Академический Документы

Профессиональный Документы

Культура Документы

ITC 312N H6 A

Загружено:

ms79Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

ITC 312N H6 A

Загружено:

ms79Авторское право:

Доступные форматы

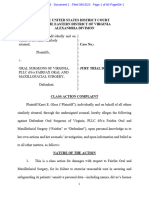

Produced by Kaelble GmbH

TUNNEL HEADING AND LOADING

MACHINE

ITC 312N - H6

Excavation boom equipment with rock breaker / bucket

combination for tunnelling in soft and medium hard ground

conditions by using bucket and hydr. hammer

Minimal cross section approx. 18 m

Diesel drive 165 kW

Electric drive 90 kW

Operating weight approx. 37,5 t

itc 312n h6

140

2450

R1

10

0

7950

4500

4050

4000

4000

3450

3600

3250

2350 - 3670 9500 2450

6700

2000

0 1 2 3m

Technical data ITC 312N H6

Drive units Operating data (H6 boom equipment)

Electro-hydraulic and Diesel hydraulic power packs each Minimal cross section approx. 18 m

with a separate pump unit with variable flow rate Machine width 2400 mm

Electric drive for emission-free work at the face Maximal height 3600 mm

Air-cooled electric motor, power at 400 Volt , 50 Hz 90 kW Transport height 2700 mm

Diesel drive for travelling and operation without electric supply. Length (dep. on conveyor) ~12000 mm

Water-cooled diesel engine. Deutz TCD2013 L06 2V Width of loading apron (adjust.) 2350-3600 mm

Power rating at 1800 r.p.m 165 kW Width of conveyor (internal) 800 mm

Diesel engine complies with emission standard Euro St. 3a Height of conveyor (internal) 800 mm

Conveyor capacity approx. 300 m/h

Electrical system Conveyor discharge height 2500-3500 mm

Total installed power 95 kW Operating weight approx. 37,5 t

Voltage (standard) 400 V - 50 Hz AC

Control voltage 230 V - 24 V DC Boom Equipment H6

Electrical system acc. to EN 60529 (IP54) Excavation boom equipment with rock breaker / bucket combination

Cable reel hydraulically driven with 90 m cable 3x95+3x16 mm for tunnelling in soft and medium hard ground conditions by using

Optional: other voltage or other frequncy bucket and hydr. hammer, including:

King post with jib and tilt-swivel console

Operators cab Tool holder with a combination of hydraulic hammer and excavation

FOPS operators cab with front protection grid gives all-round / loading bucket

visibility Automatic lubrication system for the hammer

CE conformity incl. video monitoring system fot the right and rear Water spraying device

side with colour LCD in the cab

Hydraulic system Other Equipment

Load Sense hydraulic system with combination axial piston pump It is possible to attach a range of ancillary equipment, such as

and gear pump closed cab, air conditionning, pony truck, rubber plated conveyor,

Hydr. pilot control for travelling and main working functions transverse cutting unit, soot particle filter, central greasing device,

Boom control with 2 joysticks in Euro standards fire suppressing device, water hose reel, diesel fuel and or hydraulic

Thermostatic controlled hydr. driven oil/air cooler oil filling pump, etc.

Max. hydraulic operating pressure 250-350 bar

Hydraulic oil tank 400 l Further details of attachments and accessories available upon

request.

312NH6 - 04.09.2013 - Prospectus_312N_H6_2013.PMD

Produced by KAELBLE GmbH ITC SA

www.kaelblegmbh.com info@kaelblegmbh.com +49 (0) 7952 606 60 www.itcsa.com info@itcsa.com +41 277 222 191

Вам также может понравиться

- Simba L6CДокумент4 страницыSimba L6CsasidharreddyОценок пока нет

- Simba M7 - 9851 2194 01Документ4 страницыSimba M7 - 9851 2194 01Rodrigo ContrerasОценок пока нет

- MC 86 Base CarrierДокумент6 страницMC 86 Base Carriersagar badheОценок пока нет

- 4100xpc StandardДокумент4 страницы4100xpc StandardJuanCarlosValenzuelaMedinaОценок пока нет

- Dd422i Specification Sheet EnglishДокумент4 страницыDd422i Specification Sheet EnglishMohan PreethОценок пока нет

- Boltec 335hДокумент4 страницыBoltec 335hErick AlarconОценок пока нет

- Boltec 435hДокумент4 страницыBoltec 435hErick AlarconОценок пока нет

- Sandvik Dd321 Development Drill: Technical SpecificationДокумент4 страницыSandvik Dd321 Development Drill: Technical SpecificationFERNANDO INOCENTE TRINIDAD GUERRAОценок пока нет

