Академический Документы

Профессиональный Документы

Культура Документы

Ce221 Tute4sol PDF

Загружено:

Joey KingОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Ce221 Tute4sol PDF

Загружено:

Joey KingАвторское право:

Доступные форматы

DEPARTMENT OF CIVIL ENGINEERING, IIT BOMBAY

CE 221 Solid Mechanics

Tutorial Sheet = 4 Instructor : A. Laskar / N. K. Chandiramani

1. A hollow steel shaft with external diameter 6. A steel shaft and an aluminium tube are

150 mm is required to transmit 1MW at 300 connected to a fixed support and rigid disk

rpm. Calculate a suitable internal diameter as shown in Fig. 2. Determine the maximum

for the shaft if its shear stress is not to torque which may be applied to the disk

exceed 70 MPa. Compare the torque without exceeding the shearing stresses of

carrying capacity of this shaft with a solid 120 MPa and 70 MPa in steel and

steel shaft having the same weight per unit aluminium tube respectively. Take G = 80

length and limiting shear stress. Take G = 80 GPa for steel and 27 GPa for aluminium.

GPa.

8 mm

2. A steel shaft consists of a hollow shaft 2m

long, with an outside diameter of 100 mm

and an inside diameter of 70 mm, rigidly 76 mm 50 mm

attached to a solid shaft of 1.5 m length and Fig. 2

70 mm diameter. Determine the maximum 500 mm

power that can be transmitted by the shaft at 7. A circular shaft AB consists of a 250 mm

a speed of 100 rpm without exceeding a long, 20 mm diameter steel cylinder, in

shear stress of 70 MPa and a twist of 2.5 in which a 125 mm long, 16 mm diameter

the 3.5 m length. G = 80 GPa. cavity is drilled from end B (Fig. 3). The

3. Compare the torque transmitted by a solid shaft is attached to fixed supports at both

shaft of diameter d and the torque ends, and a 120 N.m torque is applied at its

transmitted by a shaft of annular cross- mid-section Determine the torque exerted by

section of the same material with mean the shaft on both supports.

diameter d, the weight per unit length being

same for the two shafts. 125 mm

4. A solid tapered circular shaft of length L is 125 mm

fixed at one end and free on the other. The

diameter of shaft at free end is d and A

increases linearly to 2d at fixed end. The

120 N.m

shaft is subjected to a torque T at the free Fig. 3

end. Determine the angle of twist at the free B

end. 8. The composite shaft shown in Fig. 4 consists

of a 5 mm thick brass jacket (Gb = 39 GPa)

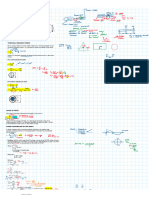

5. The solid cylindrical shaft of variable size as

bonded to a 40 mm diameter steel core (Gst

shown in mm in Fig. 1 is acted upon by the

= 77 GPa). The shaft is subjected to a 600

torque indicated. What is the maximum

N.m torque, determine (i) the maximum

shearing stress developed in the shaft, and

shearing stress in the brass jacket, (ii) the

between what two pulleys it occurs. Also

maximum shearing stress in steel core, (iii)

determine the relative twist between the end

the angle of twist of B relative to A.

pulleys. Take G = 80 GPa.

55 N.m

880 N.m

275 N.m T 2m

660 N.m

d=25 110 N.m

T

A 5 mm

d=100

d=75 40 mm

1600 Brass jacket

1000 d=75 B

1000 Steel core

2000

Fig. 1 Fig. 4

Вам также может понравиться

- Tutorial 4Документ6 страницTutorial 4Ysgn MysgnОценок пока нет

- Strength of Materials - Task 1. Chapter 3Документ3 страницыStrength of Materials - Task 1. Chapter 3NEIVER ALEVIS CASTRO JULIOОценок пока нет

- Strength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07MettkДокумент21 страницаStrength of Materials 4th Ed by Ferdinand L Singer Andrew Pytel Www07Mettkvjereme100% (3)

