Академический Документы

Профессиональный Документы

Культура Документы

Welding Defects at Friction Stir Welding: P. Podržaj, B. Jerman, D. Klobčar

Загружено:

sanjay_dutta_5Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Welding Defects at Friction Stir Welding: P. Podržaj, B. Jerman, D. Klobčar

Загружено:

sanjay_dutta_5Авторское право:

Доступные форматы

P. PODRAJ, B. JERMAN, D.

KLOBAR ISSN 0543-5846

METABK 54(2) 387-389 (2015)

UDC UDK 621.791.1:669.715=111

WELDING DEFECTS AT FRICTION STIR WELDING

Received Prispjelo: 2014-06-27

Accepted Prihvaeno: 2014-10-20

Preliminary Note Prethodno priopenje

The paper presents an overview of different types of defects at friction stir welding. In order to explain the reasons

for their occurrence a short theoretical background of the process is given first. The main emphasis is on the param-

eters that influence the process. An energy supply based division of defects into three disjoint groups was used. The

occurring defects are demonstrated on various materials.

Key words: friction stir welding, welding parameters, welding defects, friction stir channelling

INTRODUCTION faying weldpieces (see Figure 1). The tools movement

is a superposition of translational and rotational move-

Friction stir welding (FSW) is a relatively new ma- ment and must perform two primary functions. These

terial joining process. It was invented and experimen- are the frictional heating of the workpiece(s) and the

tally proven in 1991 by a welding institute in UK, which stirring of material in order to produce a joint [6]. As

also holds the associated patent rights [1]. Compared to there is axial (vertical) force acting upon the tool, the

conventional welding methods FSW consumes much heating of the workpiece is the result of the associated

less energy, produces no toxic fumes, doesnt need any friction between the tool and the workpiece and the

shielding gas or filler metal and is therefore considered plastic deformation of the workpiece material.

to be an environmentally friendly, energy efficient ma- The rate of energy input due to friction is determined

terial joining process. by the two main parameters. The first one is the rota-

Since its invention FSW has often been applied in a tional speed of the tool and the second one is the trans-

wide array of industries such as aerospace, automotive, lational speed of the tool. The FSW tool material, heat

railway, and maritime. As it is especially well suited for treatment and its geometry are also of high importance

rapid and high quality welding of 2XXX and 7XXX [7-11]. Different shapes of shoulders are for example

aluminium alloys, which are traditionally considered to shown in Figure 2.

be unweldable, it is being used increasingly in applica-

tions, where due to the weight reduction, aluminium is

Translation

the material of choice.

Recently there is however a lot of research going on

Vertical force

in order to widen the set of materials applicable for Shoulder

FSW. Mg-, Cu-, Ti-, Al-alloy matrix composites, lead,

Rotation

some steels, stainless steels, thermoplastics and differ-

Nugget

ent material combinations, particularly those with close

melting temperatures and similar behaviour such as hot Retreating

workability, have been considered [2, 3]. side

As in other welding processes it is very important to Pin

choose the right combination of welding parameters in

order to get a weld of appropriate quality. In this paper Advancing

side

the main parameters of friction stir welding and pro-

cessing will be presented together with the most com-

mon welding defects which occur if an inappropriate Figure 1 A schematic representation of a friction stir welding

combination of these parameters is used [4, 5]. [2, 12]

THEORETICAL BACKGROUND

FSW can be characterized as a solid-state joining

process which uses a non-consuming tool to join two

P. Podraj, B. Jerman, D. Klobar, Faculty of Mechanical Engineering,

University of Ljubljana, Ljubljana, Slovenia Figure 2 Different types of shoulder (shown from underneath)

METALURGIJA 54 (2015) 2, 387-389 387

P. PODRAJ et al.: WELDING DEFECTS AT FRICTION STIR WELDING

In order for achieve quality friction stir welds all the

zones must be developed and material must be stirred

well.

