Академический Документы

Профессиональный Документы

Культура Документы

Stock Specifications - Plates - S355G10 M

Загружено:

acadjournals. comАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Stock Specifications - Plates - S355G10 M

Загружено:

acadjournals. comАвторское право:

Доступные форматы

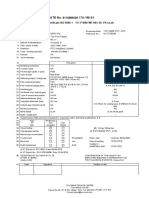

Stock Specifications - Plates

High yield structural Plates for offshore S355G10+M

S355G10+M high yield structural plates are intended for (but not limited to) use in fixed offshore structures, designed to

operate in the offshore sector.

Applicable codes and standards

BS- EN 10225:2009

Weldable structural steels for fixed offshore structures - technical delivery conditions.

Grade S 355 G 10 +M

Structural Minimum Yield Letter G Delivery condition

Symbol indicating that the following In MPa for thicknesses t 16mm. Followed by a maximum of two digits + M Thermo mechanical rolling

figures specify the minimum yield characterizing and indicating the + N Normalizing rolling

strength in MPa. (MPa = N/mm2) t 16 mm 355 MPa steel grade within the groups + Q Quenched and tempered

16 < t 25 mm 355 MPa 1, 2 or 3, as defined per table 4 of

25 < t 40 mm 345 MPa EN 10225. Thermo mechanical rolling is a rolling

40 < t 63 mm 335 MPa process in which the final

63 < t 100 mm 325 MPa deformation is carried out in a par-

ticular temperature range leading to

a material condition equivalent with

certain properties which cannot be

achieved or repeated by a heat treat-

Within EN 10225 this steel is designated as a group 3 steel which means that this grade is substantially modified ment alone.

from EN 10025-4. This steel offers enhanced through thickness ductility and impact values verified at -40C.

This grade is also known as 1.8813+M.

Chemical composition

Product analysis in % (All values are max. unless otherwise stated.)

C 0,12 Cu 0,30 Cr+Mo+Ni+Cu -

Si 0,15-0,55 N 0,010 Nb+V 0,06

Mn 1,65 Nb 0,030 Nb+V+Ti 0,08

CEV (IIW) T 75mm: 0,41

P 0,015 Ti 0,025

see formula below T > 75mm: 0,42

Pcm T 75mm: 0,21

S 0,005 V 0,060

see formula below T > 75mm: 0,22

Cr 0,20 As2 0,03

Mo 3

0,08 Sb 2

0,010 Bi2 0,010

Ni 4

0,70 Sn 2

0,020 Ca 2

0,005

Al 5

0,015/0,055 Pb 2

0,010 B2

0,0005

Mn Cr+Mo+V Ni+Cu Si Mn+Cu+Cr Ni Mo V

CEV = C + + + Pcm = C + + + + + + 5B

6 5 15 30 20 60 15 10

1

As per paragraph 8.2.3.2 of EN 10225 the Pcm-value shall apply (instead of the CEV-value, see option 9)

2

Residual elements shall be checked once every 5.000 tons per manufacturing location and shall be reported as a ladle analysis

3

For T > 75 mm with supply condition +M the maximum Mo content shall be 0,20%

4

For T > 40 mm the minimum Ni content shall be 0,30%

5

The total aluminium to nitrogen ratio shall be a minimum of 2:1. When other nitrogen binding elements are used the minimum Al value and Al:N ratio does not apply

Mechanical properties

S355G10+M

Thickness t Yield Reh Tensile Rm Reh / Rm CVN El

mm MPa (min.) MPa - -40 C %

t 16 355 max. 0,93

16 < t 25 355

50J

25 < t 40 345 470-630 22

max. 0,90 transverse

40 < t 63 335

63 < t 100 325

Available options for stock plates as per section 13 of EN 10225

Option Subject Remarks

10 PWHT* Mechanical tests include SPWHT condition for thicknesses greater than 40 mm

Strain ageing tests are carried out for thicknesses greater than or equal to 12,5 mm. Plastic strain 5%,

12 Strain ageing*

aged for 1h at 250C. Transverse CVN-values in strain aged condition min. 36/26J at -40C

Through Thickness TTP testing for thicknesses 15 mm. To meet class Z35 according to EN 10164. Through thickness

13

Testing strengths min 80% of specified minimum tensile strength for specified thickness

- Low Sulphur S 0,005% in combination with above option 13

- Hardness Hardness tested according to Vickers

18 Weldability* Pre qualification for thicknesses 40 mm up to 75 mm

*Available upon request

Surface

All surfaces have been 100% visually inspected. The surface condition does comply with EN 10163-2, class A, sub-class 3.

