Академический Документы

Профессиональный Документы

Культура Документы

Phytorid STP

Загружено:

samirbendre1Оригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Phytorid STP

Загружено:

samirbendre1Авторское право:

Доступные форматы

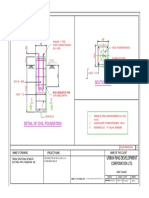

Working stress method : -Design of Wall

Permissible Stresses :-

Given Data :-

1) Unit wt. of Liquid =10 kN/m

2) Grade of Concrete (For Liquid Retaining Structure) =M-35 Mpa

3) Grade of Steel =Fe-415 MPa

4)Bending moment = 7.6 kN.m

5)Width of section = 1000 mm

6)Depth of section = 200 mm

7)Lever arm (j) = 0.861

Concrete :-(As per IS-456, Table-21, Page-81)

Direct Compressive Stress =9.0 N/mm2

Bending Stress =11.5 N/mm2

For Water Retaining structures :- (As per IS-3370 Part-II, 2009 ,Table-1 & 2 , Page-2, 3 )

Cracking due to Direct Tension =1.6 N/mm2

Cracking Tension in Bending =2.2 N/mm2

Shear =2.5 N/mm2

Reinforcement :-

Tensile stress in members under direct tension, Bending =130 N/mm2

Calculation of Uncracked B.M.Coefficient :-

st = 130 N/mm2

cbt = 2.2 N/mm2

pt % = 0.24%

therefore As (area of steel) = 0.24 %bd

Transformed area of steel into concrete =(m -1) x As

Modular Ratio = ( 280 / 3 ) x _x0001_cbc Where, ,cbc =11.50 N/mm2

= 8.12

Moment of Inertia = (1/12) X bd3 + 2(m-1) As( d/2)) = 0.0919

From theory of bending

M = ( cbt x I ) / y = 0.4042 bd2

For Liquid Retaining structures Q = 0.4042

Depth for Beam, Slab & Walls : -

Depth of beam / slab = ((B.M. x 10^6)/(0.4 = 137.12 mm

Steel for Beam & Slab : -

Ast = (B.M. x 10^6) / ( st x j x d) = 339.50 mm2/Rmt

Minimum Ast = 0.24%xbxd = 480.00 mm2/Rmt

_x0001_ Therefore provided Ast = = 339.50 mm2/Rmt

using 10 mm dia bar, ast = 79 mm2

spacing = (astx1000)/(Ast provided) = 232.70 mm

Hence we provided 10 mm Dia bar at 175 mm c/c

Working stress method : -Design of beam (5mx1.75mx0.15m)

Designed for max depth of 1.75 m

Permissible Stresses :-

Given Data :-

1) Unit wt. of Liquid = 10 kN/m

2) Grade of Concrete (For Liquid Retaining Structure) = M-35 Mpa

3) Grade of Steel = Fe-415 MPa

4)Bending moment = 30 kN.m

5)Width of section = 150 mm

6)Depth of section = 1750 mm

7)Length of beam = 5000 mm

8)Lever arm (j) = 0.861

Concrete :- (As per IS-456, Table-21, Page-81)

Direct Compressive Stress = 9.0 N/mm2

Bending Stress = 11.5 N/mm2

For Water Retaining structures :- (As per IS-3370 Part-II, 2009 ,Table-1 & 2 , Page-2, 3 )

Cracking due to Direct Tension = 1.6 N/mm2

Cracking Tension in Bending = 2.2 N/mm2

Shear = 2.5 N/mm2

Reinforcement :-

Tensile stress in members under direct tension, Bending = 130 N/mm2

Calculation of Uncracked B.M.Coefficient :-

st = 130 N/mm2

cbt = 2.2 N/mm2

pt % = 0.24%

therefore As (area of steel) = 0.24 %bd

Transformed area of steel into concrete = (m -1) x As

Modular Ratio = ( 280 / 3 ) x _x0001_cbc Where, = 11.50 N/mm2

= 8.12

Moment of Inertia = (1/12) X bd3 + 2(m-1) As( d/2)) = 0.0919

From theory of bending

M = ( cbt x I ) / y = 0.4042 bd2

For Liquid Retaining structures Q = 0.4042

Depth for Beam, Slab & Walls : -

Depth of beam / slab ((B.M. x 10^6)/(0.4042 x b)) = 703.42 mm

Steel for Beam & Slab : -

Ast (B.M. x 10^6) / ( st x j x d) = 153.16 mm2

using 16 mm dia bar, ast = 200 mm2

No of bars = Ast/ast = 0.77

Hence we provided 4 nos, 16 mm Dia bar

CHECK FOR TENSILE STRESS FOR WALLS

section modulus(z) = bt/6 = 6666666.7 mm

t' (obtained from staad-pro) = 0.37 N/mm

cbt' = M/z = 1.14 N/mm

t Clauses 4.5.1(c),4.5.2.1 and 6.3(b) = 1.6 N/mm

cbt Clauses 4.5.1(c),4.5.2.1 and 6.3(b) = 2.2 N/mm

Tensile stress as per IS-3370 (part 2) 2009, page 4

t' cbt'

