Академический Документы

Профессиональный Документы

Культура Документы

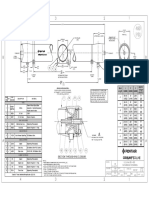

Codeline Drawing 80S45

Загружено:

betow_Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Codeline Drawing 80S45

Загружено:

betow_Авторское право:

Доступные форматы

Approx

DWG PART Dash L P S

QTY DESCRIPTION MATERIAL Weight

REF NUMBER Length IN(MM) IN(MM) IN(MM)

LB(KG)**

SHELL 75

59.75 47 20X1

Filament Wound Epoxy/Glass -1

(1518) (1194) (508) (34)

1 1 99231 SHELL composite - Head locking grooves

integrally wound in place. 99.75 87 56X1 95

-2

CF3M as per SA-351 (2534) (2210) (1422) (43)

2 A/R F/C Port

ASME Edition 2015 139.75 127 80X1 115

3 A/R F/C Port Seal Ethylene Propylene. -3

(3550) (3226) (2032) (52)

HEAD 179.75 167 64X2 137

6061-T6 as per SB-221 ASME -4

4 2 96157 Bearing Plate (4566) (4242) (1626) (62)

Edition 2015

219.75 207 78X2 161

5 2 96160 Sealing Plate Engineering Thermoplastic. -5

(5582) (5258) (1981) (73)

6 2 96162 Permeate Port Engineering Thermoplastic.

7 2 45066 Port Nut Engineering Thermoplastic. 259.75 247 92X2 181

-6

8 2 96000 Head Seal Ethylene Propylene - O - Ring (6598) (6274) (2337) (82)

9 2 45312 Perm Port Seal Ethylene Propylene - O - Ring 299.75 287 106X2 201

-7

HEAD INTERLOCK (7614) (7290) (2692) (91)

Quick Release Spiral SS-316 as per SA-479 339.75 327 120X2 223

10 2 47336 -8

Ring ASME Edition 2015 (8630) (8306) (3048) (101)

VESSEL SUPPORT

11 2+ 52169 Saddle Engineering Thermoplastic.

12 2+ 45042 Strap Assy. 304 Stainless Steel-PVC Cushion.

5/16-18 UNC,2.5''-L, 18-8 Stainless

13 4++ 46265 Strap screw.

Steel.

ELEMENT INTERFACE

14 2 A/R Adapter Engineering Thermoplastic.

15 2 52245 Adapter seal Ethylene Propylene - O - Ring

16 4 A/R PWT Seal Ethylene Propylene - O - Ring

17 1 96163 Thrust Cone Engineering Thermoplastic.

+ ++

3 each & 6 nos. furnished with length code 4,5,6,7 & 8.

ORDERING:

Using the chart below, please check the features you require

RATING: PRECAUTIONS:

DOread, understand and follow all instructions; failure to VESSEL LENGTH CODE please check one

DESIGN PRESSURE......450 PSIG take every precaution will void warranty and may result in

(3.1MPa) vessel failure MODEL 80S45 -1 -2 -3 -4 -5 -6 -7 -8

MAX. OPERATING TEMP .........190F DOmount the shell on horizontal members at span S MEMBRANE BRAND AND MODEL

(88C) using compliant vessel supports furnished; Shim saddles if

MIN. OPERATING TEMP.....20F required. Tighten hold down straps just snug Please supply adapters for the following membrane brand and specific model

(-7C) DOalign and center side ports with the manifold header. Brand_________________________ Model_______________________

FACTORY TEST PRESSURE....CE / ASME Correct, causes of misalignment in a row of vessels

675 PSIG/ 495 PSIG connected to the same header CERTIFICATION REQUIRED

(4.65 MPa)/(3.41 MPa) DOuse flexible type IPS grooved-end pipe couplings, at

Hydro testing at 1.1 times the design pressure.

side ports; allow full, 0.125 inch gap between port and

ASME Stamped and National Board Registered.

QUALIFICATION PRESSURE .....2700 PSI piping, and position piping to maximize flexibility of

In compliance with the ASME Sec X Edition 2015 but not Code Stamped.

(18.62 MPa) connection.

INTENDED USE: DOprovide flexibility in, and support for piping manifolds

Hydro testing at 1.5 times the design pressure.

The CodeLine 80S45 Fiberglass RO Pressure Vessel is so that vessel can grow in length under pressure without

CE Marked Standard.

