Академический Документы

Профессиональный Документы

Культура Документы

Graphite Heat Exchangers

Загружено:

Justin EvansАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Graphite Heat Exchangers

Загружено:

Justin EvansАвторское право:

Доступные форматы

GBH Enterprises, Ltd.

Process Engineering Guide:

GBHE-PEG-HEA-514

Graphite Heat Exchangers

Information contained in this publication or as otherwise supplied to Users is

believed to be accurate and correct at time of going to press, and is given in

good faith, but it is for the User to satisfy itself of the suitability of the information

for its own particular purpose. GBHE gives no warranty as to the fitness of this

information for any particular purpose and any implied warranty or condition

(statutory or otherwise) is excluded except to the extent that exclusion is

prevented by law. GBHE accepts no liability resulting from reliance on this

information. Freedom under Patent, Copyright and Designs cannot be assumed.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Process Engineering Guide: Graphite Heat Exchangers

CONTENTS SECTION

0 INTRODUCTION/PURPOSE 2

1 SCOPE 2

2 FIELD OF APPLICATION 2

3 DEFINITIONS 2

4 TYPES OF GRAPHITE 2

4.1 Phenolic Resin Impregnation 2

4.2 Furane Resin Impregnation 2

4.3 PTFE Impregnation 2

4.4 Carbon Impregnation 3

5 TYPES OF EXCHANGER 3

5.1 Shell and Tube 3

5.2 Cubic Block Exchangers 3

5.3 Cylindrical Graphite Block Exchangers 4

6 LIMITATIONS ON USE 4

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

7 COSTS OF GRAPHITE EXCHANGERS 6

8 RATING OF GRAPHITE EXCHANGERS 6

8.1 Rating Cylindrical Block Exchangers 6

8.2 Rating Cubic Block Exchangers 9

9 MANUFACTURERS OF GRAPHITE EXCHANGERS 10

10 REFERENCES 10

FIGURES

1 SPLIT VIEW OF A CUBIC BLOCK HEAT EXCHANGER 3

2 TYPICAL BLOCK FROM A CYLINDRICAL GRAPHITE

BLOCK HEAT EXCHANGER 5

3 GENERAL ARRANGEMENT OF A CYLINDRICAL BLOCK

GRAPHITE HEAT EXCHANGER 5

4 APPROXIMATE COSTS FOR GRAPHITE HEAT

EXCHANGERS 7

DOCUMENTS REFERRED TO IN THIS PROCESS

ENGINEERING GUIDE 11

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

0 INTRODUCTION/PURPOSE

This guide is one of a series of Heat Transfer Process Engineering Guides

produced for GBH Enterprises.

1 SCOPE

This guide discusses the material used for exchanger fabrication, describes the

types of unit available and gives guidance on how to rate thermal performance of

such units.

2 FIELD OF APPLICATION

This Guide applies to process engineers in GBH Enterprises worldwide, who

may be involved in the specification, design, rating or operation of heat transfer

equipment.

3 DEFINITIONS

For the purposes of this Guide, the following definitions apply:

Heat Transfer and Fluid Flow A cooperative research organization, with

Service (HTFS) headquarters in the UK, involved in

research into the fundamentals of heat

transfer and two phase flow and the production

of design guides and computer programs for

the design of industrial heat exchange

equipment.

4 TYPES OF GRAPHITE

Graphite, having a high resistance to corrosion and good thermal conductivity, is

a suitable material of construction for heat exchangers, particularly for highly

corrosive duties. The artificial graphite used for heat exchangers is manufactured

from a mixture of coke and pitch, which is first cured at 1000C and subsequently

recrystallized at 3000C.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Since the volatile binders have been removed during the high temperature

treatments, the graphite produced is permeable. To overcome this, a variety of

impregnations are used. The choice of impregnation

should be decided upon after consultation with a Materials Scientist, but for initial

guidance the types are given below. Note: not all manufacturers offer all of these

types.

4.1 Phenolic Resin Impregnation

The manufacturers claim this is suitable for up to 165-185C, depending on the

residual permeability of the starting graphite. The resin will in general have a

lower chemical resistance than the graphite. This may lead to a progressive

leaching out of the resin, eventually resulting in the material becoming

permeable.

