE BY "SINCO/WILSON" BY SINCO PRODUCTS OR APPROVED

No.

a) ANCHOR BOLT SHALL BE DESIGNED IN ACCORDANCE WITH EG001-ST-BOD-11-0001. EQUIVALENT.

D D

DRG

ANCHOR BOLT TYPE "A" ANCHOR BOLT TYPE "B" ANCHOR BOLT TYPE "C" ANCHOR BOLT TYPE "D" b) BOLT LENGTHS IN TABLES ARE BASED ON GRADE A36 OR F1554 GRADE 55KSI STEEL CONSTRUCTION NOTES

ncl

45 45

WITH MINIMUM DISTANCE FROM EDGE OF CONCRETE AND ASSUMED PEDESTAL SIZE AND

(I

B02 1. PRIOR TO AND DURING CONCRETING ALL BOLTS SHALL BE SECURELY HELD

REINFORCEMENT. ALL BOLT LENGTHS TO BE CHECKED FOR LAP AND DISTANCE FROM

ACTUAL PEDESTAL REINFORCEMENT AS PER NOTE 9. IN POSITION BY USE OF SUITABLY ROBUST TEMPLATES. THE SLEEVE SHALL

BE IN THE CORRECT POSITION ON THE BOLT.

43 43

2. THE TOP ELEVATION AND LOCATION OF BOLTS SHALL BE CHECKED BEFORE

PLACEMENT OF CONCRETE. PROJECTION TOLERANCE SHALL BE +10mm AND -0mm.

E B02 B02 E

3. WHERE SLEEVES ARE PROVIDED, THE FOLLOWING SHALL APPLY:

41 ANCHOR BOLT SCHEDULE (A36) ANCHOR BOLT SCHEDULE (F1554) 41

a) THE EMBEDMENT DEPTH OF SLEEVE INTO CONCRETE SHALL NOT EXCEED THE

REQUIRED SLEEVE EMBEDMENT DEPTH 'S' INDICATED IN THE TABLE.

BOLT TYPE A & B TYPE C & D H TYPE A, B, C & D SLEEVE PLATE BOLT TYPE A & B TYPE C & D H TYPE A, B, C & D SLEEVE PLATE

L L mm THREAD LENGTH (TL) Ds x S WASHER b) DURING CONCRETING SLEEVES SHALL BE PLUGGED TO PREVENT INGRESS OF

L L mm THREAD LENGTH (TL) Ds x S WASHER

mm mm mm mm mm DxT (mm) mm mm mm mm mm DxT (mm) CONCRETE / DEBRIS.

39 39

SLEEVES SHALL BE FILLED WITH NON SHRINK CEMENT BASED GROUT (UNO).

EPOXY GROUT SHALL NOT BE USED FOR THIS APPLICATION.

F c) WATER SHALL BE REMOVED FROM SLEEVES BEFORE GROUTING. F

16 580 590 460 100 50x175 50x8 15.88 580 590 460 100 50x175 50x8

d) SPECIAL CARE SHALL BE TAKEN TO ENSURE THAT SLEEVES ARE COMPLETELY

37 FILLED WITH GROUT (OR ALTERNATIVE MATERIAL INDICATED ON DRAWINGS) 37

PRIOR TO GROUTING UNDER BASE OR RING PLATES.

20 600 610 460 115 60x175 60x10 19.05 590 600 460 115 60x175 60x10

4. ANCHOR BOLT TOLERANCE ON PLAN LOCATION SHALL BE +/- 2mm

FOR BOLTS UP TO 25mm DIA & +/- 4mm FOR LARGER DIA BOLTS.

35 TOLERANCES EXCEEDING THIS TO BE AGREED WITH CONTRACTOR 35

24 660 670 500 130 70x250 75x12 25.40 810 820 650 130 70x250 75x12

5. WHEN THE BOLTS HAVE SATISFIED THE ABOVE REQUIREMENTS THEY SHALL

G BE THOROUGHLY CLEANED AND THE NECESSARY WASHER AND NUT(S) ADDED G

31.75 830 850 650 150 80x250 100x15 AS INDICATED ON THE DETAIL DRAWINGS. THE PROJECTING PORTION OF THE

30 780 790 600 150 80x250 90x15

33 BOLT SHALL THEN BE WRAPPED WITH DENSO TAPE FOR PROTECTION. 33

6. UNLESS SPECIFIED OTHERWISE ON DESIGN DRAWING, ANCHOR BOLTS SHALL

36 910 920 700 170 90x375 110x20 38.10 1120 1140 910 170 90x375 110x20 BE TIGHTENED TO A SNUG TIGHT CONDITION. THIS IS DEFINED AS THE

TIGHTNESS THAT IS ATTAINED WITH A FEW IMPACTS OF AN IMPACT WRENCH

31 31

OR THE FULL EFFORT OF A MAN USING AN ORDINARY SPUD WRENCH.

