Академический Документы

Профессиональный Документы

Культура Документы

TD Ac2 MB TCP en

Загружено:

Victor Soliz AvalosОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

TD Ac2 MB TCP en

Загружено:

Victor Soliz AvalosАвторское право:

Доступные форматы

AC 01.

2

Modbus TCP/IP

Technical data Actuator controls

General information

Actuator controls AC 01.2 for controlling multi-turn actuators of the SA/SAR .2 type range and part-turn actuators of the SQ/SQR .2 type range with

Modbus TCP/IP interface.

Features and functions

Power supply Standard voltages:

3-phase AC current 1-phase AC current

Voltages/frequencies Voltages/frequencies

Volt 110, 115, 220, 230,

380 400 415 440 460 480 500 Volt

120 240

Hz 50 50 50 60 60 60 50 Hz 60 50

Special voltages:

3-phase AC current 1-phase AC current

Voltages/frequencies Voltages/frequencies

Volt 220 230 240 525 575 575 600 660 690 Volt 208

Hz 50 50 50 50 50 60 60 50 50 Hz 60

Permissible variation of mains voltage: 10 %

Permissible variation of mains voltage: 30 % (option)

Permissible variation of mains frequency: 5 %

External supply of the electronics 24 V DC +20 %/15 %,

(option) Current consumption: Basic version approx. 250 mA, with options up to 500 mA

External power supply must have reinforced insulation against mains voltage in accordance with IEC 61010-1

and may only be supplied by a circuit limited to 150 VA in accordance with IEC 61010-1.

Current consumption Current consumption of controls depending on mains voltage:

For permissible variation of mains voltage of 10 %:

100 to 120 V AC = max. 740 mA

208 to 240 V AC = max. 400 mA

380 to 500 V AC = max. 250 mA

515 to 690 V AC = max. 200 mA

For permissible variation of mains voltage of 30 %:

100 to 120 V AC = max. 1,200 mA

208 to 240 V AC = max. 750 mA

380 to 500 V AC = max. 400 mA

515 to 690 V AC = max. 400 mA

Overvoltage category Category III according to IEC 60364-4-443

Rated power Actuator controls are designed for rated motor power, refer to Electrical data Multi-turn actuators or Part-turn

actuators

Switchgear Standard: Reversing contactors (mechanically and electrically interlocked) for

AUMA power classes A1/A2

Options: Reversing contactors (mechanically and electrically interlocked) for AUMA power class A3

Thyristor unit for mains voltage up to 500 V AC (recommended for modulating actuators) for

AUMA power classes B1, B2 and B3

The reversing contactors are designed for a lifetime of 2 million starts. For applications requiring a high num-

ber of starts, we recommend the use of thyristor units,

For the assignment of AUMA power classes, please refer to Electrical data Multi-turn actuators/Part-turn

actuators.

Control and feedback signals Via Modbus TCP/IP interface

Modbus TCP/IP interface with addi- 2 free analogue inputs (0/4 20 mA), 4 free digital inputs

tional input signals (option) - Signal transmission is made via Modbus TCP/IP interface

MODE, CLOSE, OPEN, STOP, EMERGENCY inputs, I/O interface with

0/4 20 mA input for position setpoint

- OPEN, STOP, CLOSE, EMERGENCY control inputs

- I/O interface for selecting the control type (Modbus TCP/IP or additional input signals)

- MODE for selecting between open-close duty (OPEN, STOP, CLOSE) and modulating duty (0/4 20

mA position setpoint)

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y006.711/003/en Issue 1.15 Page 1/6

AC 01.2

Modbus TCP/IP

Technical data Actuator controls

Voltage and current values of the Standard: 24 V DC, current consumption: approx. 10 mA per input

optional additional inputs

Options: 48 V DC, current consumption: approx. 7 mA per input

60 V DC, current consumption: approx. 9 mA per input

115 V DC, current consumption: approx. 15 mA per input

115V AC, current consumption: approx. 15mA per input

All input signals must be supplied with the same potential.