NDT

All plates have been ultrasonically tested in accordance with EN 10160. Ultrasonic testing has been carried out either prior to, or

after the final heat treatment and does meet the requirements of EN 10160, class S1/E2 for steels of group 3. According

EN 10225 this steel designated a group 3 steel.

Certification and traceability

All dimensions will be supplied with a 3.2 certificate according to EN 10204, endorsed by recognized and independent inspection agency.

Low stress die-stamping on head and tail of each plate.

Dimensional control

All dimensions will be supplied according to EN 10029, flatness class N, thickness class A.

Rev 1 I September 2013

Вам также может понравиться

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelДокумент2 страницыTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UОценок пока нет

- Aisi 4140 Alloy Steel (Uns g41400)Документ4 страницыAisi 4140 Alloy Steel (Uns g41400)Deepak ChaurasiaОценок пока нет

- Arcelormittal Pressure VesselДокумент10 страницArcelormittal Pressure VesselkokopirokoОценок пока нет

- Material Datea 2.4602Документ3 страницыMaterial Datea 2.4602Charwin XiaoОценок пока нет

- dpvc-09 Petrobras PDFДокумент47 страницdpvc-09 Petrobras PDFBilly TanОценок пока нет

- Chemical and Mechanical PropertiesДокумент5 страницChemical and Mechanical PropertiesAristotle MedinaОценок пока нет

- Esab Buddy TIG400iДокумент2 страницыEsab Buddy TIG400iJeganeswaranОценок пока нет

- Datasheet Sandvik 6r35 enДокумент7 страницDatasheet Sandvik 6r35 enSimone FerronОценок пока нет

- Ghibson GB015Документ2 страницыGhibson GB015Jessicalba LouОценок пока нет

- Material Product Data SheetДокумент4 страницыMaterial Product Data SheethungОценок пока нет

- Astm A105Документ1 страницаAstm A105Isaac SamuelОценок пока нет

- Data Sheet Material 2.4819Документ3 страницыData Sheet Material 2.4819BoberОценок пока нет

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Документ3 страницыHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitОценок пока нет

- 1 Scope: 1.1 Bar Stock RestrictionsДокумент5 страниц1 Scope: 1.1 Bar Stock RestrictionsMaria MadalinaОценок пока нет

- Techincal Data For PCD Dia & Torque ChartДокумент1 страницаTechincal Data For PCD Dia & Torque ChartTuff quality100% (1)

- Aa10208 FINAL - 1Документ139 страницAa10208 FINAL - 1Surendra MalasaneОценок пока нет

- Api 5l Test PressrureДокумент2 страницыApi 5l Test PressrureSıddık SarıcalarОценок пока нет

- Material Receiving & CertificateДокумент18 страницMaterial Receiving & CertificateAlbi FadjrinОценок пока нет

- Sa 414Документ4 страницыSa 414AnilОценок пока нет

- Electrodo Lincoln 7018Документ2 страницыElectrodo Lincoln 7018Erick Quan Luna100% (1)

- SA/AS1548 - 7 - 460R: XlerplateДокумент3 страницыSA/AS1548 - 7 - 460R: XlerplatenavОценок пока нет

- MTC 8,10Документ2 страницыMTC 8,10Vu NamОценок пока нет

- C-12 16.8.2 Rev 05Документ5 страницC-12 16.8.2 Rev 05prabu prasadОценок пока нет

- Impact AR500 PlateДокумент2 страницыImpact AR500 PlateMario Diez100% (1)

- IMIOrton MV SeriesДокумент4 страницыIMIOrton MV SeriesFelipe Gamboa GálvezОценок пока нет

