Академический Документы

Профессиональный Документы

Культура Документы

Elect Sect03

Загружено:

Luis Eduardo Corzo EnriquezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Elect Sect03

Загружено:

Luis Eduardo Corzo EnriquezАвторское право:

Доступные форматы

SEGQ4031 - 216 - Lesson Plan

8/02

Caterpillar Engine Electronics

Lesson Plan 13 - Electronic Component Summary

Objectives:

The students will be able to recall which electronic components are needed to for an

engine to start and run.

The students will be able to associate possible engine malfunctions with the

electronic component most likely to cause the given symptoms.

The students will sort all electrical components into three catergories: input, output,

and control.

The student will state which components are found on or off the engine.

Literature Needed:

PowerPoint Slides

Hardware Needed:

Whiteboard and markers

Projector and smartboard

Time Required:

1.5 Hours

Tasks Required by Instructor to Meet Objectives:

1. Shut off the projector, and describe the following scenario to the class:

Imagine that a brand new, electronically controlled engine has just been delivered from

the factory. It is sitting on a shipping stand here in the classrooom. We know that the

engine will run -- it passed the test cell at the factory. What would we need in order to

start it up here in the classroom?

Ask the students to brainstorm a list of items. Note the responses on the board. They

should include the following:

fuel

coolant

oil

starter

battery power

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 217 - Slide/Text Reference

8/02

harness and cables

fuses

relays

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 218 - Slide/Text Reference

8/02

Yesterday, we discussed a wide variety of electronic components. It can

seem overwhelming when we look at all the different components that

have been used over the years, on all the different engines, and on the

different applications of those engines. Today, we will simplify those

components as far as troubleshooting is concerned. There are really only

twenty five types of components, and they all can be sorted into three

main categories.

After summarizing the electronic components, we will have two lab

sessions, where you will explore the functions and uses of diagnostic

tooling. We will use ECAP (Electronic Control Analyzer and

Programmer), Caterpillar Electronic Technician (ET), a VOM, and a

test lamp. Yes, there is at least one troubleshooting procedure that still

requires the use of a test lamp.

The first lab will be conducted in the classroom, using engine

simulators. This will be followed by a lab in the shop area, with

runnable engines.

The engines are all in normal operating order. You will be able to

perform a variety of tests to see how a normal engine should respond.

Tomorrow afternoon, you will have another lab on the same engines. In

tomorrows lab, the engines will have some actual problems for you to

troubleshoot.

Imagine that a brand new, electronically controlled engine has just been

delivered from the factory. It is sitting on a shipping stand here in the

classrooom. We know that the engine will run -- it passed the test cell at

the factory. What would we need in order to start it up here in the

classroom?

Ask the students to brainstorm a list of items. Note the responses on the

board. They should include the following:

fuel

coolant

oil

starter

battery power

harness and cables

fuses

relays

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 219 - Slide/Text Reference

8/02

These are basic to any engine, electronic or mechanical. Weve always

needed these things. You are already comfortable with troubleshooting

problems related to the items on the list.

People often see an ECM on the side of the engine, and panic. If they

cannot hook up an electronic service tool and find a code, they are lost

as far as troubleshooting is concerned. Remember that the items we just

listed are necessary for any engine.

Earlier in the week, we discussed the various engines that Caterpillar

has built over the years, sorting them into categories according to their

fuel system. What were the categories? (PEEC, MEUI, HEUI)

Instructor Note: Start the projector, and go to slide #153. Distribute the

handout for the summary of the twenty five electronic components.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 220 - Slide/Text Reference

8/02

PEEC

EUI

HEUI

Slide # 152

We sort by fuel Although we have many engines, and many applications for those

systems engines, they can be sorted according to their fuel system into broad

categories for ease of troubleshooting. We will use these three

categories in our summary of electronic components.

PEEC, EUI, HEUI

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 221 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not

crank

crank

+Battery

+Battery

-Battery

-Battery

PEEC has 8

ECM

Personality Module

Parameters

EUI has 6

ECM

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

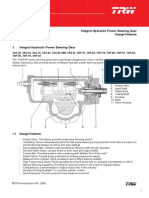

Slide # 153

Meaning of dead? All engines, regardless of the type of fuel system must have the items

that are listed at the left side of the chart.