THE MOST COMMON DEFECTS IN FSW

An inappropriate rate of heating can result in the for-

mation of FSW defects such as lack of penetration, lack

of fusion, tunnels, voids, surface grooves, excessive

flash, surface galling, nugget collapse and kissing bonds

[16]. These defects are sometimes divided into volu-

Figure 3 Different types of tool pins (a cross section and side

metric flaws and weld line flaws [17]. A more common

view) possibility is the division of the defects based on the

energy input. As it is primarily determined by the main

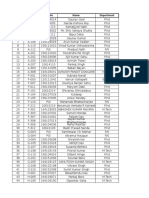

Shoulder width parameters of FSW, which are the tool rotational speed

(TR), the translational speed i.e. welding speed (WS),

TMAZ and tilt angle, these are the physical quantities used in

Unaffected Stir Unaffected the graph shown in Figure 5.

HAZ HAZ

zone zone zone

In general there is a certain range of these two pa-

rameters combinations that results in a good quality

Figure 4 Schematic representation of FSW zones based on weld. The region outside it can be divided into three

microstructure [12, 13]

areas associated with the following defects [11]:

Figure 3 on the other hand shows the most common a large mass of flash due to the excess heat input,

types of tool pins in a cross section and side view. cavity or groove-like defect caused by an insuffi-

The cross section can have various shapes. The last cient heat input,

two examples in the upper row of Figure 3 show a pin cavity produced by the abnormal stirring.

with four flutes. Pins with three flutes are also quite A typical occurrence of flash due to the excess heat

common. Often these flutes twist in a vertical direction. input is shown in Figure 6.

The tools without a pin have also been considered. It Such a weld is of an unacceptable visual appearance

should also be mentioned that the tool is often tilted. despite acceptable weld strength. This welding defect

From the microstructural point of view the cross can be easily removed by milling on the same machine.

section of the friction stir weld can be divided into four A photo of such a weld is shown in Figure 7.

distinct zones (see Figure 4). An example of a FSW welded aluminium alloy 5083

Although some of the zone names might differ from is shown in Figure 8. In Figure 8a a difference in grain

source to source, the most commonly used division is

the following one [13-15]:

Unaffected or parent (base) metal Rotational

Excess

heat Abnormal

This is the zone furthest from the weld. Despite the speed

input stirring

possible temperature variations in the zone, the material

in it has the same microstructure and mechanical prop-

erties as it had before the welding process.

Heat affected zone (HAZ)

It is the next zone in the direction towards the weld

center. The temperature variations in this zone are sig- Insufficient

nificant enough to modify microstructure and/or me- heat input

chanical properties. There is however still no plastic

deformation.

Translational (welding) speed

Thermo-mechanically affected zone (TMAZ)

Contrary to HAZ, this zone experiences plastic de- Figure 5 Range of appropriate FSW parameters [18]

formation as well. As aluminium is one of the most

commonly applied materials in FSW, this zone is often

defined to be without recrystallization. In case of some

other materials such as titanium and its alloys, austen-

itic stainless steel and copper there is recrystallization

in TMAZ as well [15].

Stir zone

Stir zone, which is sometimes also called the weld nug- Figure 6 A macrograph of a FSW with a flash due to an excess

get, is the region in TMAZ where recrystallization occurs. heat input (AlSi12)

388 METALURGIJA 54 (2015) 2, 387-389

P. PODRAJ et al.: WELDING DEFECTS AT FRICTION STIR WELDING

Figure 9 A cavity due to an insufficient heat input (AlSi12)

CONCLUSIONS

The paper presents the most common defects in the

Figure 7 A photo of a weld flash with an additional surface FSW which occur due to an inappropriate combination

groove (AlSi12)

of welding parameters (mainly translational/welding

speed and rotational speed). This results in either exces-

size between the parent metal and the stir zone is clearly

sive or insufficient heat input. Even if these parameters

observable. The fine grains in the stir zone imply a

are selected properly the defects can occur due to inap-

much improved superplastic formability. Figure 8b

propriate tilt angle, improper tool geometry or unsuita-

shows a zoomed in version of Figure 8a. It can be seen

ble control algorithm.