ADAPTER KITS

designed for continuous, long term use as housing for undue restraint; provide additional flexible joints in large

Certified by Pentair UP DOWN

reverse osmosis membrane elements to desalt typical pipes leading to manifold header.

brackish waters at pressures up to 450 psi. Any make of DOprovide overpressure protection for vessel set at not PERMEATE PORT SELECTION STREAM STREAM

eight-inch nominal diameter spiral-wound element is more than 105% of design pressure

easily accommodated; the appropriate interfacing DOinspect end closures regularly; replace components that Serial Number End

hardware for the element specified is furnished with the have deteriorated and correct causes of corrosion Size of the Permeate Port 1 1.25 1.5

vessel. DO Lubricate seals sparingly, using nonpetroleum

Based lubricants, i.e. Parker Super O-lube, Type of Connection FNPT MNPT BSPTM BSPTF IPS GROOVED SANITARY

The CodeLine 80S45 is designed in accordance with the Glycerin or suitable silicone based lubricants.

engineering standards of the Boiler and Pressure Vessel Material of Construction Noryl SS316L Zeron 100

Code of the American Society of Mechanical Engineers DO NOTwork on any component until first verifying that Non Serial Number End

(ASME) as per Section X Edition 2015. At small pressure is relieved from vessel

additional cost vessels can be inspected during DO NOTmake rigid piping connections to ports or clamp Size of the Permeate Port 1 1.25 1.5

construction by an ASME Authorized Inspector and vessel in any way that resists growth of fiberglass shell

ASME Code stamped. Type of Connection FNPT MNPT BSPTM BSPTF IPS GROOVED SANITARY

under pressure;

*** DIA = 0.015 in. (0.4mm) and Material of Construction Noryl SS316L Zeron 100

*** L = 0.2 in. (6mm) for a length code 8 vessel

The CodeLine 80S45 must be installed, operated and DO NOT hang piping manifolds from ports or use vessel in Note:

maintained in accordance with the listed precautions and any way to support other components Standard offering is 1.0 FNPT in Noryl.

good industrial practice to assure safe operation over a DO NOTtighten Permeate Port connection more than one 1.25 & 1.5 BSPTF, 1.25 & 1.5 FNPT and 1.25 SANITARY connections cannot be offered

long service life. turn past hand tight Sanitary permeate port cannot be offered in Noryl

DO NOT operate vessel without connecting both Permeate

The high performance Filament wound FRP shell must be

Ports internally to complete set of elements or otherwise STRAP ASSEMBLY

allowed to expand under pressure; undue restraint at

plug ports internally so that external piping connection is Standard SS304 Optional SS316 Optional SS316L

support points or piping connections can cause leaks to

not subjected to feed pressure

develop in the shell. This side-ported vessel requires FEED/CONCENTRATE PORT SELECTION

DO NOTinstall Spacer on downstream end of vessel

special precautions in mounting and connection to piping

DO NOToperate vessel without Thrust Cone installed Material of Construction Standard CF3M Optional Duplex SS (CD3MN)

so that the vessel will not be subjected to excessive stress

downstream Optional Super Duplex SS (CD3MWCuN)

due to bending moments acting at the side openings in the

DO NOTpressurize vessel until double-checking to verify

fiberglass shell. The end closure, incorporating close

that the Locking Ring is in place and fully seated. Configuration Standard - CF3M 1D5D

fitting, interlocking metal components, must be kept dry

DO NOToperate vessel at pressure and temperature in Optional Multi port: (Refer SPEC.SHEET/PM/1.5-3 for Multi ports selection).

and free of corrosion; deterioration can lead to

excess of its rating. 2.5 Ports not available in 90 Configuration.

catastrophic mechanical failure of the head.

DO NOToperate vessel with permeate pressure in excess of

Pentair will assist the purchaser in determining the 125 psi at 190F (0.86 Mpa at 880 C). Serial number end PORT SIZE CODE

suitability of this standard vessel for their specific DO NOTtolerate leaks or allow end closures to be routinely D 1 GROOVED END

operating conditions. The final determination however, wetted in any way Opposite end

including evaluation of the standard material of DO NOToperate outside the pH range 3-11. E 2 GROOVED END

construction for compatibility with the specific corrosive BEARING PLATE MATERIAL

environment, shall be the responsibility of the purchaser. F 2 GROOVED END

For complete information on proper use of the vessel

Alternate materials with enhanced corrosion resistance are Please refer to the 80S Series USERS GUIDE 94182. Standard 6061 T6 Aluminium

available on special order.