+ 1

t cbt

0.23125 + 0.518182 0.23125 HENCE OK

Base Pressure:

Vertical

Node L/C

Fy N/mm2

Max Px 2 1 DL 0.024

Min Px 2 1 DL 0.024

Max Py 123 4 COMBINATION LOAD CASE 4 0.057

Min Py 123 3 EARTH -0.004

Max Pz 2 1 DL 0.024

Min Pz 2 1 DL 0.024

As max base pressure calculated from staad-pro is 0.057 N/mm2

so it is calculated as = 57 kN/m2

SBC of soil = 80 kN/m2

If max base pressure < S.B.C. of soil, then OK

Therefore, OK

Вам также может понравиться

- Civil Works Field Quality Plan ChecklistДокумент4 страницыCivil Works Field Quality Plan ChecklistPraba GaranОценок пока нет

- Thrust 2 eДокумент6 страницThrust 2 eWaheed AhmadОценок пока нет

- Sludge Management Techniques for Wastewater TreatmentДокумент33 страницыSludge Management Techniques for Wastewater TreatmentAndrew Marquez DonaireОценок пока нет

- Rectangular Steel Bar DesignДокумент2 страницыRectangular Steel Bar DesignAmit Kumar PaulОценок пока нет

- Design of Rectangular Water TankДокумент212 страницDesign of Rectangular Water TankJEFFY JACOBОценок пока нет

- DESIGN TEST SETUP BEAM LOADSДокумент3 страницыDESIGN TEST SETUP BEAM LOADSSantosh ZunjarОценок пока нет

- UPDATED MARKET RATESДокумент21 страницаUPDATED MARKET RATESMD Maruf HussainОценок пока нет

- Intze Tank-175kL Design 18M STAGING BASI BLOCK - SMTДокумент55 страницIntze Tank-175kL Design 18M STAGING BASI BLOCK - SMTRajendra MittalОценок пока нет

- Truss DRGДокумент1 страницаTruss DRGkvamshi_1971Оценок пока нет

- RCC Retaining Wall1Документ20 страницRCC Retaining Wall1Karim PathanОценок пока нет

- Slab design and load calculationДокумент6 страницSlab design and load calculationRajib MaharjanОценок пока нет

- SHRT ColДокумент3 страницыSHRT ColashokОценок пока нет

- How To Remove Floride From WaterДокумент45 страницHow To Remove Floride From WaterAkash Mandal100% (1)

- 1 X 10 PDFДокумент14 страниц1 X 10 PDFTatsamYadavОценок пока нет

- 50,000-Liter OHSR Design for Village in MohaliДокумент22 страницы50,000-Liter OHSR Design for Village in MohaliEr Navneet JassiОценок пока нет

- Department of Civil Engineering List of Indian Road Congress (Irc)Документ7 страницDepartment of Civil Engineering List of Indian Road Congress (Irc)senthilncc100% (1)

- Wind Load2Документ1 страницаWind Load2Waqar FaziОценок пока нет

- Larsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreДокумент1 страницаLarsen & Toubro Limited - Ecc Division: Engineering Design and Research CentreOuseppachan AmbookenОценок пока нет

- Intze Tank-50kL Design 18M STAGING - SBC 8TON PER SMTДокумент53 страницыIntze Tank-50kL Design 18M STAGING - SBC 8TON PER SMTRajendra MittalОценок пока нет

- IS 1597 1 1992 Rubble Stone PDFДокумент18 страницIS 1597 1 1992 Rubble Stone PDFArunkumarОценок пока нет

- Water TankДокумент26 страницWater Tankabhi aroteОценок пока нет

- Design of Shear KeyДокумент13 страницDesign of Shear KeyRonnie SmithОценок пока нет

- Combined Footing With Unequal OverhangДокумент47 страницCombined Footing With Unequal OverhanggyanthОценок пока нет