- PTS Controller: Over Fuel Dispensers and ATG Systems For Petrol StationsДокумент161 страницаPTS Controller: Over Fuel Dispensers and ATG Systems For Petrol StationsdawitОценок пока нет

- Bridge Erection MachinesДокумент73 страницыBridge Erection Machinesstavros_sterg80% (5)

- 3 1-TorsionstressandstrainДокумент19 страниц3 1-TorsionstressandstrainKim HarlyОценок пока нет

- Torsion PDFДокумент3 страницыTorsion PDFPoveAlmeida Vladi100% (1)

- ME-1203 Solid Mechanics-EEE (Solved Problem Slide)Документ9 страницME-1203 Solid Mechanics-EEE (Solved Problem Slide)sadfОценок пока нет

- Assignment 6Документ3 страницыAssignment 6radhikaОценок пока нет

- ES 13 1920A Problem Set 2Документ5 страницES 13 1920A Problem Set 2Charmaine ColetaОценок пока нет

- Assignment 5Документ3 страницыAssignment 5Rohit KumarОценок пока нет

- Tutorial 3Документ2 страницыTutorial 3AmrinaAkmal0% (1)

- ME-6503 Design of Machine Elements - 16 MarksДокумент12 страницME-6503 Design of Machine Elements - 16 MarksMadhu MithaОценок пока нет

- Refresher No.1 (MDSP)Документ5 страницRefresher No.1 (MDSP)LeysheyОценок пока нет

- 2017 A10Документ2 страницы2017 A10Vy ThoaiОценок пока нет

- Ce234 Topic 06-07Документ31 страницаCe234 Topic 06-07Nicholas Bonn SingОценок пока нет

- Sheet 4 Torsional Loads and Shaft Deformations - MechatronicsДокумент3 страницыSheet 4 Torsional Loads and Shaft Deformations - MechatronicsAhmed AlaaОценок пока нет

- MOM I - Module 45Документ8 страницMOM I - Module 45Muhammad HabibОценок пока нет

- Notes Ch.3-Es205Документ4 страницыNotes Ch.3-Es205indayieee.12Оценок пока нет

- Machine Design Problem New 28.07.09Документ22 страницыMachine Design Problem New 28.07.09muzahed100% (1)

- Department of Civil Engineering CEA 1120 - Tutorial Sheet # 9 TorsionДокумент2 страницыDepartment of Civil Engineering CEA 1120 - Tutorial Sheet # 9 TorsionSijuKalladaОценок пока нет

- Strenth of Mech - AssignmentsДокумент12 страницStrenth of Mech - AssignmentsProf. Anurag KumarОценок пока нет

- TORSIONДокумент5 страницTORSIONJobert CajayonОценок пока нет

- MECHANICS (ME10001) : AluminumДокумент2 страницыMECHANICS (ME10001) : AluminumRahulОценок пока нет

- ME-2127 Solid Mechanics-MSEДокумент14 страницME-2127 Solid Mechanics-MSEFazle RabbyОценок пока нет

- Internal Test-II Dme. Section BДокумент3 страницыInternal Test-II Dme. Section BManivannanОценок пока нет

- 3-1 DMM1 (Nov 2009 Regular)Документ9 страниц3-1 DMM1 (Nov 2009 Regular)micmechОценок пока нет

- DME - Assignment - IДокумент3 страницыDME - Assignment - ISathis KumarОценок пока нет

- CE133P-2 4Q2021 Assimilation of WSD PrincipleДокумент10 страницCE133P-2 4Q2021 Assimilation of WSD PrincipleJemuel FloresОценок пока нет

- SOM AssignmentДокумент6 страницSOM Assignmentshreyas shahОценок пока нет

- Welded Stoppers and ClipsДокумент3 страницыWelded Stoppers and ClipsMaan MrabetОценок пока нет

- STL203SДокумент6 страницSTL203SClaudioОценок пока нет

- MIDTERM EXAM - GC32Ar - Principles of Reinforced Concrete DesignДокумент2 страницыMIDTERM EXAM - GC32Ar - Principles of Reinforced Concrete DesignJan Angelo CiudadanoОценок пока нет