Optional Stainless Steel 316L

Specifications are subject to change without notice.

Note: Please refer to 99321 for sanitary details and refer page-3 for optional Part numbers.

DWG. NO. 99161-Q. PENTAIR PAGE 2 OF 3.

BEARING PLATE PART NUMBERS SEALING PLATE PART NUMBERS

PERMEATE PORT SIZE ALUMINIUM SS316L # #

1.0"/1.25" 96476

Standard used for Aluminium BP 96160

96157

1.5" 96411 97373 Optional used for SS316L BP 96477

PERM PORT RETAINER RING & PORT NUT PART

STRAP ASSEMBLY PART NUMBERS

NUMBERS

1.0" / 1.25" Standard Port nut 45066

SS304 SS316 SS316L

1.5" Port Retainer Ring 45247 45042 46926+ 94371+

F/C PORT & SEAL PART NUMBER

SIZE *CF3M **CD3MN ***CD3MWCuN SEAL

1.5" 98024 97353 96507 96077

2.0" 98025 97357 96643 96078

2.5" 98026 97364 96556 96079

PERMEATE PORT PART NUMBERS & PERMPORT TO F/C PORT OFFSET DISTANCE

FNPT MNPT BSPTF BSPTM IPS GROOVED

SIZE MATERIAL PART PART PART PART PART

NUMBER DIM "A" NUMBER DIM "A" NUMBER DIM "A" NUMBER DIM "A" NUMBER DIM "A"

NORYL 96162 5.5 97659 6.5 96301 5.5 97660 6.5 97661 6.8

1.0" SS316L # # 96752 5.5 97347 6.5 97351 5.5 97355 6.5 97322 6.8

#

ZERON 100 97349 5.5 97348 6.5 97352 5.5 97356 6.5 97293 6.8

NORYL NA NA 97655 6.5 NA NA 97360 6.5 97662 6.8

1.25" SS316L # # NA NA 96487 6.5 NA NA 97362 6.5 97311 6.8

#

ZERON 100 NA NA 97359 6.5 NA NA 97363 6.5 97365 6.8

NORYL NA NA 97663 6.1 NA NA 97369 6.1 97656 6.7

1.5" SS316L # # NA NA 97368 6.1 NA NA 97371 6.1 97449 6.7

#

ZERON 100 NA NA 97292 6.1 NA NA 97372 6.1 97374 6.7

Вам также может понравиться

- Materials Data for Cyclic Loading: Low-Alloy SteelsОт EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsРейтинг: 5 из 5 звезд5/5 (2)

- Codeline Drawing 80S45 PDFДокумент3 страницыCodeline Drawing 80S45 PDFHardik VavdiyaОценок пока нет

- Codeline Drawing 80S30Документ3 страницыCodeline Drawing 80S30Hardik VavdiyaОценок пока нет

- Pressure Vessel-80S100Документ2 страницыPressure Vessel-80S100IbrahimОценок пока нет

- Codeline Ecoline Drawing 80-450 Rev Q Total PDFДокумент2 страницыCodeline Ecoline Drawing 80-450 Rev Q Total PDFHardik VavdiyaОценок пока нет

- Codeline Drawing 80S15Документ3 страницыCodeline Drawing 80S15jugal ranaОценок пока нет

- Drawing Codeline-80S30 PDFДокумент3 страницыDrawing Codeline-80S30 PDFjohandi johandiОценок пока нет

- Appendix E - Drawings & Data SheetДокумент21 страницаAppendix E - Drawings & Data SheetsajanchaudhariОценок пока нет

- DWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Документ3 страницыDWG REF QTY Number Description Material Shell: Dash Length L IN (MM) P IN (MM) S IN (MM) Approx Weight LB (KG)Dillip DasОценок пока нет

- Codeline Drawing 40E100Документ2 страницыCodeline Drawing 40E100Hoàng Anh Tuấn NguyễnОценок пока нет

- Codeline Drawing 40S30 Non CodedДокумент2 страницыCodeline Drawing 40S30 Non CodedHardik VavdiyaОценок пока нет

- Codeline Drawing 40L30NДокумент2 страницыCodeline Drawing 40L30NArmando Corral BlancoОценок пока нет

- Codeline Drawing 80E30Документ2 страницыCodeline Drawing 80E30Aravind RaoОценок пока нет