- Install ARC BDS TM in under 5 stepsДокумент2 страницыInstall ARC BDS TM in under 5 stepstrmpereiraОценок пока нет

- Analysis No. 10(A) for overhead sign rate calculationДокумент3 страницыAnalysis No. 10(A) for overhead sign rate calculationBilal A BarbhuiyaОценок пока нет

- Rigid Pavement Design InputsДокумент17 страницRigid Pavement Design InputsrajОценок пока нет

- Combined FootingДокумент6 страницCombined FootingSuu ChateОценок пока нет

- Design of Wall Like ColumnДокумент4 страницыDesign of Wall Like Columnvishnumani3011Оценок пока нет

- Chequred PlateДокумент2 страницыChequred PlateKumar Prasanna HNОценок пока нет

- Construction of Salam Abad-Dard Kote Road: Pradhan Mantri Gram Sadak YojanaДокумент5 страницConstruction of Salam Abad-Dard Kote Road: Pradhan Mantri Gram Sadak Yojanamunishant1Оценок пока нет

- IS 3370 (Part 3) 1967 R 1999Документ14 страницIS 3370 (Part 3) 1967 R 1999Nayag Singh100% (1)

- Hydralic Calculation SheetДокумент13 страницHydralic Calculation SheetJayantha GamageОценок пока нет

- Watertank 1Документ16 страницWatertank 1Anand.5Оценок пока нет

- Design of Foundation for Arch Bridge TransportДокумент1 страницаDesign of Foundation for Arch Bridge TransportvibishnanОценок пока нет

- Design of Ring Girder SupportДокумент3 страницыDesign of Ring Girder Supportvishal guptaОценок пока нет

- PIle FoundationДокумент6 страницPIle FoundationsaravananОценок пока нет

- Design of Hidden Beam Data and CalculationsДокумент1 страницаDesign of Hidden Beam Data and CalculationsKulal SwapnilОценок пока нет

- Raft FDN DesignДокумент12 страницRaft FDN DesignMariappan .PОценок пока нет

- Design of Flash Mixer at Kurawar - 1AДокумент13 страницDesign of Flash Mixer at Kurawar - 1AAnonymous RREG0QJWОценок пока нет

- Design of Wall For Water Tank Both Side WaterДокумент19 страницDesign of Wall For Water Tank Both Side Waterrushicivil1Оценок пока нет

- RW6Документ19 страницRW6devesh singhОценок пока нет

- Two Way Slab - IS Code - LSMДокумент12 страницTwo Way Slab - IS Code - LSMNitesh SinghОценок пока нет

- P PDFДокумент49 страницP PDFaanchaljasujaОценок пока нет

- Jammu - Drain Design Note - RCCДокумент11 страницJammu - Drain Design Note - RCCVijay ChauhanОценок пока нет

- Summary of IS 3370 Detailing RequirementsДокумент2 страницыSummary of IS 3370 Detailing RequirementsKanaiyalal N. ShethОценок пока нет

- Concrete Compressive Strength Test ResultsДокумент6 страницConcrete Compressive Strength Test ResultsSurajit SahaОценок пока нет

- Column Design ExcelДокумент4 страницыColumn Design Excelvimal patelОценок пока нет

- Sump .XLS (7.00 Lakhs)Документ58 страницSump .XLS (7.00 Lakhs)subramanyam kumarОценок пока нет

- Over Head Gantry 1Документ1 страницаOver Head Gantry 1darshanОценок пока нет

- Unit III Trickling Filter DesignДокумент1 страницаUnit III Trickling Filter Designधीरज कुमारОценок пока нет

- Foundation Design f1Документ2 страницыFoundation Design f1Sampath Kumar KandasamyОценок пока нет

- Design of Walkway Slab (WS1) ReinforcementДокумент2 страницыDesign of Walkway Slab (WS1) ReinforcementRaju SainiОценок пока нет

- Beam Design CalculationsДокумент8 страницBeam Design Calculationsprajjwal patidarОценок пока нет

- S2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersДокумент2 страницыS2 - Floor / Roof: Design of Two - Way Slab With Provision For Torsion at CornersMuhammed Sabah100% (1)

- FFB2Документ8 страницFFB2prajjwal patidarОценок пока нет

- 400 KLДокумент31 страница400 KLRK PROJECT CONSULTANTSОценок пока нет

- Design of T-BeamДокумент6 страницDesign of T-BeamDineshОценок пока нет

- Slab & BeamДокумент34 страницыSlab & BeamVishruth JainОценок пока нет

- Imps - Short Wall (My - Vertical) : Calculation of SteelДокумент12 страницImps - Short Wall (My - Vertical) : Calculation of Steelpearl kachhawahОценок пока нет

