Академический Документы

Профессиональный Документы

Культура Документы

Column Former Fast Form

Загружено:

Việt Vớ VẩnАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Column Former Fast Form

Загружено:

Việt Vớ VẩnАвторское право:

Доступные форматы

COLUMN FORMERS

Introduction:

BAG Column Formers are a single use formwork system that gives an excellent

smooth fair face surface finish. Our Column Formers are manufactured by welding

together several layers of high quality polyethylene coated kraft paper, which are

spirally wound and bonded together by heating the polyethylene. Once this step is

complete, a water resistant foil is also spirally wound over the kraft paper, sealing the

column against humidity. This manufacturing process requires no additional adhesives

which reduces the wall thickness, making the BAG Column Formers light and easy to

handle.

Designs:

Lined - BAG Column Formers have a PVC liner which is fitted the whole length of the

inner diameter the Column Former, this provides an impeccably smooth finish. BAG

Column Formers will only leave a hairline seam on the concrete from the point where

the liner joint meets.

Unlined - BAG Column Formers are also available unlined for applications

where surface finish is not critical. This Column Former will leave a spirall effect

on the finished column.

Square - BAG can offer sqaure or rectangular columns on request, made from

our standard Column Fomer with an additional polystyrene insert, manufactured

to your specific requirements.

Bespoke - BAG can also offer made to order bespoke designs. Please contact

our sales team for more details.

Advantages:

Light easy to handle as opposed to steel shuttering.

Labour saving.

Easy to strip, no mould oils required.

Quality fair faced finish.

Can be used for protective cover for the completed columns.

Water Resistant:

The column formers are water resistant due to the manufacturing

process and the outer layer of foil, both of which seal the column

former against humidity. Protection will be required when stocking

in direct contact with rain and water.

DISCLAIMER:

Please note BAG Column Formers are Water Resistant, not Water Proof.

t. South: 0203 507 183 4 / 3 / 2 t. North: 01472488230 / 488660 / 485640

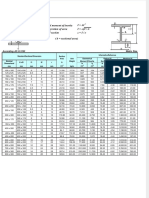

Circular Range:

Tube I/D Tube Wall Maximum Pour Concrete Re- Weight

(mm) Thickness (mm) Height (mtr) quired (m3/mtr) (kg/mtr)

150 2.80 6.0 0.018 1.24

200 2.80 6.0 0.031 1.63

240 3.20 6.0 0.045 1.96

250 3.20 6.0 0.049 2.08

300 3.20 6.0 0.071 2.38

350 3.70 6.0 0.096 3.09

400 4.10 6.0 0.126 3.52

450 4.10 6.0 0.159 4.50

500 4.60 6.0 0.196 5.44

550 4.60 6.0 0.237 5.99

600 5.00 6.0 0.283 6.53

650 5.00 4.0 0.332 7.16

700 5.00 4.0 0.385 7.71

750 5.00 4.0 0.442 8.26

800 5.50 4.0 0.502 8.81

850 5.50 4.0 0.567 9.36

900 5.50 4.0 0.636 9.91

950 5.50 4.0 0.708 10.46

1000 5.90 4.0 0.785 11.11

1100 5.90 4.0 0.950 12.11

1200 5.90 4.0 1.130 13.21

Caution:

The concrete pour speed should not exceed more than 4 metres per hour.

Concrete can be poured into the BAG Column former via skip or bucket

for diameters of up to 450mm and lengths of 4 metres. Larger sizes will

require concrete to be placed by a pump and hose.

Concrete should be placed slowly to eliminate air entrapment between the

tube liner. Do not force column formers into position.

t. South: 0203 507 183 4 / 3 / 2 t. North: 01472488230 / 488660 / 485640

Installation:

BAG Column Formers are very light and can be transported without any

handling equipment. The tubes can be secured on the base using

timber which is fixed to the floor or decking as required. The top of

the tube can either be secured using timber or with our own

tension belt system. When using our system you are able to fix

three sloped bearings with a 120 degree angle. Normally two

fixing points are sufficient at a 90 degree angle. If the Column

Former is 7 metres or more we recommend that an additional

fixing point is used at the middle point of the tube.

Storage:

BAG Column Formers are manufactured with a water resistant

coating for extra durability. Our Column Formers can be stored vertically

or horizontally, Protection will be required when stocking in direct contact

with rain and water.

