Академический Документы

Профессиональный Документы

Культура Документы

SIP-SOP03-R0-2017 SOP Temperature Transmitter Calibration

Загружено:

Dwi Mulyanti DwimulyantishopАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

SIP-SOP03-R0-2017 SOP Temperature Transmitter Calibration

Загружено:

Dwi Mulyanti DwimulyantishopАвторское право:

Доступные форматы

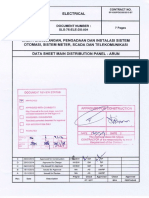

STANDARD OPERATION PROCEDURE

SIP-SOP-03

INSTRUMENT CALIBRATION PROCEDURE

TEMPERATURE TRANSMITTER

Document No: SIP-SOP03-R0-2017

Date: 25.07.2017 Rev: 0 Created by: AAA Checked by: AAA

A. Overview

In industrial process industries, temperature measurement equipment usually has two components: a

sensing device such as an RTD or thermocouple and a transmitter to read and relay the signal to the

control system.

All sensors, including RTDs, drift with time. Thus, testing the transmitter and not the sensor could result in

misjudgment regarding a systems performance. To avoid this potential problem, process instrument

mmanufacturers recommend including the temperature sensor in loop calibration to prove the

effectiveness of the entire system.

B. Calibrating a Temperature Transmitter at Bench

Seventy-five percent of the errors in a temperature measurement system come from the sensor. Choose

a temperature standard with a 90 degree angle bend to ensure both the temperature standard and the

transmitter fi in the dry-well at the same time.

To Perform The Test

For every calibration, its need to refer Temperature transmitters specification manual instruction for

calibrating the specific Temperature transmitter and also concern to Temperature transmitter position

installation on field as following below.

Calibration Procedure-Temperature Transmitter Page 1

STANDARD OPERATION PROCEDURE

SIP-SOP-03

INSTRUMENT CALIBRATION PROCEDURE

TEMPERATURE TRANSMITTER

Document No: SIP-SOP03-R0-2017

Date: 25.07.2017 Rev: 0 Created by: AAA Checked by: AAA

Step

Step Items Description

No.

1 Isolate the sensor from the process.

Fully immerse the sensor into a precision temperature source such as a dry-well or bath

2

capable of covering the required temperature range.

Connect the temperature standard and 4-20 mA output of the transmitter to a suitable meter or

3

calibrator (for example, the process electronics meter)

Power the loop. (The Temperature calibrator and the process electronics in a Field Metrology

4

Well have this capability).

Adjust the temperature of the bath or dry-well to each of the test points. (With Field Metrology

5

Wells, these test points can be preprogrammed and automated.)

At each test point, monitor and record the readings of the temperature standard and the local

6

or remote readings connected to the transmitter output.

Also, record the 4-20 mA output of the transmitter to determine which device needs adjustment

7

if an adjustment is required.

Calibration Procedure-Temperature Transmitter Page 2

Вам также может понравиться

- Calibrate HART DP TransmitterДокумент3 страницыCalibrate HART DP TransmitterDwi Mulyanti Dwimulyantishop100% (1)

- Sop SRTC Cal Sop T 05 (Temp. Gauge) - LabДокумент3 страницыSop SRTC Cal Sop T 05 (Temp. Gauge) - Labsureshcal131Оценок пока нет

- Standard Check List: Pressure TransmiterДокумент3 страницыStandard Check List: Pressure TransmiterROUNAK MANDALОценок пока нет

- Calibration and Measurement Capability of Gas Analysis at NIMTДокумент15 страницCalibration and Measurement Capability of Gas Analysis at NIMTTrịnh Đức HạnhОценок пока нет

- 003-Megger - Insulation TesterДокумент4 страницы003-Megger - Insulation TesterAjlan KhanОценок пока нет

- Control Valve Calibration Procedure (Fisher HC6010)Документ14 страницControl Valve Calibration Procedure (Fisher HC6010)Karen Cain93% (15)

- Calibrate Pressure Gauge ProcedureДокумент1 страницаCalibrate Pressure Gauge ProcedureKram Alim VillonОценок пока нет