- Underground Tank Design and Reinforcement DetailsДокумент2 страницыUnderground Tank Design and Reinforcement Detailsaaditya chopadeОценок пока нет

- Structural Audit of BridgeДокумент3 страницыStructural Audit of Bridgesamirbendre10% (1)

- Major Bridge Levels - Mar 01,2019Документ13 страницMajor Bridge Levels - Mar 01,2019samirbendre1Оценок пока нет

- Preliminary Column SizingДокумент2 страницыPreliminary Column Sizingsamirbendre1100% (1)

- Construction of 6 lane outer ring road foundation detailsДокумент1 страницаConstruction of 6 lane outer ring road foundation detailssamirbendre1100% (1)

- Construction of 6 lane outer ring road foundation detailsДокумент1 страницаConstruction of 6 lane outer ring road foundation detailssamirbendre1100% (1)

- Design of Plate GirderДокумент85 страницDesign of Plate Girdersamirbendre1100% (2)

- D K Stadium. G.AДокумент3 страницыD K Stadium. G.Asamirbendre1Оценок пока нет

- VVVMC Ring Road Rob Structural Quantities NalasoparaДокумент4 страницыVVVMC Ring Road Rob Structural Quantities Nalasoparasamirbendre1Оценок пока нет

- Bus WashДокумент10 страницBus Washsamirbendre1Оценок пока нет

- Ornamental Fishery Shed Estimate1Документ1 страницаOrnamental Fishery Shed Estimate1samirbendre1Оценок пока нет

- Construction of 6 lane outer ring road foundation detailsДокумент1 страницаConstruction of 6 lane outer ring road foundation detailssamirbendre1100% (1)

- Construction of 6 lane outer ring road foundation detailsДокумент1 страницаConstruction of 6 lane outer ring road foundation detailssamirbendre1100% (1)

- GAD - 1 - Major Bridge On Tapi RiverДокумент1 страницаGAD - 1 - Major Bridge On Tapi Riversamirbendre1Оценок пока нет

- Design of Class of Pipe As Per Layout of Zone 1Документ8 страницDesign of Class of Pipe As Per Layout of Zone 1samirbendre1Оценок пока нет

- Construction of 6 lane outer ring road foundation detailsДокумент1 страницаConstruction of 6 lane outer ring road foundation detailssamirbendre1100% (1)

- KBMC Sewerage Scheme - Wier Design ReportДокумент6 страницKBMC Sewerage Scheme - Wier Design Reportsamirbendre1Оценок пока нет

- PT I Girder Design 20mДокумент18 страницPT I Girder Design 20msamirbendre1Оценок пока нет

- PT Slab Bridge Deck 20 MДокумент8 страницPT Slab Bridge Deck 20 Msamirbendre1Оценок пока нет

- O and MДокумент37 страницO and Msamirbendre1Оценок пока нет

- GAD - 2 - Major Bridge On Tapi RiverДокумент1 страницаGAD - 2 - Major Bridge On Tapi Riversamirbendre1Оценок пока нет

- Cost Summary For Strcutures of 90m - ORR - 17.02.2018Документ1 страницаCost Summary For Strcutures of 90m - ORR - 17.02.2018samirbendre1Оценок пока нет

- Geotech Surat ReportДокумент104 страницыGeotech Surat Reportsamirbendre167% (3)

- 22-03-2013 19:29:08, Gbanerjee, DWG To PDF - Pc3, Iso Full Bleed A3 (297.00 X 420.00 MM), 1:1.42178, GbaДокумент4 страницы22-03-2013 19:29:08, Gbanerjee, DWG To PDF - Pc3, Iso Full Bleed A3 (297.00 X 420.00 MM), 1:1.42178, Gbasamirbendre1Оценок пока нет

- Pier Jacketing ReportДокумент5 страницPier Jacketing Reportsamirbendre1100% (1)

- Tapi River Bridge Cost20022018Документ1 страницаTapi River Bridge Cost20022018samirbendre1Оценок пока нет

- ALCON EstimateДокумент2 страницыALCON Estimatesamirbendre1Оценок пока нет

- Water Tank Side Wall 12x6x16Документ2 страницыWater Tank Side Wall 12x6x16samirbendre1Оценок пока нет

- FRP 1Документ1 страницаFRP 1samirbendre1Оценок пока нет

- Canal Design ParametersДокумент1 страницаCanal Design Parameterssamirbendre1Оценок пока нет

