Академический Документы

Профессиональный Документы

Культура Документы

Fabrication and Analysis of Thermo Electricgenerator For Power Generator

Загружено:

Akash SaxenaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Fabrication and Analysis of Thermo Electricgenerator For Power Generator

Загружено:

Akash SaxenaАвторское право:

Доступные форматы

ISSN (Online) : 2319 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science, E ngineering and Technology

An ISO 3297: 2007 Certified Organization, Volume 3, Special Issue 1, February 2014

International Conference on Engineering Technology and Science-(ICETS14)

On 10th & 11th February Organized by

Department of CIVIL, CSE, ECE, EEE, MECHNICAL Engg. and S&H of Muthayammal College of Engineering, Rasipuram, Tamilnadu, India

Fabrication and Analysis of Thermo Electric

Generator For Power Generator

AravindKaruppaiah.C1, Ganesh.S2, Dileepan.T3, Jayabharathi.S4

Student, Department of Mechanical Engineering, Sri Manakula Vinayagar Engineering College, Madagadipet,

Puducherry- 605 107, India1, 2, 3

Assistant Professor, Department of Mechanical Engineering, Sri Manakula Vinayagar Engineering College,

Madagadipet, Puducherry- 605 107, India4

Abstract: The Thermo Electric Generator can be used produces direct current (DC) to a load (RL) having a

to produce power using the exhaust waste heat from IC terminal voltage (V) and a terminal current (I). There is no

engines (automobiles). This power can be used to intermediate energy conversion process. For this reason,

charge the battery of automobiles (two-wheelers). This thermoelectric power generation is classified as direct

system of charging the battery reduces the fuel power conversion. The amount of electrical power

consumption and battery life is also increased. generated is given by I2RL, or VI.

The project describes the design and analysis of

TEG with the material used. The factors affecting the A unique aspect of thermoelectric energy

efficiency of TEG are studied. The properties of the conversion is that the direction of energy flow is

material, efficiency of TEG and the heat transfer in reversible. So, for instance, if the load resistor is removed

TEG are also studied using ANSYS. and a DC power supply is substituted, the thermoelectric

The objective of the project is to produce power device can be used to draw heat from the heat source

from the waste sources. To reduce the heat let into the element and lower its temperature. In this configuration,

atmosphere. To reduce the fuel consumption of the reversed energy-conversion process of thermoelectric

automobiles. To increase the life of the battery used in devices is invoked, using electrical power to pump heat

automobiles. and produce refrigeration.

Keywords- TEG, battery, fuel consumption

I. INTRODUCTION

A. Thermo Electric Generator

The thermo electric generator (TEG) is the

system used to generate power from low temperatures that

is less than 1000K as heat input. It is best method for

recovery of exhaust heat. It can be used in many fields

such as automobiles, boilers wood stoves etc. The

efficiency of a TEG depends on the thermo electric

materials. The main research of the world is to use the

renewable energy. The main advantage of TEG is that it

uses green energy. The TEG is mainly based on the

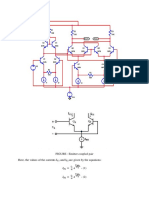

principle of Seebeck effect. The efficiency of a thermo Fig.2 experimental setup

electric generator is about 5%. A heat source provides the

high temperature, and the heat flows through a

thermoelectric converter to a heat sink, which is

maintained at a temperature below that of the source. The

temperature differential across the converter

Copyright to IJIRSET www.ijirset.com 1508

ISSN (Online) : 2319 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science, E ngineering and Technology

An ISO 3297: 2007 Certified Organization, Volume 3, Special Issue 1, February 2014

International Conference on Engineering Technology and Science-(ICETS14)

On 10th & 11th February Organized by

Department of CIVIL, CSE, ECE, EEE, MECHNICAL Engg. and S&H of Muthayammal College of Engineering, Rasipuram, Tamilnadu, India

B. Thermo Electric Material

Thermoelectric materials (those which are

employed in commercial applications) can be conveniently

divided into three groupings based on the temperature

range of operation. Alloys based on Bismuth (Bi) in

combinations with Antimony (An), Tellurium (Te) or

Selenium (Se) are referred to as low temperature materials

and can be used at temperatures up to around 450K. The

intermediate temperature range - up to around 850K is the

regime of materials based on alloys of Lead (Pb) while

thermo-elements employed at the highest temperatures are

fabricated from SiGe alloys and operate up to 1300K.

