Академический Документы

Профессиональный Документы

Культура Документы

Shimano ST 6510 Service Instructions SI 6C80D 001 ENG

Загружено:

Mathieu AubertАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Shimano ST 6510 Service Instructions SI 6C80D 001 ENG

Загружено:

Mathieu AubertАвторское право:

Доступные форматы

General Safety Information Operation Installation Assembling the bracket

and lever

WARNING Rear Front Lever A : Shifts from smaller to larger rear sprocket.

F Installation to the handlebar Installing the shifting cable 1. Put the cable hook in to the bearing member, and

Lever B : Shifts from larger to smaller rear sprocket.

F Install the outer stopper for set the return spring.

Obtain and read the service instructions carefully prior to Secure the assembly with the installation nut on the outside

Lever a : Shifts from smaller to larger chainring.

F Cable used Handle default the rear chainwheels with

installing the parts. Lever b : Shifts from larger to smaller chainring.

F of the bracket. Pull the bracket cover position

Inner cable (stainless steel) f 1.2 mm the handle in the default Set the end of the spring in

Loose, worn, or damaged parts may cause injury to the rider. back and use a 5 mm Allen Bracket cover

the hole in the bearing

position.

We strongly recommend only using genuine Shimano key to tighten the bolt. Cable hook

member. Note that the

replacement parts. spring has a right and left

Obtain and read the service instructions carefully prior to Lever F

B Lever F

b

SP40 sealed outer casing () side.

installing the parts. All levers return to the starting position when f 4 mm 2. Pass the inner cable through, and set the outer casing.

5 mm Allen key

If adjustments are not carried out correctly, the chain may Lever F

A Lever F

a released. Bearing

SP40 Return spring

SEALED

Be sure leave some excess in the outer casing, even if member

come off and this may cause you to fall off the bicycle which

cutting it to the full length of the handlebars.

could result in serious injury.

Read these Technical Service Instructions carefully, and keep SP40 outer casing () f 4 mm Hole

Installation nut

them in a safe place for later reference. Operation of rear derailleur lever SP40

Lever F

A : Shifts from smaller to larger rear sprocket. Lever FB : Shifts from larger to smaller rear sprocket.

Note A has a click stop at positions , , and .

Lever F Press lever F

B once to shift from a larger to one smaller Tightening torque: 2. Set the special installation tool for the return spring.

Operation of the levers related to gear shifting should be sprocket. 6 - 8 Nm {50 - 70 in. lbs.}

made only when the front chainwheel is turning.

Outer stopper

For smooth operation, always be sure to use the specified In the case of carbon handlebars, it may be necessary to Outer casing Return spring installation tool

outer casing and the bottom bracket cable guide. lower the tightening torque in order to prevent damage to (TL-ST02)

Grease the inner cable and the inside of the outer casing the handlebar. Please consult the bicycle or handlebar Inner cable

before use to ensure that they slide properly. manufacturer regarding the appropriate level of tightening

Because the high cable resistance of a frame with internal torque for carbon handlebars. Wire lead

cable routing would impair the SIS function, this type of frame

Lever F

B

should not be used. Click

The end of the outer casing which has the aluminum Lever F

A lever F

A

start position lever FB Installation of the brake cable Inserting the inner cable

cap should be at the derailleur side. 4-mm cap Click start position Insert the inner cable into the outer casing from the end

Cable used f 1.6 mm with the marking on it. Apply grease from the end with the Confirm

Click Inner cable (stainless steel) marking in order to maintain cable operating Make sure the outer

efficiency. casing is firmly seated 3. First insert the sensor cable into the bracket body,

Derailleur side E.x. : from 4th to 3rd f 5 mm in the outer stopper. and then assemble the bracket body and lever

: Shifts one sprocket SLR outer casing Marking body. Be careful that the end of the return spring

Aluminum cap Plastic cap or 4-mm cap E.x. : from 3rd to 4th Cutting the outer casing does not protrude from the hole in the bearing

When cutting the outer casing, cut the opposite end to the member at this time.

Be sure to leave some excess cable, even if cutting it to

The cycle computers shown in the table below are compatible. the full length of the handlebars. end with the marking. After cutting the outer casing, make Bracket

the end round so that the inside of the hole has a uniform

Meter unit SC-6500 / SC-6501 / SC-M500 diameter. Maintenance

Bracket sensor unit SM-6500*1/ SM-6500-RS / SM-6501 1. Tilt the lever in (as when shifting) to make it easier to

: Quick-shifts two sprockets pass the cable through the cable hook. Bracket and lever disassembly Lever

*1 Caution on operation

The bracket cover must be replaced. E.x. : from 3rd to 5th

Note: 1. Remove the sensor cap,

( ST-6510 ---> Replace with bracket cover for ST-6501.