- Drawing 80AQ15-60 Non CodedДокумент2 страницыDrawing 80AQ15-60 Non Codeddaus nasОценок пока нет

- Stellite 21Документ2 страницыStellite 21Mohsen ParpinchiОценок пока нет

- High Static Ducted Technical Manual 2016-Rev.4Документ149 страницHigh Static Ducted Technical Manual 2016-Rev.4soqhОценок пока нет

- Eng CS Epp-1376 1401-1Документ2 страницыEng CS Epp-1376 1401-1Siniša VučinićОценок пока нет

- Transmission ProductsДокумент42 страницыTransmission ProductsPritam SinghОценок пока нет

- 06-Air Inlet and Exhaust SystemДокумент29 страниц06-Air Inlet and Exhaust SystemSidney RodriguesОценок пока нет

- Tabla Compartiva Fluidos Hidraulicos - FormexДокумент4 страницыTabla Compartiva Fluidos Hidraulicos - Formexirvingsr91Оценок пока нет

- System Components: CV-98 Cylinder Shipping AssemblyДокумент2 страницыSystem Components: CV-98 Cylinder Shipping AssemblyGerardo R. Aquino0% (1)

- Tsa 2Документ6 страницTsa 2Amit SurtiОценок пока нет

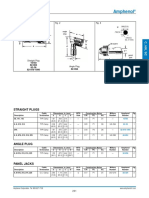

- HN Amphenol Plugs & JacksДокумент1 страницаHN Amphenol Plugs & Jackshafidz asyrafОценок пока нет

- Drive Unit Compl For Roller Screen: Drawing-No. Name Revision Assembly Group Format Part-NoДокумент2 страницыDrive Unit Compl For Roller Screen: Drawing-No. Name Revision Assembly Group Format Part-Nokev YОценок пока нет

- Anderson Grapa Pistola PDFДокумент2 страницыAnderson Grapa Pistola PDFJason Dennis100% (1)

- XL2B PumpДокумент2 страницыXL2B PumpJuan NietoОценок пока нет

- Air Pak SCBA Ordering Specifications (HS 6701)Документ8 страницAir Pak SCBA Ordering Specifications (HS 6701)QHSE ManagerОценок пока нет

- Primacorelw-71 en PDFДокумент2 страницыPrimacorelw-71 en PDFsattar12345Оценок пока нет

- Stellite 6Документ2 страницыStellite 6백승훈Оценок пока нет

- 38G-4 Safety Thermal Relief ValvesДокумент1 страница38G-4 Safety Thermal Relief ValvesThiên KhánhОценок пока нет

- IgnitionДокумент26 страницIgnitionRyan ActonОценок пока нет

- 8" Kpak Plus Modules: High Productivity Zero Bypass Ultrafiltration Modules For Electrocoat PaintДокумент2 страницы8" Kpak Plus Modules: High Productivity Zero Bypass Ultrafiltration Modules For Electrocoat Paintjeffersonfrias100% (1)

- Rhino Valves CatalogueДокумент174 страницыRhino Valves CatalogueLizaDuPlessisОценок пока нет

- Angled Low Profile Unit CoolersДокумент2 страницыAngled Low Profile Unit CoolersClarence JarlosОценок пока нет

- Membrane BWRO SUEZ-AG-LДокумент2 страницыMembrane BWRO SUEZ-AG-LEko SОценок пока нет

- Stellite 6Документ2 страницыStellite 6Shreenivas ThakurОценок пока нет

- Class 125 Bronze: Butterfly Valves - 200 PsiДокумент1 страницаClass 125 Bronze: Butterfly Valves - 200 Psithilina lakhithaОценок пока нет

- Avk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300Документ2 страницыAvk Gate Valve, Flanged, Pn25 02/67-030: EN 558-2 S.15/DIN F5, Bronze CC499K Wedge Nut, DN50-300kad-7Оценок пока нет

- Kunkle Relief ValveДокумент4 страницыKunkle Relief ValveJonathanHarker DPZОценок пока нет

- General Service Solenoid Valves: ConstructionДокумент3 страницыGeneral Service Solenoid Valves: ConstructionAditya B. RyantoОценок пока нет

- 3642 3742 Repair Parts - R36 3742 R4 02 21 - WebДокумент2 страницы3642 3742 Repair Parts - R36 3742 R4 02 21 - Webcristhian.sebastian.12Оценок пока нет