4.2 Furane Resin Impregnation

This has a similar operational range to phenolic resin. It is not usually specified

by GBH Enterprises, the phenolic impregnation being regarded as standard.

4.3 PTFE Impregnation

This offers both higher corrosion resistance than the resins, and a higher

operating temperature (up to 230C), but at a higher price, typically twice that of

resin impregnated graphite. Note, however, that the PTFE used for impregnation

is a relatively low molecular weight polymer and can be prone to leaching in

some conditions. PTFE impregnated graphite also has a lower mechanical

strength than the resin impregnated material.

4.4 Carbon Impregnation

This is the ultimate in corrosion resistance and operating temperature (up to

400C in oxidizing environments, and 1000C in reducing conditions) but costs

about three times the price of a resin impregnated exchanger.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

5 TYPES OF EXCHANGER

There are three basic types of heat exchanger using graphite as a material of

construction.

5.1 Shell and Tube

These units are similar in general form to conventional shell and tube

exchangers, with tubes and tubesheets fabricated from graphite. The mechanical

properties of graphite require careful design of the tube-tubesheet joints and

influence the dimensions, but the manufacturers have evolved designs which,

treated with reasonable care, can give good service. It is possible to re-tube

the units.

Graphite tubular exchangers have been built with surface areas over 1000 m2

and tube lengths of 6.7 m (22 feet), although one manufacturer states that the

maximum length of their tubes without a joint is 4 m. Standard designs have shell

diameters between 200 to 1880 mm (8" to 74"). Tube diameters typically range

from 25 x 16 mm (1" x 5/8") up to 51 x 38 mm (2" x 1 ").

The design pressure of the exchangers is limited to 6 bar on both sides. This

form of construction is usually the most expensive per m2 of heat transfer area

(see Clause 7).

5.2 Cubic Block Exchangers

These exchangers consist of single cuboid blocks of graphite, (in the case of

some manufacturers, built up from thinner layers cemented together),

compressed between cast iron clamping plates, see Figure 1. There is a series of

parallel holes or slots between opposing faces of the block for the passage of

process and service fluids, the rows of holes alternating through the block.

Headers are bolted to four faces of the block for the inlet and outlet of the

fluids. The headers can be lined with graphite or PTFE. A variety of multi-pass

arrangements can be accommodated by incorporating partitions on the inside of

the headers.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

FIGURE 1 SPLIT VIEW OF A CUBIC BLOCK HEAT EXCHANGER

The exchangers come in standard size ranges. Two European manufacturers

produce two ranges which are essentially identical between the manufacturers.

In one of these, usually designated type 'A', both sets of holes are cylindrical,

with a diameter of 9.5 mm (3/8"). The surface areas on both sides are equal, the

largest units having 14 m2 of heat transfer surface. In type 'B' blocks, the service

side is similar to the type A units, but the process side consists of a series of

slots 9.5 mm by 3.2 mm (3/8" by 1/8"). This results in a surface area for that

side almost twice that of the other side, with a maximum heat transfer surface of

28 m2. The choice of which type to use will be governed by the heat transfer and

pressure drop requirements of the particular duty.

Manufacturer A also offer the designs developed by a leading USA

manufacturer. These have process holes of 5/32" and service holes of 3/8" giving

process areas of up to 93 m2 (1000 ft2) with service areas of half the process

area.

The maximum permissible operating pressure of a cubic block is usually 5 bar g.

Cubic block exchangers are significantly more compact than graphite shell and

tube units with the same heat transfer surface. They are the cheapest graphite

exchanger per m2 of heat transfer area, but are limited in maximum area (see

Clause 7). They are commonly used in the fine chemicals and pharmaceutical

industries, where their resistance to a wide range of chemicals makes them

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

attractive on multi-product plants. The Works generally try to standardize on a

limited range of sizes to reduce spares holdings and allow modular

construction.

