Академический Документы

Профессиональный Документы

Культура Документы

PDS For 1101 Rev 00

Загружено:

Dinesh VaghelaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

PDS For 1101 Rev 00

Загружено:

Dinesh VaghelaАвторское право:

Доступные форматы

PDS-SILO-1101 Released for Enquiry

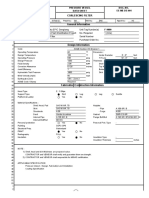

Sudeep Pharma Ltd. Process Data Sheet Rev : OO Sheet 1 OF 2

Nandesari CYLINDRICAL SILO FOR Calcium carbonate

Tag No: SILO 1101 - 02 Location: OSBL DCP PLANT Quantity required: 2 nos.

Yes, bottom Horizontal No Jacketed No

Type: Vertical cone Diameter - O D 1900 mm Bottom Cone ht. 1300 mm

Gross Capacity 9620 Liters Height 3000 mm Lugs 4 nos.

3

Bulk density 600 kgs/m

Shell Jacket

Working Capacity in kgs / Liters 9620 / 8177

Working pressure: bar Atmospheric Working pressure: bar NOT APPLICABLE

Design pressure: bar Vendor to specify Design pressure:

Working temperature oC: 45 Working temperature oC:

Design temperature oC: 100 Design temperature oC:

Material of Construction: SS 316 Material of Construction:

PP & FRP thickness ***** Corrosion Allowance in mm:

Name of Fluid: Dry CaCO3 Powder Name of Fluid:

Shell Thickness: ***** Shell Thickness:

Bottom Cone Thickness: ***** Dish end Thickness:

Specific Gravity 0.6000 Specific Gravity

Top Cover Thickness *****

Support type: Lugs: Legs Yes Saddles: No

Nozzles Schedule

ID. No. Description Degree of location Size in mm Location Rating Nos. required

N1 Powder Inlet ***** Shell top # 150 1

N2 Vent for clean air ***** Shell top # 150 1

N3 Spare for safety ***** Shell top # 150 1

N4 Level switch for maximum level ***** Side # 150 1

N5 Level switch for minimum level ***** Side # 150 2

N6 Manhole 500 Shell top # 150 1

N7 Bottom Outlet ***** Cone bottom # 150 1

Manhole on bottom cone with flush

N8 arrangement of blind flange 500 Cone # 150 1

***** Vendor to specify

NOTE: NOZZLE & LUGS - LOCATION & ORIENTATION WILL

BE FINALISED ON APPROVAL OF GAD SUNBMITTED BY

VENDOR

Remarks:

1 Supplier has to confirm mechanical design for given design pressure

2 Supplier to provide the GA drawing of vessel for the approval

3 All the nozzle pipes heavy schedule seamless pipe

4 All the Gaskets will be used of CAF

5 Nuts & Bolts used in the assembly will be of suitable to pressure rating

6 Three stiffners should be provided for all nozzles 50 mm diameter & lower

7 All spare nozzels should be supplied with blind flange.

8 Design as per Good Engineering Practise

9 Tank to be installed as per guidelines of supplier

10

Revision #. R0

Date: 31/8/2017

Prepared by: MSD

Checked by: SDD Prepared by: Tro Consultants

Approved by:

PDS for Silo 10 KL REV 02 1 of 2

PDS-SILO-1101 Released for Enquiry

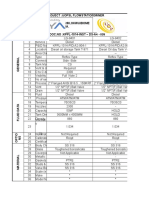

Sudeep Pharma Ltd. Process Data Sheet Rev : OO Sheet 2 OF 2

Nandesari CYLINDRICAL SILO FOR Calcium carbonate

Tag No: SILO 1101 - 02 Location: OSBL DCP PLANT Quantity required: 2 nos.

*****

LATER

3000 mm

O D 1900 mm

54

deg.

13000 mm

NOTES.

1.Cone angle 54 degrees

2. Vendor to ensure there there is no ratholing

3. Vendor to ensure there is no bridging

4. Vendor to design puematic conveying system

5. Vendor to decide powder inlet nozzle & location of baghouse

Revision #. R0 R1 R2

Date: 31/8/2017

Prepared by: MSD

Checked by: SDD

Prepared by: Tro Consultants

Approved by:

PDS for Silo 10 KL REV 02 2 of 2

Вам также может понравиться

- G225iexm08-Srp-M-Dwg-0003 - Rev A4Документ55 страницG225iexm08-Srp-M-Dwg-0003 - Rev A4BALASUBRAMANIAM MEGHANADHОценок пока нет

- KCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Документ9 страницKCD 11176R2: 11176R2.xlsx Page 1 of 9 6/14/22Anonymous bHh1L1Оценок пока нет

- EBARA Horizontal Split Case Pump ManualДокумент6 страницEBARA Horizontal Split Case Pump ManualRido MardanОценок пока нет

- Data Sheet Item 2Документ3 страницыData Sheet Item 2Bagus SigitОценок пока нет

- DATASHEET DCP ExtinguisherДокумент1 страницаDATASHEET DCP ExtinguishershabahatОценок пока нет

- Avk Gate Valve, Flanged, Pn10/16 02/66-006: EN 558-2 S.15/DIN F5, Position Indicator, NBR, DN40-400Документ3 страницыAvk Gate Valve, Flanged, Pn10/16 02/66-006: EN 558-2 S.15/DIN F5, Position Indicator, NBR, DN40-400kad-7Оценок пока нет

- SAP FILTER-20-SEPT-2019-1220D-Rev0Документ3 страницыSAP FILTER-20-SEPT-2019-1220D-Rev0Hasmukh DaveОценок пока нет

- DatasheetДокумент2 страницыDatasheetnirmalОценок пока нет

- Swing Check Valve Rubber DiscДокумент2 страницыSwing Check Valve Rubber DiscsathishОценок пока нет

- Rectangular Tank Design - RoarksДокумент3 страницыRectangular Tank Design - RoarksSakthi Vel100% (1)

- Hh6310-Z - Deep Groove Ball Bearings SKFДокумент1 страницаHh6310-Z - Deep Groove Ball Bearings SKFIrfan Ali ShabirОценок пока нет

- Anexo Fire PumpsДокумент37 страницAnexo Fire PumpsTommy salimОценок пока нет

- Ps Pipeline SDN BHD: Detail Engineering Design For KVDT T-501 Diesel Tank Conversion To Ulg95 T-501 Tank DatasheetДокумент3 страницыPs Pipeline SDN BHD: Detail Engineering Design For KVDT T-501 Diesel Tank Conversion To Ulg95 T-501 Tank DatasheetBukhory Ahmad TajudinОценок пока нет

- Manual Valves Datasheet. Rev 1Документ7 страницManual Valves Datasheet. Rev 1eke23Оценок пока нет

- SAP FILTER-May-2020-1200Dia-Rev - PДокумент4 страницыSAP FILTER-May-2020-1200Dia-Rev - PHasmukh DaveОценок пока нет

- Cálculo de BridasДокумент9 страницCálculo de BridasRIVFОценок пока нет

- Expansion Bellow SpecificationДокумент1 страницаExpansion Bellow SpecificationASHWINI BHOSALEОценок пока нет

- IBR Calculation SheetДокумент9 страницIBR Calculation Sheetinder0% (1)

- Datasheet Coagulant TankДокумент1 страницаDatasheet Coagulant TankRicardo NapitupuluОценок пока нет

- Technical Order AcceptanceДокумент1 страницаTechnical Order AcceptanceRazip IsmailОценок пока нет

- Contoh SoalДокумент13 страницContoh Soalmarkus andikaОценок пока нет

- BV3VДокумент4 страницыBV3Vv8wfm8d8r7Оценок пока нет

- Brochure LPDA, 50 HZДокумент6 страницBrochure LPDA, 50 HZTAUFIQ ARIEF NUGRAHAОценок пока нет

- Bectel ASME Process Cal R2Документ21 страницаBectel ASME Process Cal R2Sivakumar SelvarajОценок пока нет

- APS104-06 Paint System - Steel WorkДокумент9 страницAPS104-06 Paint System - Steel WorkJose MachadoОценок пока нет

- Quotation For TP-ALP-21-213 SURGE VESSEL 1m3Документ2 страницыQuotation For TP-ALP-21-213 SURGE VESSEL 1m3Port VideoОценок пока нет

- 06-35-006 Avkcms en 427228Документ2 страницы06-35-006 Avkcms en 427228bre brilianОценок пока нет

- 2/2 Way Direct Acting Solenoid Valve: Uflow AutomationДокумент4 страницы2/2 Way Direct Acting Solenoid Valve: Uflow AutomationkarthikОценок пока нет

- CPV Process Valve ActuatorДокумент12 страницCPV Process Valve ActuatormarklaforestОценок пока нет

- Specification For Adsorbent Bed Accumulator Item No: V-05202Документ3 страницыSpecification For Adsorbent Bed Accumulator Item No: V-05202amlanfacebookОценок пока нет