ST-5500-CA ---> Replace with ST-5500-C. ) Lever FB will also move when lever F A is operated, but

be careful not to apply pressure to lever FB . Similarly

The front lever cannot be tilted to

the inside until lever F

b is pushed

Attach the same outer end cap to the cut end of the outer

casing.

and the use a 2 mm Allen

key to remove the lever

Sensor cap

be careful not to press lever FA when operating lever once or twice.

Read the service instructions for the cycle computer also. stud set screw on the Make sure the spring is properly positioned.

Parts are not guaranteed against natural wear or deterioration B . Gears will not shift when both levers are pressed

F Outer end cap bottom of the bracket.

resulting from normal use. : Quick-shifts three sprockets simultaneously.

For maximum performance we highly recommend Shimano E.x. : from 3rd to 6th

lubricants and maintenance products. Be sure to read these service instructions in conjunction with

For any questions regarding methods of installation, the service instructions for the RD-6500 / RD-6500-GS / Rear lever

adjustment, maintenance or operation, please contact a RD-5500 / RD-5501 / RD-5500-GS / RD-5501-GS before use. Pull Lever F

b

Lever stud set screw

2 mm Allen key

professional bicycle dealer. Push lever F B at least 8 times

to make sure the mechanism

Tilt is in top gear Lever F

B 4. Align the stud holes, and then press-fit

Operation of front derailleur levers Operation of front derailleur levers before installing. Operate at 2. Insert a 2.5 mm Allen key or similar tool into the lever the lever stud.

Technical Service Instructions SI-6C80D-001 (FD-6500 / FD-5500 / FD-5501) (FD-6503 / FD-5503 / FD-5504) 2. Pass the inner cable through.

least 8 times stud hole, and tap it gently with a plastic mallet to push

Lever stud

Lever F

a : Shifts from smaller to larger front chainring. Lever F

a : Shifts from smaller to larger front chainring. out the lever stud. When the lever stud comes out, the

Depress the brake lever, and then Cable hole bracket body and lever body can be disassembled.

ST-6510 Cable hook

pass the inner cable through the After this, pull the sensor cable out from the bracket

body.

cable hole.

ST-5500-CA Shimano Note:

Sensor

Lever stud set

ST-5510 Total Integration Inner cable

When removing screw

the sensor cable,

ST-R600 2

Inner cable

do not apply too

much force when Sensor cable The correct position is for

Lever F

a Lever F

a pulling the cable, the round hollow on the

lever Fa lever Fa lever stud to be aligned

start position start position

otherwise the

1 3. Fix the outer guide to the inner cable, and set the angled sensor may with the lever stud set

In order to realize the best performance, we recommend that If the cable hook does not align with the shifting cable

member in the bracket. become damaged. screw.

the following combination be used. If operation of lever F

a does not If operation of lever F

a dose not hole, press lever F

B again until it does, and then install

complete the chainring shift stroke, complete the chainring shift stroke, Note: Do not wipe the grease on the inner cable off. the cable. Use a tool to hold

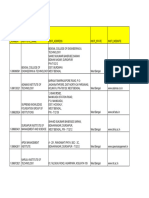

Series ULTEGRA operate lever F a again for the operate lever F a again for the Also, be careful that the inner cable does not pick the sensor in place

distance (X') to complete that part of distance (X') to complete that part of up dust and foreign matter. and pull the cable Bracket 5. Remove the return

Shifting lever ST-6510 / ST-R600 the lever stroke (X) which was short. the lever stroke (X) which was short.

body

Cable hook

out carefully. spring installation tool

Outer casing SP40 Lever body with pliers.