- Jacketed Weld Strength CheckДокумент10 страницJacketed Weld Strength CheckKshitiz SikkaОценок пока нет

- Air Carbon Arc GougingДокумент3 страницыAir Carbon Arc GougingMuhammad Fitransyah Syamsuar PutraОценок пока нет

- FT0019Документ2 страницыFT0019rmimo1993Оценок пока нет

- Bio Energiser Hair Boost Caffeine Power Tonic MSDS October 2016Документ3 страницыBio Energiser Hair Boost Caffeine Power Tonic MSDS October 2016Alexander JefferyОценок пока нет

- XRF BR41146 Arl Optimx WDXRF SpectrometerДокумент8 страницXRF BR41146 Arl Optimx WDXRF SpectrometerGilson JoseОценок пока нет

- Inorganic Chemistry: Concept Based NotesДокумент63 страницыInorganic Chemistry: Concept Based NotesijdnsОценок пока нет

- CEMB 111 Concrete Flexural Strength LabДокумент7 страницCEMB 111 Concrete Flexural Strength LabhamedОценок пока нет

- Die-Materials classEDITДокумент45 страницDie-Materials classEDITSatya AsatyaОценок пока нет

- Spe 1266 G PDFДокумент6 страницSpe 1266 G PDFDarayt Jimenez100% (1)

- CBSE Class 11 and 12 Chemistry Notes The P-Block ElementsДокумент45 страницCBSE Class 11 and 12 Chemistry Notes The P-Block ElementsPrabhuPalanichamy50% (2)

- Triazine DyesДокумент30 страницTriazine DyesRoxanaОценок пока нет

- Experiment 3 Biotransformation Reactions - Reduction of Carbonyls With Whole Plant PartsДокумент4 страницыExperiment 3 Biotransformation Reactions - Reduction of Carbonyls With Whole Plant PartsTEN CHEANG100% (1)

- Material Safety Data Sheet (PKE)Документ8 страницMaterial Safety Data Sheet (PKE)ffeedsupplierОценок пока нет

- Astm A29Документ16 страницAstm A29Nacer KisyОценок пока нет

- Audit Criteria: AC7114/1S REV. MДокумент47 страницAudit Criteria: AC7114/1S REV. MCaio Fazzioli TavaresОценок пока нет

- Polyflex 448: High Build EpoxyДокумент2 страницыPolyflex 448: High Build EpoxycesarОценок пока нет

- DNAfractalantenna 1Документ8 страницDNAfractalantenna 1Guilherme UnityОценок пока нет

- Gamma RayДокумент5 страницGamma RayDenisha Betaci GultomОценок пока нет

- Typical Specification - Russian PCI Coal - KravaskyДокумент1 страницаTypical Specification - Russian PCI Coal - Kravaskynaresh adusumilliОценок пока нет

- Pravara Rural College Pharmacy Industrial Training ReportДокумент28 страницPravara Rural College Pharmacy Industrial Training ReportSudarshan GhogareОценок пока нет

- Contamination Control Requirements: Space ShuttleДокумент34 страницыContamination Control Requirements: Space ShuttlectrubasОценок пока нет

- Metabolisme ImmunometabolismДокумент25 страницMetabolisme ImmunometabolismOKE channelОценок пока нет

- On-Line Monitoring of Bacterial and Pathogen Load Through Adenosine TriphosphateДокумент8 страницOn-Line Monitoring of Bacterial and Pathogen Load Through Adenosine TriphosphateKhoiril NОценок пока нет

- TiO2 (RC 635)Документ1 страницаTiO2 (RC 635)medo.k016Оценок пока нет

- Coordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFДокумент20 страницCoordinated Sciences IGSCE 0654 - s12 - QP - 63 PDFjanovaОценок пока нет

- EcoFlame B-971 MSDSДокумент8 страницEcoFlame B-971 MSDSZirve PolimerОценок пока нет

- Wobbe Index Calorific Value Handout Natural GasДокумент8 страницWobbe Index Calorific Value Handout Natural GasZuli VívnesОценок пока нет

- SOFTENING POINTДокумент8 страницSOFTENING POINTSusi MulyaniОценок пока нет

- Ewald Summation Method for Calculating Ionic Crystal Configuration EnergiesДокумент19 страницEwald Summation Method for Calculating Ionic Crystal Configuration Energieservina dwiОценок пока нет

- C12HДокумент129 страницC12Hkhudhayer1970Оценок пока нет