5.3 Cylindrical Graphite Block Exchangers

These units are built up in modular fashion from standard cylindrical graphite

blocks. The blocks are mounted inside a steel shell. The process fluid normally

flows through a series of holes drilled longitudinally down the blocks, successive

blocks being arranged so that the holes line up. The 'service' fluid flows through a

second set of holes or slots, drilled at right angles to, and passing between,

neighboring rows of process holes. PTFE gaskets between the blocks prevent

cross contamination. Baffles between the blocks and the shell allow several

cross passes for the service fluid. If the 'service' fluid is also corrosive, the shell

may be lined with PTFE. More than one process pass is possible. The

mechanical design, in which the blocks are held in compression by spring loaded

tie rods, requires these units to be mounted vertically. See Figures 2 and 3.

Hole sizes typically range between 8 mm and 35 mm. Blocks are available in

diameters up to 1.8 m. The largest units may have up to 1000 m2 of surface,

making them comparable with shell and tube units. The design pressure for the

process side is typically 5-6 bar; for the service side 8 bar is normal.

6 LIMITATIONS ON USE

Graphite is a relatively weak material, which can be damaged by mechanical

shock. However, treated with reasonable care, this should not cause problems.

The shell and tube types are probably the least sturdy, although several of these

units gave many years of satisfactory service on several European plants, their

life being limited by gradual leaching of the resin impregnation rather than

mechanical failure. On the other hand, a large shell and tube unit on one site

location in Europe suffered from failure early in its life. Although there was some

suspicion that this may have been damaged during installation, the unit was

replaced by a cylindrical block type.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

FIGURE 2 TYPICAL BLOCK FROM A CYLINDRICAL GRAPHITE

BLOCK HEAT EXCHANGER

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

FIGURE 3 GENERAL ARRANGEMENT OF A CYLINDRICAL BLOCK

GRAPHITE HEAT EXCHANGER

Because of the brittle nature of the graphite, care must be taken in plant design

to avoid placing high loads onto the branches of the exchangers. It may also be

necessary to provide some isolation to prevent vibrations from other equipment

being transmitted to the exchanger.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Manufacturer A states that the block types are able to handle differential

temperatures of 100 -120C. Shell and tube units are more limited. As a result of

its high conductivity, graphite has a good tolerance to thermal shock. However,

this information is for guidance only, and the manufacturer should be consulted in

particular cases.

7 COSTS OF GRAPHITE EXCHANGERS

It is not possible to provide definitive statements on whether one type of

exchanger will be more expensive than another in general terms; each case has

to be taken on its merits. A comparison on the basis of pounds per unit area will

be misleading unless the achieved heat transfer coefficients are similar. Some

duties fit better than others into a particular exchanger type. Moreover, the

installed cost will be several times the main plant item cost, and installation

factors may differ with different exchanger types.

Figure 4 shows some data produced for the MPI cost of several exchanger types

as a function of area. The types covered are graphite tubes in a carbon steel

shell, cubic blocks with phenolic resin impregnation and cubic blocks with PTFE

impregnation. Also shown for comparison are data for shell and tube exchangers

with all carbon steel construction and with stainless steel tubes in a carbon steel

shell. It can be seen that graphite is comparable in cost with the stainless steel

units.

Note:

These costs are for guidance only. Manufacturers should be approached for firm

data.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

8 RATING OF GRAPHITE EXCHANGERS

The manufacturers of graphite exchangers normally offer a range of standard

sizes. Many (but not all) of them have a thermal design capability. However,

there is still the need for GBH Enterprises to check their designs, particularly for

difficult duties such as multi-component condensation.

Graphite shell and tube units offer no thermal rating problem; the normal shell

and tube programs (commercially available) can be used with the tube

dimensions supplied by the manufacturers. Manufacturer A quote the thermal

conductivity of the graphite in the radial direction (without the resin film) as 35-64

W/m.K.

Block exchangers cannot be modeled so easily with standard computer

programs. If the fluids handled are both single phase, hand calculations should

present no real problem, as the individual heat transfer coefficients can be

estimated using modified versions of the Sieder & Tate equations (see below).

For modeling a condenser, however, hand calculations can be particularly

difficult. Nonetheless, it is possible to use normal shell and tube programs to

model the performance of block exchangers, as outlined below.