- Atr Oz RC Drill Rig Tech Sheet 1Документ9 страницAtr Oz RC Drill Rig Tech Sheet 1dhruvdaruwala.officialОценок пока нет

- York Ducted InverterДокумент2 страницыYork Ducted InverterjABU100% (1)

- DT621 - Teknik KatalogДокумент4 страницыDT621 - Teknik KatalogEmrah MertyürekОценок пока нет

- RB T 100 en 905 730 2Документ4 страницыRB T 100 en 905 730 2Poro ChanОценок пока нет

- Working Principle of Flash WeldingДокумент3 страницыWorking Principle of Flash WeldingasadtouqeierОценок пока нет

- Perforadora Voladura TMB25Документ4 страницыPerforadora Voladura TMB25eleon07Оценок пока нет

- Dev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishДокумент4 страницыDev Drill Rig - Sandvik Dd421-Specification-Sheet-EnglishBBBBBBОценок пока нет

- Dd421 Specification Sheet EnglishДокумент4 страницыDd421 Specification Sheet Englisheduama0% (1)

- Liebherr LRB 125xl Piling and Drilling Rig Technical Data Spec Sheet Eng 10539140Документ12 страницLiebherr LRB 125xl Piling and Drilling Rig Technical Data Spec Sheet Eng 10539140Tomasz CzОценок пока нет

- Technical Description: 1 Demag Wall Mounted Slewing Jib Crane 1000 KG X 4000 MM JC-W-270-KBK-BR-M-1000-4000Документ3 страницыTechnical Description: 1 Demag Wall Mounted Slewing Jib Crane 1000 KG X 4000 MM JC-W-270-KBK-BR-M-1000-4000nasif andriantoОценок пока нет

- TM2500 BrochureДокумент8 страницTM2500 BrochuregustiramadaniОценок пока нет

- Seaharvest 650 HP Workover Rig Technical Specs1Документ20 страницSeaharvest 650 HP Workover Rig Technical Specs1Ali mohammad100% (1)

- W200H enДокумент2 страницыW200H enAsad AijazОценок пока нет

- XS54871 2800XPC DC BroДокумент8 страницXS54871 2800XPC DC BroDenis Armando100% (1)

- Atlas CopcoДокумент4 страницыAtlas CopcoFRANK PRUDENCIO OBREGONОценок пока нет

- InternshipДокумент41 страницаInternshipMin Kyaw HtetОценок пока нет

- RB WL3C-9851 2179 01Документ4 страницыRB WL3C-9851 2179 01FRANK PRUDENCIO OBREGONОценок пока нет

- Jumbo Dd421Документ4 страницыJumbo Dd421Anonymous Iu8A4JC100% (2)

- 351 Pit ViperДокумент6 страниц351 Pit Vipereddyfredy100% (1)

- EDM 95K SeriesДокумент2 страницыEDM 95K SerieskingsfordathleeОценок пока нет

- Vertical Axis Wind Turbine Power System Model: DS1500 Roduct SpecificationsДокумент2 страницыVertical Axis Wind Turbine Power System Model: DS1500 Roduct SpecificationsRene Alexander Barrera CardenasОценок пока нет

- SpecificationsДокумент4 страницыSpecificationsSebastian VasquezОценок пока нет

- Boomer 104-1432 PDFДокумент4 страницыBoomer 104-1432 PDFanon_478395499Оценок пока нет

- Liebherr Hs 8100 Hs Cable Excavator Data Spec Sheet 10098997 EnglishДокумент16 страницLiebherr Hs 8100 Hs Cable Excavator Data Spec Sheet 10098997 EnglishWalterGentileОценок пока нет

- Technical Data Hydraulic Excavator: L L L L L L L L L LДокумент4 страницыTechnical Data Hydraulic Excavator: L L L L L L L L L LMeinardi NapohОценок пока нет

- 6.0 Systemair BKF 560d6 F400-Ext 03Документ7 страниц6.0 Systemair BKF 560d6 F400-Ext 03febousОценок пока нет

- Specification Sheet EnglishДокумент4 страницыSpecification Sheet EnglishLMОценок пока нет

- 6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDДокумент58 страниц6HI Reversible Cold Rolling 1350 MM, 550 MPM: Client: PLASTOCHEM India Pvt. LTDSANTOSH TIWARIОценок пока нет

- TMX R: Designed To Make A DifferenceДокумент4 страницыTMX R: Designed To Make A Differencenifaldi88Оценок пока нет

- NHP Module High Power Nickel-Metal Hydride Module: ApplicationsДокумент2 страницыNHP Module High Power Nickel-Metal Hydride Module: ApplicationsAaron MalekОценок пока нет

