Академический Документы

Профессиональный Документы

Культура Документы

Calculation Thickness of Tube : Design Data

Загружено:

Mohammad HamdaniОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Calculation Thickness of Tube : Design Data

Загружено:

Mohammad HamdaniАвторское право:

Доступные форматы

DOC.

NO :

PROGRAM NAME : TUBE01 REV.NO :

VERSION : 1.0 PAGE : /

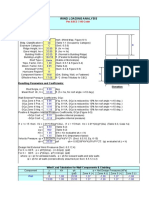

*** CALCULATION THICKNESS OF TUBE ***

**DESIGN DATA** ITEM.NO : E-5217

MATERIAL = A179

OUTSIDE DIA. OF TUBE Do = 19.05 mm

USED THICKNESS t= 2.11 mm

ALLOWABLE STRESS S= 9.42 Kg/mm2

CORROSION ALLOWANCE C= 1.5 mm

JOINT EFFICIENCY E= 1

DESIGN TUBE LENGTH L= 3000 mm

1. UNDER INTERNAL PRESSURE

DESIGN TEMPRATURE T= 180 C

o

DESIGN PRESSURE P= 0.030 Kg/mm2

P x Ro

t1 = + C

S E + 0.4P

0.03 x 9.525

= + 1.5 = 1.53 mm

9.42 x 1 + 0.4 x 0.03

2. UNDER EXTERNAL PRESSURE

DESIGN TEMPERATURE T= 200 C

o

DESIGN PRESSURE P' = 0.085 Kg/mm2

Do / ( t - C ) = 19.05 / ( 2.11 - 1.5 ) 31.230

L / Do = 3000 / 19.05 = 157.48

FOR TUBES HAVING ( Do / ( t - C ) VALUE > 10

FROM CHART, FACTOR A = 0.016 ; B= 13800 PSI = 9.7 Kg/mm2

THE MAXIMUM ALLOWABLE EXTERNAL PRESSURE

4xB

Pa1 = -------------------------

3 x Do / ( t - C )

4 x 9.70

= -------------------------- = 0.41413823 Kg/mm2

3 x 19.05 / ( 2.11 - 1.5 )

P' = 0.085 Kg/mm^2 < Pa = 0.414 Kg/mm^2 O.K !!

FOR TUBES HAVING ( Do / ( t - C ) VALUE < 10

FOR TUBES HAVING ( Do / ( t - C ) VALUE > 10

4xB

Pa1 = -------------------------

3 x Do / ( t - C )

4 x 9.70

= -------------------------- = 0.414138 Kg/mm2

3 x 19.05 / ( 2.11 - 1.5 )

2.167 x ( t - C )

Pa1 = [ ------------------------ - 0.0833 ] x B

Do

2.167 x ( 2.11 - 1.5 )

= [ ------------------------ - 0.0833 ] x 9.70 = -0.135 Kg/mm2

19.05

2xSx(t-C) (t-C)

Pa2 = -------------------------- [ 1 - -------------]

Do Do

2 x 9.42 x ( 2.11 - 1.5 ) ( 2.11 - 1.5 )

= -------------------------- [ 1 - ------------------ ] = 58.396 Kg/mm2

19.05 19.05

P' = 0.085 Kg/mm^2 < Pa = 0.414 Kg/mm^2 O.K !!

0.414138

Вам также может понравиться

- Rean Water Tech Pvt. LTD.: Isolated Footing DesignДокумент5 страницRean Water Tech Pvt. LTD.: Isolated Footing DesignSougata MondalОценок пока нет

- Base Plate DesignДокумент4 страницыBase Plate DesignPradeep Kumar RajОценок пока нет

- Weld ConnectionДокумент1 страницаWeld ConnectionAnonymous xcFcOgMiОценок пока нет

- KT Type Truss Connection - LRFDДокумент11 страницKT Type Truss Connection - LRFDkalpanaadhiОценок пока нет

- AISC Properties ViewerДокумент3 страницыAISC Properties Viewerchriscivil12Оценок пока нет

- Combined FootingДокумент7 страницCombined FootingMohammed ElemamОценок пока нет

- Base Plate Design1Документ2 страницыBase Plate Design1Rafael GarciaОценок пока нет

- 22.5 KW Solar StructureДокумент5 страниц22.5 KW Solar StructureTejas VarmaОценок пока нет

- Controlling Forces Wind FactorДокумент3 страницыControlling Forces Wind FactorRajib MaharjanОценок пока нет