Although the above mentioned materials still remain the

cornerstone for commercial and practical applications in

thermoelectric power generation, significant advances have

been made in synthesizing new materials and fabricating

Fig.2 experimental setup

material structures with improved thermoelectric

performance. Efforts have focused primarily on improving

the materials figure-of-merit, and hence the conversion

efficiency, by reducing the lattice thermal conductivity.

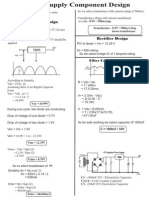

C. Battery Charging System

The existing system of charging the battery for

automobiles consumes 10 % of the fuel, and hence the

efficiency of the engine is reduced. This system is to be

replaced by TEG system of charging the battery which is

light in weight and battery life also can be increased.

FACTORS AFFCTING THE EFFICENCY OF TEG

Thermo Electric Material

Hot source

Cold source

Heat transfer

Fig.3 TEG assembly model

II. EXPERIMENTAL SETUP

TE-GENERATOR

The experimental setup for testing is shown

Based on this Seebeck effect,

thermoelectric devices can act as electrical power

generators. A schematic diagram of a simple

thermoelectric power generator operating based on

Seebeck effect.

Copyright to IJIRSET www.ijirset.com 1509

ISSN (Online) : 2319 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science, E ngineering and Technology

An ISO 3297: 2007 Certified Organization, Volume 3, Special Issue 1, February 2014

International Conference on Engineering Technology and Science-(ICETS14)

On 10th & 11th February Organized by

Department of CIVIL, CSE, ECE, EEE, MECHNICAL Engg. and S&H of Muthayammal College of Engineering, Rasipuram, Tamilnadu, India

In a system where both ends are kept at a constant

temperature relative to each other (a constant heat current

flows from one end to the other), there is a constant

diffusion of carriers. If the rate of diffusion of hot and cold

carriers were equal, there would be no net change in

charge. However, the diffusing charges are scattered by

impurities, imperfections, and lattice vibrations. If the

scattering is energy dependent, the hot and cold carriers

will diffuse at different rates. This will create a higher

density of carriers at one end of the material, and the

distance between the positive and negative charges

produces a potential difference; an electrostatic voltage.

This electric field, however, will oppose the

uneven scattering of carriers, and equilibrium will be

reached where the net number of carriers diffusing in one

Fig.4 principle of TEG direction is cancelled by the net number of carriers moving

in the opposite direction from the electrostatic field. This

means the thermo power of a material depends greatly on

As shown in figure, heat is transferred at a rate of Qhfrom impurities, imperfections, and structural changes (which

a high-temperature heat source maintained at Th to the hot often vary themselves with temperature and electric field),

junction, and it is rejected at a rate of Ql to a low- and the thermo power of a material is a collection of many

temperature sink maintained at Tl from the cold junction. different effects.

Based on Seebeck effect, the heat supplied at the hot

junction causes an electric current to flow in the circuit and III. THERMO ELECTRIC MATERIAL

electrical power is produced.

Using the first-law of thermodynamics (energy The thermo electric material used in this project is

conservation principle) the difference between Qh and Ql is silicon and germanium. The material is selected on the

the electrical power output we. It should be noted that this basis of power factor , figure of merit and melting

power cycle intimately resembles the power cycle of a heat point.The performance of thermoelectric materials can be

engine (Carnot engine), thus in this respect a expressed as

thermoelectric power generator can be considered as a

unique heat engine.

Charge carriers in the materials (electrons in

metals, electrons and holes in semiconductors, ions in ionic Where Z is the thermoelectric material figure-of-merit, is

conductors) will diffuse when one end of a conductor is at the Seebeck coefficient given by

a different temperature than the other. Hot carriers diffuse

from the hot end to the cold end, since there is a lower

density of hot carriers at the cold end of the conductor.

Cold carriers diffuse from the cold end to the hot end for

the same reason.

Where,

If the conductor were left to reach equilibrium,

this process would result in heat being distributed evenly R is the electric resistivity (inverse of electric conductivity)

throughout the conductor. The movement of heat (in the and k is the total thermal conductivity. This figure-of-merit

form of hot charge carriers) from one end to the other is

called a heat current. As charge carriers are moving, it is may be made dimensionless by multiplying by

also an electrical current. (average absolute temperature of hot and cold plates of the

thermoelectric module, K),

Copyright to IJIRSET www.ijirset.com 1510

ISSN (Online) : 2319 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science, E ngineering and Technology

An ISO 3297: 2007 Certified Organization, Volume 3, Special Issue 1, February 2014

International Conference on Engineering Technology and Science-(ICETS14)

On 10th & 11th February Organized by

Department of CIVIL, CSE, ECE, EEE, MECHNICAL Engg. and S&H of Muthayammal College of Engineering, Rasipuram, Tamilnadu, India

HOT SOURCE

The Hot source is the waste gas present in IC

And engine. A copper plate is used to transmit the heat from the

engine to the generator. Copper has the high thermal

conductivity and high melting point.