The statement, The engine is dead, can have different meanings to

different people.

Is is completely dead, such that there is no clicking sound when the

starter switch is engaged?

Does the starter solenoid click once, followed by silence?

Is there a click, click, click sound?

Does the starter crank the engine slowly, and then stop?

Does the engine crank at normal starting speed, but will not start?

Each of these symptoms is a clue to the problem. With the possible

exception of the last bulleted item above, none of these are symptoms of

an electronic problem.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 222 - Slide/Text Reference

8/02

Ask the class the following questions:

Question: What could cause the engine to be completely dead (no

clicking sound when the starter switch is turned to the start position?

Answer: Either a completely dead battery, or an open connection

somewhere in the starting circuit (bad starter switch, open fuse relay or

disconnect, broken or disconnected wire or cable).

Question: What could cause the starter solenoid to click once, followed

by silence?

Answer: A bad solenoid or starter, a nearly dead battery, or a locked

engine (hydraulically or mechanically locked up).

Question: What could cause a click, click, click sound?

Answer: A bad solenoid or starter, or a nearly dead battery.

Question: What could cause the engine to crank slowly, and then stop?

Answer: A low battery.

Question: What could cause the engine to crank at normal starting

speed, yet not start?

Answer: Possibilities include lack of fuel, lack of air, mechanical

damage to the engine wherein it has no compression, or a problem with

an electronic component. In this situation, there is not a problem with

the battery or starting circuit. All engines must have a complete circuit

with the battery.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 223 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not

crank

crank

+Battery

+Battery

-Battery

-Battery

PEEC has 8

Starter

Starter ECM

Harness

Harness Personality Module

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

EUI has 6

ECM

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 154

First, Battery & Battery power, together with the starting circuit, is the first item on our

starter circuit list of conditions needed for the engine to start and run. Battery power is

needed by all engines, mechanical as well as PEEC, EUI, or HEUI

electronic engines.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 224 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not

crank

crank

+Battery

+Battery

-Battery

-Battery

PEEC has 8

Starter

Starter ECM

Harness

Harness Personality Module

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

Maybe

Maybe all

all OEM

OEM EUI has 6

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 155

Typically, the battery and starting circuit are OEM supplied. Problems

in this category are really not even engine problems.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 225 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery

-Battery

-Battery

PEEC

Starter

Starter ECM

Harness

Harness Personality Module

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

Maybe

Maybe all

all OEM

OEM EUI

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

Parameters

HEUI

ECM

Personality Module

Parameters

Slide # 156

Regardless of whether the engine has a PEEC, EUI, or HEUI fuel

system, it must have:

A functional ECM: The way to check the ECM is to rule out all other

ECM

causes. However, in nearly every case, if you can communicate with the

ECM, the ECM is not defective.

A functional Personality Module: People sometimes dont realize that

P/M a new ECM will not communicate until it has been FLASHed with

software (or had a chip installed in the older ECMs). Also, like any

other computer file, the personality module can be corrupted . Be

careful to select the correct file to be Flashed in an ECM. In nearly

every case, if the service tool can communicate with the ECM, the

Personality Module is not defective.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 226 - Slide/Text Reference

8/02

Properly configured parameters: Some parameters will allow the

engine to crank, but not start. Some will even limit or prevent cranking.

Parameters are very useful. Programmable with an electronic service

Parameters tool, such as ET, they are really the only thing possible to work on

inside an ECM.

Theft Deterrent is an example of a truck engine parameter that could

Theft Deterrent cause the condition of cranks but wont start. If this parameter is

enabled, it prevents the engine from starting until the operator has

entered a four character password. To enable the system, the operator

must enter the password before the engine is shut off. Then, when the

engine is shut off, it will not restart until the password has been entered

correctly via the CAT ID dash display (the operator could also use

Pocket Tech to enter the password). Passwords can be any combination

of numeric or alpha characters.

3500 Series engines are shipped without oil or coolant, to save

Shipping w/out oil transportation costs. To protect the engine, the following parameters are

or coolant

set to zero to prevent startup until the engine has been properly

commissioned:

Crank cycle & Crank Cycle parameter limits how many times the engine can try to

duration set to 0

crank.

Crank Duration parameter limits how long the engine can crank on each

attempt.