- Material Data Sheet For NH25-35MICДокумент2 страницыMaterial Data Sheet For NH25-35MICJean-Noël LerouxОценок пока нет

- GPT - Honeywell Pressure SensorДокумент10 страницGPT - Honeywell Pressure SensorKaran Bir SinghОценок пока нет

- Supplier Comparison 0.22: Grade C % Max MN% Max S % M P % MaxДокумент13 страницSupplier Comparison 0.22: Grade C % Max MN% Max S % M P % MaxShihab Aziz0% (1)

- 023 147 Ind ReqДокумент2 страницы023 147 Ind ReqKishore KumarОценок пока нет

- Thermanit 17-06 (Boehler)Документ1 страницаThermanit 17-06 (Boehler)queno1Оценок пока нет

- Analyzing & Testing. Dilatometry. Method, Instruments, Applications From - 180 C To 2800 C. Leading Thermal AnalysisДокумент36 страницAnalyzing & Testing. Dilatometry. Method, Instruments, Applications From - 180 C To 2800 C. Leading Thermal AnalysisMary SmileОценок пока нет

- WWW Wollastonalloys Com Materials 2Документ8 страницWWW Wollastonalloys Com Materials 2Mark RomeroОценок пока нет

- Sa 299Документ3 страницыSa 299Web LogueandoОценок пока нет

- Thành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateДокумент2 страницыThành Phần, Cơ Tính JIS G4801 SUP10 Steel PlateĐình Sỹ TTPОценок пока нет

- C43Документ1 страницаC43rudramansingh123Оценок пока нет

- WeldOlet 3,6,9KДокумент8 страницWeldOlet 3,6,9KSubramanian Shanmuga SundaramОценок пока нет

- Dynamic Balancing MachineДокумент4 страницыDynamic Balancing Machine.x100% (1)

- Certificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBДокумент1 страницаCertificate No. / 74 / W/ 01: Welder S Certificate ISO 9606-1 111 P BW FM1 RB T 20 PA SS, NBDeepak Das100% (1)

- SWRCH18AДокумент2 страницыSWRCH18AHari SuthanОценок пока нет

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresДокумент8 страницWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesОценок пока нет

- Din 17100Документ4 страницыDin 17100Sheby SandyОценок пока нет

- 8-1280-13 Pipe Class HF-1Документ4 страницы8-1280-13 Pipe Class HF-1Jesus MendezОценок пока нет

- Ss Grade 50 - Galvanized Steel Coils & SheetsДокумент1 страницаSs Grade 50 - Galvanized Steel Coils & SheetshealgoseОценок пока нет

- Asian Paints Apcothane CF 674 PDFДокумент1 страницаAsian Paints Apcothane CF 674 PDFANUP KUMAR MITRAОценок пока нет

- Tabla Torqueo de PernosДокумент1 страницаTabla Torqueo de PernosErnesto LinaresОценок пока нет

- Hydro Aluminium - AlSi7Mg0.6Документ2 страницыHydro Aluminium - AlSi7Mg0.6Raj PrasanthОценок пока нет

- Corrosion Resistance TablesДокумент9 страницCorrosion Resistance TablesManoj BОценок пока нет

- Guia de Materiales - MatricesДокумент11 страницGuia de Materiales - MatricesGracielaОценок пока нет

- Inspection CertificateДокумент1 страницаInspection CertificateAtanasio PerezОценок пока нет

- TES 101-158 - 7 - Hi PDFДокумент8 страницTES 101-158 - 7 - Hi PDFRossoОценок пока нет

- b2020-Tdc-Fas-004 Fasteners r3Документ2 страницыb2020-Tdc-Fas-004 Fasteners r3Ramalingam PrabhakaranОценок пока нет

- Aisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFДокумент1 страницаAisi 1043 Steel - Hot Rolled Bar (Uns g10430) PDFfeltofsnakeОценок пока нет

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedДокумент1 страницаThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not Contractedlijojose1Оценок пока нет

- Infoprd-Geomet 500-gb PDFДокумент2 страницыInfoprd-Geomet 500-gb PDFSannohashi MFGОценок пока нет