that there is a lack of penetration at the weld root. Such

a weld is not acceptable due to the inferior weld strength

especially in the case of a dynamic loading. It should be

REFERENCES

emphasized that this kind of defect is very difficult to [1] W. M. Thomas, E. D. Nicholas, J. C. Needham, M. G.

detect using non-destructive testing methods. Murch, P. Temple-Smith, C. J. Dawes, Friction-stir butt

welding. GB Patent No. 9125978.8, International patent

Figure 9 is showing a macrograph of a FSW welded application No. PCT/GB92/02203 (1991).

aluminium alloy AlSi12 made with an insufficient heat [2] G. Cam, International Materials Reviews, 56 (2011), 1-48.

input, which resulted in a weld cavity. Such a weld is of [3] H. K. D. H. Bhadeshia and T. DebRoy, Science and

course unacceptable as well. It can however be detected Technology of Welding and Joining, 14 (2009), 193-196.

using non-destructive testing methods. In some cases [4] D. Klobar, L. Kosec, B. Kosec, J. Tuek, Engineering Fai-

such a cavity (channel) is however exactly what is de- lure Analysis, 20 (2012) 1, 43-53.

[5] A. Smolej, D. Klobar, B. Skaza, A. Nagode, E. Slaek, V.

sired. Such a process is called friction stir channelling Dragojevi and S. Smolej, Materials Science and Enginee-

(FSC) [19]. The most typical application of FSC is the ring: A, 590 (2014), 239-245.

production of heat exchangers. [6] R. S. Mishra, Z. J. Ma, Materials Science and Engineering,

R50 (2005), 1-78.

[7] S. Sattari, H. Bisadi, M. Sajed, International Journal of

Mechanics and Applications, 2 (2012), 1-6.

[8] Y. N. Zhang, X. Cao, S. Larose and P. Wanjara, Canadian

Metallurgical Quarterly, 51 (2012), 250-261.

[9] R. Rai, A. De, H. K. D. H. Bhadeshia and T. DebRoy,

Science and Technology of Welding & Joining, 2011, 16,

325-342.

[10] J. Brni, M. anaija, G. Turkalj, D. Lanc, T. Pepelnjak, B.

Barii, G. Vukeli, M. Bri, Mater. Manuf. Process. 24

(2009) 7/8, 758-762.

[11] G. Kosec, A. Nagode, I. Budak, A. Antic, B. Kosec: Engi-

neering Failure Analysis, 18 (2011) 1, 450-454.

[12] Z. Bergant, J. Grum, Journal of heat treatment and mate-

rials, 69 (2014)2, 114-123.

[13] R. Nandan, T. DebRoy, H. K. D. H. Bhadeshia, Progress in

Materials Science, 53 (2008), 980-1023.

[14] A. Barcellona, G. Buffa, L. Fratini, D. Palmeri, Journal of

Materials Processing Technology, 177 (2006), 340-344.

[15] Z. H. Fu, D. Q. He, H. Wang, Journal of Wuhan University

of Technology, 19 (2004), 61-64.

[16] J. W. Qian, J. L. Li, F. Sun, J. T. Xiong, F. S. Zhang, X. Lin,

Progress in Materials Science, 68 (2013) 175-178

[17] P. L. Threadgill, Science and Technology of Welding and

Joining, 12 (2007) 357-360

[18] Y. G. Kim, H. Fujii, T. Tsumura, T. Komazaki, K. Nakata,

Materials Science and Engineering A, 415 (2006) 250-254.

[19] C. Vidal, V. Infante and P. Vilaa, International Journal of

Figure 8 A micrograph of FSW weld root in aluminium alloy Fatigue, 62 (2014), 85-92.