Status signals Via Modbus TCP/IP interface

Modbus TCP/IP interface with addi- Additional output signals (only available in combination with additional input signals)

tional output signals (option) Binary output signals

6 programmable output contacts

- 5 potential-free NO contacts with one common, max. 250 V AC, 1 A (resistive load)

Default conguration: End position CLOSED, end position OPEN, selector switch REMOTE, torque

fault CLOSE, torque fault OPEN

- 1 potential-free change-over contact, max. 250 V AC, 5 A (resistive load)

Default conguration: Collective fault signal (torque fault, phase failure, motor protection tripped)

6 programmable output contacts

- 5 potential-free change-over contacts with one common, max. 250 V AC, 1 A (resistive load)

- 1 potential-free change-over contact (max. 250 V AC, 5 A)

6 programmable output contacts

- 6 potential-free change-over contacts without one common, per contact max. 250 V AC, 5 A (resis-

tive load)

All binary output signals must be supplied with the same potential.

Analogue output signal for position feedback

Galvanically isolated position feedback E2 = 0/4 20 mA (load max. 500 )

Local controls Standard: Selector switch LOCAL - OFF - REMOTE (lockable in all three positions)

Push buttons OPEN, STOP, CLOSE, RESET

- Local STOP

The actuator can be stopped via push button Stop of local controls if the selector

switch is in position REMOTE. Not activated when leaving the factory.

6 indication lights:

- End positions and running indication CLOSED (yellow), torque fault CLOSE (red),

motor protection tripped (red), torque fault OPEN (red), end position and running

indication OPEN (green), Bluetooth (blue)

Graphic LC display, illuminated

Option: Special colours for the indication lights:

- End position CLOSED (green), torque fault CLOSE (blue), torque fault OPEN (yellow),

motor protection tripped (violet), end position OPEN (red)

Bluetooth Bluetooth class II chip, version 2.1 with a range up to 10 m in industrial environments. Supports the SPP

communication interface Bluetooth prole (Serial Port Prole).

Programming software:

AUMA CDT, commissioning and diagnostic tool for Windows-based PCs, PDAs and smartphones

Application functions Standard: Switch-off mode adjustable

- Limit or torque seating for end positions OPEN and CLOSED

Torque by-pass, adjustable up to 5 seconds (no torque monitoring during start-up time)

Start and end of stepping mode as well as ON and OFF times (1 to 1,800 seconds) can be

set individually for directions OPEN and CLOSE.

Any 8 intermediate positions between 0 and 100 %, reaction and signal behaviour pro-

grammable

Positioner:

- Setpoint position via Modbus TCP/IP interface

- Automatic adaptation of dead band (adaptive behaviour selectable)

- Change-over between OPEN-CLOSE control and setpoint control via Modbus TCP/IP

interface

Option: PID controller with adaptive positioner, 0/4 20 mA inputs for process setpoint and

actual process value

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y006.711/003/en Issue 1.15 Page 2/6

AC 01.2

Modbus TCP/IP

Technical data Actuator controls

Safety functions (options) EMERGENCY operation, behaviour programmable

- Digital input low active (option), or via eldbus interface

- Reaction can be selected: Stop, run to end position CLOSED, run to end position OPEN, run to inter-

mediate position

- Torque monitoring can be by-passed during EMERGENCY operation

- Thermal protection can be by-passed during EMERGENCY operation (only in combination with ther-

moswitch within actuator, not with PTC thermistor).

Enable local controls via Modbus TCP/IP interface Thus, actuator operation can be enabled or disabled via

push buttons on the local controls.

Local STOP

- The actuator can be stopped via push button Stop of local controls if the selector switch is in position

REMOTE. Not activated when leaving the factory.

