Академический Документы

Профессиональный Документы

Культура Документы

Tabela Metais Shigley

Загружено:

Clair FrighettoАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tabela Metais Shigley

Загружено:

Clair FrighettoАвторское право:

Доступные форматы

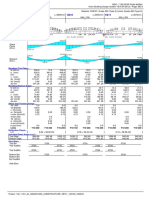

1046

Table A24

Mechanical Properties of Three Non-Steel Metals

(a) Typical Properties of Gray Cast Iron

[The American Society for Testing and Materials (ASTM) numbering system for gray cast iron is such that the numbers correspond to the minimum

tensile strength in kpsi. Thus an ASTM No. 20 cast iron has a minimum tensile strength of 20 kpsi. Note particularly that the tabulations are

typical of several heats.]

Fatigue

Shear Stress-

Tensile Compressive Modulus Modulus of Endurance Brinell Concentration

ASTM Strength Strength of Rupture Elasticity, Mpsi Limit* Hardness Factor

Number Sut, kpsi Suc, kpsi Ssu, kpsi Tension Torsion Se, kpsi HB Kf

20 22 83 26 9.614 3.95.6 10 156 1.00

25 26 97 32 11.514.8 4.66.0 11.5 174 1.05

30 31 109 40 1316.4 5.26.6 14 201 1.10

35 36.5 124 48.5 14.517.2 5.86.9 16 212 1.15

40 42.5 140 57 1620 6.47.8 18.5 235 1.25

50 52.5 164 73 18.822.8 7.28.0 21.5 262 1.35

60 62.5 187.5 88.5 20.423.5 7.88.5 24.5 302 1.50

*Polished or machined specimens.

The modulus of elasticity of cast iron in compression corresponds closely to the upper value in the range given for tension and is a more constant value than that for tension.

Table A24

Mechanical Properties of Three Non-Steel Metals (Continued)

(b) Mechanical Properties of Some Aluminum Alloys

[These are typical properties for sizes of about 21 in; similar properties can be obtained by using proper purchase

specifications. The values given for fatigue strength correspond to 50(107) cycles of completely reversed stress.

Alluminum alloys do not have an endurance limit. Yield strengths were obtained by the 0.2 percent offset method.]

Aluminum Strength Elongation Brinell

Association Yield, Sy, Tensile, Su, Fatigue, Sf, in 2 in, Hardness

Number Temper MPa (kpsi) MPa (kpsi) MPa (kpsi) % HB

Wrought:

2017 O 70 (10) 179 (26) 90 (13) 22 45

2024 O 76 (11) 186 (27) 90 (13) 22 47

T3 345 (50) 482 (70) 138 (20) 16 120

3003 H12 117 (17) 131 (19) 55 (8) 20 35

H16 165 (24) 179 (26) 65 (9.5) 14 47

3004 H34 186 (27) 234 (34) 103 (15) 12 63

H38 234 (34) 276 (40) 110 (16) 6 77

5052 H32 186 (27) 234 (34) 117 (17) 18 62

H36 234 (34) 269 (39) 124 (18) 10 74

Cast:

319.0* T6 165 (24) 248 (36) 69 (10) 2.0 80

333.0 T5 172 (25) 234 (34) 83 (12) 1.0 100

T6 207 (30) 289 (42) 103 (15) 1.5 105

335.0* T6 172 (25) 241 (35) 62 (9) 3.0 80

T7 248 (36) 262 (38) 62 (9) 0.5 85

*Sand casting.

Permanent-mold casting.

(c) Mechanical Properties of Some Titanium Alloys

Yield, Sy Strength Elongation Hardness

(0.2% offset) Tensile, Sut in 2 in, (Brinell or

Titanium Alloy Condition MPa (kpsi) MPa (kpsi) % Rockwell)

Ti-35A Annealed 210 (30) 275 (40) 30 135 HB

Ti-50A Annealed 310 (45) 380 (55) 25 215 HB

Ti-0.2 Pd Annealed 280 (40) 340 (50) 28 200 HB

Ti-5 Al-2.5 Sn Annealed 760 (110) 790 (115) 16 36 HRC

Ti-8 Al-1 Mo-1 V Annealed 900 (130) 965 (140) 15 39 HRC

Ti-6 Al-6 V-2 Sn Annealed 970 (140) 1030 (150) 14 38 HRC

Ti-6Al-4V Annealed 830 (120) 900 (130) 14 36 HRC

Ti-13 V-11 Cr-3 Al Sol. 1 aging 1207 (175) 1276 (185) 8 40 HRC

Commercially pure alpha titanium.