5083 with a kissing bond caused by a lack of Note: The responsible translator for English language is Urka Letonja,

penetration Moar. Prevajanje, Slovenia

METALURGIJA 54 (2015) 2, 387-389 389

Вам также может понравиться

- 30xa 100t PDFДокумент162 страницы30xa 100t PDFleung ka kitОценок пока нет

- Practical CS ProcessingДокумент483 страницыPractical CS ProcessinganAMUstudent100% (2)

- UntitledДокумент17 страницUntitledSedat100% (1)

- Ken Holt 06 The Secret of Hangman's InnДокумент216 страницKen Holt 06 The Secret of Hangman's InnPastPresentFuture100% (2)

- Rolling Contact Fatigue of Case Carburized 2017 International Journal of FaДокумент18 страницRolling Contact Fatigue of Case Carburized 2017 International Journal of FaAnonymous bjD4fCiОценок пока нет

- BZY Series Tension Meter ManualДокумент29 страницBZY Series Tension Meter ManualJORGE SANTANDER0% (1)

- Day 1 Training Material FlowДокумент200 страницDay 1 Training Material FlowGhazouani AymenОценок пока нет

- Calculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementДокумент52 страницыCalculate Breakeven Point in Units and Revenue Dollars: Intermediate Cost Analysis and ManagementNavice Kie100% (1)

- Welding Defects at Friction Stir Welding: Metalurgija - Sisak Then Zagreb - April 2015Документ4 страницыWelding Defects at Friction Stir Welding: Metalurgija - Sisak Then Zagreb - April 2015Navaz MohammadОценок пока нет

- Various Parameter Effects On Friction SДокумент7 страницVarious Parameter Effects On Friction SmanishcguptaОценок пока нет

- Friction Stir Spot Welding of Dissimilar Materials: An OverviewДокумент6 страницFriction Stir Spot Welding of Dissimilar Materials: An OverviewLinaceroОценок пока нет

- Shrivastava 2015Документ9 страницShrivastava 2015mounir0607Оценок пока нет

- 1 s2.0 S1005030217300658 MainДокумент8 страниц1 s2.0 S1005030217300658 MainBilay CernaОценок пока нет

- A Critical Review On Friction Stir Based ProcessesДокумент9 страницA Critical Review On Friction Stir Based ProcessesrrrrrОценок пока нет

- Refrensi 2 ElsevierДокумент10 страницRefrensi 2 Elseviergangdukuh251Оценок пока нет

- Welding Parameter Selection and Short Fatigue Crack Growth of Dissimilar Aluminum Alloy Friction Stir Welded JointДокумент9 страницWelding Parameter Selection and Short Fatigue Crack Growth of Dissimilar Aluminum Alloy Friction Stir Welded Jointforough bashtinОценок пока нет

- A Review On Friction Stir Spot Welding Joints of Dissimilar Aluminium Alloys PDFДокумент5 страницA Review On Friction Stir Spot Welding Joints of Dissimilar Aluminium Alloys PDFMaros SaОценок пока нет

- Friction Stir Welding - Process and Its Variables: A ReviewДокумент8 страницFriction Stir Welding - Process and Its Variables: A ReviewMulyanto MulyonoОценок пока нет

- Ijs R Off 2013123Документ5 страницIjs R Off 2013123KKN UNP - FKM UNAND 2020 NAGARI PADANG GANTINGОценок пока нет

- A Critical Review of Friction Stir Welding Process: January 2015Документ19 страницA Critical Review of Friction Stir Welding Process: January 2015Anis dakhlaouiОценок пока нет

- FSWДокумент24 страницыFSWpariОценок пока нет

- Submerged Arc Welding A Review PaperДокумент4 страницыSubmerged Arc Welding A Review PaperSudhanshu KumarОценок пока нет

- Friction Stir Spot Welding For Automotive Applications: Necdet ÇAPARДокумент5 страницFriction Stir Spot Welding For Automotive Applications: Necdet ÇAPARLinaceroОценок пока нет

- Tensile Properties of Friction Stir Welded Joints of 2024 Aluminum Alloys in Different Heat-Treated-StateДокумент11 страницTensile Properties of Friction Stir Welded Joints of 2024 Aluminum Alloys in Different Heat-Treated-StateRikko Putra YouliaОценок пока нет

- A Review of Conical Tool Feature VariatiДокумент4 страницыA Review of Conical Tool Feature Variatiالسيد ابراهيم عبدالعزيز عبداللهОценок пока нет