EMERGENCY Stop push button (latching) interrupts electrical operation, irrespective of the selector switch

position

Interlock, enabling the operation commands OPEN or CLOSE via Modbus TCP/IP interface

Monitoring function Valve overload protection (adjustable), results in switching off and generates fault signal

Motor temperature monitoring (thermal monitoring), results in switching off and generates fault indica-

tion

Monitoring the heater within actuator, generates warning signal

Monitoring of permissible on-time and number of starts (adjustable), generates warning signal

Operation time monitoring (adjustable), generates warning signal

Phase failure monitoring, results in switching off and generates fault signal

Automatic correction of rotation direction upon wrong phase sequence (3-ph AC current)

Diagnostic function Electronic device ID with order and product data

Logging of operating data: A resettable counter and a lifetime counter each for:

- Motor running time, number of starts, torque switch trippings in end position CLOSED, limit switch

trippings in end position CLOSED, torque switch trippings in end position OPEN, limit switch trippings

in end position OPEN, torque faults CLOSE, torque faults OPEN, motor protection trippings

Time-stamped event report with history for setting, operation and faults:

- Status signals according to NAMUR recommendation NE 107: "Failure", "Function check", "Out of

specication", "Maintenance required"

Torque characteristics (for version with MWG in actuator)

- 3 torque characteristics (torque-travel characteristic) for opening and closing directions can be saved

separately. Torque characteristics stored can be shown on the display.

Motor protection evaluation Standard: Monitoring the motor temperature in combination with thermoswitches within actuator

motor

Options: Thermal overload relay in controls combined with thermoswitches within actuator

PTC tripping device in combination with PTC thermistors within actuator motor

Electrical connection Standard: AUMA plug/socket connector with screw-type connection

Options: Terminals or crimp connection

Gold-plated control plug (pins and sockets)

Threads for cable entries Standard: Metric threads

Options: Pg-threads, NPT-threads, G-threads

Wiring diagram (basic version) TPCAC000-1A1-A5E0 TPA00R1AA-0A1-000

Further options for Non-intrusive version with MWG in the actuator

Setting of limit and torque switching via local controls

Torque feedback signal Via Modbus TCP/IP interface

Galvanically isolated analogue output 0/4 20 mA (load max. 500 ) (option), only possible in combination

with output contacts

Wiring diagram (basic version) TPCAC000-1A1-A5E0 TPA00R100-0I1-000

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y006.711/003/en Issue 1.15 Page 3/6

AC 01.2

Modbus TCP/IP

Technical data Actuator controls

Settings/programming the Modbus TCP/IP interface

Setting the Modbus interface Baud rate, parity and Modbus address are set via the display of the AC 01.2

Setting the Modbus gateway Settings are made via web server

Default setting of the IP interface:

IP address selection

Type of address Static IP

Static IP Address 192.168.255.1

Subnet Mask 255.255.0.0

Default gateway 192.168.0.1

Commands and signals of the Modbus TCP/IP interface

Process representation output OPEN, STOP, CLOSE, position setpoint, RESET, EMERGENCY operation command, enable LOCAL, Interlock

(command signals) OPEN/CLOSE

Process representation input End positions OPEN, CLOSED

(feedback signals) Actual position value

Actual torque value, requires magnetic limit and torque transmitter (MWG) in actuator

Selector switch in position LOCAL/REMOTE

Running indication (directional)

Torque switches OPEN, CLOSED

Limit switches OPEN, CLOSED

Manual operation by handwheel or via local controls

Analogue (2) and digital (4) customer inputs

Process representation input Motor protection tripped

(fault signals) Torque switch tripped in mid-travel

One phase missing

Failure of analogue customer inputs

Behaviour on loss of communication The behaviour of the actuator is programmable:

Stop in current position

Travel to end position OPEN or CLOSED

Travel to any intermediate position

Execute last received operation command

General Modbus TCP/IP data

Communication protocol Modbus TCP/IP according to IEC 61158 and IEC 61784

Network topology Star topology, point-to-point wiring

Transmission medium IEC IEEE 802.3, cable recommendation: Cat.6A

Transmission rate/cable length Baud rate of 10/100 Mbits/s

Maximum cable length: 100 m

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y006.711/003/en Issue 1.15 Page 4/6

AC 01.2

Modbus TCP/IP

Technical data Actuator controls

Supported Modbus functions 01 Read Coil Status

(services)