42 1080 1110 850 190 100x375 130x25 44.45 1340 1360 1100 190 100x375 130x25 7. EXPANSION ANCHOR BOLTS SHALL BE INSTALLED AS PER MANUFACTURER'S

H H

RECOMMENDATIONS AND INSTRUCTIONS.

8. CHEMICAL ANCHOR BOLTS SHALL BE INSTALLED AS PER MANUFACTURER'S

29 29

RECOMMENDATIONS AND INSTRUCTIONS.

EG001-MT-SPE-11-0009 GALVANISING OF STRUCTURES

27 27

NOTE :-

VENDOR SPECIFIC BOLT SIZES NOT SHOWN ON THIS DWG EG001-ST-BOD-11-0001 STRUCTURAL DESIGN CRITERIA

J WILL BE AS SHOWN ON DESIGN DRGS J

REFERENCE SPECIFICATIONS

25 25

23 23

K K

21 21

GENERAL STEELWORK NOTES

O EG001-ST-STD-11-GPWA0001-001

LEGEND AND ABBREVIATIONS

GENERAL CONCRETE NOTES

EG001-CV-STD-11-GPWA0017-001

INSTRUCTIONS LEGEND AND ABBREVIATIONS

PROJECTION

19 19

TOC ELEV. REFERENCE DOCUMENTS

C

THEORETICAL PROJECTION GENERAL GUIDANCE FOR BOLT SELECTION

THEORETICAL PROJECTION IS OBTAINED BY: A+B+C (SEE FDN BOLTS TYPE

L L

B

DWG.) EQUIPMENT

WHERE A / C B / D EXPANSION BOLT CHEMICAL BOLT

GROUT A

PLATE THICKNESS

A = THE THICKNESS OF GROUT * *

17 17

B = THICKNESS OF BASE PLATE TO BE ANCHORED STACKS X

C = MINIMUM 2.5 0 COMPRESSORS X

THREADING TOWER-REACTORS-VERTICAL VESSELS WITH SKIRT X

EXCHANGERS SADDLES AND HORIZONTAL VESSELS X B02 23-Oct-2015 RE-ISSUED FOR REVIEW JH KHJ MCS GH AB MP

- FOR PROJECTION LENGTH 200 mm

15 15

THE THREADING LENGTH SHALL CORRESPOND TO THE VERTICAL VESSELS ON STEEL LEGS SUPPORTS X

PROJECTION LENGTH. FURNACES - SPHERES X B01 28-Jan-2012 APPROVED FOR DESIGN JWD MCS MCS GH MP

SEE FDN

M - FOR PROJECTION LENGTH 200 mm STEEL STRUCTURES X M

DRAWINGS A01 17-Dec-2014 ISSUED FOR REVIEW JWD MCS MCS GH MP

THE THREADING LENGTH SHALL BE 200 mm MAX. (REFER TO NOTE 5) PIPE RACKS X

13 INCLINED STAIRS X LEAD CHIEF

DATE REASON FOR ISSUE 13

REV BY CKD

ENG ENG

AEM PEM

LADDERS X X

MINOR EQUIPMENT X X X

DRAWN: J.W.DUGGAN CHECKED: M.CHANDRASEKHAR

A - 2 - 16 - 570 - 430 - S - 90 - (2) - W PIPING SUPPORT & FOUNDATIONS ON R.C. PAVING X X

PUMPS X

11 AGREEMENT No. GPO-WND-FPI-14-004 THIRD ANGLE PROJECTION

11

UNLESS OTHERWISE NOTED

STANDARD WASHER

N * SEE CONSTRUCTION NOTE 7 & 8 N

(IF REQD.)