- XXAAXXДокумент8 страницXXAAXXMuhammad Emirzan FirdausОценок пока нет

- 1º Manual Retroescavadeira 416E Julho 2007 (193 243)Документ51 страница1º Manual Retroescavadeira 416E Julho 2007 (193 243)Cristian SpositoОценок пока нет

- Bill of Quantity: Fabrikasi 5 (Lima) Unit Tube Bundle 11-E-108, 11-E-109, 11-E-110A, 11-E-110B, 11-E-122, Tahun 2013Документ3 страницыBill of Quantity: Fabrikasi 5 (Lima) Unit Tube Bundle 11-E-108, 11-E-109, 11-E-110A, 11-E-110B, 11-E-122, Tahun 2013moddysОценок пока нет

- Et&s-Mep Materail SpecificationДокумент1 страницаEt&s-Mep Materail Specificationneng oudomОценок пока нет

- Technical - Spec SkirtДокумент25 страницTechnical - Spec SkirtStructures ProductionОценок пока нет

- Gfps Datasheet 561 562 Cone Check Valve enДокумент8 страницGfps Datasheet 561 562 Cone Check Valve encarnaticshankОценок пока нет

- TPT 20221220a Rev.1Документ5 страницTPT 20221220a Rev.1Kaajma EngineeringОценок пока нет

- Prensa Cables Armados Con Compound - 02Документ1 страницаPrensa Cables Armados Con Compound - 02Vipper80Оценок пока нет

- MODEL 350EC16: Globe ValveДокумент8 страницMODEL 350EC16: Globe Valvekeyur1109Оценок пока нет

- AVKДокумент2 страницыAVKpiscesguy78Оценок пока нет

- Heat Exchanger Vendor Bid Evaluation Table - Key DataДокумент1 страницаHeat Exchanger Vendor Bid Evaluation Table - Key DatakasraОценок пока нет

- G-Series: Typical ApplicationsДокумент3 страницыG-Series: Typical ApplicationsMbc spunkyОценок пока нет

- PSA Cast-In Plates - Technical Data SheetДокумент7 страницPSA Cast-In Plates - Technical Data SheetGnansabesan JathurschanОценок пока нет

- Heritage Smoke-Spill Series: N NO Oiissee D DA Atta AДокумент2 страницыHeritage Smoke-Spill Series: N NO Oiissee D DA Atta AAhmed ShahenОценок пока нет

- FA AGM Cat 061112 SДокумент12 страницFA AGM Cat 061112 SVinh TrươngОценок пока нет

- Apepdcl: Technical SpecificationsДокумент312 страницApepdcl: Technical Specificationskapila venkata subramanyamОценок пока нет

- SQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsДокумент9 страницSQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsSUJAL SHAH - SKIPPER LIMITEDОценок пока нет

- Butterfly ValveДокумент2 страницыButterfly ValveKELVIN TECHNOLOGIESОценок пока нет

- DWG BrochureДокумент4 страницыDWG BrochureMiguel BentoОценок пока нет

- Pressure Analysis of A Flange: Linear Multi-Body AnalysisДокумент19 страницPressure Analysis of A Flange: Linear Multi-Body Analysisbetow_Оценок пока нет

- PV Elite WebinarДокумент24 страницыPV Elite WebinarAndrea Hank LattanzioОценок пока нет

- Analysis of Dished Head and Skirt Joint of Pressure Vessel Using FEA MethodДокумент4 страницыAnalysis of Dished Head and Skirt Joint of Pressure Vessel Using FEA MethodIJSTEОценок пока нет

- Padeye CalculationДокумент6 страницPadeye CalculationKarun DasОценок пока нет

- E 3305-0!04!11 GewichtsreduzierterSpeicher LQДокумент4 страницыE 3305-0!04!11 GewichtsreduzierterSpeicher LQbetow_Оценок пока нет

- Appendix D - Padeye Design DNV 2.-1Документ2 страницыAppendix D - Padeye Design DNV 2.-1chorged100% (1)

- Tonkaflo Pumps As Series: Installation, Operation, and Maintenance ManualДокумент38 страницTonkaflo Pumps As Series: Installation, Operation, and Maintenance Manualbetow_Оценок пока нет

- Tonkaflo Pumps As Series: Installation, Operation, and Maintenance ManualДокумент38 страницTonkaflo Pumps As Series: Installation, Operation, and Maintenance Manualbetow_Оценок пока нет

- Laboratory 1 - Identification of Minerals and Rocks - NewДокумент16 страницLaboratory 1 - Identification of Minerals and Rocks - NewMohammad Firdaus Hakimi B. BorhannudinОценок пока нет