8.1 Rating Cylindrical Block Exchangers

In a cylindrical block exchanger, for most duties, the process fluid will be flowing

through the longitudinal holes, which can be regarded as the tubes of a

conventional exchanger. Shell and tube computer program methods should

apply.

The service side geometry is different from a shell and tube unit, so the program

methods for calculating shell side coefficient do not apply. Most shell and tube

rating programs, however, allow the user to specify the heat transfer coefficient

for either side. Provided that this coefficient remains reasonably constant, this

should allow the program to predict correctly the

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

FIGURE 4 APPROXIMATE COSTS FOR GRAPHITE HEAT EXCHANGERS

overall performance. In many cases the service fluid will be a single phase liquid,

e.g. cooling water, so this is a reasonable supposition. If the service fluid is

condensing steam, although the coefficient will not be constant, it is likely not to

be controlling, so the actual value is not critical.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

The basic approach to the rating is as follows: (This method is based on that

given in Reference!1, modified to accommodate the use of standard shell and

tube programs.)

(a) Equate the tube count to the number of process holes in the block, and

the tube inside diameter to the hole diameter.

(b) Choose some nominal value for the tube wall thickness; 2 mm is

reasonable. This gives the equivalent tube outside diameter, which will be

used by the shell and tube program. Ideally, one should calculate an

equivalent ligament thickness, but as the thermal resistance of the

graphite ligament is low, (Reference 1 quotes a coefficient of 8700

W/m2.K), any errors introduced will be small.

(c) Estimate the service side coefficient. For a single phase fluid, the modified

Sieder-Tate equation given by Reference 1 should be used. Note that this

gives the transition Reynolds number for the service side of the block

between laminar and transition flow as only 300, compared with 2100 for

normal tubes, and between transition and turbulent as 3000, compared

with 10000.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

For condensing steam, the service resistance is unlikely to be critical.

10000 W/m2.K is a reasonable value.

If the service side channels are slots rather than holes, see the paragraph

on 'B' type cubic blocks below.

(d) Correct this coefficient by the ratio of the actual service side heat transfer

area to the area based on the equivalent tube od. given above. Use this

corrected coefficient in the shell and tube program.

(e) The service pressure drop given by the shell and tube program will not be

relevant. For an exchanger from Manufacturer A, the service pressure

drop can be estimated using the method given in Reference 1.

The above approach assumes that you have details of the geometry of the

blocks. If a manufacturer has been approached for a design, they should be

asked to supply the necessary data. If you are doing a preliminary rating based

on manufacturer's literature, not all data may be available. It may be necessary to

estimate some items from others.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

8.1.1 Commercially Available Programs

The method outlined above for calculating service side coefficients and

pressure drops is typically incorporated into commercially available

computer programs, including manufacturers published data, on their

standard blocks.

8.2 Rating Cubic Block Exchangers

For the type 'A' blocks, where both process and service sides have cylindrical

holes, a similar approach to the cylindrical block method described above can be

used. However, the effects of the pass arrangements in the block have to be

considered.

A unit with only one pass on each side is operating in cross flow, whereas most

of the shell and tube programs assume co- or counter current flow. Commercially

available programs can be used to model X shells.

For a multi-pass arrangement on both sides, it is probably best to consider the

unit as a single pass with the tube length equal to the path length. This ignores

the effects of the turn-round regions.

For a type 'B' unit, the problem is slightly more complex because of the non-

circular nature of the slots. An equivalent (hydraulic mean) diameter approach is

necessary.

If the perimeter of a slot is P, its surface A and cross sectional area X, then the

equivalent diameter is:

A pipe of this diameter has a cross section Xe and surface area Ae given by:

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

If we use this hydraulic mean diameter with the number of tubes equated to the

number of slots, both the surface area and the mass flux will be incorrect.

However, if the ratio of the number of tubes in the shell and tube model to the

number of slots is changed such that:

then the shell and tube model will have the correct surface area and correct

mass flux.

For the standard slot geometry of the type 'B' cubic block,

The service side coefficient will need to be adjusted for the area ratio in a similar

manner to that for the cylindrical block.