- NSCE 40-250-92-P25VCS4, 110gpm@167ftДокумент4 страницыNSCE 40-250-92-P25VCS4, 110gpm@167ftMujtabaОценок пока нет

- Input ValuesДокумент5 страницInput ValuesmasoodОценок пока нет

- Salt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDДокумент3 страницыSalt Pumps Data Sheet Xi'An Space Huawei Chemical & Biological Engineering Co - LTDkayaltharanОценок пока нет

- Avk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400Документ2 страницыAvk Gate Valve, Flanged, Pn16 02/21-003: EN558/3 (BS), AISI316 Stem, A4 Bolts, 500 M EP Coating, DN50-400umair186Оценок пока нет

- Lug Calculation 1Документ2 страницыLug Calculation 1Sachin5586Оценок пока нет

- Coalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Документ2 страницыCoalescing Filter: Pressure Vessel Doc. No. Data Sheet EE-ME-DS-001Elias EliasОценок пока нет

- Data Sheet Tq-04 RLL Eppetroecuador Epn Rev CДокумент10 страницData Sheet Tq-04 RLL Eppetroecuador Epn Rev CFrancesco GuardiniОценок пока нет

- Viking SPK K 14Документ16 страницViking SPK K 14Ehab SharabОценок пока нет

- 40.17models V2725 V2726Документ6 страниц40.17models V2725 V2726Riaz EbrahimОценок пока нет

- Piping Isometric DrawingДокумент2 страницыPiping Isometric DrawingMohd Sami UddinОценок пока нет

- Calorifier Data SheetДокумент4 страницыCalorifier Data SheetgksakthiОценок пока нет

- Technical Data Sheet For Shell and Tube Heat Exchager Design SpecificationДокумент5 страницTechnical Data Sheet For Shell and Tube Heat Exchager Design SpecificationSakthi VelОценок пока нет

- Volute Pumps Sihi: SupernovaДокумент10 страницVolute Pumps Sihi: SupernovaLuis Fernando collazosОценок пока нет

- Level Gauge Data Sheet for UOPSL Flowstation ProjectДокумент4 страницыLevel Gauge Data Sheet for UOPSL Flowstation ProjectBABILIN VОценок пока нет

- MN-89242-22-7 SpecДокумент6 страницMN-89242-22-7 Specrenhat parulian sitorusОценок пока нет

- Avk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300Документ2 страницыAvk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300kad-7Оценок пока нет

- Api 650 Data Sheet (BWT-01)Документ4 страницыApi 650 Data Sheet (BWT-01)Rajesh K PillaiОценок пока нет

- Firelock V34, K8.0 Model V3428 Quick Response: See Victaulic Publication 10.01 For More DetailsДокумент4 страницыFirelock V34, K8.0 Model V3428 Quick Response: See Victaulic Publication 10.01 For More DetailscesarОценок пока нет

- Design Calculation-Spacer SpoolДокумент8 страницDesign Calculation-Spacer SpoolHasmukh Dave100% (1)

- Vendor Document Cover SheetДокумент75 страницVendor Document Cover Sheetmujahed_muhammedОценок пока нет

- STC (Buffer Tank 25KL) - Calc PDFДокумент4 страницыSTC (Buffer Tank 25KL) - Calc PDFAvril Rindra T PОценок пока нет

- Avk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300Документ2 страницыAvk Gate Valve, Flanged, Pn25 15/67-003: EN 558-2 S.15/DIN F5, ISO Top Flange, DN50-300kad-7Оценок пока нет

- Solid Filter - DatasheetДокумент1 страницаSolid Filter - Datasheetbmanojkumar16Оценок пока нет

- 10BFFRM2D0Документ4 страницы10BFFRM2D0Diego BarriosОценок пока нет

- CR 1 CI Sluice Valve Non Rising ISIДокумент1 страницаCR 1 CI Sluice Valve Non Rising ISIVishal ShivaОценок пока нет

- Technical DrawingДокумент6 страницTechnical DrawingRosyad AminОценок пока нет

- Condensate Tank - For 250Документ3 страницыCondensate Tank - For 250Sakthi VelОценок пока нет

- Parts Breakdown Sheet: Elite Two Handle Kitchen FaucetДокумент1 страницаParts Breakdown Sheet: Elite Two Handle Kitchen FaucettechtronicsОценок пока нет

- Pocket Guide to Flanges, Fittings, and Piping DataОт EverandPocket Guide to Flanges, Fittings, and Piping DataРейтинг: 3.5 из 5 звезд3.5/5 (22)