- Project Name: Item Description Quantity Unit Rate TotalДокумент23 страницыProject Name: Item Description Quantity Unit Rate TotalAlexandruDanielОценок пока нет

- Slab Design of Partially Fixed Circular SlabДокумент4 страницыSlab Design of Partially Fixed Circular SlabBithika DattaОценок пока нет

- Sectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)Документ49 страницSectional Properties of Rolled Steel Joists (Ref: Is: 808 - 1989 & Is: 12778 - 2004)rohitnrgОценок пока нет

- Tandem: I. Reaction From Midas Iii. Cross Section of Moment Plate Due To The Tension Load at Top FlangeДокумент5 страницTandem: I. Reaction From Midas Iii. Cross Section of Moment Plate Due To The Tension Load at Top FlangeBrent SeeОценок пока нет

- RHS DesignДокумент2 страницыRHS Designsivaraju1Оценок пока нет

- Atasehir Gardens Podium OF: Member: LocationДокумент7 страницAtasehir Gardens Podium OF: Member: LocationklynchelleОценок пока нет

- Load Calculation: Self-Weight of Materials SL No Material Density (KN/M)Документ6 страницLoad Calculation: Self-Weight of Materials SL No Material Density (KN/M)ajith chandranОценок пока нет

- L Shaped Retaining WallДокумент64 страницыL Shaped Retaining WallKelvin LauОценок пока нет

- Simple Connection of Angles For TENSIONДокумент92 страницыSimple Connection of Angles For TENSIONfaizan ashiqueОценок пока нет

- WALLPRES ExcavationДокумент11 страницWALLPRES ExcavationShekh Muhsen Uddin AhmedОценок пока нет

- Wind CalculatorДокумент12 страницWind Calculatorilyasmd7Оценок пока нет

- Design of Staircase - 10182021Документ1 страницаDesign of Staircase - 10182021Bry RamosОценок пока нет

- Moment ConnectionДокумент5 страницMoment ConnectionjanethОценок пока нет

- Steel SectionsДокумент48 страницSteel SectionsJeison MedinaОценок пока нет

- 2 PDFДокумент1 страница2 PDFSujit RasailyОценок пока нет

- Option Mine CalculatorДокумент88 страницOption Mine CalculatorVarinder AnandОценок пока нет

- Pile Cap Design - ColumnsДокумент7 страницPile Cap Design - ColumnsJule LobresОценок пока нет

- Design of Secondary Beams For U.D.L Proj.-Lab (Upper Flange Is Considered To Be Effectively Held) Dimensions of BeamДокумент6 страницDesign of Secondary Beams For U.D.L Proj.-Lab (Upper Flange Is Considered To Be Effectively Held) Dimensions of BeamRakesh SharmaОценок пока нет

- Bolt Design and Embedment Length CheckДокумент6 страницBolt Design and Embedment Length CheckHarish M PОценок пока нет

- Wind Load GTPOGTДокумент2 страницыWind Load GTPOGTAnonymous 2CMPbqwBОценок пока нет

- Report For: PAX-40919-01 LP Compressor After Cooler - HBHДокумент36 страницReport For: PAX-40919-01 LP Compressor After Cooler - HBHRajasekar MeghanadhОценок пока нет

- Column Design Name of Work:-: PK - Nandwana@yahoo - Co.inДокумент27 страницColumn Design Name of Work:-: PK - Nandwana@yahoo - Co.innsureshbabu0% (1)

- Shear Strength Controls 21.65 Kips/bolt: Section at AДокумент4 страницыShear Strength Controls 21.65 Kips/bolt: Section at AmaheshbandhamОценок пока нет

- Design of Shear Connector For Composite Bending ActionДокумент2 страницыDesign of Shear Connector For Composite Bending ActionankitОценок пока нет

- Civil/Structural Calculation SheetДокумент19 страницCivil/Structural Calculation Sheetfbaxter22Оценок пока нет

- Design of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)Документ3 страницыDesign of Pile: 400Mm Dia Pile Design (Applicable For 0M-0.5M Fill)sivaОценок пока нет

- 1th SectionДокумент10 страниц1th SectionfaridullahОценок пока нет

- Steel Beam Marked B6Документ27 страницSteel Beam Marked B6Babu SundararamanОценок пока нет

- Combined FootingДокумент2 страницыCombined FootingakhilОценок пока нет

- Design of Cantilever Slab As Per Is 456 2000Документ2 страницыDesign of Cantilever Slab As Per Is 456 2000dhanasekaran33% (3)