Stripping:

BAG Column Formers can be stripped after 48 hours.

Our Column Formers are designed and manufactured with a steel wire that runs inside the layers

to provide a quick and easy stripping system. Once stripped the former can be reused as a

protective cover for the finished concrete pillar thus removing any chance of damage afterwards.

t. South: 0203 507 183 4 / 3 / 2 t. North: 01472488230 / 488660 / 485640

Square Range:

Internal Tube O/D Maximum Pour Concrete Required Weight

Dimensions (mm) (mm) Height (mtr) (m3/mtr) (kg/mtr)

200 x 200 300 6.0 0.040 3.10

240 x 240 360 6.0 0.057 3.90

250 x 250 374 6.0 0.062 4.00

300 x 300 458 6.0 0.090 5.20

350 x 350 514 6.0 0.122 6.00

400 x 400 586 6.0 0.160 7.60

450 x 450 666 6.0 0.202 8.70

500 x 500 736 6.0 0.250 9.80

Rectangular Range:

Internal Tube O/D Maximum Pour Concrete Required Weight

Dimensions (mm) (mm) Height (mtr) (m3/mtr) (kg/mtr)

175 x 200 280 6.0 0.035 2.90

200 x 240 330 6.0 0.048 3.50

200 x 250 341 6.0 0.050 3.80

200 x 300 398 6.0 0.060 4.60

200 x 350 428 6.0 0.070 5.20

200 x 400 478 6.0 0.080 6.00

200 x 450 536 6.0 0.090 7.20

200 x 500 582 6.0 0.100 8.30

240 x 300 409 6.0 0.072 4.60

240 x 350 437 6.0 0.084 5.00

240 x 400 473 6.0 0.096 5.80

240 x 500 548 6.0 0.102 6.90

250 x 300 414 6.0 0.075 4.80

250 x 350 456 6.0 0.087 5.20

250 x 400 510 6.0 0.100 6.40

250 x 500 600 6.0 0.125 8.50

300 x 350 494 6.0 0.105 6.50

300 x 400 534 6.0 0.120 6.70

300 x 450 578 6.0 0.135 7.10

300 x 500 620 6.0 0.150 8.70

350 x 400 564 6.0 0.140 6.90

350 x 500 674 6.0 0.175 8.50

400 x 500 674 6.0 0.200 9.20

t. South: 0203 507 183 4 / 3 / 2 t. North: 01472488230 / 488660 / 485640

Column Formers with a difference:

BAG Column Formers are the only ones available on the UK market with a textured finish option.

Several different finshes are available on request.

Pattern 001 Pattern 002

Pattern 003 Pattern 004

Pattern 005 Pattern 006

Pattern 007 Pattern 008

t. South: 0203 507 183 4 / 3 / 2 t. North: 01472488230 / 488660 / 485640

t. South: 0203 507 183 4 / 3 / 2 t. North: 01472488230 / 488660 / 485640

Offices / Depots:

Fast Form Systems Ltd (Head office UK )

Unit 1 Omega Business ParkEstate Road 6

Grimsby

N.E.Lincs

DN31 2TG

T: 01472 488230 / 488660 / 485640

E: info@fastformsystems.com

Delivery Depots London & Andover

Product Range:

Temporary Formwork & Falsework Plywood

Plastic, Concrete & Wire Spacers Reinforcement Continuity Systems

Slab Accessories Formwork Systems & Accessories

Magnet Systems Piling Accessories

Cast-in Channel Lifting & Fixing Systems

Precast Accessories Double Walling Accessories

Screed Rails Chemicals & Sprayers

Вам также может понравиться

- Sagar Engineering Works JaipurДокумент6 страницSagar Engineering Works JaipurSagarОценок пока нет

- Model 7041-A Flange-Ansi Class 125/150Документ2 страницыModel 7041-A Flange-Ansi Class 125/150Zaira LorenaОценок пока нет

- Pipe ScheduleДокумент2 страницыPipe ScheduleRajeev ChandelОценок пока нет

- Mesh Size Tyler Astm-E11 Bs-410 Din-4188Документ4 страницыMesh Size Tyler Astm-E11 Bs-410 Din-4188Yoyon SuparionoОценок пока нет