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Refinery Process Stream Purification Refinery Process Catalysts Troubleshooting Refinery Process Catalyst Start-Up / Shutdown

Activation Reduction In-situ Ex-situ Sulfiding Specializing in Refinery Process Catalyst Performance Evaluation Heat & Mass

Balance Analysis Catalyst Remaining Life Determination Catalyst Deactivation Assessment Catalyst Performance

Characterization Refining & Gas Processing & Petrochemical Industries Catalysts / Process Technology - Hydrogen Catalysts /

Process Technology Ammonia Catalyst Process Technology - Methanol Catalysts / process Technology Petrochemicals

Specializing in the Development & Commercialization of New Technology in the Refining & Petrochemical Industries

Web Site: www.GBHEnterprises.com

Вам также может понравиться

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Sigma Phase in 309 Anchor RefractoryДокумент7 страницSigma Phase in 309 Anchor RefractoryJustin EvansОценок пока нет

- Safe Use of Plant EquipmentДокумент140 страницSafe Use of Plant EquipmentFrancisco M. RamosОценок пока нет

- JOB SAFETY ANALYSIS FOR WELDINGДокумент2 страницыJOB SAFETY ANALYSIS FOR WELDINGSravan Dasari100% (3)

- Technical Advice Sheet - 5 Dealing With Dampness in Old WallsДокумент10 страницTechnical Advice Sheet - 5 Dealing With Dampness in Old WallsLasha ShartavaОценок пока нет

- VW Touareg MaintenanceДокумент102 страницыVW Touareg MaintenanceNick PОценок пока нет

- Electrolysis PDFДокумент37 страницElectrolysis PDFHarini SridharanОценок пока нет

- AFV Modeller 97 2017-11-12 - SuperunitedkingdomДокумент67 страницAFV Modeller 97 2017-11-12 - Superunitedkingdomjoausmaximus100% (5)

- Foam Testing Options and AccessoriesДокумент8 страницFoam Testing Options and AccessoriesJustin EvansОценок пока нет

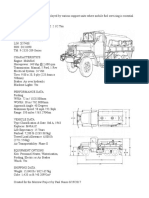

- M49A2CДокумент2 страницыM49A2CArmySGTОценок пока нет

- Asupu Nano BubblesДокумент10 страницAsupu Nano BubblesAgung50% (2)

- Kiln TroubleshootingДокумент36 страницKiln TroubleshootingJustin Evans92% (13)

- Completion TechniqueДокумент143 страницыCompletion TechniquenaefmubarakОценок пока нет

- Niessen, Walter R.-Combustion and Incineration Processes - Applications in Environmental Engineering, Fourth Edition-CRC Press (2010)Документ800 страницNiessen, Walter R.-Combustion and Incineration Processes - Applications in Environmental Engineering, Fourth Edition-CRC Press (2010)Mohamed Tarek KamarОценок пока нет

- Datasheet-Sandvik-Sx-En-V2021-11-05 11 - 37 Version 1Документ6 страницDatasheet-Sandvik-Sx-En-V2021-11-05 11 - 37 Version 1Justin EvansОценок пока нет

- Thermal Spray CoatingsДокумент13 страницThermal Spray CoatingsChan Shiaw SyanОценок пока нет

- Wordcom's WhistleblowerДокумент2 страницыWordcom's WhistleblowerJustin EvansОценок пока нет

- Angela Merkel Articles Rev1Документ11 страницAngela Merkel Articles Rev1Justin EvansОценок пока нет

- Hello GunaДокумент10 страницHello GunaMajed Abou AlkhirОценок пока нет

- Case 6Документ4 страницыCase 6Bujana BujanaОценок пока нет

- Victoria Chemical AДокумент41 страницаVictoria Chemical AJustin EvansОценок пока нет

- Worldwide Paper CaseДокумент11 страницWorldwide Paper CaseJustin EvansОценок пока нет

- Annual Report 2020 Parkson CentroДокумент160 страницAnnual Report 2020 Parkson CentroJustin EvansОценок пока нет

- Guna FIbresДокумент15 страницGuna FIbresJustin EvansОценок пока нет

- Guna FIbresДокумент15 страницGuna FIbresJustin EvansОценок пока нет

- Worldwide Paper CaseДокумент11 страницWorldwide Paper CaseJustin EvansОценок пока нет