- Slab Steel Calculation (Ground Floor) : Two Way SlabsДокумент2 страницыSlab Steel Calculation (Ground Floor) : Two Way SlabsHemant SonawadekarОценок пока нет

- Built Up Welding Calculation BeamДокумент1 страницаBuilt Up Welding Calculation Beamabou92Оценок пока нет

- 8224 Grating No HeaderДокумент69 страниц8224 Grating No HeadervishalnalwarОценок пока нет

- Civil Design CriteriaДокумент13 страницCivil Design CriteriaFikriansyahIndraSaputraОценок пока нет

- Anchor Bolt CheckДокумент1 страницаAnchor Bolt CheckihpeterОценок пока нет

- Raft 2Документ17 страницRaft 2Kushan Dhanushka NanayakkaraОценок пока нет

- Span/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span FactorДокумент1 страницаSpan/Eff - Depth Ratio Fs Modification Ten. Factor Modification Com. Factor Actual Span/effe - Depth Allowable Span/eff. Depth Long Span Factorshamen amarasekaraОценок пока нет

- Indes Enginnering: Design Code - IS800:2007Документ2 страницыIndes Enginnering: Design Code - IS800:2007KARTHIK SGОценок пока нет

- Bearing CheckДокумент6 страницBearing CheckdhanushkaОценок пока нет

- Lifting Lug Weld DesignR1aДокумент1 страницаLifting Lug Weld DesignR1aJohnclaude ChamandiОценок пока нет

- Simple Loan Calculator: Loan Values Loan SummaryДокумент11 страницSimple Loan Calculator: Loan Values Loan Summarypile raftОценок пока нет

- Baseplate Cirrcle 2018 - HUTATI LAPДокумент11 страницBaseplate Cirrcle 2018 - HUTATI LAPThinh ViproОценок пока нет

- Beam Design With Deflection CheckДокумент7 страницBeam Design With Deflection Checkkiran raghukiranОценок пока нет

- ASCE705 Wind LoadДокумент2 страницыASCE705 Wind LoadNithin M.TОценок пока нет

- Retaining Wall 03Документ13 страницRetaining Wall 03HanafiahHamzahОценок пока нет

- MDOT GussetPlate LRFR Analysis 265108 7Документ27 страницMDOT GussetPlate LRFR Analysis 265108 7Vietanh PhungОценок пока нет

- Footing - SubstationДокумент84 страницыFooting - Substationsam nacionОценок пока нет

- Vessel Design CalculationДокумент22 страницыVessel Design CalculationAh Leng LauОценок пока нет

- TM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)Документ13 страницTM-CP1-PMT-0070 Att.4 - Strength Calculation For Bellows (Sample)jhunkujha11Оценок пока нет

- Ejma 2000Документ7 страницEjma 2000jhunkujha11Оценок пока нет

- Rean Water Tech Pvt. LTD.: Isolated Footing Design (F1)Документ6 страницRean Water Tech Pvt. LTD.: Isolated Footing Design (F1)Anonymous R9xyiBEОценок пока нет

- MTO Field Erected Tank (PBMSJ) Rev 0 Sept. 27, 2017Документ1 страницаMTO Field Erected Tank (PBMSJ) Rev 0 Sept. 27, 2017Mohammad HamdaniОценок пока нет

- Manpower Schedule Field Erected Tank (PBMSJ Rev. 0 Sept. 27, 2017Документ1 страницаManpower Schedule Field Erected Tank (PBMSJ Rev. 0 Sept. 27, 2017Mohammad HamdaniОценок пока нет

- Equipt Schedule Field Erected Tank (PBMSJ Rev. 0 Sept. 27, 2017-1Документ1 страницаEquipt Schedule Field Erected Tank (PBMSJ Rev. 0 Sept. 27, 2017-1Mohammad HamdaniОценок пока нет

- Ayuda Asme B36.10M PDFДокумент26 страницAyuda Asme B36.10M PDFEdgargar100% (1)

- PV CALC 1Документ25 страницPV CALC 1Mohammad HamdaniОценок пока нет

- Nanofiber Article1 PDFДокумент4 страницыNanofiber Article1 PDFMohammad HamdaniОценок пока нет