- Thomas, Johnson, Wiesner - 2003 - Friction Stir Welding-Recent Developments in Tool and Process Technologies-AnnotatedДокумент6 страницThomas, Johnson, Wiesner - 2003 - Friction Stir Welding-Recent Developments in Tool and Process Technologies-AnnotatedAHMED SAMIR ALEMDARОценок пока нет

- Dependence of Overload Performance Spot 2008Документ6 страницDependence of Overload Performance Spot 2008Vipin MishraОценок пока нет

- Metals 12 02099Документ58 страницMetals 12 02099Bosco BeloОценок пока нет

- Vaidya Et Al. - 2006 - Assessment of Fracture and Fatigue Crack Propagation of Laser Beam and Friction Stir Welded Aluminium and Magnesi-AnnotatedДокумент8 страницVaidya Et Al. - 2006 - Assessment of Fracture and Fatigue Crack Propagation of Laser Beam and Friction Stir Welded Aluminium and Magnesi-AnnotatedMinnu KothakotaОценок пока нет

- 2019 A Review On Resistance Spot Welding of Steel MaterialДокумент13 страниц2019 A Review On Resistance Spot Welding of Steel Materialguravshubham7777Оценок пока нет

- Biro 2012Документ16 страницBiro 2012Denbe SantosОценок пока нет

- Fuller 2006Документ11 страницFuller 2006Taguis VelascoОценок пока нет

- Friction Stir Welding FSW ProcessДокумент6 страницFriction Stir Welding FSW ProcessEdwinОценок пока нет

- Corrosion Susceptibility and Mechanical Properties of Friction Stir Welded AA2024 T3 JointsДокумент10 страницCorrosion Susceptibility and Mechanical Properties of Friction Stir Welded AA2024 T3 JointsRamanvlrОценок пока нет

- 1 s2.0 S0261306907000404 MainДокумент12 страниц1 s2.0 S0261306907000404 Mainsunil sinhmarОценок пока нет

- Friction Stir Welding FSW Final ReportДокумент28 страницFriction Stir Welding FSW Final ReportShashank Verma100% (1)

- Influence of Rotational Speed On MechaniДокумент8 страницInfluence of Rotational Speed On Mechaniالسيد ابراهيم عبدالعزيز عبداللهОценок пока нет

- Murshid Imam-2017Документ22 страницыMurshid Imam-2017Shine KunnathОценок пока нет

- Failure Behavior of Resistance Spot Welded Low CarДокумент10 страницFailure Behavior of Resistance Spot Welded Low CarLuis Allan GarciaОценок пока нет

- Effect of Welding Speed On The Microstructure and Texture Development in The Individual Weld Zone of Friction Stir Welded DP780 SteelДокумент14 страницEffect of Welding Speed On The Microstructure and Texture Development in The Individual Weld Zone of Friction Stir Welded DP780 SteelARUNPRAKASH SОценок пока нет

- 1 s2.0 S2238785420318676 MainДокумент13 страниц1 s2.0 S2238785420318676 MainAHMED SAMIR ALEMDARОценок пока нет

- Journal of Manufacturing Processes: Z.L. Ni, F.X. Ye TДокумент15 страницJournal of Manufacturing Processes: Z.L. Ni, F.X. Ye TMukesh KumarОценок пока нет

- Review On FSWДокумент18 страницReview On FSWbvnareshОценок пока нет

- Fundamentals of Friction Stir Welding, Its Application, and AdvancementsДокумент50 страницFundamentals of Friction Stir Welding, Its Application, and Advancementsjose ramirez cruzОценок пока нет

- Vahid Daeizadeh and Meghdad MollaeiДокумент8 страницVahid Daeizadeh and Meghdad MollaeiSagar Jadhav MaliОценок пока нет

- Zhang2020 AnnotatedДокумент13 страницZhang2020 AnnotatedAHMED SAMIR ALEMDARОценок пока нет

- Critical Review of Automotive Steels Spot WeldingДокумент44 страницыCritical Review of Automotive Steels Spot WeldingJoselo HRОценок пока нет

- Materials 16 03513 v2Документ13 страницMaterials 16 03513 v2vivian40136Оценок пока нет