- PVRVДокумент4 страницыPVRVbkkbrazil100% (1)

- Nama Obat Saluran CernaДокумент4 страницыNama Obat Saluran Cernadewi puspitaОценок пока нет

- Isi BukuДокумент183 страницыIsi BukuHayat Hamzah DawiОценок пока нет

- Analisis Fitokimia Daun Pepaya (Carica Papaya L.) A'yun Et Al.Документ7 страницAnalisis Fitokimia Daun Pepaya (Carica Papaya L.) A'yun Et Al.Cahaya Medika1Оценок пока нет

- TSS-TI-021-02 Chalking of Epoxy Surfaces PDFДокумент2 страницыTSS-TI-021-02 Chalking of Epoxy Surfaces PDFYeoh chun yenОценок пока нет

- Concentration of Solutions DLPДокумент3 страницыConcentration of Solutions DLPLouise Meara Severo70% (10)

- 7 Accuracy of Rating ModelДокумент154 страницы7 Accuracy of Rating ModelSambeet MallickОценок пока нет

- ThermalPhysics 1 SolnsДокумент24 страницыThermalPhysics 1 Solnsrbebeau100% (2)

- Furnace AC Example PDFДокумент5 страницFurnace AC Example PDFhanafiОценок пока нет

- Rapid Fire NewДокумент85 страницRapid Fire NewvarunsanghiОценок пока нет

- Atago PAL-1 Refractometer Instruction ManualДокумент5 страницAtago PAL-1 Refractometer Instruction ManualJosé CamposОценок пока нет

- Exotic TarantulasДокумент82 страницыExotic TarantulasThiago MartinsОценок пока нет

- Recommended Construction Guidelines For Full Depth Reclamation (FDR) Using Bituminous StabilizationДокумент13 страницRecommended Construction Guidelines For Full Depth Reclamation (FDR) Using Bituminous StabilizationDao Phuc LamОценок пока нет

- Heat-Resistant Pressure-Vessel Steels: Mechanical Properties Available DimensionsДокумент1 страницаHeat-Resistant Pressure-Vessel Steels: Mechanical Properties Available DimensionsRamachandran SundararamanОценок пока нет

- 3 HerbsДокумент260 страниц3 HerbsWahyu Edwin SОценок пока нет

- METALS Structured Questions and Worked SolutionsДокумент9 страницMETALS Structured Questions and Worked SolutionsYoviОценок пока нет

- Industrial PRO FH239Документ8 страницIndustrial PRO FH239giulianogjОценок пока нет

- Nutrient Recovery From Wastewater Stream PDFДокумент10 страницNutrient Recovery From Wastewater Stream PDFPedro RipaceОценок пока нет

- Remazol Ultra RGB Feb 2010Документ23 страницыRemazol Ultra RGB Feb 2010rauftextile0% (2)

- Mechanical Properties of Ultra-High-Performance Concrete Enhanced With Graphite Nanoplatelets and Carbon NanofibersДокумент10 страницMechanical Properties of Ultra-High-Performance Concrete Enhanced With Graphite Nanoplatelets and Carbon NanofibersRUSNA KPОценок пока нет

- Binding Energy Worksheet - 3Документ4 страницыBinding Energy Worksheet - 3Ysabela BernardoОценок пока нет

- Recrystallization: Activity No. 6Документ6 страницRecrystallization: Activity No. 6Mary Jean SteffenОценок пока нет

- 772838Документ2 страницы772838Wilder Atalaya ChavezОценок пока нет

- NEW Sonotech UT-X Powder PDFДокумент2 страницыNEW Sonotech UT-X Powder PDFanmosОценок пока нет

- Prria MemoДокумент4 страницыPrria MemoRebecca C. LewisОценок пока нет

- Preparation of Standard Solutions and Acid-Base TitrationДокумент4 страницыPreparation of Standard Solutions and Acid-Base TitrationJhon Jasper ApanОценок пока нет

- Research Proposal - Chaper 1Документ10 страницResearch Proposal - Chaper 1Kia Javar100% (1)

- Design and Analysis of Shock AbsorberДокумент12 страницDesign and Analysis of Shock AbsorberSILAMBARASANОценок пока нет

- Fischer Esterification of Benzyl AcetateДокумент3 страницыFischer Esterification of Benzyl AcetateMarjory CastilloОценок пока нет