- InteractionsДокумент24 страницыInteractionsSimona TocanieОценок пока нет

- Characterisation Lecture 1 - 2013Документ5 страницCharacterisation Lecture 1 - 2013Justin EvansОценок пока нет

- Sample Cert 350-LF2Документ1 страницаSample Cert 350-LF2Justin EvansОценок пока нет

- Rotary Dryer DrawingДокумент1 страницаRotary Dryer DrawingJustin EvansОценок пока нет

- MATS 10221 Lecture Handout 2011Документ82 страницыMATS 10221 Lecture Handout 2011Justin EvansОценок пока нет

- Vav Lab Room Airflow Lowdown On TurndownДокумент8 страницVav Lab Room Airflow Lowdown On TurndownJustin EvansОценок пока нет

- Basic Principles and Application of Electron Channeling in A Scanning Electron Microscope For Dislocation AnalysisДокумент8 страницBasic Principles and Application of Electron Channeling in A Scanning Electron Microscope For Dislocation AnalysisMichael AbereОценок пока нет

- A Summary PresentationДокумент6 страницA Summary PresentationJustin EvansОценок пока нет

- Inspection ReportДокумент58 страницInspection ReportJustin EvansОценок пока нет

- Hardness and EtchДокумент2 страницыHardness and EtchJustin EvansОценок пока нет

- Demolition Contractor Guide to Safe Concrete Demolition MethodsДокумент20 страницDemolition Contractor Guide to Safe Concrete Demolition MethodsjayadushОценок пока нет

- V410065 en US FactSheet Main 01Документ1 страницаV410065 en US FactSheet Main 01Janeth MendozaОценок пока нет

- Esquema Inverter FujiДокумент18 страницEsquema Inverter FujiRicardo Nicolau WerlangОценок пока нет

- Tower Signal BoqДокумент2 страницыTower Signal Boqrafael velardeОценок пока нет

- SRA166 210 01A BrochureДокумент2 страницыSRA166 210 01A BrochureXanti Zabala Da RosaОценок пока нет

- Catalog 64 5000 Series Subatmospheric Pressure Regulator Tescom en 5351134Документ4 страницыCatalog 64 5000 Series Subatmospheric Pressure Regulator Tescom en 5351134Titus PrizfelixОценок пока нет

- Fracture Mechanics Practical FileДокумент21 страницаFracture Mechanics Practical Filesubashish100% (1)

- 15 ASME Secc VIII Part ULT Alternative Rules For Pressure Vesse PDFДокумент14 страниц15 ASME Secc VIII Part ULT Alternative Rules For Pressure Vesse PDFTroxterPS3Оценок пока нет

- Design and Construction of Underground Metro InfrastructureДокумент225 страницDesign and Construction of Underground Metro InfrastructuredebapriyoОценок пока нет

- Keystone Better Mann CatalogДокумент12 страницKeystone Better Mann CatalogSpencer100% (1)

- Kast O Lite 30 LI Plus Mixing PDFДокумент2 страницыKast O Lite 30 LI Plus Mixing PDFLove NóОценок пока нет

- Discharger: Operating InstructionsДокумент18 страницDischarger: Operating InstructionsWaleed MouhammedОценок пока нет

- PDFДокумент123 страницыPDFPrakash WarrierОценок пока нет

- HydroComfort Product BrochureДокумент12 страницHydroComfort Product BrochureHydroComfort100% (1)

- Asme CCase 2091-2Документ2 страницыAsme CCase 2091-2ADAMJSRAOОценок пока нет

- GMK4115Документ28 страницGMK4115SeksiОценок пока нет

- CAT6 Modular Plug Installation GuideДокумент2 страницыCAT6 Modular Plug Installation GuideAndrés CisnerosОценок пока нет

- Heat Pump - SiUS341615E - Final PDFДокумент337 страницHeat Pump - SiUS341615E - Final PDFMurilo AquinoОценок пока нет

- Homemade RF Step AttenuatorДокумент8 страницHomemade RF Step Attenuatorngt881Оценок пока нет