9 9

No. OF NUTS REQD. ABOVE GRIP

LENGTH OF THREADS (mm)

SLEEVE WHERE USED

7 7

'H' DIM (mm) WND PROJECT INTERNAL (BECHTEL CONFIDENTIAL)

O O

O/A LENGTH OF BOLT (mm)

5 DIAMETER OF BOLT (d) (mm) PROJECT TITLE 5

NO. REQD.

BP WEST NILE DELTA GAS DEVELOPMENT PROJECT

SCALE

DRAWING TITLE

BOLT TYPE

3

STRUCTURAL CONCRETE STANDARDS NTS 3

DRG SIZE

P SAMPLE ANCHOR BOLT NUMBERING LEGEND ANCHOR BOLT DETAILS P

CAST-IN ANCHORS

A1

1 DRAWING No. (Incl. Sheet No.) No.of Sheets REV. 1

EG001-CV-STD-11-GPWA0024-001 001 B02

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21

jhartnet \\inxs95097\EG001_IssPDFArch NONE 23-OCT-2015 10:51 ORIGINAL SIGNED AND HELD IN DCC EG001-CV-STD-11-GPWA0024-001-RevB02-DC2.dgn

Вам также может понравиться

- Fixotec Technical CatalogueДокумент71 страницаFixotec Technical CatalogueSaqib AliОценок пока нет

- Anchor Bolt - ACIДокумент10 страницAnchor Bolt - ACIYatendra TyagiОценок пока нет

- Structural Design ManhoursДокумент3 страницыStructural Design ManhoursSiva ShankarОценок пока нет

- Bolt Capacity HT Bolt & Anchor BoltДокумент9 страницBolt Capacity HT Bolt & Anchor BoltMadhava PadiyarОценок пока нет

- TP 1U61A CV 1800 CAL 0030 R0 - Trestle Supp ReportДокумент224 страницыTP 1U61A CV 1800 CAL 0030 R0 - Trestle Supp Reportramesh_madkatte1082Оценок пока нет

- Calculation 240 (Rev02)Документ15 страницCalculation 240 (Rev02)KM YapОценок пока нет

- Civil Works MtoДокумент28 страницCivil Works MtoNassim SabriОценок пока нет

- Specification For Supply and Fabrication of Steel Structure-Gas de FranceДокумент18 страницSpecification For Supply and Fabrication of Steel Structure-Gas de Francehappale2002Оценок пока нет

- Pip Ste 03360 Heat Exchanger and Horizontal Vessel Design GuideДокумент42 страницыPip Ste 03360 Heat Exchanger and Horizontal Vessel Design GuideAymen MohammedОценок пока нет

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreДокумент1 страницаLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenОценок пока нет

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionДокумент4 страницыConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part3-Pull Out Strength in TensionVenu GopalОценок пока нет

- Load Comb Generator For STAAD, ETABS, SAFEДокумент606 страницLoad Comb Generator For STAAD, ETABS, SAFEBev GegonaОценок пока нет

- BLNG Ce 818010298560001Документ66 страницBLNG Ce 818010298560001Venkatesh PrasathОценок пока нет

- Calculation Report For New Substation Building C0148.64-2.41-680-B-EДокумент361 страницаCalculation Report For New Substation Building C0148.64-2.41-680-B-EkarthiОценок пока нет

- 1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandДокумент79 страниц1100-CV-CAL-005 - Foundation Calculation For Gas Pipeline Pig Receiver - Rev 2verandRianto FelissimoОценок пока нет

- IBC 2006 SEISMIC PARAMETER For StaadДокумент22 страницыIBC 2006 SEISMIC PARAMETER For Staadutoy032367Оценок пока нет

- Verification Example Extended Moment End-Plate: GeometryДокумент5 страницVerification Example Extended Moment End-Plate: Geometryngocnn100% (2)

- 1401 0101 Design Basis Report Ver 1Документ22 страницы1401 0101 Design Basis Report Ver 1mustafazahmedОценок пока нет

- Client: Project: Estimate No: Contract No: Sheet No: C06-C4/1Документ7 страницClient: Project: Estimate No: Contract No: Sheet No: C06-C4/1Krish ChandОценок пока нет

- Dj1 Dj2 Unb Unt Unl Ver 1.5Документ2 страницыDj1 Dj2 Unb Unt Unl Ver 1.5ajayssarode100% (1)