- TDS 11594044 PrepPureДокумент4 страницыTDS 11594044 PrepPurenanang fakhrudinОценок пока нет

- 2.2 - Details of Shell & Tube H.EДокумент110 страниц2.2 - Details of Shell & Tube H.ENader GaafarОценок пока нет

- Embankment Settlement Eng-TipsДокумент9 страницEmbankment Settlement Eng-Tipsshadabg04Оценок пока нет

- Sieve SizeДокумент3 страницыSieve SizeSse SteelОценок пока нет

- D-01 Model 7041 Flange Adapter-Ansi Class 125150Документ4 страницыD-01 Model 7041 Flange Adapter-Ansi Class 125150Daniel SanОценок пока нет

- Table 8 Commercial Pipe Sizes and Wall ThicknessesДокумент1 страницаTable 8 Commercial Pipe Sizes and Wall ThicknessesYahia Abou-ShoshaОценок пока нет

- AISC Steel Handbook - ProtectedДокумент100 страницAISC Steel Handbook - ProtectedJohn Renzel Rivera IIIОценок пока нет

- WN 300Документ7 страницWN 300ANANDAN NОценок пока нет

- Nss WF Ibeam TableДокумент5 страницNss WF Ibeam TableNico ScheggiaОценок пока нет

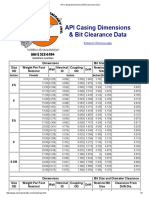

- API Casing Dimensions & Bit Clearance DataДокумент3 страницыAPI Casing Dimensions & Bit Clearance Datamm_niknafs6123Оценок пока нет

- 4 Steel Pipe Sans 719Документ1 страница4 Steel Pipe Sans 719Roddy TeeОценок пока нет

- Tyler: ASTM Sieve Chart and EquivalentsДокумент1 страницаTyler: ASTM Sieve Chart and EquivalentsWilder CubaОценок пока нет

- API 5ct S Pipe Drifts Casing Data ChartДокумент1 страницаAPI 5ct S Pipe Drifts Casing Data ChartghanОценок пока нет

- Tabla #1. Tracción en Acero Laminado en CalienteДокумент10 страницTabla #1. Tracción en Acero Laminado en CalienteMarco Steven Morales SarzosaОценок пока нет

- ASME B16.5-Flanges Class 150Документ1 страницаASME B16.5-Flanges Class 150radziОценок пока нет

- New - Customer Tariff New2 - (F)Документ1 страницаNew - Customer Tariff New2 - (F)Collins MghaseОценок пока нет

- 2 0 - 2 1 8% 2 0 - 2 3.3 3 2 4 0 - 4 (M.) Max 8 0 - 8 V.D. KM/H Radios Minimos 70 KM/H Peraltes MaxДокумент10 страниц2 0 - 2 1 8% 2 0 - 2 3.3 3 2 4 0 - 4 (M.) Max 8 0 - 8 V.D. KM/H Radios Minimos 70 KM/H Peraltes MaxJean Sarmiento ChucuyaОценок пока нет

- CPA 55E/65E Type A Flow Conditioner - Raised Face - FOEДокумент1 страницаCPA 55E/65E Type A Flow Conditioner - Raised Face - FOEJerОценок пока нет

- Slip On Flanges - ANSI B16.5: Class 150 LBДокумент5 страницSlip On Flanges - ANSI B16.5: Class 150 LBJosé A. RamírezОценок пока нет

- Amipox Well Casing Catlogue FДокумент5 страницAmipox Well Casing Catlogue Fjibran_akram93Оценок пока нет

- (In) (In) : Schedule 10 20 30 STD 40 60 XS 80 100 120 140 160 XXS Nominal Pipe Size Outside Diameter Wall Thickness (In)Документ1 страница(In) (In) : Schedule 10 20 30 STD 40 60 XS 80 100 120 140 160 XXS Nominal Pipe Size Outside Diameter Wall Thickness (In)dimaszrizkiОценок пока нет

- Dokumen - Tips - Tabel Baja Profil WFPDFДокумент7 страницDokumen - Tips - Tabel Baja Profil WFPDFEvan ImamОценок пока нет

- Horizontal Tank Chart 2Документ4 страницыHorizontal Tank Chart 2גרבר פליקסОценок пока нет