- 353 35435 ME357 2011 4 2 1 Sheet MD2Документ10 страниц353 35435 ME357 2011 4 2 1 Sheet MD2adel nabhanОценок пока нет

- CIV E270 - Assignment No. 5Документ5 страницCIV E270 - Assignment No. 5Schehzeb ManzarОценок пока нет

- SheetДокумент2 страницыSheetRoma Raquepo RingorОценок пока нет

- Department of Mechanical Engineering MD - II: Tutorial Sheet For Fatigue Consideration in Design (Session 2020-21)Документ2 страницыDepartment of Mechanical Engineering MD - II: Tutorial Sheet For Fatigue Consideration in Design (Session 2020-21)djadja nakamayaОценок пока нет

- Worksheet 2021Документ3 страницыWorksheet 2021Layike AlemayehuОценок пока нет

- RefM 14 - Ultimate Strength Design (T-Beams)Документ1 страницаRefM 14 - Ultimate Strength Design (T-Beams)usueОценок пока нет

- Assignment QuestionДокумент15 страницAssignment QuestionPratik WalimbeОценок пока нет

- Unit 4 AssignmentsДокумент5 страницUnit 4 AssignmentsbattuarunОценок пока нет

- Machine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01Документ10 страницMachine Design & Industrial Drafting SUBJECT CODE:-2141907 Tutorial - 01The AIRS CreationsОценок пока нет

- Pile Cap DesignДокумент13 страницPile Cap DesigngnanaОценок пока нет

- Solid Mechanics QuestionsДокумент3 страницыSolid Mechanics QuestionsUnknownОценок пока нет

- Base PlateДокумент3 страницыBase Platearit bhattacharyaОценок пока нет

- Pile Cap DesignДокумент13 страницPile Cap DesignWahid wrbelОценок пока нет

- Reg - No:: Ii) Design A Rectangular Key For The Following Application: A ShaftДокумент3 страницыReg - No:: Ii) Design A Rectangular Key For The Following Application: A ShaftManivannanОценок пока нет

- Strength of Materials - Task 1. Chapter 2.Документ4 страницыStrength of Materials - Task 1. Chapter 2.Jesus RodeloОценок пока нет

- Question Bank SOM-IIДокумент6 страницQuestion Bank SOM-IISurjit Kumar GandhiОценок пока нет

- L10 TorsionДокумент3 страницыL10 TorsionAngelica Shane A. SaludoОценок пока нет

- Mechanics of Solids GTU PapersДокумент17 страницMechanics of Solids GTU Papersvaibhav shahОценок пока нет

- Design of Machine Elements 2 Jan 2018 (2010 Scheme)Документ2 страницыDesign of Machine Elements 2 Jan 2018 (2010 Scheme)KishoreОценок пока нет

- Chapter - 3 - Torsion - Class ExamplesДокумент14 страницChapter - 3 - Torsion - Class ExamplesCandice MdakaОценок пока нет

- AE Civil Paper IДокумент3 страницыAE Civil Paper INaveen KaleraОценок пока нет

- QP Pe Series 2Документ2 страницыQP Pe Series 2AADARS M SОценок пока нет

- ME3170 - Tutorial 5 ShaftsДокумент2 страницыME3170 - Tutorial 5 Shaftsme20btech11034Оценок пока нет

- Tutorial Chapter 1Документ1 страницаTutorial Chapter 1Melvin Shady PereiraОценок пока нет

- SOMДокумент14 страницSOMAditya ojhaОценок пока нет

- Cylindrical Compression Helix Springs For Suspension SystemsОт EverandCylindrical Compression Helix Springs For Suspension SystemsОценок пока нет

- Tutorial Chapter 2Документ5 страницTutorial Chapter 2Naasir SheekeyeОценок пока нет

- Lab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveДокумент7 страницLab Manual 10: Z-Transform and Inverse Z-Transform Analysis ObjectiveSyed Waqas ShahОценок пока нет