- 10.1016@j.matpr.2020.02.166 AA6061 and AA5052Документ5 страниц10.1016@j.matpr.2020.02.166 AA6061 and AA5052V.v. TaguisОценок пока нет

- Constantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFДокумент9 страницConstantin 2017 IOP Conf. Ser. Mater. Sci. Eng. 252 012038 PDFMeet PatelОценок пока нет

- Influence of Process Parameters On Microstructure and Mechanical Properties in AA2024-T3 Friction Stir WeldingДокумент10 страницInfluence of Process Parameters On Microstructure and Mechanical Properties in AA2024-T3 Friction Stir WeldingYazid HelalОценок пока нет

- JMR&T-2023 Final PaperДокумент20 страницJMR&T-2023 Final PaperUroš TrdanОценок пока нет

- Trans NonferrousMet Soc China29201918241835Документ13 страницTrans NonferrousMet Soc China29201918241835omerОценок пока нет

- Review Corrosion Behavior of Friction Stir Welded Magnesium AlloysДокумент6 страницReview Corrosion Behavior of Friction Stir Welded Magnesium AlloysSAYON DEYОценок пока нет

- Investigation of Tool Offset On Mechanical Properties of Dissimilar AA6061-T6 and AA7075-T6 Joint in Parallel FSW ProcessДокумент10 страницInvestigation of Tool Offset On Mechanical Properties of Dissimilar AA6061-T6 and AA7075-T6 Joint in Parallel FSW ProcessOumaymaОценок пока нет

- Notch Defect Interaction in Additively Manufact 2019 International Journal oДокумент11 страницNotch Defect Interaction in Additively Manufact 2019 International Journal oMUIN ABDULLAH-ALОценок пока нет

- Resistance Welding of FeCrNiSi AlloyДокумент18 страницResistance Welding of FeCrNiSi Alloytqzw7p8m2kОценок пока нет

- Figner - FSSW Between Al and Steel Automotive Sheets Influence of Welding Parameters On Mechanical Properties and MicrostructureДокумент12 страницFigner - FSSW Between Al and Steel Automotive Sheets Influence of Welding Parameters On Mechanical Properties and MicrostructurePaula InesОценок пока нет

- Friction Stir Welding and Processing: R.S. Mishra, Z.Y. MaДокумент78 страницFriction Stir Welding and Processing: R.S. Mishra, Z.Y. MaMed BENYASSSINEОценок пока нет

- On Improved Fatigue Properties of Aluminum Alloy 5086 Weld JointsДокумент14 страницOn Improved Fatigue Properties of Aluminum Alloy 5086 Weld Jointsjianxiaoma150Оценок пока нет

- Tribological and Impact Toughness Performance of Friction Stir Processed AA7075Engineering Research ExpressДокумент13 страницTribological and Impact Toughness Performance of Friction Stir Processed AA7075Engineering Research ExpressRamanvlrОценок пока нет

- 2014 M. Divya, C.R DasДокумент10 страниц2014 M. Divya, C.R DasPRATEEK KUMARОценок пока нет

- 1 s2.0 S104458031832028X MainДокумент8 страниц1 s2.0 S104458031832028X MainRamanvlrОценок пока нет

- Analysis of Fatigue-Related Aspects of FCAW and GMAW Butt-Welded Joints in A Structural SteelДокумент13 страницAnalysis of Fatigue-Related Aspects of FCAW and GMAW Butt-Welded Joints in A Structural Steelalex totiОценок пока нет

- Spot Welding of 6061 Aluminum Alloy by Friction Stir Spot Welding ProcessДокумент4 страницыSpot Welding of 6061 Aluminum Alloy by Friction Stir Spot Welding Processosama1928Оценок пока нет

- Agreement of Dealership Between Manufacturer and FДокумент2 страницыAgreement of Dealership Between Manufacturer and Fsanjay_dutta_5Оценок пока нет

- External Flow ContinuedДокумент12 страницExternal Flow Continuedsanjay_dutta_5Оценок пока нет

- 2018 - 01 - 27 CE648 Assignment 1 (Theoretical)Документ1 страница2018 - 01 - 27 CE648 Assignment 1 (Theoretical)sanjay_dutta_5Оценок пока нет