- Calibration All PDFДокумент42 страницыCalibration All PDFMubasher91% (11)

- SOP For Calibration of Temperature GaugesДокумент3 страницыSOP For Calibration of Temperature Gaugesget_engineer0550% (2)

- DKD R 6 2 t5 e PDFДокумент9 страницDKD R 6 2 t5 e PDFDragan IlicОценок пока нет

- EURAMET-cg-08 V 2.1 ChangesДокумент18 страницEURAMET-cg-08 V 2.1 ChangesGilberto Andrés JuradoОценок пока нет

- Calibration of Absolute Pressure TransmitterДокумент4 страницыCalibration of Absolute Pressure Transmitterget_engineer05Оценок пока нет

- CAT CP 1 (T) Calibration of RTDДокумент4 страницыCAT CP 1 (T) Calibration of RTDAmar Singh100% (1)

- Calibration Procedure - Pressure TransmitterДокумент1 страницаCalibration Procedure - Pressure TransmittersathyanduraisamyОценок пока нет

- Procedure - Testing and Calibration For Process InstrumentДокумент10 страницProcedure - Testing and Calibration For Process InstrumentjabpunОценок пока нет

- 1.SOP For Calibratioon of Pressure GaugesДокумент3 страницы1.SOP For Calibratioon of Pressure Gaugesget_engineer05100% (1)

- Zero Calibration of Flowmeters ProcedureДокумент1 страницаZero Calibration of Flowmeters Procedureaswin26Оценок пока нет

- Control Valve CalibrationДокумент2 страницыControl Valve CalibrationBruno Megam K100% (3)

- Calibration Procedure Oxygen Analyzer (Furnace Stack)Документ9 страницCalibration Procedure Oxygen Analyzer (Furnace Stack)ArdvarkОценок пока нет

- PH Electrodes 2724 To 2726 From GF SignetДокумент6 страницPH Electrodes 2724 To 2726 From GF Signetguita riefОценок пока нет

- Standard Procedure For Calibration of GaugesДокумент12 страницStandard Procedure For Calibration of Gaugessharif sayyid al mahdalyОценок пока нет

- 01 Pressure Gauge CalibrationДокумент3 страницы01 Pressure Gauge CalibrationSantosh Odiyar0% (1)

- Control Valve Calibration StepsДокумент3 страницыControl Valve Calibration StepsMuhammad BairuniОценок пока нет

- Method Statement For Conductivity MeterДокумент2 страницыMethod Statement For Conductivity MeterMuhamed RasheedОценок пока нет

- Digital Multimeter CalibrationДокумент6 страницDigital Multimeter CalibrationKhalidОценок пока нет

- Accreditation No: LAB 131Документ9 страницAccreditation No: LAB 131Doulat RamОценок пока нет

- Flow & Level Calibration Notes: Differential Pressure Transmitter CalibrationДокумент9 страницFlow & Level Calibration Notes: Differential Pressure Transmitter Calibrationterio16100% (1)

- EG 15-14-1.2 Instrument Calibration: ScopeДокумент21 страницаEG 15-14-1.2 Instrument Calibration: ScopeaminОценок пока нет

- Calibration of Temperature SensorsДокумент13 страницCalibration of Temperature SensorsSubhash KОценок пока нет

- List of TCVN 2010: Số hiệu Tên tài liệuДокумент244 страницыList of TCVN 2010: Số hiệu Tên tài liệuTcp Vn0% (1)

- U 5753 Centrifuge 17300Документ1 страницаU 5753 Centrifuge 17300NENO BHUBANESWAR100% (1)

- Lab Report Temperature TransmitterДокумент12 страницLab Report Temperature Transmitterathira sОценок пока нет

- Field Operator: Diploma in Mechanical EngineeringДокумент5 страницField Operator: Diploma in Mechanical Engineeringjohn MОценок пока нет

- Calibrate Fire & Gas Detection SystemsДокумент5 страницCalibrate Fire & Gas Detection Systemskirandevi1981Оценок пока нет

- Calibrate Pressure Transmitter in 4 StepsДокумент2 страницыCalibrate Pressure Transmitter in 4 StepssupercontrollerОценок пока нет