Review - Battery,

ECM, P/M, So far, we have looked at four items on the chart that could prevent an

Parameters engine from starting, even if it will crank properly. These requirements

apply to all electronic engines:

Battery Power

ECM

Personality Module

Parameters

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 227 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery

-Battery

-Battery

PEEC has 8

Starter

Starter ECM

Harness

Harness Personality Module

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

Maybe

Maybe all

all OEM

OEM EUI has 6

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 157

Separate For the remaining items that are necessary to start an engine, we need to

be specific as to what type of engine we are working on:

PEEC - 8

PEEC engines have four more requirements in order to start (eight

altogether).

EUI - 6

EUI engines have two more requirements (six altogether).

HEUI - 7

HEUI engines have three more requirements (seven altogether).

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 228 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery

-Battery

-Battery

PEEC has 8

Starter

Starter ECM

Harness

Harness Personality Module

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

Maybe

Maybe all

all OEM

OEM EUI has 6

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 158

Inputs The arrows pointing into the ECM represent inputs from sensors that are

required to start the engine.

The arrows pointing out of the ECM represent outputs to actuators that

Outputs

are required to start the ECM.

We will first consider the PEEC engines, then EUI, and then the HEUI.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 229 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor

-Battery

-Battery

PEEC has 8

Starter

Starter ECM

Harness

Harness Personality Module

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

Maybe

Maybe all

all OEM

OEM EUI has 6

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

VSS

VSS

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 159

8v input - engine The PEEC engine must have an input signal from its 8 volt engine speed

speed sensor. Remember, this is a sensor that provides speed information only.

It is not a speed/timing sensor. The PEEC engine will start and run

without input from its timing position sensor.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 230 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor

-Battery

-Battery

PEEC has 8

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid

Harness

Harness Personality Module

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

Maybe

Maybe all

all OEM

OEM EUI has 6

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 160

5v/2vshutoff The PEEC engine must also have a working shutoff solenoid. If there is

solenoid, a problem in the shutoff solenoid, or in its related circuit, the fuel rack

will not move from the shutoff position, and the engine will get no fuel.

With all other systems functional, the engine would crank but would not

start.

Note to instructor: Demonstrate the sound made by a functional shutoff

Demonstrate click

if possible

solenoid on a classroom engine simulator. When the key is turned to the

on position, but the engine is not started, the solenoid should click once

loudly, then once again more softly. The first click is the solenoid

plunger being pulled in as the coil is energized. The second click is the

plunger being released. This is an example of an ETR (Energized To

Run) solenoid.

Notice the 5V/2V notation on the chart. The ECM supplies five volts to

pull the plunger back, then drops to two volts to hold it back during

normal engine operation. This gives longer coil life.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 231 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor

-Battery

-Battery

PEEC has 8

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator

Switches

Switches Parameters

Fuses

Fuses

Relays

Relays

Maybe

Maybe all

all OEM

OEM EUI has 6

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 161

Rack BTM The PEEC engine must have a working 0V-4V Rack BTM (Brushless

Torque Motor) on 3400 product, or an Actuator on 3512 PEEC.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 232 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor

-Battery

-Battery

PEEC has 8

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator

Switches

Switches Parameters

Fuses

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor,

Relays

Relays wont

wont shut

shut down

down

Maybe

Maybe all

all OEM

OEM EUI has 6

Mech.

Mech. & & Elect

Elect Eng

Eng ECM

Not

Not engine

engine problem

problem

Personality Module

Parameters

HEUI has 7

ECM

Personality Module

Parameters

Slide # 162

Rack sensor, The final requirement for any PEEC engine to start is a functional rack

wont shutdown if position sensor. The notation on the chart that says, wont SD means

signal lost

wont shut down. This is a reminder that the engine will continue to

run if the rack position sensor signal is lost while the engine is running.

If the signal is lost while the engine is running, the PEEC ECM

Speed governing, automatically uses speed governing. In this mode, it compares the

wont restart current duty cycle from the throttle position and the current rpm from

without rack

the speed sensor to set a ratio. It then maintains this ratio of speed

sensor

versus duty cycle to run the engine. However, once the engine is shut

off it will not restart without a rack position signal.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 233 - Slide/Text Reference

8/02

We have now covered the eight required items for any PEEC engine to

start and run. Except for the rack position signal, the loss of any of the

other requirements will shut down a running engine.