- M2-CV-RC-D-005 (Anchor Bolt Details)Документ19 страницM2-CV-RC-D-005 (Anchor Bolt Details)neerajОценок пока нет

- Quotation 1Документ1 страницаQuotation 1Daniyal Khursheed0% (1)

- Mononobe Okabe CalculatorДокумент2 страницыMononobe Okabe Calculatorginlemon86Оценок пока нет

- GB1516 Sac 240 CV RP 0004 - BДокумент69 страницGB1516 Sac 240 CV RP 0004 - BkkkkОценок пока нет

- V0 2000 CT Des 0001 - QДокумент65 страницV0 2000 CT Des 0001 - QKike MoraОценок пока нет

- Steel Section AISC360-10Документ4 страницыSteel Section AISC360-10osman_sultan100% (1)

- Embedded Plates Calculation - Part 2Документ8 страницEmbedded Plates Calculation - Part 2Mai CОценок пока нет

- 4 Anchor Bolts Base PlateДокумент285 страниц4 Anchor Bolts Base Platetitir bagchiОценок пока нет

- Sk-cl-c-130 Rev.c Steel Connection (Beam Connection)Документ25 страницSk-cl-c-130 Rev.c Steel Connection (Beam Connection)Zulfikar N JoelОценок пока нет

- Anchor Bolt and Base PlateДокумент4 страницыAnchor Bolt and Base Platevijaystructural100% (1)

- ANP E C0 000 GS 001-4-0 - Design Specification For Civil and StructuralДокумент83 страницыANP E C0 000 GS 001-4-0 - Design Specification For Civil and StructuralAndrew LimbongОценок пока нет

- Spreader Beam Design ExamplesДокумент3 страницыSpreader Beam Design ExamplesBogdan DSAОценок пока нет

- Foundation LoadingsДокумент1 страницаFoundation Loadingsmanish318Оценок пока нет

- AISC 13ed - LRFD Bolted Moment Connections Post r4Документ614 страницAISC 13ed - LRFD Bolted Moment Connections Post r4kfischer13Оценок пока нет

- GCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Документ19 страницGCMT-13-CIV-SPC-005 Civil Specification Fencing and Gates Materials (IFA - RevC)Dwiadi Cahyabudi100% (1)

- Direct Analysis and Its Implentation in Staad - Pro: Applies ToДокумент15 страницDirect Analysis and Its Implentation in Staad - Pro: Applies ToZULFIKAR AZANОценок пока нет

- Anchor BoltДокумент15 страницAnchor BoltRyan Wiratama67% (3)

- Aramco Bolt SizesДокумент1 страницаAramco Bolt SizesMuhammad Najam AbbasОценок пока нет

- 2 HoardingДокумент1 страница2 HoardingAkhilesh KajarekarОценок пока нет

- Concrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionДокумент6 страницConcrete Anchor Foundation Bolt Design Calculations With Example As Per ACI 318 Appendix D-Part2-Breakout Strength in TensionVenu GopalОценок пока нет

- Structural Steel DesignДокумент8 страницStructural Steel DesignNassim SabriОценок пока нет

- Sample Shear ConnectionДокумент1 страницаSample Shear ConnectionmaheshbandhamОценок пока нет

- Clipconn Bolt Weld 13Документ42 страницыClipconn Bolt Weld 13NEOОценок пока нет

- Anchor BoltsДокумент33 страницыAnchor BoltsAlberico Muratori100% (3)

- Sleeper - Is456Документ21 страницаSleeper - Is456arit bhattacharyaОценок пока нет

- Section B-B Section C-C: 0-8936-2 Golden Triangle Polymers Company LLCДокумент1 страницаSection B-B Section C-C: 0-8936-2 Golden Triangle Polymers Company LLCLester MuscaОценок пока нет

- BC 5300&5380 (1) FluidicДокумент8 страницBC 5300&5380 (1) FluidicCHARLIE BRICEОценок пока нет

- General NotesДокумент1 страницаGeneral Notesmustafa1989ocОценок пока нет

- Pnid ExamplesДокумент1 страницаPnid Examplessecret soldierОценок пока нет

- B224-FCC-LT-PID-111-11011 TO 11047 - LEGEND P&IDsДокумент33 страницыB224-FCC-LT-PID-111-11011 TO 11047 - LEGEND P&IDsSahadev SinghaОценок пока нет