1047

Вам также может понравиться

- Tabel 8.1Документ1 страницаTabel 8.1topan hidayatОценок пока нет

- Data BookДокумент71 страницаData BookRi ŚhiОценок пока нет

- ZN Alloy PropertiesДокумент1 страницаZN Alloy PropertiesTien VuОценок пока нет

- 01f Hyundai Supercored 71H Data Sheet 2022Документ2 страницы01f Hyundai Supercored 71H Data Sheet 2022DHANEESH VELLILAPULLIОценок пока нет

- SF-71 en EngДокумент2 страницыSF-71 en EngbvbarcОценок пока нет

- 21 - Khairunnisa SalsabilaДокумент8 страниц21 - Khairunnisa SalsabilaAsa SalsaОценок пока нет

- Hoja Tecnica Varillas Has Super - Astm A193 - Grado B7Документ2 страницыHoja Tecnica Varillas Has Super - Astm A193 - Grado B7Mark AovОценок пока нет

- Zee Section Properties & Design Capacities (AISI-1996)Документ3 страницыZee Section Properties & Design Capacities (AISI-1996)Adam MillerОценок пока нет

- Flange BCD & Bolt C/S Area For Flange CheckДокумент4 страницыFlange BCD & Bolt C/S Area For Flange CheckAnirban ChatterjeeОценок пока нет

- Weld Consumables DetailsДокумент8 страницWeld Consumables Details9440864459Оценок пока нет

- Chain Din766 PDFДокумент5 страницChain Din766 PDFMiguelRagas100% (1)

- CLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)Документ4 страницыCLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)PeterWayОценок пока нет

- Katalog Komposisi Lengkap New VersionДокумент8 страницKatalog Komposisi Lengkap New VersionSontani PurnamaОценок пока нет

- Safe Gard Performance 2017Документ2 страницыSafe Gard Performance 2017LОценок пока нет

- MK GEL v8 r1Документ2 страницыMK GEL v8 r1Jagan VenkateshОценок пока нет

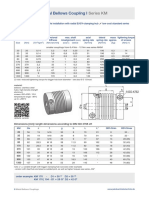

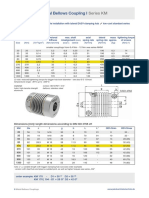

- Metal Bellows Coupling I: Series KMДокумент1 страницаMetal Bellows Coupling I: Series KMIsmael RiosОценок пока нет

- ESAB Dual Shield 7100 UltraДокумент3 страницыESAB Dual Shield 7100 UltrahaldunОценок пока нет

- Aberdare Low Voltage Cables SectionДокумент5 страницAberdare Low Voltage Cables Sectionorkuma shiaondoОценок пока нет

- Aberdare Low Voltage Cables Section PDFДокумент5 страницAberdare Low Voltage Cables Section PDFPercy GoitsemangОценок пока нет

- Ilovepdf MergedДокумент23 страницыIlovepdf MergedAhmad AdnanОценок пока нет

- Weight Calculation FlangesДокумент16 страницWeight Calculation FlangesshazanОценок пока нет

- Designacion: Propiedades Mecanicas Aceros Aceros Galvanizados Astm A653Документ1 страницаDesignacion: Propiedades Mecanicas Aceros Aceros Galvanizados Astm A653karob87Оценок пока нет

- Correction To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsДокумент2 страницыCorrection To SCI-P202, "Blue Book", 6th Edition Higher Grade HSFG BoltsTimОценок пока нет

- Torque ValuesДокумент1 страницаTorque ValuesfadhlidzilОценок пока нет

- ASTC RailingДокумент44 страницыASTC RailingSAGAR BARAVKARОценок пока нет

- Conductor Construction For Insulated Cables and WiresДокумент4 страницыConductor Construction For Insulated Cables and Wires陆华林Оценок пока нет

- Datasheet KMДокумент1 страницаDatasheet KMAlexander DíazОценок пока нет

- Cable ELEXOR BT-MTДокумент4 страницыCable ELEXOR BT-MTespiripitiberto espiripitiflauticoОценок пока нет

- Fujitsu Troubleshooting Guide PDFДокумент6 страницFujitsu Troubleshooting Guide PDFИвайло ГайдарскиОценок пока нет

- 2wt Arita Ci Bfly VLV Uni Flanged MalaysiaДокумент2 страницы2wt Arita Ci Bfly VLV Uni Flanged MalaysiaannaomarОценок пока нет