- Kompetensi Keahlian Nama Alat Spesifikasi Tayang Harga Link: Daftar Peralatan Pendidikan Kejuruan Di E-Katalog TAHUN 2020Документ4 страницыKompetensi Keahlian Nama Alat Spesifikasi Tayang Harga Link: Daftar Peralatan Pendidikan Kejuruan Di E-Katalog TAHUN 2020Muhammad Sidik BBMОценок пока нет

- Dd422i Specification Sheet EnglishДокумент4 страницыDd422i Specification Sheet EnglishAbdalla Mohamed AbdallaОценок пока нет

- Overall Dimensions HLRM 170-4SДокумент2 страницыOverall Dimensions HLRM 170-4SScHasZerОценок пока нет

- KMA 220 en (9a6)Документ8 страницKMA 220 en (9a6)Tomasz StawickiОценок пока нет

- dd321 Specification Sheet EnglishДокумент4 страницыdd321 Specification Sheet Englishgkqztsy9skОценок пока нет

- Digital DC Drive Control: C Rotation L CL C LДокумент4 страницыDigital DC Drive Control: C Rotation L CL C LAlejandro Fernandez100% (1)

- Dd422ie Specification Sheet English 3Документ4 страницыDd422ie Specification Sheet English 3P. Morales EdgarОценок пока нет

- DD422iE Development Drill: Technical SpecificationДокумент4 страницыDD422iE Development Drill: Technical SpecificationCindy MoralesОценок пока нет

- Dd422ie Specification Sheet English 4Документ4 страницыDd422ie Specification Sheet English 4P. Morales EdgarОценок пока нет

- Dd422ie Specification Sheet English 1Документ4 страницыDd422ie Specification Sheet English 1P. Morales EdgarОценок пока нет

- Dd422ie Specification Sheet English 2Документ4 страницыDd422ie Specification Sheet English 2P. Morales EdgarОценок пока нет

- Dd321 Specification Sheet EnglishДокумент4 страницыDd321 Specification Sheet EnglishNelson Valles AvilaОценок пока нет

- 5GEB22 Offshore 20125 D OTC2013Rev1Документ2 страницы5GEB22 Offshore 20125 D OTC2013Rev1TonyОценок пока нет

- 215 ACE C: Leading To Future Innovative Design UpgradeДокумент2 страницы215 ACE C: Leading To Future Innovative Design UpgradeAnindito W WicaksonoОценок пока нет

- Alternador Avi128 PDFДокумент2 страницыAlternador Avi128 PDFPascual MtzОценок пока нет

- 060-Da 2700HPДокумент4 страницы060-Da 2700HPcosty_transОценок пока нет

- Liebherr Hs 8130 HD Duty Cycle Crawler Crane Technical Data Sheet Spec Specifications 16224 0 2Документ12 страницLiebherr Hs 8130 HD Duty Cycle Crawler Crane Technical Data Sheet Spec Specifications 16224 0 2JusmaWahidahОценок пока нет

- Datos Tecnicos Top Drive JH 250 TonДокумент11 страницDatos Tecnicos Top Drive JH 250 Tonjdjd69486gmail.comОценок пока нет

- Cassette INVERTER YTKKE 18 To 55 YORKДокумент2 страницыCassette INVERTER YTKKE 18 To 55 YORKAlejandroОценок пока нет

- Lorentz Ps4000Документ26 страницLorentz Ps4000SINES FranceОценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2От EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Оценок пока нет

- Qurani Ayaat K AnwarДокумент62 страницыQurani Ayaat K Anwarmsheraz_14Оценок пока нет

- Learn The Principles of Business WritingДокумент92 страницыLearn The Principles of Business Writingpop3alyОценок пока нет

- A Practical Guide To Swing TradingДокумент76 страницA Practical Guide To Swing TradingHemlata Gupta100% (1)

- Smart Strategies For Small Business PDFДокумент6 страницSmart Strategies For Small Business PDFbook2mindОценок пока нет

- Deen E EllahiДокумент91 страницаDeen E EllahiGhulam RiazОценок пока нет

- Inside The Guru Mind - Peter Drucker PDFДокумент15 страницInside The Guru Mind - Peter Drucker PDFKhiet PhamОценок пока нет

- Sides Marketing & Sales - Strategic Marketing Handbook PDFДокумент64 страницыSides Marketing & Sales - Strategic Marketing Handbook PDFIulia FrunzeОценок пока нет

- The Qur'an and Modern ScienceДокумент22 страницыThe Qur'an and Modern ScienceYounus AliОценок пока нет

- Lessons From HistoryДокумент96 страницLessons From Historyatoz2033Оценок пока нет

- The Little Book of LeadershipДокумент48 страницThe Little Book of Leadershipms79Оценок пока нет