- 6505 MHДокумент10 страниц6505 MHJulio Güissa57% (7)

- PE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1Документ1 страницаPE1007-00GAD10-XJ00-446303 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZОценок пока нет

- Electrical Wiring: DN 32 DN 32Документ1 страницаElectrical Wiring: DN 32 DN 32juring bitolaОценок пока нет

- General NotesДокумент1 страницаGeneral Notesmustafa1989ocОценок пока нет

- Fin Pid GnalДокумент113 страницFin Pid GnalVijay GuptaОценок пока нет

- 143H and 163H Motor Grader Hydraulic System Ripper AttachmentДокумент2 страницы143H and 163H Motor Grader Hydraulic System Ripper AttachmentMohamed Harb100% (1)

- 65 93 PR Pid 01090 - 0001 - BДокумент1 страница65 93 PR Pid 01090 - 0001 - BgeocaustasОценок пока нет

- L L L L: Section Section SectionДокумент1 страницаL L L L: Section Section SectionajmainОценок пока нет

- PE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1Документ1 страницаPE1007-00GAD10-XJ00-446302 Piping Isometrics - Rev 1JOSUE FERNANDO FERNANDEZОценок пока нет

- wm-558 2d Drawing PDFДокумент5 страницwm-558 2d Drawing PDFEgidijus DaukšysОценок пока нет

- SD.24 Handrial PDFДокумент1 страницаSD.24 Handrial PDFajmainОценок пока нет

- Steel Supports ListДокумент4 страницыSteel Supports ListajmainОценок пока нет

- SD 08Документ1 страницаSD 08ajmainОценок пока нет

- 86Документ1 страница86ajmainОценок пока нет

- L L L L: Section Section SectionДокумент1 страницаL L L L: Section Section SectionajmainОценок пока нет

- 85Документ1 страница85ajmainОценок пока нет

- Piping General Arrangement Cooling Tower Water System AreaДокумент1 страницаPiping General Arrangement Cooling Tower Water System AreaajmainОценок пока нет

- SPEДокумент15 страницSPEajmainОценок пока нет

- SD.23 Standard Ladder (Safety Gate)Документ1 страницаSD.23 Standard Ladder (Safety Gate)ajmainОценок пока нет

- Free Issue MaterialДокумент1 страницаFree Issue MaterialajmainОценок пока нет

- Method of MeasurmentДокумент3 страницыMethod of MeasurmentajmainОценок пока нет

- D-90-1331-210 - Rev 0 - Sheet 1 of 2Документ1 страницаD-90-1331-210 - Rev 0 - Sheet 1 of 2ajmainОценок пока нет

- STДокумент23 страницыSTajmainОценок пока нет

- (B.O.Q) Supply & Install 2Документ2 страницы(B.O.Q) Supply & Install 2ajmainОценок пока нет

- D 90 1331 202 RevAДокумент1 страницаD 90 1331 202 RevAajmainОценок пока нет

- For Construction: Bio-Fuel Ethanol Plant in Northern Region ProjectДокумент24 страницыFor Construction: Bio-Fuel Ethanol Plant in Northern Region ProjectajmainОценок пока нет

- S-00-1390-001 Rev 0 (Hot Insulation Specifications For BOP)Документ20 страницS-00-1390-001 Rev 0 (Hot Insulation Specifications For BOP)ajmain100% (1)

- D 90 1331 205 RevAДокумент1 страницаD 90 1331 205 RevAajmainОценок пока нет

- D 90 1331 208 RevAДокумент1 страницаD 90 1331 208 RevAajmainОценок пока нет

- D 90 1331 211 RevAДокумент1 страницаD 90 1331 211 RevAajmainОценок пока нет

- D 90 1331 201 RevAДокумент1 страницаD 90 1331 201 RevAajmainОценок пока нет

- D 90 1331 200 RevAДокумент1 страницаD 90 1331 200 RevAajmainОценок пока нет

- D 90 1331 203 RevAДокумент1 страницаD 90 1331 203 RevAajmainОценок пока нет

- D 90 1331 202 RevA PDFДокумент1 страницаD 90 1331 202 RevA PDFajmainОценок пока нет

- C-90-1331-200 - Rev 0Документ114 страницC-90-1331-200 - Rev 0ajmainОценок пока нет