- Design of Columns Under Vertical Loads ONLYДокумент10 страницDesign of Columns Under Vertical Loads ONLYmannshiОценок пока нет

- Documentos VariosДокумент5 страницDocumentos VariosIgnacio Obando PaniaguaОценок пока нет

- Pipe Schedule Chart InchДокумент1 страницаPipe Schedule Chart InchLeroy Ambrosio GabineteОценок пока нет

- Upvc PipesДокумент1 страницаUpvc PipesMuneer mahammadОценок пока нет

- Drilling Jar SpecДокумент2 страницыDrilling Jar SpecPetroMan CMОценок пока нет

- Kelly Pipe Chart (Updated)Документ1 страницаKelly Pipe Chart (Updated)joesamsoОценок пока нет

- Inch - MM Conversions: Revised Feb 2011Документ1 страницаInch - MM Conversions: Revised Feb 2011kamaldhar007Оценок пока нет

- 32nd Camera Auction - Result List 01Документ2 страницы32nd Camera Auction - Result List 01Raúl GraphicsОценок пока нет

- Particle Size Conversion: Inches MM Microns Standard (MM) Mesh Sieve Opening Sieve DesignationДокумент1 страницаParticle Size Conversion: Inches MM Microns Standard (MM) Mesh Sieve Opening Sieve DesignationsayoneeОценок пока нет

- Ce322 - Quantify SurveyingДокумент5 страницCe322 - Quantify SurveyingBG GuillermoОценок пока нет

- Appendix 5. Standard Screen Scales PDFДокумент3 страницыAppendix 5. Standard Screen Scales PDFJorell PaguioОценок пока нет

- RecordsДокумент1 страницаRecordsapi-255115234Оценок пока нет

- RecordsДокумент1 страницаRecordsapi-255115234Оценок пока нет

- Blind Flanges ANSI B16.5 600lbsДокумент1 страницаBlind Flanges ANSI B16.5 600lbsvinonaguОценок пока нет

- Beban StatisДокумент38 страницBeban StatisSir PaldeyОценок пока нет

- Segments ImmobilierДокумент1 страницаSegments ImmobilierABDELAZIZ HAYOUNОценок пока нет

- Dimensões Das TubulaçõesДокумент2 страницыDimensões Das TubulaçõesAlice Boll AltieriОценок пока нет

- Shear Strength ResultДокумент14 страницShear Strength ResultPrateek Soumya SharmaОценок пока нет

- Tabel Baja JISДокумент2 страницыTabel Baja JISAlfin HidayatullahОценок пока нет

- Economic Range Nylon Cable TieДокумент1 страницаEconomic Range Nylon Cable TieGovind ChaudhariОценок пока нет

- Series 71Документ1 страницаSeries 71luisgonzalezf95Оценок пока нет

- Specifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Документ3 страницыSpecifications Mechanical Properties at Room Temperature: Gas List Tube (En 10255)Manish StauffenbergОценок пока нет

- Spectru ProiectareДокумент27 страницSpectru ProiectareHoria Ionut MihneaОценок пока нет

- Spectru ProiectareДокумент27 страницSpectru ProiectareHoria Ionut MihneaОценок пока нет

- G3192 - WFДокумент2 страницыG3192 - WFAdhie RakhmadiОценок пока нет

- (In) (In) : Outside Diameter ScheduleДокумент2 страницы(In) (In) : Outside Diameter SchedulemusaveerОценок пока нет

- Wideflange PDFДокумент4 страницыWideflange PDFandОценок пока нет

- Mesh Inch Micron Conversion ChartДокумент1 страницаMesh Inch Micron Conversion ChartAhmed IsmailОценок пока нет

- GRP Price List May2013 DSGДокумент2 страницыGRP Price List May2013 DSGpeeramohamedОценок пока нет

- Slab Drain 03 BbsДокумент26 страницSlab Drain 03 BbsLaturОценок пока нет

- Cmpl-Bolt and Torque Specifications UsДокумент3 страницыCmpl-Bolt and Torque Specifications UsYanina CamonesОценок пока нет

- Math Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesОт EverandMath Practice Simplified: Decimals & Percents (Book H): Practicing the Concepts of Decimals and PercentagesРейтинг: 5 из 5 звезд5/5 (3)