Gears 18 27 Angled member of Inner cable

Full gear shift stroke Full gear shift stroke outer guide

Front derailleur FD-6500 FD-6503 Actual stroke Actual stroke Lever and bearing assembly

x x Make sure that the inner end is firmly seated in the

Front chainwheel FC-6500 FC-6503 Bracket

cable hook. disassembly

Bottom bracket BB-6500 x' x' Inner end 1. Remove the cable hook. Cable hook

Outer guide

Lever F

b : Shifts from largest chainring to intermediate Lever F

b : Shifts from largest chainring to intermediate Return spring

Rear derailleur RD-6500 RD-6500-GS (Parts sold separately)

installation tool

chainring. chainring. Cable hook

Freehub FH-6500

Cassette sprocket CS-6500

Chain CN-HG93 / CN-7701

Bottom bracket cable guide SM-SP17

Sensor Cap

6. Tighten the lever stud set

Lever F

b

4. Set the outer casing on the inner cable, and in the screw until it is even with the

Series SHIMANO 105 lever Fb Lever F

b

Front lever surface of the bracket.

start position bracket along the outer guide.

Shifting lever ST-5500-CA / ST-5510 / ST-R600

lever Fb

2. Disassemble using the special tool and Lastly, install the sensor cap.

start position Outer casing Push lever F b at least

When lever F b is operated, there is one click where trimming (the two - three times a 5 mm Allen key.

Outer casing SP40

noise prevention mechanism) engages, Make sure that the inner before installing.

Gears 18 27 Lever F

b

and a second stronger click when the end is firmly seated in the Operate at least 2 - 3 times

gear shift stroke is completed. After cable hook.

Front derailleur FD-5500 / FD-5501 FD-5503 / FD-5504 Lever F

b : Shifts from intermediate chainring to smallest Torque tightening during assembly:

Lever stud set screw

trimming, the next push will complete Cable guide

Front chainwheel FC-5501 / FC-5502 FC-5504 / FC-5505 the gear shift stroke. chainring. 8 - 10 Nm {70 - 85 in. lbs.}

Gear shift Cable hook Pull the brake lever

2 mm Allen key

Bottom bracket BB-5500 complete stroke (as when braking) to pass Shifting cable hole Tightening torque:

Outer holder 1 Nm {8 in. lbs.}

RD-5500 / RD-5500-GS / the inner cable through the

Rear derailleur shifting cable hole, and set

RD-5501 RD-5501-GS Trim operation Inner end

Click it in the outer casing. Special tool (TL-ST01)

Freehub FH-5500 / FH-5501 Click Gear shift

complete stroke 5 mm Allen key

Cassette sprocket CS-HG70-9

Trimming (noise prevention operation)

Replacing the bracket cover

Chain CN-HG73 3. Disassemble as shown.

If the chain is on the large front chainwheel and the Click Outer casing The tabs on the bracket cover each fit to a matching

Bottom bracket cable guide SM-SP17 Click 5. Bring the outer casing along the front of the handlebar slot on the bracket.

larger rear sprocket, the chain will rub in the front Inner cable

derailleur plate, producing a characteristic noise. When and cover it with the outer guide. Now cut the outer

guide to the length of the handlebar, and tape it Outer stopper

this happens, press lever F b lightly (to the point where

it clicks); this causes the front derailleur to temporarily in place. 1. Install the outer stopper to the down tube.

Outer guide

move slightly towards the smaller Direct mount seat (M5) R

chainwheel, thereby eliminating Caution on operation Outer stopper

the noise.

Lever Fb will also move when lever F a is operated, Installation bolt Do not disassemble any further as reassembly

Note the markings:

but be careful not to apply pressure to lever Fb. may not be possible. R : for right

One Holland, Irvine, California 92618, U.S.A. Phone: +1-949-951-5003 L : for left

Similarly be careful not to press lever F a when Tape Outer casing

operating lever Fb . Gears will not shift when both 3mm Allen key

Be sure to regrease.

Grease

Industrieweg 24, 8071 CT Nunspeet, The Netherlands Phone: +31-341-272222 Chain position Movement of the levers are pressed simultaneously.

front derailleur

Wipe a little rubbing alcohol

3-77 Oimatsu-cho, Sakai-ku, Sakai-shi, Osaka 590-8577, Japan Be sure to read these service instructions in conjunction with

inside the bracket cover to

These service instructions are printed on recycled paper. the service instructions for the FD-6500 / FD-6503 / Tightening torque:

Please note: specifications are subject to change for improvement without notice. (English)

FD-5500 / FD-5501 / FD-5503 / FD-5504 before use.

make installation easier.