02 Read Input Status

03 Read Holding Registers

04 Read Input Registers

05 Force Single Coil

15 (0FHex) Force Multiple Coils

06 Preset Single Register

16 (10Hex) Preset Multiple Registers

17 (11Hex) Report Slave ID

08 Diagnostics:

00 00 Loopback

00 10 (0AHex) Clear Counters and Diagnostic Register

00 11 (0BHex) Return Bus Message Count

00 12 (0CHex) Return Bus Communication Error Count

00 13 (0DHex) Return Bus Exception Error Count

00 14 (0EHex) Return Slave Message Count

00 15 (0FHex) Return Slave No Response Count

00 16 (10Hex) Return Slave NAK Count

00 17 (11Hex) Return Slave Busy Count

00 18 (12Hex) Return Character Overrun Count

Service conditions

Use Indoor and outdoor use permissible

Mounting position Any position

Installation altitude 2 000 m above seal level

> 2,000 m above sea level on request

Ambient temperature Standard: 25 C to +70 C

Humidity Up to 100 % relative humidity across the entire permissible temperature range

Enclosure protection according to Standard: IP68 with AUMA 3-phase AC motor/1-phase AC motor

EN 60529 For special motors differing enclosure protection: refer to name plate

Option: DS Terminal compartment additionally sealed against interior (double sealed)

According to AUMA denition, enclosure protection IP68 meets the following requirements:

Depth of water: maximum 8 m head of water

Duration of continuous immersion in water: Max. 96 hours

Up to 10 operations during continuous immersion

Modulating duty is not possible during continuous immersion.

Pollution degree Pollution degree 4 (when closed)

according to EN 60664-1

Corrosion protection Standard: KS Suitable for use in areas with high salinity, almost permanent condensation, and

high pollution.

Options: KX Suitable for use in areas with extremely high salinity, permanent condensation,

and high pollution.

Finish coating Powder paint

Two-component iron-mica combination

Colour Standard: AUMA silver-grey (similar to RAL 7037)

Option: Available colours on request

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y006.711/003/en Issue 1.15 Page 5/6

AC 01.2

Modbus TCP/IP

Technical data Actuator controls

Accessories

Wall bracket AC 01.2 mounted separately from the actuator, including plug/socket connector. Connecting cable on

request.

Recommended for high ambient temperatures, difficult access, or in case of heavy vibration during service.

Cable length between actuator and AC 01.2 max. 100 m. Not suitable for version with potentiometer in the

actuator. Instead of the potentiometer, the actuator has to be equipped with an electronic position transmit-

ter. Cable length for non-intrusive version with MWG in the actuator max. 100 m. Requires separate data

cable for MWG.

Programming software for PC AUMA CDT

Further information

Weight Approx. 7 kg (with AUMA plug/socket connector)

EU Directives Electromagnetic Compatibility (EMC): (2004/108/EC)

Low Voltage Directive: (2006/95/EC)

Machinery Directive: (2006/42/EC)

Reference documents Brochure Electric actuators for industrial valve automation

Dimensions Multi-turn actuators with AUMATIC integral controls

Dimensions Part-turn actuators with AUMATIC integral controls

We reserve the right to alter data according to improvements made. Previous documents become invalid with the issue of this document.

Y006.711/003/en Issue 1.15 Page 6/6

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (345)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)

- VI. HelicoptersДокумент147 страницVI. HelicopterssreekanthОценок пока нет

- TM4320 PDFДокумент85 страницTM4320 PDFandres cortezОценок пока нет

- FCE 331 Strength of Materials IIA CAT, January 2022Документ2 страницыFCE 331 Strength of Materials IIA CAT, January 2022devОценок пока нет

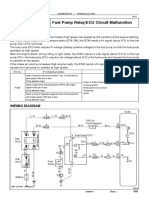

- DTC P1200 Fuel Pump Relay/ECU Circuit MalfunctionДокумент4 страницыDTC P1200 Fuel Pump Relay/ECU Circuit MalfunctiononealОценок пока нет