The PEEC engines are perhaps the most difficult to troubleshoot. The

older technology gives only limited codes to indicate what is wrong.

If you have verified that all eight electronic requirements are functional,

Non electronic yet the engine will still not start and run, it is not due to an electronic

problem -- look elsewhere. Remember, even electronic engines wont

run without fuel!

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 234 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor

-Battery

-Battery

PEEC has 8

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator

Switches

Switches Parameters

Fuses

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor,

Relays

Relays wont

wont shut

shut down

down

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

Personality Module

Parameters

13.2v

13.2v

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

ECM

Personality Module

Parameters

Slide # 163

Now lets consider the EUI and HEUI requirements.

You still need Battery, ECM, Personality Module, and Parameters.

You also need a working speed/timing sensor (or sensors), so that the

EUI, HEUI ECM will know when to actuate the injectors.

Varieties of speed/timing sensors are:

ADEM II active

12.5v & 13.2v

The brass bodied, 12.5 volt active S/T sensor used on the 3176

The aluminum alloy bodied, 13.2 volt active S/T sensor on ADEM II

engines

The passive sensors used on ADEM III (ADEM 2000) engines.

ADEM III passive

Note: the passive speed/timing sensors work the same way on EUI and

HEUI engines, and troubleshoot in the same manner.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 235 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not

crank

crank not

not start

start communicate

communicate

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor

-Battery

-Battery

PEEC has 8

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator

Switches

Switches Parameters

Fuses

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor,

Relays

Relays wont

wont shut

shut down

down

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

Personality Module

Parameters 95-105v

95-105v EUI

EUI

13.2v

13.2v

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

ECM

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Slide # 164

Injectors EUI and HEUI engines also need proper functioning injectors.

95 to 105v dc

Remember that the injectors are powered by 95 to 105 Volts pulsating

SAFETY DC. Be careful when working around the injectors or the wiring for the

injectors. You could injure yourself, or someone else. For example,

dont perform an injector solenoid test while your partner is working

under the valve covers.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 236 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor

-Battery

-Battery

PEEC has 8

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator

Switches

Switches Parameters

Fuses

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor,

Relays

Relays wont

wont shut

shut down

down

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

Personality Module

Parameters 95-105v

95-105v EUI

EUI

13.2v

13.2v

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

ECM

0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Slide # 165

HEUI - IAPCV On HEUI engines, the final requirement to start and run the engine is a

working IAPCV (Injection Actuation Pressure Control Valve). Without

the IAPCV regulating the pressure of the actuation oil (under control of

the ECM) there will not be enough pressure available to actuate the unit

injectors.

Note: Although the IAP (Injection Actuation Pressure) sensor is not

IAP sensor listed on the chart, it could fail in a mode where it would prevent the

engine from starting. If the sensor is incorrectly signaling the ECM that

the actuation pressure is below 870 psi (735 psi on the older 3126

engines), regardless of what the actuation pressure really is, the ECM

will not actuate the injectors.

IAP sensor open - If the IAP sensor is simply unhooked, or has an open circuit, the ECM

defaults

will provide a default voltage to the IAPCV, and the engine will start

and run without a functioning IAP sensor.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 237 - Slide/Text Reference

8/02

Instructor Note: Point out the header information across the top of the

Information on top slide (also on the student handouts).

No crank

No Crank: If the engine will not crank at all, there is a starting system

problem, as described earlier.

One of the

requirements

Cranks & Wont Start: This is the symptom that might indicate a lack of

lacking one or more of the eight requirements for the PEEC engines, the six

requirements for the EUI engines, or the seven requirements for the

HEUI engines.

No Communication: This could be caused by a defective ECM, a

ECM, P/M, battery,

service

missing or corrupted Personality Module, lack of battery voltage to the

tool/cables ECM, or a problem with the electronic service tool or its connecting

cables.

Intermittent Starts but Stalls, or Speed Burps: These conditions could be caused by

problem intermittent problems with one or more of the components that are

needed to start and run the engine, if the problem occurs after the engine

is started (lost battery power to the ECM, loose personality module

chip, lost speed or speed/timing signal, lost power to the shutoff

solenoid, lost connection to the rack BTM or actuator, or lost

connection to the IAPCV, depending on what engine is involved).