- Comp SA36, IS 2062, SA516 GR 60Документ2 страницыComp SA36, IS 2062, SA516 GR 60RajendraОценок пока нет

- Metal matrix composites: Processing and InterfacesОт EverandMetal matrix composites: Processing and InterfacesR EverettОценок пока нет

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987От EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonОценок пока нет

- Plates - S420G2 M PDFДокумент2 страницыPlates - S420G2 M PDFAdisak AumpiemОценок пока нет

- TWI Enrolment Form PDFДокумент4 страницыTWI Enrolment Form PDFacadjournals. comОценок пока нет

- ASTM - STP436 Electron FractographyДокумент236 страницASTM - STP436 Electron Fractographyacadjournals. comОценок пока нет

- A Comparative Multi Disciplinary Policy Review in Wind Energy Developments in Europe by VeraДокумент22 страницыA Comparative Multi Disciplinary Policy Review in Wind Energy Developments in Europe by Veraacadjournals. comОценок пока нет

- M CR 601r1Документ14 страницM CR 601r1nazari123Оценок пока нет

- Slenderness Effects in ColumnsДокумент11 страницSlenderness Effects in ColumnsDaniyal AhmadОценок пока нет

- Management Lesson: How Is A Paradigm Created... ?Документ11 страницManagement Lesson: How Is A Paradigm Created... ?Vineeth100% (4)

- Cost of Wind Energy PDFДокумент111 страницCost of Wind Energy PDFacadjournals. comОценок пока нет

- Sample Pages From FDG PDFДокумент5 страницSample Pages From FDG PDFBoom KubОценок пока нет

- EEA Invite 2016Документ1 страницаEEA Invite 2016acadjournals. comОценок пока нет

- Bolt Head Fillet Stress Concentration Factors in Cylindrical Pressure VesselsДокумент6 страницBolt Head Fillet Stress Concentration Factors in Cylindrical Pressure Vesselsacadjournals. comОценок пока нет

- 2011 3 11 2 Review of Generator Systems For Direct-Drive Wind Turbines PDFДокумент11 страниц2011 3 11 2 Review of Generator Systems For Direct-Drive Wind Turbines PDFacadjournals. comОценок пока нет

- Design Principles of Welded Structures - JointsДокумент9 страницDesign Principles of Welded Structures - Jointsacadjournals. comОценок пока нет

- ABAQUS Element Selection CriteriaДокумент45 страницABAQUS Element Selection Criteriacoteesh100% (1)

- Wind Turbine AnalysisДокумент10 страницWind Turbine AnalysiststamaОценок пока нет

- CERTIFIED Quality EngineerДокумент16 страницCERTIFIED Quality Engineeracadjournals. comОценок пока нет

- Cswip Rules & Code of EthicsДокумент2 страницыCswip Rules & Code of EthicsHafdi NawfalОценок пока нет

- A Multi-Objective Optimization Framework For Offshore Wind Turbine Farm LayoutДокумент42 страницыA Multi-Objective Optimization Framework For Offshore Wind Turbine Farm Layoutacadjournals. comОценок пока нет

- Code of ConductДокумент1 страницаCode of Conductangeloflight179Оценок пока нет

- Bending ResistanceДокумент3 страницыBending ResistancedinaarzinaОценок пока нет

- CERTIFIED Quality EngineerДокумент16 страницCERTIFIED Quality Engineeracadjournals. comОценок пока нет

- Phase EquilibriaДокумент10 страницPhase Equilibriaacadjournals. comОценок пока нет

- 3 Pin Plug Presentation FinalДокумент22 страницы3 Pin Plug Presentation Finaljaygamer100% (2)

- TLT-501 (02) Mix Design Method For Soil-Cement Mixtures 1.0 SCOPEДокумент9 страницTLT-501 (02) Mix Design Method For Soil-Cement Mixtures 1.0 SCOPEagus wahyudiОценок пока нет

- DX DiagДокумент27 страницDX DiagCecep AdjaОценок пока нет

- Pure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)Документ2 страницыPure Racing Performance.: All-New 2019 TVS Apache RTR 180 (BS IV)sandeep sehrawatОценок пока нет