TIME (mins) EXHAUST

TEMPERATURE()

15 145

The term 2/R is referred to as the electrical 30 151

power factor. In general, a thermoelectric power generator

exhibits low efficiency due to the relatively small 45 162

dimensionless figure-of-merit of currently 60 175

available thermoelectric materials. The conversion

efficiency of a thermoelectric power generator defined as

the ratio of power delivered to the heat input at the hot

junction of the thermoelectric device, is given by COLD SOURCE

The cold source is given by the air cooling

system with the help of the fins. The fins are made up of

aluminum. Aluminum is used because of its light weight

and more cooling capacity. Based on the heat to be

dissipated number of fins is calculated as 20.

Air cooling system is efficient than water cooling

system and also water cooling system requires a separate

tank and a circulation system.

The cold sources temperature is the room temperature

and it is around 26-30.

Fig.6 Aluminum fin

HEAT TRANSFER

Figure 5: Performance of Thermoelectric Materials at

Various Temperatures The heat transfer in exhaust pipe is done using

ansys.

Copyright to IJIRSET www.ijirset.com 1511

ISSN (Online) : 2319 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science, E ngineering and Technology

An ISO 3297: 2007 Certified Organization, Volume 3, Special Issue 1, February 2014

International Conference on Engineering Technology and Science-(ICETS14)

On 10th & 11th February Organized by

Department of CIVIL, CSE, ECE, EEE, MECHNICAL Engg. and S&H of Muthayammal College of Engineering, Rasipuram, Tamilnadu, India

Figure 7: Heat transfer in exhaust pipe. TIME EXHAUST OUTPUT CHARGING

MINS TEMPERATURE VOLTAGE VOLTAGE

The ansys result shows that the exhaust temperature is () ( V) (V)

maximum at the left end i.e at the source. The temperature

reduces as it moves further. Convection heat transfer takes 15 145 6.00 5.5

place in the exhaust pipe. At first the flow is said to be 30 151 10.00 9.6

turbulent and it changes to laminar.

45 162 14.50 14.0

IV. RESULT

60 175 17.50 16.5

EXPERIMENT OUTPUT

The experiment setup is made and following results

were inhered.

TEMPERATURE & VOLTAGE

20

18

16

14

VOLTAGE

12

10

8

6

4

2

0

145 151 162 175

TEMPERATURE

Copyright to IJIRSET www.ijirset.com 1512

ISSN (Online) : 2319 8753

ISSN (Print) : 2347 - 6710

International Journal of Innovative Research in Science, E ngineering and Technology

An ISO 3297: 2007 Certified Organization, Volume 3, Special Issue 1, February 2014

International Conference on Engineering Technology and Science-(ICETS14)

On 10th & 11th February Organized by

Department of CIVIL, CSE, ECE, EEE, MECHNICAL Engg. and S&H of Muthayammal College of Engineering, Rasipuram, Tamilnadu, India

6. Thermoelectric Exhaust Energy Recovery with Temperature

OUT PUT VOLTAGE & Control through Heat Pipes

Jorge MARTINS, Francisco P. BRITO, L.M. GONCALVES,

CHARGING VOLTAGE Joaquim ANTUNES

7. Technologies to recover exhaust heat from internal combustion

18 engines

16 R. Saidur a, M.Rezaei a, W.K.Muzammil a, M.H.Hassan a, S.Paria

CHARGING VOLTAGE

a, M.Hasanuzzaman b,n

14

12

10

8

6

4

2

0

6 10 14.5 17.5

OUTPUT VOLTAGE

ACKNOWLEDGMENT

We are very thankful and grateful to our

Department Head Dr.K.Velmurugan, Co-ordinator

Mr.G.B.M.Mohanraj, and our beloved sister Ms.K.

Krishnapriya whose great support, valuable advices,

suggestions and tremendous help enabled us in completing

our project. They have been a great source of inspiration to

us.

V. CONCLUSION

We conclude that TEG system of charging the

battery could reduce the fuel consumption and also battery

life used in automobiles could be increased. It is the best

method for recovery of waste exhaust heat. The main

advantage of TEG is that it produces power from the waste

heat source.