- Rahu/Ketu Dasha: Nomenclature KP Astro Vedic D Dasha Mahadasha B Bhugti Anterdasha A Antra PratiantardashaДокумент3 страницыRahu/Ketu Dasha: Nomenclature KP Astro Vedic D Dasha Mahadasha B Bhugti Anterdasha A Antra PratiantardashaDinesh VaghelaОценок пока нет

- Rahu/Ketu Dasha: Nomenclature KP Astro Vedic D Dasha Mahadasha B Bhugti Anterdasha A Antra PratiantardashaДокумент3 страницыRahu/Ketu Dasha: Nomenclature KP Astro Vedic D Dasha Mahadasha B Bhugti Anterdasha A Antra PratiantardashaDinesh VaghelaОценок пока нет

- Typical SpecificationsДокумент4 страницыTypical SpecificationsDinesh VaghelaОценок пока нет

- Best Big, Fat, Chewy Chocolate Chip CookieДокумент1 страницаBest Big, Fat, Chewy Chocolate Chip CookieDinesh VaghelaОценок пока нет

- White Chocolate Cheesecake With White Chocolate Brandy SauceДокумент1 страницаWhite Chocolate Cheesecake With White Chocolate Brandy SauceDinesh VaghelaОценок пока нет

- Refrigerator Cookies IIIДокумент1 страницаRefrigerator Cookies IIIDinesh VaghelaОценок пока нет

- Thai Peanut Chicken Lo MeinДокумент1 страницаThai Peanut Chicken Lo MeinDinesh VaghelaОценок пока нет

- Typical SpecificationsДокумент4 страницыTypical SpecificationsDinesh VaghelaОценок пока нет

- INDVSD032Документ1 страницаINDVSD032Dinesh VaghelaОценок пока нет

- 3 Automotive Chassis Design v2Документ62 страницы3 Automotive Chassis Design v2Leela Krishna VegiОценок пока нет

- Sarah's Banana Bread MuffinsДокумент1 страницаSarah's Banana Bread MuffinsDinesh VaghelaОценок пока нет

- Savory Croissant QuicheДокумент1 страницаSavory Croissant QuicheDinesh VaghelaОценок пока нет

- Peanut Butter Chip Chocolate CookiesДокумент1 страницаPeanut Butter Chip Chocolate CookiesDinesh VaghelaОценок пока нет

- Banana Crumb MuffinsДокумент1 страницаBanana Crumb MuffinsDinesh VaghelaОценок пока нет

- Amazing No Cook Spinach Artichoke DipДокумент1 страницаAmazing No Cook Spinach Artichoke DipDinesh VaghelaОценок пока нет

- Mexican Beef SupremeДокумент1 страницаMexican Beef SupremeDinesh VaghelaОценок пока нет

- Basis of Heat Exchanger DesignДокумент2 страницыBasis of Heat Exchanger DesignDinesh VaghelaОценок пока нет

- Easy Sesame Noodles RecipeДокумент1 страницаEasy Sesame Noodles RecipeDinesh VaghelaОценок пока нет

- Cake Mix Cinnamon RollsДокумент1 страницаCake Mix Cinnamon RollsDinesh VaghelaОценок пока нет

- Pressure Parts Designed to Codes and StandardsДокумент2 страницыPressure Parts Designed to Codes and StandardsDinesh VaghelaОценок пока нет

- Flange DesignДокумент6 страницFlange DesignDinesh VaghelaОценок пока нет

- Basis of Heat Exchanger DesignДокумент2 страницыBasis of Heat Exchanger DesignDinesh VaghelaОценок пока нет

- Tanks - EngineeringchecksДокумент5 страницTanks - EngineeringchecksDinesh VaghelaОценок пока нет

- Plate Design Type of Plates Square Rectangular CircularДокумент1 страницаPlate Design Type of Plates Square Rectangular CircularDinesh VaghelaОценок пока нет

- Fabrication of Heavy Wall Reactors in Crmo V PlatesДокумент24 страницыFabrication of Heavy Wall Reactors in Crmo V PlatesDinesh Vaghela100% (1)

- Castor Wheel DimensionsДокумент1 страницаCastor Wheel DimensionsDinesh VaghelaОценок пока нет

- Pressure Drop and Vent Sizing Calculations for 2500 Litre Diesel TankДокумент5 страницPressure Drop and Vent Sizing Calculations for 2500 Litre Diesel TankDinesh VaghelaОценок пока нет

- Castor Wheel DimensionsДокумент1 страницаCastor Wheel DimensionsDinesh VaghelaОценок пока нет

- 3 Pressure Vessels Design Manufacturers MersenДокумент12 страниц3 Pressure Vessels Design Manufacturers MersenekinathОценок пока нет