- Combined Bearing/Freewheel - CSK - CSK..2RS - Stieber ClutchДокумент2 страницыCombined Bearing/Freewheel - CSK - CSK..2RS - Stieber ClutchborischechenkoОценок пока нет

- CLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)Документ4 страницыCLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)PeterWayОценок пока нет

- ReinforcementДокумент34 страницыReinforcementKristle Jane VidadОценок пока нет

- Aluminum Conductors Steel Reinforced (Acsr) : Conductor Data SheetДокумент2 страницыAluminum Conductors Steel Reinforced (Acsr) : Conductor Data Sheetmarab12Оценок пока нет

- Stieber CSK35-M-C5Документ2 страницыStieber CSK35-M-C5Johnatas GamaОценок пока нет

- 09 DirectshearДокумент4 страницы09 DirectshearSAFE SERVICES LHRОценок пока нет

- KS Jis (Ok)Документ26 страницKS Jis (Ok)Tran Anh TuanОценок пока нет

- Crosby G-209R ROV ShackleДокумент1 страницаCrosby G-209R ROV ShacklenatОценок пока нет

- Bar Properties: Dywidag Threadbar Reinforcing Steel ASTM A615 (Grade 75 & 80)Документ2 страницыBar Properties: Dywidag Threadbar Reinforcing Steel ASTM A615 (Grade 75 & 80)Zdravko VidakovicОценок пока нет

- Basic Data For Aluminium Conductors Steel Reinforced (Acsr) As Per Is 398 (PART - II) : 1996Документ2 страницыBasic Data For Aluminium Conductors Steel Reinforced (Acsr) As Per Is 398 (PART - II) : 1996anuragpugaliaОценок пока нет

- Butterfly Valve DatasheetДокумент2 страницыButterfly Valve DatasheetKanthan DevanОценок пока нет

- Table A-20 AND A-21Документ3 страницыTable A-20 AND A-21mohamed.hassan031Оценок пока нет

- 02 Guide RCCP p16-p54 Dimensional CharacteristicsДокумент41 страница02 Guide RCCP p16-p54 Dimensional CharacteristicsTonny SuakОценок пока нет

- CHARACTERISTICS OF COMPACT STRANDED CONDUCTORS IN ALUMINIUM ALLOY (AAAC Compacted)Документ2 страницыCHARACTERISTICS OF COMPACT STRANDED CONDUCTORS IN ALUMINIUM ALLOY (AAAC Compacted)ManuelОценок пока нет

- WeldingДокумент1 страницаWeldingNОценок пока нет

- Material BreakdownДокумент5 страницMaterial BreakdownjaymarОценок пока нет

- SEW Brak Coil ResistancesДокумент8 страницSEW Brak Coil ResistancesVictorОценок пока нет

- Stieber Type Csk-Csk2rs-EnДокумент2 страницыStieber Type Csk-Csk2rs-Ena04205Оценок пока нет

- I - Steel Butt - Welding Pipe FittingsДокумент26 страницI - Steel Butt - Welding Pipe FittingstruongОценок пока нет

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Документ4 страницыCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayОценок пока нет

- Catalog Standard Motor LTS PDFДокумент20 страницCatalog Standard Motor LTS PDFYogesh BadheОценок пока нет

- Codo 90º Codo 180º: Asme B16.9 Asme B16.9Документ3 страницыCodo 90º Codo 180º: Asme B16.9 Asme B16.9Corona CoronitaОценок пока нет

- BEAM DESIGN - As Per DTAДокумент4 страницыBEAM DESIGN - As Per DTAmuhammed sabir v aОценок пока нет

- Parameters For U-Type Steel GB/T4697-2008Документ2 страницыParameters For U-Type Steel GB/T4697-2008Luong Bui DangОценок пока нет

- Aluminum Conductors Steel Reinforced (Acsr) : Conductor Data SheetДокумент13 страницAluminum Conductors Steel Reinforced (Acsr) : Conductor Data SheetHope DandaraОценок пока нет

- Calcul GrinziДокумент107 страницCalcul GrinziAndriana DeacuОценок пока нет

- AcsrДокумент1 страницаAcsrtongaiОценок пока нет

- Tabela Aço ShigleyДокумент3 страницыTabela Aço ShigleyClair FrighettoОценок пока нет

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- The Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyОт EverandThe Uniqueness of Biological Materials: International Series of Monographs in Pure and Applied Biology: ZoologyОценок пока нет