- GWS 1-08-Att.1-R1Документ7 страницGWS 1-08-Att.1-R1solrac4371Оценок пока нет

- CaissonДокумент12 страницCaissonBrian OndigoОценок пока нет

- Stone Cladding Design PDFДокумент3 страницыStone Cladding Design PDFAli SaifОценок пока нет

- QP10-Q-612 Rev0 Typical SSD-1 Security FenceДокумент1 страницаQP10-Q-612 Rev0 Typical SSD-1 Security Fencenawajha0% (1)

- B. Tech. EXAMINATION, May 2017: No. of Printed Pages: 06 Roll No. ......................Документ3 страницыB. Tech. EXAMINATION, May 2017: No. of Printed Pages: 06 Roll No. ......................ramphalОценок пока нет

- 1906 - BCO Spec ConcertinaДокумент8 страниц1906 - BCO Spec ConcertinaRaviОценок пока нет

- Journal of Sustainable Mining: Research PaperДокумент13 страницJournal of Sustainable Mining: Research PaperAlket DhamiОценок пока нет

- CAEA v15 ANSYS Composite DamageДокумент24 страницыCAEA v15 ANSYS Composite DamageDavid MartinsОценок пока нет

- Solution: WL WL WLДокумент6 страницSolution: WL WL WLJohn Resty RamosОценок пока нет

- Structural Controls For Climate Responsive Design (For Cooling Purpose)Документ31 страницаStructural Controls For Climate Responsive Design (For Cooling Purpose)mehtabhumikaaОценок пока нет

- Rapid WallsДокумент13 страницRapid WallsGeetha_shnОценок пока нет

- V2100 System Aerosol RO01 GDH682Документ3 страницыV2100 System Aerosol RO01 GDH682Juan SantosОценок пока нет

- DS11S1 - (1970) An Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of Wrought Carbon Steel PDFДокумент102 страницыDS11S1 - (1970) An Evaluation of The Elevated Temperature Tensile and Creep-Rupture Properties of Wrought Carbon Steel PDFJacques StrappeОценок пока нет

- A Comparison of Concrete Steel and Timber Construction EssayДокумент4 страницыA Comparison of Concrete Steel and Timber Construction EssayJordan Kurt S. Gu100% (3)

- Column Design BS 8110.1985Документ114 страницColumn Design BS 8110.1985aries pambudiОценок пока нет

- Experimental Study of Strengthening For Increased Shear Bearing CapacityДокумент9 страницExperimental Study of Strengthening For Increased Shear Bearing CapacityBenzaamia AliОценок пока нет

- FORMUL Product-Catalogue PDFДокумент84 страницыFORMUL Product-Catalogue PDFADARA SARLОценок пока нет

- AAC Block Adhesive TDS NEWДокумент2 страницыAAC Block Adhesive TDS NEWAakriti VermaОценок пока нет

- Stress Analysis - Creo-Simulate-220813Документ35 страницStress Analysis - Creo-Simulate-220813saad HussainОценок пока нет

- Relationship Between Density and Moisture ContentДокумент2 страницыRelationship Between Density and Moisture ContentivanОценок пока нет

- Plasma Freezer (PLT 151) PDFДокумент2 страницыPlasma Freezer (PLT 151) PDFNeeraj YadavОценок пока нет

- Technology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishДокумент8 страницTechnology Liquid Coating Resins Liquid Coating Resins Product Range Emea EnglishUsama AwadОценок пока нет

- 5.0 Fabrication-8 PDFДокумент1 страница5.0 Fabrication-8 PDFRohit KambleОценок пока нет

- BoqДокумент50 страницBoqSaid KarimОценок пока нет

- Functional Products Cold Flow Improver PD-600 TDSДокумент1 страницаFunctional Products Cold Flow Improver PD-600 TDSAndrija SoldoОценок пока нет

- Abstract Passive SolarДокумент8 страницAbstract Passive Solargirish110100% (1)

- Sheet - 2-Iternal Incompressible Viscous FlowДокумент1 страницаSheet - 2-Iternal Incompressible Viscous FlowS.A. BeskalesОценок пока нет

- Tds Dura-Pure sn95-sb5Документ1 страницаTds Dura-Pure sn95-sb5agus sutiawanОценок пока нет

- Section A PipeДокумент18 страницSection A PipeOsama sayedОценок пока нет

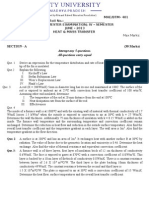

- HMT Question PaperДокумент1 страницаHMT Question PaperSanjay GomastaОценок пока нет