- Design Principles For Thick CylindersДокумент18 страницDesign Principles For Thick CylindersDinesh VaghelaОценок пока нет

- 8L22HLX Parts CatalogДокумент95 страниц8L22HLX Parts CatalogRafael HerreraОценок пока нет

- NDIR Type Infrared Gas Analyzer Type ZKJ-3Документ97 страницNDIR Type Infrared Gas Analyzer Type ZKJ-3Yoga SanОценок пока нет

- Introduction To Skipfish - ClubHACK MagazineДокумент4 страницыIntroduction To Skipfish - ClubHACK MagazineAulia Haq AqobyОценок пока нет

- Trantech BrochureДокумент4 страницыTrantech BrochureOmar Reinoso TigreОценок пока нет

- Instruction Manual - Eaton Internormen CCM 01 - Set Contamination Control Monitor, E, 2.5Документ47 страницInstruction Manual - Eaton Internormen CCM 01 - Set Contamination Control Monitor, E, 2.5Anshuman AgrawalОценок пока нет

- Easy and Accurate Distribution Transformer TestingДокумент8 страницEasy and Accurate Distribution Transformer TestingBash MatОценок пока нет

- Cummins QuickServe Online2Документ1 страницаCummins QuickServe Online2Anugerah PradanaОценок пока нет

- TorsionДокумент3 страницыTorsionTannyVaneОценок пока нет

- Shear Forces and Bending Moments: Understanding Structural AnalysisДокумент2 страницыShear Forces and Bending Moments: Understanding Structural AnalysisKang Lee76% (25)

- Victor Canete PDFДокумент2 страницыVictor Canete PDFMelvi PeñasОценок пока нет

- Programming a Synth for Wind Control (part 1Документ3 страницыProgramming a Synth for Wind Control (part 1CirrusStratusОценок пока нет

- Purchasing and Supply ManagementДокумент78 страницPurchasing and Supply Managementbilm100% (2)

- Festo Motion Control Platform FMCP-M Powered by FPosBДокумент32 страницыFesto Motion Control Platform FMCP-M Powered by FPosBgerardo floresОценок пока нет

- Telergon s7 EnglishДокумент3 страницыTelergon s7 EnglishjdbОценок пока нет

- Developing Vietnamese Cadastral Data Standards Based On ISO 19100 (3576)Документ12 страницDeveloping Vietnamese Cadastral Data Standards Based On ISO 19100 (3576)Đại Hải ThủyОценок пока нет

- It 504 A Artificial Intelligence Dec 2020Документ4 страницыIt 504 A Artificial Intelligence Dec 2020ABHIMAT PANDEYОценок пока нет

- CE8395 QB - by WWW - Easyengineering.net 1Документ18 страницCE8395 QB - by WWW - Easyengineering.net 1sureshkumarОценок пока нет

- CATIA V5R17 Chain & Sprocket Simulation ExplainedДокумент35 страницCATIA V5R17 Chain & Sprocket Simulation ExplainedBill Harbin50% (2)

- Astm d4694 09 Def FWDДокумент3 страницыAstm d4694 09 Def FWDJuan Casia Boza100% (1)

- EC-155B1 Complimentary Flight Manual - Section 7 Description and SystemsДокумент118 страницEC-155B1 Complimentary Flight Manual - Section 7 Description and SystemsFlightdispatch Airjuan100% (1)

- Telsinex Installation Guide Ver2.0Документ46 страницTelsinex Installation Guide Ver2.0Ludgério PedroОценок пока нет

- Blasting and Painting ProcedureДокумент9 страницBlasting and Painting Procedureisukuru67% (12)

- PCAD SchematicДокумент430 страницPCAD SchematicAnonymous gH8rfDОценок пока нет

- Glycol Dehydration UnitДокумент11 страницGlycol Dehydration UnitarispriyatmonoОценок пока нет

- DNC MagazineДокумент49 страницDNC MagazineNizamudheen kОценок пока нет

- Santosh ResumeДокумент4 страницыSantosh ResumeSantosh KumarОценок пока нет

- Charles Correa 1Документ21 страницаCharles Correa 1NupurAgrawalОценок пока нет

- Mahindra&mahindraДокумент95 страницMahindra&mahindraAshik R GowdaОценок пока нет

- SAP Fiori Launchpad For Developers - Architecture OverviewДокумент12 страницSAP Fiori Launchpad For Developers - Architecture OverviewsanasriОценок пока нет

- ROR coding standards guide for clean codeДокумент2 страницыROR coding standards guide for clean codeHarish KashyapОценок пока нет