- Phantom Drophead Coupé Product Overview World PDFДокумент24 страницыPhantom Drophead Coupé Product Overview World PDFViệt Vớ VẩnОценок пока нет

- Vinfast and The Electric Vehicle Market in VietnamДокумент6 страницVinfast and The Electric Vehicle Market in VietnamViệt Vớ VẩnОценок пока нет

- Washington,: This Between Agency (EPA) 1 Speed CodeДокумент9 страницWashington,: This Between Agency (EPA) 1 Speed CodeViệt Vớ VẩnОценок пока нет

- Wraith: Rolls-Royce Motor CarsДокумент21 страницаWraith: Rolls-Royce Motor CarsViệt Vớ VẩnОценок пока нет

- Rolls Royce Dawn Model Overview RoWДокумент28 страницRolls Royce Dawn Model Overview RoWChanManОценок пока нет

- VA Rolls RoyceДокумент11 страницVA Rolls RoyceViệt Vớ VẩnОценок пока нет

- Product Range: Rolls-Royce Motor CarsДокумент35 страницProduct Range: Rolls-Royce Motor CarsViệt Vớ VẩnОценок пока нет

- (ME65B ME75B) User Manual PDFДокумент222 страницы(ME65B ME75B) User Manual PDFpoluxjaОценок пока нет

- Handbook Safety PDFДокумент219 страницHandbook Safety PDFJia IdrisОценок пока нет

- Gift WorldДокумент25 страницGift WorldViệt Vớ Vẩn100% (1)

- Ghost Overview Brochure DigitalДокумент48 страницGhost Overview Brochure DigitalViệt Vớ VẩnОценок пока нет

- Led TV: User ManualДокумент26 страницLed TV: User ManualViệt Vớ VẩnОценок пока нет

- Phantom 240x180 150dpiДокумент29 страницPhantom 240x180 150dpiViệt Vớ VẩnОценок пока нет

- E229578 RRC Phantom Consumer Booklet PTДокумент24 страницыE229578 RRC Phantom Consumer Booklet PTnaveenbaskaranОценок пока нет

- J5500 LED TV: Product HighlightsДокумент4 страницыJ5500 LED TV: Product HighlightsViệt Vớ VẩnОценок пока нет

- HYUNDAI GRAN I10-2015Документ23 страницыHYUNDAI GRAN I10-2015DavisCahuatijo100% (1)

- Grand I10 Ebrochure 2017 PDFДокумент8 страницGrand I10 Ebrochure 2017 PDFViệt Vớ VẩnОценок пока нет

- H29 Sekisankijyun 3Документ536 страницH29 Sekisankijyun 3Việt Vớ VẩnОценок пока нет

- 251 BestBondEP752Документ2 страницы251 BestBondEP752Việt Vớ VẩnОценок пока нет

- 2012 2013 Sustainability ReportДокумент94 страницы2012 2013 Sustainability ReportViệt Vớ VẩnОценок пока нет

- Osha Construction PDFДокумент65 страницOsha Construction PDFAlex Xocoxic PeinadoОценок пока нет

- 2018 Mazda6: 2017 Los Angeles Auto Show Press Kit Canadian SpecificationsДокумент9 страниц2018 Mazda6: 2017 Los Angeles Auto Show Press Kit Canadian SpecificationsViệt Vớ Vẩn100% (1)

- 2014 2015 Sustainability ReportДокумент102 страницы2014 2015 Sustainability ReportViệt Vớ VẩnОценок пока нет

- New Road Form BrochureДокумент12 страницNew Road Form BrochureViệt Vớ VẩnОценок пока нет

- Apple Ccessory Design GuidelinesДокумент176 страницApple Ccessory Design GuidelinesViệt Vớ VẩnОценок пока нет

- Kumkang Kind PipeДокумент24 страницыKumkang Kind PipeViệt Vớ VẩnОценок пока нет

- Kia MorningДокумент2 страницыKia MorningViệt Vớ VẩnОценок пока нет

- Pfsolutions BrochureДокумент24 страницыPfsolutions BrochureViệt Vớ VẩnОценок пока нет

- Beamform Brochure Fast FormДокумент1 страницаBeamform Brochure Fast FormViệt Vớ VẩnОценок пока нет