- Fluk Ammeter CalibrationДокумент250 страницFluk Ammeter CalibrationASHUTOSH BHATTОценок пока нет

- Thermocouple Calibration FurnaceДокумент4 страницыThermocouple Calibration FurnaceAHMAD YAGHIОценок пока нет

- Temperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Документ40 страницTemperature Sensors: Sensytemp Tsp311, Tsp321, Tsp331Tin ThanОценок пока нет

- Control Valve CalibrationДокумент3 страницыControl Valve CalibrationsujitОценок пока нет

- Instrument CalibrationДокумент16 страницInstrument Calibrationditi17p50% (2)

- Calibration Techniques and Process: Abdul Latif, Pe H (NI)Документ69 страницCalibration Techniques and Process: Abdul Latif, Pe H (NI)Engr Umair AzizОценок пока нет

- Is 13875 1 1993Документ17 страницIs 13875 1 1993KOSAKA LABОценок пока нет

- Calibration ProcedureДокумент28 страницCalibration ProcedureWilmer EgeaОценок пока нет

- Method Statement For PH MeterДокумент2 страницыMethod Statement For PH MeterMuhamed RasheedОценок пока нет

- Method Statement Pressure RecorderДокумент2 страницыMethod Statement Pressure RecorderMuhamed RasheedОценок пока нет

- 02-Calibration & Control of Measuring & Monitoring DevicesДокумент1 страница02-Calibration & Control of Measuring & Monitoring DeviceskitekОценок пока нет

- Certificate of CalibrationДокумент2 страницыCertificate of CalibrationMiguel Angel Pacahuala CristobalОценок пока нет

- NIMT-CNL-SP No. 601 Standard Procedure for Calibration of Pressure Measuring Instruments Hydraulic TypeДокумент18 страницNIMT-CNL-SP No. 601 Standard Procedure for Calibration of Pressure Measuring Instruments Hydraulic Typeamelchan_tiqueОценок пока нет

- How To Calibrate An IR Thermometer - Frank Liebmann 2017-06-21Документ35 страницHow To Calibrate An IR Thermometer - Frank Liebmann 2017-06-21CALIBRATION TRACKING100% (1)

- Calibration Certificate SampleДокумент1 страницаCalibration Certificate SampleAbdul Wahaab Khokhar100% (3)

- Practice 2Документ4 страницыPractice 2AniitaVásconezОценок пока нет

- Calibration TolerancesДокумент3 страницыCalibration Tolerancesbertan dağıstanlıОценок пока нет

- Bellingham Stanley Refractometer Adp 440 Plus Manual PDFДокумент87 страницBellingham Stanley Refractometer Adp 440 Plus Manual PDFĐăng LưuОценок пока нет

- Calibration of AnemometerДокумент4 страницыCalibration of AnemometerAhmet ŞenОценок пока нет

- Sip-Sop04-R0-2017 Sop DPT Level CalibrationДокумент2 страницыSip-Sop04-R0-2017 Sop DPT Level CalibrationDwi Mulyanti DwimulyantishopОценок пока нет

- Petrochemical Industry Calibration SolutionsДокумент2 страницыPetrochemical Industry Calibration SolutionsAnonymous IXswcnWОценок пока нет

- How Can I Make Loop Check For Pressure Transmitter and Temperature TransmitterДокумент11 страницHow Can I Make Loop Check For Pressure Transmitter and Temperature Transmittersushant_jhawer100% (1)

- Method Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWДокумент8 страницMethod Statement of Calibration Field Instrument: Rantu Dedap Geothermal Power Plant Project Capacity 220 MWsugeng wahyudiОценок пока нет

- CLB 21303 Process Instrumentation and ControlДокумент48 страницCLB 21303 Process Instrumentation and ControlSyafiqIsmiОценок пока нет

- CLB 21303 Process Instrumentatio N and ControlДокумент48 страницCLB 21303 Process Instrumentatio N and ControlanisОценок пока нет

- Arteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesДокумент1 страницаArteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFДокумент5 страницSLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- 576560Документ1 страница576560Dwi Mulyanti DwimulyantishopОценок пока нет