- Karzoon Ki JangДокумент27 страницKarzoon Ki Jangms79Оценок пока нет

- RibaДокумент23 страницыRibams79Оценок пока нет

- Contract of EmploymentДокумент5 страницContract of EmploymentFarisОценок пока нет

- Glass V Oral Surgeons of Virginia PLLC Vaedce-23-01246 0001.0Документ80 страницGlass V Oral Surgeons of Virginia PLLC Vaedce-23-01246 0001.0Sam OrlandoОценок пока нет

- Universal Declaration of Human RightsДокумент36 страницUniversal Declaration of Human RightsJanine Regalado100% (4)

- Bugreport Fog - in SKQ1.211103.001 2023 04 10 19 23 21 Dumpstate - Log 9097Документ32 страницыBugreport Fog - in SKQ1.211103.001 2023 04 10 19 23 21 Dumpstate - Log 9097chandrakanth reddyОценок пока нет

- LC1D40008B7: Product Data SheetДокумент4 страницыLC1D40008B7: Product Data SheetLê Duy MinhОценок пока нет

- 7 Hive NotesДокумент36 страниц7 Hive NotesSandeep BoyinaОценок пока нет

- A Case Study On Mahindra's Blue Sense Application Project by RohitДокумент43 страницыA Case Study On Mahindra's Blue Sense Application Project by RohitrohitОценок пока нет

- Polymer AbbreviationsДокумент9 страницPolymer AbbreviationsFernando GuerreroОценок пока нет

- Ass2 mkt1009Документ11 страницAss2 mkt1009thang5423Оценок пока нет

- HPДокумент71 страницаHPRazvan OracelОценок пока нет

- Activity 3 Data SheetДокумент9 страницActivity 3 Data SheetEli GabuatОценок пока нет

- Global Competitiveness ReportДокумент7 страницGlobal Competitiveness ReportSHOIRYAОценок пока нет

- CHAPTER ONE Structural GeologyДокумент46 страницCHAPTER ONE Structural GeologyAfolabi Eniola AbiolaОценок пока нет

- MCQ Criminal Law 1Документ18 страницMCQ Criminal Law 1Clark Vincent Ponla0% (1)

- Sop ECUДокумент5 страницSop ECUSumaira CheemaОценок пока нет

- Heist Story ScriptДокумент3 страницыHeist Story Scriptapi-525637110Оценок пока нет

- RICS APC Candidate Guide-Aug 2015-WEB PDFДокумент24 страницыRICS APC Candidate Guide-Aug 2015-WEB PDFLahiru WijethungaОценок пока нет

- FDI and FIIДокумент17 страницFDI and FIIsharathОценок пока нет

- BUSINESS PROPOSAL-dönüştürüldü-2Документ15 страницBUSINESS PROPOSAL-dönüştürüldü-2Fatah Imdul UmasugiОценок пока нет

- Electricity at Work - Safe Working Practices HSG85Документ27 страницElectricity at Work - Safe Working Practices HSG85Sivakumar NatarajanОценок пока нет

- Module 7 - Materials Management Configuration For Goods Receipts Reach - Ucf.eduДокумент12 страницModule 7 - Materials Management Configuration For Goods Receipts Reach - Ucf.eduAjitabh SinghОценок пока нет

- Mangla Refurbishment Project Salient FeaturesДокумент8 страницMangla Refurbishment Project Salient FeaturesJAZPAKОценок пока нет

- AmeloblastomaДокумент4 страницыAmeloblastomaMarïsa CastellonОценок пока нет

- Overhead Line SolutionsДокумент8 страницOverhead Line SolutionsDomingo O Chavez PeñaОценок пока нет

- SCH 415 Computer Applications in Chemistry: at The End of This Unit You Should Be Able To General ObjectiveДокумент21 страницаSCH 415 Computer Applications in Chemistry: at The End of This Unit You Should Be Able To General ObjectiveFELIX ORATIОценок пока нет

- Design Calculation of Braking System (Landcruiser) : AbstractДокумент4 страницыDesign Calculation of Braking System (Landcruiser) : AbstractDr. Aung Ko LattОценок пока нет

- 010 Informed Search 2 - A StarДокумент20 страниц010 Informed Search 2 - A StarRashdeep SinghОценок пока нет

- SIFI-131 Fire Protection in Electrical Equipment RoomsДокумент8 страницSIFI-131 Fire Protection in Electrical Equipment RoomsemiljanlazeОценок пока нет

- Efqm Success-Story-Book LRДокумент34 страницыEfqm Success-Story-Book LRabdelmutalabОценок пока нет

- Design Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectДокумент1 страницаDesign Calculation Sheet: Project No: Date: Sheet No.:1 1 Computed By: SubjectAbdelfatah NewishyОценок пока нет