- 9.2 Chalk DustДокумент18 страниц9.2 Chalk DustDane NarzolesОценок пока нет

- International Maritime Solid Bulk Cargoes (IMSBC) CodeДокумент18 страницInternational Maritime Solid Bulk Cargoes (IMSBC) CodeJasper Abrantes100% (1)

- HP Mini 210-2120br PC Broadcom Wireless LAN Driver v.5.60.350.23 Pour Windows 7 Download GrátisДокумент5 страницHP Mini 210-2120br PC Broadcom Wireless LAN Driver v.5.60.350.23 Pour Windows 7 Download GrátisFernandoDiasОценок пока нет

- 1ST Term S1 Physics-1Документ33 страницы1ST Term S1 Physics-1onos arereОценок пока нет

- Assignment3 (Clarito, Glezeri BSIT-3A)Документ9 страницAssignment3 (Clarito, Glezeri BSIT-3A)Jermyn G EvangelistaОценок пока нет

- CV - Nguyen Quang HuyДокумент5 страницCV - Nguyen Quang HuyĐoan DoãnОценок пока нет

- Hyundai Monitor ManualДокумент26 страницHyundai Monitor ManualSamОценок пока нет

- Lululemon Style GuideДокумент15 страницLululemon Style Guideapi-263257893Оценок пока нет

- A033Документ24 страницыA033PRANAV GOYALОценок пока нет

- Renderoc LA55Документ2 страницыRenderoc LA55Mansoor AliОценок пока нет

- IDS701Документ26 страницIDS701Juan Hidalgo100% (2)

- Notice Format 2024 BatchДокумент1 страницаNotice Format 2024 BatchAriОценок пока нет

- What Is Aggregate DemandqwertДокумент9 страницWhat Is Aggregate DemandqwertShahana KhanОценок пока нет

- Leyson vs. OmbudsmanДокумент12 страницLeyson vs. OmbudsmanDNAAОценок пока нет

- SYKES - Telework Work Area AgreementДокумент2 страницыSYKES - Telework Work Area AgreementFritz PrejeanОценок пока нет

- Elo BLP Neutral en Web.5573Документ8 страницElo BLP Neutral en Web.5573Ichsanul AnamОценок пока нет

- Labor LawДокумент6 страницLabor LawElden Cunanan BonillaОценок пока нет

- Software Requirement SpecificationДокумент10 страницSoftware Requirement SpecificationSushil SarrafОценок пока нет

- Abhijit Auditorium Elective Sem 09Документ3 страницыAbhijit Auditorium Elective Sem 09Abhijit Kumar AroraОценок пока нет

- 2 - McCullough HospitalДокумент2 страницы2 - McCullough HospitalGuru Charan ChitikenaОценок пока нет

- Tales of Mystery Imagination and Humour Edgar Allan Poe PDFДокумент289 страницTales of Mystery Imagination and Humour Edgar Allan Poe PDFmatildameisterОценок пока нет

- Fadm Project 5 ReportДокумент4 страницыFadm Project 5 ReportVimal AgrawalОценок пока нет

- VTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFДокумент176 страницVTP Renault 6.14.1 Web Version - Pdf.pagespeed - Ce.c T5zGltXA PDFIbrahim AwadОценок пока нет

- Amt in A Nutshell - ExplainedДокумент2 страницыAmt in A Nutshell - ExplainedMis El100% (2)

- Partial Discharge Diagnostic Testing and Monitoring Solutions For High Voltage CablesДокумент55 страницPartial Discharge Diagnostic Testing and Monitoring Solutions For High Voltage CablesElsan BalucanОценок пока нет

- Graphene/Metal Organic Framework Composites As Adsorbents For Adsorption Chiller ApplicationsДокумент88 страницGraphene/Metal Organic Framework Composites As Adsorbents For Adsorption Chiller ApplicationsNajam Ul QadirОценок пока нет

- Nyush Ds Cs Capstone Outline TemplateДокумент2 страницыNyush Ds Cs Capstone Outline TemplateFresh Prince Of NigeriaОценок пока нет

- Brand Plan - SingulairДокумент11 страницBrand Plan - Singulairshashank100% (2)

- Nogales V Capitol Medical CenterДокумент2 страницыNogales V Capitol Medical CenterGraceОценок пока нет

- 8th Mode of FinancingДокумент30 страниц8th Mode of FinancingYaseen IqbalОценок пока нет