- Support frames selection chart for British, American and Italian standard boxesДокумент1 страницаSupport frames selection chart for British, American and Italian standard boxesDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-LI-002 Electrical Equipment List - Arun, Rev. 1 - AFCДокумент5 страницSLS-75-ELE-LI-002 Electrical Equipment List - Arun, Rev. 1 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- Technical OfferДокумент9 страницTechnical OfferDwi Mulyanti DwimulyantishopОценок пока нет

- Support frames selection chart for British, American and Italian standard boxesДокумент1 страницаSupport frames selection chart for British, American and Italian standard boxesDwi Mulyanti DwimulyantishopОценок пока нет

- 572004Документ1 страница572004Dwi Mulyanti DwimulyantishopОценок пока нет

- 89239Документ1 страница89239Dwi Mulyanti DwimulyantishopОценок пока нет

- Wallis Complete Cat.Документ7 страницWallis Complete Cat.Dwi Mulyanti DwimulyantishopОценок пока нет

- TdsДокумент1 страницаTdsDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-CL-005 0.48 KV-0.4 KV Transformer Sizing - Arun, Rev. 0 - AFCДокумент6 страницSLS-75-ELE-CL-005 0.48 KV-0.4 KV Transformer Sizing - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- Arteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesДокумент1 страницаArteor: Italian / US Standards 83.5 MM Fixing Centres - Flush Mounting Boxes, Support Frames and PlatesDwi Mulyanti DwimulyantishopОценок пока нет

- XT SACE Tmax XTДокумент18 страницXT SACE Tmax XTDwi Mulyanti DwimulyantishopОценок пока нет

- CCTVДокумент16 страницCCTVDwi Mulyanti Dwimulyantishop100% (1)

- SLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFДокумент5 страницSLS-75-ELE-DS-004 Data Sheet UPS System - Arun, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-001 Legend and Symbol - Belawan, Rev. 0 - AFCДокумент1 страницаSLS-95-ELE-DW-001 Legend and Symbol - Belawan, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DS-001 Data Sheet LV Switchgear and MCC - Arun, Rev. 0 - AFCДокумент7 страницSLS-75-ELE-DS-001 Data Sheet LV Switchgear and MCC - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-005 Electrical Equipment Layout at Electrical Room - Belawan, Rev. 0 - AFCДокумент1 страницаSLS-95-ELE-DW-005 Electrical Equipment Layout at Electrical Room - Belawan, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, Rejected PDFДокумент1 страницаSLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, Rejected PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFC PDFДокумент1 страницаSLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCДокумент2 страницыSLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFC PDFДокумент1 страницаSLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFC PDFDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFCДокумент1 страницаSLS-95-ELE-DW-010 Panel Schedule - Belawan, Rev. 1 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCsДокумент1 страницаSLS-75-ELE-DW-011 Grounding and Lightning Layout - Arun, Rev. 0 - AFCsDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, RejectedДокумент1 страницаSLS-70-CIV-DW-002 Civil, Structure & Architecture General Notes, Rev-A, RejectedDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFCДокумент1 страницаSLS-75-ELE-DW-015 Electrical Connection Diagram For MOV - Arun, Rev. 0 - AFCDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DB-001 Civil Design Basis, Rev C - App W CommentДокумент36 страницSLS-70-CIV-DB-001 Civil Design Basis, Rev C - App W CommentDwi Mulyanti DwimulyantishopОценок пока нет

- Sls-70-Civ-db-001 Civil Design Basis, Rev. D - AfdДокумент36 страницSls-70-Civ-db-001 Civil Design Basis, Rev. D - AfdDwi Mulyanti DwimulyantishopОценок пока нет

- SLS-70-CIV-DB-001 Civil Design Basis, Rev B - App W CommentДокумент36 страницSLS-70-CIV-DB-001 Civil Design Basis, Rev B - App W CommentDwi Mulyanti DwimulyantishopОценок пока нет

- SA Engineering College Statistics and Numerical Methods NotesДокумент8 страницSA Engineering College Statistics and Numerical Methods NotesRaja Nirmal KumarОценок пока нет