Apr. 2007 by Shimano Inc. XBC SZK Printed in Japan. 6. Finally, wrap the handlebar with the finish tape. 1.5 - 2 Nm {13 - 18 in. lbs.}

Вам также может понравиться

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- Core ValuesДокумент1 страницаCore ValuesIan Abel AntiverosОценок пока нет

- Aleutia Solar Container ClassroomДокумент67 страницAleutia Solar Container ClassroomaleutiaОценок пока нет

- B I o G R A P H yДокумент17 страницB I o G R A P H yRizqia FitriОценок пока нет

- Latched, Flip-Flops, and TimersДокумент36 страницLatched, Flip-Flops, and TimersMuhammad Umair AslamОценок пока нет

- Perancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratДокумент8 страницPerancangan Crushing Plant Batu Andesit Di PT Nurmuda Cahaya Desa Batujajar Timur Kecamatan Batujajar Kabupaten Bandung Barat Provinsi Jawa BaratSutan AdityaОценок пока нет

- 50114a Isolemfi 50114a MonoДокумент2 страницы50114a Isolemfi 50114a MonoUsama AwadОценок пока нет

- PC Model Answer Paper Winter 2016Документ27 страницPC Model Answer Paper Winter 2016Deepak VermaОценок пока нет

- WBДокумент59 страницWBsahil.singhОценок пока нет

- Toeic: Check Your English Vocabulary ForДокумент41 страницаToeic: Check Your English Vocabulary ForEva Ibáñez RamosОценок пока нет

- Julia Dito ResumeДокумент3 страницыJulia Dito Resumeapi-253713289Оценок пока нет

- Sem4 Complete FileДокумент42 страницыSem4 Complete Fileghufra baqiОценок пока нет

- 1 in 8.5 60KG PSC Sleepers TurnoutДокумент9 страниц1 in 8.5 60KG PSC Sleepers Turnoutrailway maintenanceОценок пока нет

- Dwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFДокумент35 страницDwnload Full Principles of Economics 7th Edition Frank Solutions Manual PDFmirthafoucault100% (8)

- Safety Procedures in Using Hand Tools and EquipmentДокумент12 страницSafety Procedures in Using Hand Tools and EquipmentJan IcejimenezОценок пока нет

- HatfieldДокумент33 страницыHatfieldAlex ForrestОценок пока нет

- Cummin C1100 Fuel System Flow DiagramДокумент8 страницCummin C1100 Fuel System Flow DiagramDaniel KrismantoroОценок пока нет

- WAQF Podium Design Presentation 16 April 2018Документ23 страницыWAQF Podium Design Presentation 16 April 2018hoodqy99Оценок пока нет

- Gas Dynamics and Jet Propulsion 2marksДокумент15 страницGas Dynamics and Jet Propulsion 2marksAbdul rahumanОценок пока нет

- Model 255 Aerosol Generator (Metone)Документ20 страницModel 255 Aerosol Generator (Metone)Ali RizviОценок пока нет

- Mechanical Production Engineer Samphhhhhle ResumeДокумент2 страницыMechanical Production Engineer Samphhhhhle ResumeAnirban MazumdarОценок пока нет

- Technology Based Project: Special Track 1)Документ14 страницTechnology Based Project: Special Track 1)Kim ChiquilloОценок пока нет

- Injections Quiz 2Документ6 страницInjections Quiz 2Allysa MacalinoОценок пока нет

- BSC HTM - TourismДокумент4 страницыBSC HTM - Tourismjaydaman08Оценок пока нет

- Economic Review English 17-18Документ239 страницEconomic Review English 17-18Shashank SinghОценок пока нет

- LM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorДокумент21 страницаLM2576/LM2576HV Series Simple Switcher 3A Step-Down Voltage RegulatorcgmannerheimОценок пока нет

- Module 2 MANA ECON PDFДокумент5 страницModule 2 MANA ECON PDFMeian De JesusОценок пока нет

- Epson Stylus Pro 7900/9900: Printer GuideДокумент208 страницEpson Stylus Pro 7900/9900: Printer GuideJamesОценок пока нет

- Progressive Muscle RelaxationДокумент4 страницыProgressive Muscle RelaxationEstéphany Rodrigues ZanonatoОценок пока нет

- Wholesale Terminal Markets - Relocation and RedevelopmentДокумент30 страницWholesale Terminal Markets - Relocation and RedevelopmentNeha Bhusri100% (1)

- Contents EEMUA Publication 190 Edition1 May 2015Документ4 страницыContents EEMUA Publication 190 Edition1 May 2015Aditya JainОценок пока нет