- 2018 - 02 - 01 CE648 Assignment 2 (Numerical)Документ1 страница2018 - 02 - 01 CE648 Assignment 2 (Numerical)sanjay_dutta_5Оценок пока нет

- Gate Admit CardДокумент1 страницаGate Admit Cardsanjay_dutta_5Оценок пока нет

- Doctor of Philosophy (PH.D in Law)Документ2 страницыDoctor of Philosophy (PH.D in Law)sanjay_dutta_5Оценок пока нет

- Education ERP - A Panacea PDFДокумент3 страницыEducation ERP - A Panacea PDFsanjay_dutta_5Оценок пока нет

- Badarpur Electrical Circle APDCL, CAR, BadarpurghatДокумент2 страницыBadarpur Electrical Circle APDCL, CAR, Badarpurghatsanjay_dutta_5Оценок пока нет

- Advt1 2016Документ9 страницAdvt1 2016sanjay_dutta_5Оценок пока нет

- Agvb 2015 08-01-107 Specimen Copy Form Offering Premises Standard FormatДокумент5 страницAgvb 2015 08-01-107 Specimen Copy Form Offering Premises Standard Formatsanjay_dutta_5Оценок пока нет

- Cucurbituril Homologues and Derivatives: New Opportunities in Supramolecular ChemistryДокумент10 страницCucurbituril Homologues and Derivatives: New Opportunities in Supramolecular Chemistrysanjay_dutta_5Оценок пока нет

- ASSAMESE Reject PDFДокумент4 страницыASSAMESE Reject PDFsanjay_dutta_5Оценок пока нет

- Education ERP - A PanaceaДокумент3 страницыEducation ERP - A Panaceasanjay_dutta_5Оценок пока нет

- MA 201: Lecture - 16 Properties of Fourier Series and Fourier IntegralДокумент25 страницMA 201: Lecture - 16 Properties of Fourier Series and Fourier Integralsanjay_dutta_5Оценок пока нет

- Assamese RejectДокумент4 страницыAssamese Rejectsanjay_dutta_5Оценок пока нет

- Bus Timings 2010Документ4 страницыBus Timings 2010Borad Madan BarkacharyОценок пока нет

- Challan: Application No / Reg. No: 127508 Application No / Reg. No: 127508 Application No / Reg. No: 127508Документ2 страницыChallan: Application No / Reg. No: 127508 Application No / Reg. No: 127508 Application No / Reg. No: 127508sanjay_dutta_5Оценок пока нет

- SletДокумент1 страницаSletsanjay_dutta_5Оценок пока нет

- Chord ChartДокумент1 страницаChord Chartsanjay_dutta_5Оценок пока нет

- List of Residents Yet To SubmitДокумент2 страницыList of Residents Yet To Submitsanjay_dutta_5Оценок пока нет

- OpenInnovation IITGДокумент18 страницOpenInnovation IITGsanjay_dutta_5Оценок пока нет

- Quantum Mechanics - IV Quantum Mechanics - IV 30.10.2015Документ14 страницQuantum Mechanics - IV Quantum Mechanics - IV 30.10.2015sanjay_dutta_5Оценок пока нет

- Annual Calender 2017 IESДокумент1 страницаAnnual Calender 2017 IESAdam JensenОценок пока нет

- We Wish You A Merry Christmas: Guitar, Key of GДокумент1 страницаWe Wish You A Merry Christmas: Guitar, Key of Gsanjay_dutta_5Оценок пока нет

- Metals: A Finite Element Model To Simulate Defect Formation During Friction Stir WeldingДокумент15 страницMetals: A Finite Element Model To Simulate Defect Formation During Friction Stir Weldingsanjay_dutta_5Оценок пока нет

- How To Simulate A Friction Stir Welding With ANSYSДокумент7 страницHow To Simulate A Friction Stir Welding With ANSYSGin GiamОценок пока нет

- Nomination Form For HMCДокумент3 страницыNomination Form For HMCsanjay_dutta_5Оценок пока нет