- Anodizing AluminumДокумент7 страницAnodizing AluminumyunitaparerОценок пока нет

- 1 An Introduction To Project Management: 2007 Dennis Lock and His Licensors. All Rights ReservedДокумент32 страницы1 An Introduction To Project Management: 2007 Dennis Lock and His Licensors. All Rights ReservedOmar Ahmed ElkhalilОценок пока нет

- Anu DR Salim IJBARR Vol 1 Issue 11 Sept 2015 313 317 PDFДокумент6 страницAnu DR Salim IJBARR Vol 1 Issue 11 Sept 2015 313 317 PDFRutwik JoshiОценок пока нет

- Rumusan 3Документ42 страницыRumusan 3Den limboongОценок пока нет

- Technical Data Sheet F Peng 201504Документ1 страницаTechnical Data Sheet F Peng 201504Anonymous VRspXsmОценок пока нет

- ZONE 15 - Super Markets & Grocery PDFДокумент5 страницZONE 15 - Super Markets & Grocery PDFKaushik RaviОценок пока нет

- Automated Guided VehicleДокумент12 страницAutomated Guided VehiclePedro José SuárezОценок пока нет

- Elastomer For Heavy Engineering ApplicationsДокумент23 страницыElastomer For Heavy Engineering Applicationsalwil144548Оценок пока нет

- Types of Cargo: and A Little GrammarДокумент43 страницыTypes of Cargo: and A Little GrammarSariОценок пока нет

- Cat LogisticsДокумент6 страницCat LogisticsSai VasudevanОценок пока нет

- Short Course Mechanical-TestingДокумент35 страницShort Course Mechanical-TestingAndrei CostacheОценок пока нет

- 3 and 4 Point Bend Fixtures, CortestДокумент2 страницы3 and 4 Point Bend Fixtures, CortestzhiqianxuОценок пока нет

- Inspection and Test ProcedureДокумент8 страницInspection and Test Proceduregaehdd1100% (1)

- Voltas Case StudyДокумент26 страницVoltas Case StudyVarsha MalviyaОценок пока нет

- Proses StrategiДокумент39 страницProses StrategiMaz IfikОценок пока нет

- Skl-Wp2: Water-Washable Visible PenetrantДокумент3 страницыSkl-Wp2: Water-Washable Visible PenetrantRussell ShacklefordОценок пока нет

- Ultra Thin WhitetoppingДокумент36 страницUltra Thin WhitetoppingAnil Kumsr T B100% (1)

- Speciality Graphite Materials: FOR Continuous CastingДокумент6 страницSpeciality Graphite Materials: FOR Continuous Castingramadan slimОценок пока нет

- Milk Supply Chain of Visakha DairyДокумент30 страницMilk Supply Chain of Visakha DairyHavish SrinivasulaОценок пока нет

- 3D Printing Seminar REPORT-srijanДокумент26 страниц3D Printing Seminar REPORT-srijanSrijan UpadhyayОценок пока нет

- Reebaklens RR: Constructive SolutionsДокумент2 страницыReebaklens RR: Constructive Solutionssyed AffanОценок пока нет

- GRE PipeДокумент4 страницыGRE PipeMohamed GuezguezОценок пока нет

- Economic Structure of IndiaДокумент22 страницыEconomic Structure of IndiaShreedhar DeshmukhОценок пока нет

- Kaowool Paper 1260Документ2 страницыKaowool Paper 1260praveentienОценок пока нет

- What Is Plastic?: Manufacturing Processes For PlasticsДокумент2 страницыWhat Is Plastic?: Manufacturing Processes For PlasticsJesse Jones SeraspeОценок пока нет

- Types of Adhesives: Structural Adhesives Refer To Relatively Strong Adhesives That Are Normally Used WellДокумент2 страницыTypes of Adhesives: Structural Adhesives Refer To Relatively Strong Adhesives That Are Normally Used WellmedanonakamaОценок пока нет

- 4 3answersДокумент39 страниц4 3answersjagcha64100% (1)

- Amplify Io 3701Документ2 страницыAmplify Io 3701Julio GarcíaОценок пока нет

- ERP-A Manufacturing PerspectiveДокумент16 страницERP-A Manufacturing PerspectivemsulgadleОценок пока нет

- The Performance Meets The Promise: Vectra Series Models GL & XLДокумент12 страницThe Performance Meets The Promise: Vectra Series Models GL & XLNicolás Villarin100% (1)