- Introduction To Chaos: The Damped, Driven, Nonlinear PendulumДокумент14 страницIntroduction To Chaos: The Damped, Driven, Nonlinear PendulumKikkuОценок пока нет

- Omnibus Risk EstimatorДокумент6 страницOmnibus Risk EstimatorConta do CerberusОценок пока нет

- WDH-SL3 Iom M01M40N13-07 - 1542713324932Документ72 страницыWDH-SL3 Iom M01M40N13-07 - 1542713324932irwantino susilo100% (1)

- Evaluating Capital ProjectsДокумент254 страницыEvaluating Capital Projectsariff_sodriОценок пока нет

- LC08 L1TP 120065 20180318 20180403 01 T1 MTLДокумент4 страницыLC08 L1TP 120065 20180318 20180403 01 T1 MTLrendy aswinОценок пока нет

- Microsoft OfficeДокумент1 страницаMicrosoft OfficesavinaumarОценок пока нет

- Crane Wheels-General InformationДокумент3 страницыCrane Wheels-General InformationArvind VaishОценок пока нет

- Energy Audit Report by CPRIДокумент247 страницEnergy Audit Report by CPRImag_ktps20021520100% (2)

- Oracle Database 11g Transparent Data EncryptionДокумент40 страницOracle Database 11g Transparent Data EncryptionYelena BytenskayaОценок пока нет

- Omega PTFE Needle Valve - FVLT100Документ1 страницаOmega PTFE Needle Valve - FVLT100XavierОценок пока нет

- Configuring Routing by Using Routing and Remote AccessДокумент31 страницаConfiguring Routing by Using Routing and Remote AccessLacus ClyneОценок пока нет

- Design and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionДокумент4 страницыDesign and Implementation of Audio Transceiver Using Infrared Laser For Audio Signal DetectionGoitom HaileОценок пока нет

- Earthquake EnginneringДокумент11 страницEarthquake EnginneringkkkОценок пока нет

- Postmodernity in PiДокумент2 страницыPostmodernity in Pixhardy27Оценок пока нет

- Question For Practice Oracle (11g) With AnswersДокумент32 страницыQuestion For Practice Oracle (11g) With AnswersAnonymous J8V2pZZ100% (4)

- The Whys and Wherefores of Microphone Array Crosstalk in Multichannel Microphone Array DesignДокумент6 страницThe Whys and Wherefores of Microphone Array Crosstalk in Multichannel Microphone Array DesignmewarulesОценок пока нет

- Efectele Pe Termen Lung Ale Alaptatului OMSДокумент74 страницыEfectele Pe Termen Lung Ale Alaptatului OMSbobocraiОценок пока нет

- Reflexive Pronoun: Object SubjectДокумент5 страницReflexive Pronoun: Object SubjectSiti Sarah Abdullah100% (1)

- AC Induction Motors - How AC Motors WorkДокумент10 страницAC Induction Motors - How AC Motors WorkBraulio IrrutiaОценок пока нет

- 50 Input Output Practice Questions 1606810110009 OBДокумент17 страниц50 Input Output Practice Questions 1606810110009 OBJavid QuadirОценок пока нет

- MTU-JB RadiatorsДокумент11 страницMTU-JB Radiatorsnanthu7090Оценок пока нет

- The Effect of Axial Flow Velocity On Annular Gap Windage Power LossДокумент12 страницThe Effect of Axial Flow Velocity On Annular Gap Windage Power Losskien nguyenОценок пока нет

- GGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilДокумент5 страницGGGB6023 Tugasan Tutorial 3 - P69060 Mior SyazrilAmizan AbdullahОценок пока нет

- Final Formula SheetДокумент1 страницаFinal Formula SheetFaryalОценок пока нет

- Precima Frenos FDW ATEX Operating InstructionsДокумент6 страницPrecima Frenos FDW ATEX Operating InstructionsToni RenedoОценок пока нет

- P103154 - 7.00 - Doc - Manual - 8000 WindlassДокумент43 страницыP103154 - 7.00 - Doc - Manual - 8000 WindlassDanОценок пока нет