- MA 201: Lecture - 17 Fourier Transforms and It's PropertiesДокумент27 страницMA 201: Lecture - 17 Fourier Transforms and It's Propertiessanjay_dutta_5Оценок пока нет

- Sorting Algorithms in Fortran: Dr. Ugur GUVENДокумент10 страницSorting Algorithms in Fortran: Dr. Ugur GUVENDHWANIT MISEОценок пока нет

- Financial Analysis of Ashok LeylandДокумент120 страницFinancial Analysis of Ashok LeylandSiva Kumaravel0% (1)

- Lecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodДокумент5 страницLecture 5: Triangulation Adjustment Triangulation: in This Lecture We Focus On The Second MethodXogr BargarayОценок пока нет

- SOP For Operation & Calibration of PH Meter - QualityGuidancesДокумент9 страницSOP For Operation & Calibration of PH Meter - QualityGuidancesfawaz khalilОценок пока нет

- The King's Avatar - Chapter 696 - Guild Feature - Gravity TalesДокумент5 страницThe King's Avatar - Chapter 696 - Guild Feature - Gravity TalesMayhaaaОценок пока нет

- College Invitation Letter - Managedia 2023Документ2 страницыCollege Invitation Letter - Managedia 2023Sandeep DeyОценок пока нет

- Lahainaluna High School Cafeteria: Lahaina, Maui, HawaiiДокумент42 страницыLahainaluna High School Cafeteria: Lahaina, Maui, HawaiiKeerthy MoniОценок пока нет

- Bill - AKIJДокумент3 страницыBill - AKIJm.tanjil2005Оценок пока нет

- 1evolution of O and M TheoryДокумент27 страниц1evolution of O and M TheoryTracy AdraОценок пока нет

- Interection 2 Reading Teacher's Book PDFДокумент165 страницInterection 2 Reading Teacher's Book PDFتركي الزهراني0% (1)

- COSO DefinEDДокумент21 страницаCOSO DefinEDRefdy AnugrahОценок пока нет

- Police Cranston School Committee Member Stole PTO FundsДокумент1 страницаPolice Cranston School Committee Member Stole PTO FundsashaydelineОценок пока нет

- Ijrpr2741 Study On Investor Perception Towards Stock Market InvestmentДокумент19 страницIjrpr2741 Study On Investor Perception Towards Stock Market InvestmentAbhay RanaОценок пока нет

- Hybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and DemonstratedДокумент4 страницыHybrid Neural-Network - Genetic Algorithm Technique For Aircraft Engine Performance Diagnostics Developed and Demonstratedmohamad theibechОценок пока нет

- SRM 7 EHP 4 Release Notes PDFДокумент18 страницSRM 7 EHP 4 Release Notes PDFMOHAMMED SHEHBAAZОценок пока нет

- List of Famous Cities On River Banks in The WorldДокумент2 страницыList of Famous Cities On River Banks in The WorldDiptangshu DeОценок пока нет

- T10 - PointersДокумент3 страницыT10 - PointersGlory of Billy's Empire Jorton KnightОценок пока нет

- Moinho Disco PKM PDFДокумент6 страницMoinho Disco PKM PDFPaulo WilkerОценок пока нет

- Expansions Meet Health Care Needs: Economists Question Trump Plan FiguresДокумент10 страницExpansions Meet Health Care Needs: Economists Question Trump Plan FiguresThe Daily Tar HeelОценок пока нет

- Asme Bladder Accumulator DatasheetДокумент3 страницыAsme Bladder Accumulator DatasheetSamad A BakarОценок пока нет

- JHS Integrated Science Preamble, Jan 2012 - FinalДокумент15 страницJHS Integrated Science Preamble, Jan 2012 - Finalfrank adamsОценок пока нет

- Et200sp Im 155 6 PN ST Manual en-US en-USДокумент47 страницEt200sp Im 155 6 PN ST Manual en-US en-USayaz officeОценок пока нет

- Nokia 3g Full Ip CommissioningДокумент30 страницNokia 3g Full Ip CommissioningMehul JoshiОценок пока нет