- The role of root canal fillings in endodontic successДокумент9 страницThe role of root canal fillings in endodontic successYassir MudharОценок пока нет

- Physics Internal AssessmentДокумент14 страницPhysics Internal AssessmentRachitОценок пока нет

- ACET208 Theodolite PresentationДокумент6 страницACET208 Theodolite Presentationsilverm_4Оценок пока нет

- Dual Nature of LightДокумент15 страницDual Nature of LightUriahs Victor75% (4)

- Curriculum Vitae: Jnana Ranjan Das 1. Career ObjectiveДокумент5 страницCurriculum Vitae: Jnana Ranjan Das 1. Career ObjectiveJyoti Tecno PowerОценок пока нет

- Study Materials For Mechanical EngineersДокумент63 страницыStudy Materials For Mechanical EngineersOmprakash ManharОценок пока нет

- Grade 9: Coordinate GeometryДокумент5 страницGrade 9: Coordinate GeometryEduGainОценок пока нет

- MAVEN: Motion Analysis and Visualization of Elastic Networks and Structure Ensembles Version 1.1 User's Manual ContentsДокумент30 страницMAVEN: Motion Analysis and Visualization of Elastic Networks and Structure Ensembles Version 1.1 User's Manual ContentsOscar DedОценок пока нет

- Lahore University of Management Sciences: EE539 - Radar SystemsДокумент3 страницыLahore University of Management Sciences: EE539 - Radar SystemsDr-Raghad Al-FahamОценок пока нет

- Low and High Pressure: Wind Weather MoleculesДокумент4 страницыLow and High Pressure: Wind Weather MoleculesAmirah fsОценок пока нет

- Ising ModelДокумент5 страницIsing Modeldecerto252Оценок пока нет

- Xxii Paper 51Документ9 страницXxii Paper 51kjyeom_258083906Оценок пока нет

- Mec 424 - Laboratory Report: Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingДокумент24 страницыMec 424 - Laboratory Report: Free Vibration Experiment - Natural Frequency of Spring Mass System Without DampingWan AimanОценок пока нет

- Properties of CompoundsДокумент15 страницProperties of CompoundsPrasad YarraОценок пока нет

- E401Документ4 страницыE401Katrina BucudОценок пока нет

- Forensic Chemistry ToxicologyДокумент139 страницForensic Chemistry ToxicologyCeasar Estrada94% (18)

- Calcul Evaltn-Embankments Reinforced With geocells-FEM-2015Документ14 страницCalcul Evaltn-Embankments Reinforced With geocells-FEM-2015Rakesh KapoorОценок пока нет

- Math at Grade 4Документ9 страницMath at Grade 4api-239942675Оценок пока нет

- Berco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inДокумент1 страницаBerco Product FA 6E: General Information Fa 6E 12040002 Idler Group, With Tensioning Device Not Integrated inrameshОценок пока нет

- A Study of The Effect of Blasting Vibration On Green ConcreteДокумент160 страницA Study of The Effect of Blasting Vibration On Green ConcreteNattHemat HulinОценок пока нет

- Computer Graphics and AnimationДокумент2 страницыComputer Graphics and AnimationManoj PrasadОценок пока нет

- Chocolate RheologyДокумент7 страницChocolate RheologyAdil AnwarОценок пока нет

- Newtons Law of MotionДокумент14 страницNewtons Law of MotionJohn Irvin M. AbatayОценок пока нет

- OSHA Confined Space Standards and HazardsДокумент93 страницыOSHA Confined Space Standards and HazardsPrimelift Safety Resources LimitedОценок пока нет

- M1 Lab ReportДокумент6 страницM1 Lab Reportweimingf0% (2)

- Chemistry Test 1 July 2019 BatchДокумент3 страницыChemistry Test 1 July 2019 BatchDaОценок пока нет

- History of Buckling of ColumnДокумент10 страницHistory of Buckling of ColumnSorin Viorel CrainicОценок пока нет

- Direct Shear Test ResultsДокумент19 страницDirect Shear Test ResultsAh Gus100% (9)