- C-90-1323-011 - Rev 0Документ20 страницC-90-1323-011 - Rev 0ajmainОценок пока нет

- C-90-1323-010 - Rev 0Документ46 страницC-90-1323-010 - Rev 0ajmain100% (1)

- C-90-1323-008 - Rev 0Документ25 страницC-90-1323-008 - Rev 0ajmainОценок пока нет

- C-90-1323-009 - Rev 0Документ21 страницаC-90-1323-009 - Rev 0ajmainОценок пока нет

- Structure of WaterДокумент5 страницStructure of Waterapi-233981890Оценок пока нет

- Organic Chemistry ReviewerДокумент1 страницаOrganic Chemistry Reviewerniyah austeroОценок пока нет

- ProductCatalog PYROMATIONДокумент212 страницProductCatalog PYROMATIONDiego John Gavilanes UvidiaОценок пока нет

- How To Produce Metanol (Ebook) PDFДокумент210 страницHow To Produce Metanol (Ebook) PDFelfainsyahОценок пока нет

- Components Catalouge PDFДокумент338 страницComponents Catalouge PDFtarek100% (1)

- Determination of Crystal Structure and Crystallite SizeДокумент17 страницDetermination of Crystal Structure and Crystallite SizeRohit SatheshОценок пока нет

- Beams: Diagrams and Formulas For Various Loading ConditionsДокумент34 страницыBeams: Diagrams and Formulas For Various Loading ConditionsgaganОценок пока нет

- Rotary EvaporatorДокумент4 страницыRotary EvaporatorArif FerdianОценок пока нет

- Process Flow Description - LatestДокумент3 страницыProcess Flow Description - LatestJheffersonОценок пока нет

- Chemical Waste Log Book 2011 PDFДокумент15 страницChemical Waste Log Book 2011 PDFVictor AniekanОценок пока нет

- Gravity Dam StabilityДокумент14 страницGravity Dam StabilityHarilal Kishan67% (3)

- SCIENCE 10 - Q4 - MOD5 - Chemical Reaction For BookletfДокумент12 страницSCIENCE 10 - Q4 - MOD5 - Chemical Reaction For BookletfRetep ArenОценок пока нет

- Análisis de Ciclo de VidaДокумент12 страницAnálisis de Ciclo de VidaOscar VicenteОценок пока нет

- Mechanics Particle Adhesion FullДокумент92 страницыMechanics Particle Adhesion Fullingenious2011Оценок пока нет

- Chemistry Practical Manual 2021Документ50 страницChemistry Practical Manual 2021Jagdish PrajapatiОценок пока нет

- Reference - PIM-SU-3541-D - HydrotestДокумент14 страницReference - PIM-SU-3541-D - Hydrotestaslam.ambОценок пока нет

- MADICA 2018 ProgramДокумент17 страницMADICA 2018 ProgramathmaniОценок пока нет

- Cleaning InstructionsДокумент1 страницаCleaning Instructionsdiegoachurra.qОценок пока нет

- Aashto r37 (GPR)Документ11 страницAashto r37 (GPR)Carlos RosasОценок пока нет

- Europrene INTOL POLIMERIДокумент28 страницEuroprene INTOL POLIMERIRubik ArtОценок пока нет

- Process Plant Estimating StandardsДокумент15 страницProcess Plant Estimating StandardsCarl Williams75% (4)

- Astm CatalogДокумент13 страницAstm CatalogjswldeepОценок пока нет

- Din 580-Lifting Eye Bolts PDFДокумент1 страницаDin 580-Lifting Eye Bolts PDFAntohi CatalinОценок пока нет

- Ronnel AC Design Solution 2Документ36 страницRonnel AC Design Solution 2Xype LanderОценок пока нет

- Multiple Choice Questions emДокумент21 страницаMultiple Choice Questions emvaibhavmn100% (2)

- Volumetric CalculationsДокумент9 страницVolumetric CalculationsFuad MohamedОценок пока нет

- Chapter 2 AbsorptionДокумент94 страницыChapter 2 AbsorptionaradayОценок пока нет

- Lapox AR 101 PDFДокумент2 страницыLapox AR 101 PDFOsama GabrОценок пока нет

- Clickductor EngДокумент20 страницClickductor EngmahmoudglobaltechОценок пока нет