REFERENCES

1. Saidur R. A review on electrical motors energy use and energy

savings. Renewable and Sustainable Energy Reviews

2010;14(3):87798.

2. Saidur R, Atabani AE, Mekhilef S. A review on electrical and

thermal energy for industries. Renewable and Sustainable Energy

Reviews 2011;15(4):207386

3. G.P. Meisner, Thermoelectrics Application Workshop, San

Diego(2011).

4. Thermo electric generator: Non Convectional Energy Resouse By

G.D. Rai.

5. Non convention energy resources By B. H. khan.

Copyright to IJIRSET www.ijirset.com 1513

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Java RingДокумент12 страницJava RingMegha OmshreeОценок пока нет

- Security Alarm CircuitДокумент3 страницыSecurity Alarm Circuitmanishsingla88100% (1)

- II-II - EM&I - Unit-IV - Question BankДокумент5 страницII-II - EM&I - Unit-IV - Question BankRachananjali Kunamneni KethineniОценок пока нет

- StacoAVR2 PDFДокумент20 страницStacoAVR2 PDFmaungОценок пока нет

- Isp MACH4128 VДокумент74 страницыIsp MACH4128 VjyotiОценок пока нет

- Refurbishing A Clansman Battery: Colin Guy G4DDIДокумент2 страницыRefurbishing A Clansman Battery: Colin Guy G4DDIScott WyattОценок пока нет

- BJT Gibert MultiplierДокумент5 страницBJT Gibert MultiplierJyoti GoyalОценок пока нет

- 700-HG Power Relay: - Description Contact Ratings Wiring Diagrams Coil Voltage Cat. NoДокумент1 страница700-HG Power Relay: - Description Contact Ratings Wiring Diagrams Coil Voltage Cat. NoArif KhanОценок пока нет

- Impulse Testing of TransformersДокумент20 страницImpulse Testing of TransformersSantosh VardhanОценок пока нет

- Tda 7269Документ8 страницTda 7269JCMОценок пока нет

- LDR Physics Project 1Документ18 страницLDR Physics Project 1ARTHUR BALAJI RОценок пока нет

- Description: Technical DataДокумент17 страницDescription: Technical DataDhivya NОценок пока нет

- NMIДокумент36 страницNMIVipan SharmaОценок пока нет

- Overview of Power Integrity Solutions On Package and PCB: Decoupling and EBG IsolationДокумент39 страницOverview of Power Integrity Solutions On Package and PCB: Decoupling and EBG IsolationIsmaiel KaladiОценок пока нет

- CV ApplicationsGuideДокумент59 страницCV ApplicationsGuidenewgenerationОценок пока нет

- Pulse and Digital Circuits - Linear Wave ShapingДокумент132 страницыPulse and Digital Circuits - Linear Wave ShapingSasi Bhushan100% (2)

- Power Supply Design 2Документ1 страницаPower Supply Design 2Kunal Khandelwal100% (2)

- Sursa de Tensiune - DatasheetДокумент2 страницыSursa de Tensiune - DatasheetAdrianaОценок пока нет

- Morse Code Astable OscillatorДокумент2 страницыMorse Code Astable OscillatorFeher Catalin100% (1)

- LCD Monitor TV: Service ManualДокумент44 страницыLCD Monitor TV: Service ManualRolando perezОценок пока нет

- Encoder White PaperДокумент9 страницEncoder White Papersaneie99Оценок пока нет

- Capacitors and Dielectric PDFДокумент29 страницCapacitors and Dielectric PDFJACOB MERCADOОценок пока нет

- Kvas 100Документ98 страницKvas 100Vikash Kumar PrasadОценок пока нет

- Automatic Street LightДокумент60 страницAutomatic Street LightYogesh Kadam 813100% (1)

- Lista Tonere Pentru CartuseДокумент182 страницыLista Tonere Pentru CartuseNelu NeluОценок пока нет

- Miller Thunderbolt XL AC-DCДокумент2 страницыMiller Thunderbolt XL AC-DCMphilipT100% (1)

- SR100-36P W 12 V DC Data SaroДокумент2 страницыSR100-36P W 12 V DC Data SaroWalteros AugustoОценок пока нет

- PPT RE2-introductionДокумент23 страницыPPT RE2-introductionLutfyОценок пока нет

- CAT 910 Charging SystemДокумент15 страницCAT 910 Charging SystemYober Emilio Nato AcostaОценок пока нет

- Knowles MLC Catalogue 2016Документ102 страницыKnowles MLC Catalogue 2016SalvadorОценок пока нет