- GPR Import DisplayДокумент2 страницыGPR Import DisplayAlexandra GereaОценок пока нет

- OMN-FAC-170 Specification For MV & LV Electrical CableДокумент13 страницOMN-FAC-170 Specification For MV & LV Electrical Cablesumit kumarОценок пока нет

- GSM Modem PDFДокумент2 страницыGSM Modem PDFFalling SkiesОценок пока нет

- Catalog: Conduit, Elbows, Couplings and NipplesДокумент44 страницыCatalog: Conduit, Elbows, Couplings and NipplesbahrowiadiОценок пока нет

- 1756 pp015 - en P PDFДокумент2 страницы1756 pp015 - en P PDFreinaldomdОценок пока нет

- Catalogo Kaeser PDFДокумент7 страницCatalogo Kaeser PDForlando_ubaldoОценок пока нет

- SAP Business Connector SAP Adapter GuideДокумент254 страницыSAP Business Connector SAP Adapter GuideJungmoo KimОценок пока нет

- Hyundai DF507S 1Документ6 страницHyundai DF507S 1ookyilwin3795Оценок пока нет

- Chapter 19 - Decision-Making Under RiskДокумент29 страницChapter 19 - Decision-Making Under RiskBich Lien PhamОценок пока нет

- How To - Establish IPSec VPN Using Vigor Draytek ADSLДокумент8 страницHow To - Establish IPSec VPN Using Vigor Draytek ADSLthangnmОценок пока нет

- Assigment BEGДокумент5 страницAssigment BEGDanielNathОценок пока нет

- Advanced Motion Controls Sr30a40acДокумент11 страницAdvanced Motion Controls Sr30a40acElectromateОценок пока нет

- Digital HV Insulation Tester 10KV KM 2804 inДокумент1 страницаDigital HV Insulation Tester 10KV KM 2804 inindustrialindiaОценок пока нет

- GP 14-01 Noise ControlДокумент12 страницGP 14-01 Noise Controlzepol051Оценок пока нет

- CAS Protocols Reference ManualДокумент156 страницCAS Protocols Reference Manualtesting11Оценок пока нет

- 2003 Nissan Altima 2.5 Serivce Manual PBДокумент8 страниц2003 Nissan Altima 2.5 Serivce Manual PBAndy DellingerОценок пока нет

- Lubrizol Hydraulic FluidsДокумент6 страницLubrizol Hydraulic Fluidsrohit_12346Оценок пока нет

- tn-17 Crosslinked Polyethylene Pex PDFДокумент14 страницtn-17 Crosslinked Polyethylene Pex PDFTitus FelixОценок пока нет

- Standby 5 0 0 e K W 6 2 5 K V A 60 HZ 1800 RPM 480 Volts: Diesel Generator SetДокумент6 страницStandby 5 0 0 e K W 6 2 5 K V A 60 HZ 1800 RPM 480 Volts: Diesel Generator Setlpolo12Оценок пока нет

- 53258-03 (Mach 2.1), GL2-GL2000-RCA-3.0kДокумент7 страниц53258-03 (Mach 2.1), GL2-GL2000-RCA-3.0kBalboaWaterОценок пока нет

- VFD Wiring Best Practices - AP040076EN PDFДокумент5 страницVFD Wiring Best Practices - AP040076EN PDFIsmael Ochoa JimenezОценок пока нет

- 440001-2 (Ari-Armaturen) Control ValvesДокумент36 страниц440001-2 (Ari-Armaturen) Control ValvesnitestarОценок пока нет

- KSP06 DatasheetДокумент2 страницыKSP06 DatasheetJose BenavidesОценок пока нет

- Holdpeak 1356 enДокумент39 страницHoldpeak 1356 enGabrielyNoelia GarayОценок пока нет

- 2010 Transit BrochureДокумент16 страниц2010 Transit BrochureHomer Skelton Ford of MillingtonОценок пока нет

- BS 3148Документ10 страницBS 3148muhammad iqbalОценок пока нет