- One Word SubstitutionДокумент5 страницOne Word SubstitutionPranaykant Singh PanwarОценок пока нет

- Qüestionari KPSI.: ActivitiesДокумент2 страницыQüestionari KPSI.: ActivitiesfrancisОценок пока нет

- Laws of ThermoДокумент13 страницLaws of ThermofabyunaaaОценок пока нет

- Dystopian LiteratureДокумент3 страницыDystopian LiteratureLol LeeОценок пока нет

- Practicality and Efficiency: Presented By: Grace EscabasДокумент11 страницPracticality and Efficiency: Presented By: Grace EscabasMiaeОценок пока нет

- Applied-Signed Product Cordial Labeling and - Santhi.mДокумент6 страницApplied-Signed Product Cordial Labeling and - Santhi.mImpact JournalsОценок пока нет

- NewspaperДокумент1 страницаNewspaperMustafa Nabeel ZamanОценок пока нет

- Competitive Analysis: Features: Smart IrrigationДокумент2 страницыCompetitive Analysis: Features: Smart IrrigationRoseanne RamonОценок пока нет

- Anti FoundationalismДокумент4 страницыAnti FoundationalismKostasBaliotisОценок пока нет

- I. Company Data 1.1. Company ProfileДокумент19 страницI. Company Data 1.1. Company ProfileMhy AcajaОценок пока нет

- Interpreting The Venus CycleДокумент2 страницыInterpreting The Venus Cyclemurx2100% (1)

- Binary Arithmetic Operations: Prof. R.Ezhilarasie Assistant Professor School of Computing SASTRA Deemed To Be UniversityДокумент26 страницBinary Arithmetic Operations: Prof. R.Ezhilarasie Assistant Professor School of Computing SASTRA Deemed To Be UniversityEzhil RamanathanОценок пока нет

- Avenger 220 Cruise Street BS IVДокумент79 страницAvenger 220 Cruise Street BS IVShubham AatopartsОценок пока нет

- SQAAU SM Assignment BriefДокумент10 страницSQAAU SM Assignment BriefJamil NassarОценок пока нет

- Pro-Watch Ecosystem: The Power of TheДокумент1 страницаPro-Watch Ecosystem: The Power of TheNik SiagОценок пока нет

- Dakshin Dinajpur TP ListДокумент5 страницDakshin Dinajpur TP ListDeb D Creative StudioОценок пока нет

- Urban Problems and SolutionsДокумент12 страницUrban Problems and SolutionsJohn Lloyd Agapito50% (2)

- Key Term Arabic Meaning Link: Life ScienceДокумент5 страницKey Term Arabic Meaning Link: Life ScienceReemОценок пока нет

- UntitledДокумент44 страницыUntitledFrancesco TauroОценок пока нет

- Virtual Screening of Natural Products DatabaseДокумент71 страницаVirtual Screening of Natural Products DatabaseBarbara Arevalo Ramos100% (1)

- Best Actor and Actress Adjudication Rubric 41950cb9a3Документ3 страницыBest Actor and Actress Adjudication Rubric 41950cb9a3Sarah Jhoy SalongaОценок пока нет

- Please Complete The Information Requested Below: COMPANY NAME: X2 Logics Staffing Solution, IncДокумент2 страницыPlease Complete The Information Requested Below: COMPANY NAME: X2 Logics Staffing Solution, Incwasim riyazОценок пока нет

- Paket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Документ3 страницыPaket B Listening Ujian Sekolah Bahasa Inggris SMK Tahun Pelajaran 2022-2023Nadiah PutriОценок пока нет

- Mcs Text BookДокумент309 страницMcs Text Bookkancha_basu2447100% (1)

- FLIGHT Punta Arenas - SantiagoДокумент3 страницыFLIGHT Punta Arenas - SantiagoАртем ПичугинОценок пока нет

- Tavistock PrimerДокумент13 страницTavistock PrimerSharon Schaff100% (1)