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 238 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

Personality Module

Parameters 95-105v

95-105v EUI

EUI

13.2v

13.2v

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Slide # 166

Proper operation Electronic components not yet mentioned on the chart are necessary for

components proper engine operation, but none of them will prevent the engine from

starting. Some components may cause the engine to shut down after it

starts, depending on the way the protection parameters are set. For

example, a defective oil pressure sensor that reads lower than actual oil

pressure could cause a shutdown if the parameter for low oil pressure is

set to shutdown mode.

PEEC Boost, The 3406 PEEC truck engine has a transducer module to measure boost

timing & BTM pressure. It also has a timing position sensor and a timing position BTM

that are needed to maintain proper timing advance for the engine. None

of these will prevent the engine from starting. They also will not shut

the engine down if a fault occurs. They could cause the engine to have

poor performance if they are faulty or mis-calibrated.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 239 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

95-105v Saver

Saver

Parameters 95-105v EUI

EUI

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Engine

Engine retarder

retarder

Slide # 167

Exhaust brakes, Exhaust brakes are electronic components found on many truck engines.

brakesaver,

Jacobs & PAC 3406 PEEC, 3406E, C-15, and C-16 may have a brake saver that is

controlled electronically.

The EUI engines may have Jacobs or PAC brakes.

The 3126 HEUI engines may have a guillotine type exhaust brake that

is at least partially controlled by the ECM.

Braking circuits All of these brake circuits can be complex to troubleshoot, because of

complex the number of switches and sensor inputs that are involved. See the

appropriate Electronic Troubleshooting Guide for the engine with which

you are working.

Also, a Jacobs or PAC brake should never be engaged with cold engine

Cold operation of

oil. The cold, viscous oil may not drain rapidly enough from the brake

brakes

housing and could lead to a condition where the engine is braking and

fueling the injectors at the same time.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 240 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

Parameters 95-105v EUI

EUI

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Engine

Engine retarder

retarder

Slide # 168

Vehicle speed - Another electronic component (physically located off the engine) is the

speed vehicle speed sensor. Older engines also have a speed buffer to

misinterpreted,

speed limit

strengthen the vehicle speed sensor signal.

A faulty or misadjusted vehicle speed sensor can lead to engine

complaints. For example:

A sensor that incorrectly sends a speed signal when a truck is not

moving may cause the ECM to take the engine out of P.T.O. mode.

A faulty signal could interract with parameters such as vehicle speed

limit, and cause the engine to cut off or limit fuel to the engine.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 241 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Engine

Engine retarder

retarder

Slide # 169

TPS - idle only A throttle position sensor (typically physically located off the engine)

that is not calibrated, or is defective, will not prevent the engine from

starting. However, without a valid TPS signal, the engine will only idle.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 242 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Exhaust

Exhaust

Brake

Brake switch

switch

Engine

Engine retarder

retarder

Slide # 170

Exhaust brakes There are also various OEM supplied switches that provide input to the

ECM.

The exhaust brake switch is one example

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 243 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Exhaust

Exhaust

Brake

Brake switch

switch

PTO

PTO switch

switch Engine

Engine retarder

retarder

Slide # 171

PTO switch The P.T.O. switch is another example.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 244 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Exhaust

Exhaust

Brake

Brake switch

switch

PTO

PTO switch

switch Engine

Engine retarder

retarder

Fan

Fan switch

switch

Slide # 172

Cooling fan - The cooling fan switch may or may not be controlled by one of the

output of ECM ECMs multi-function outputs.

Note to Instructor: If possible, look at this circuit during the diagnostic

tooling lab later today.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 245 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Engine

Engine retarder

retarder

Fan

Fan switch

switch

Slide # 173

Service brake, There are other switches, such as the service brake, clutch, and cruise

clutch, cruise control, that provide inputs to the ECM.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 246 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Engine

Engine retarder

retarder

Fan

Fan switch

switch Fan

Fan & & inlet

inlet

air

air heater

heater

Slide # 174

Cooling fan or Output signals from the ECM may control the engine cooling fan, or the

inlet air heater inlet air heater (on 3126 and C-9 engines).

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 247 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

95-105v

95-105v EUI

EUI

Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches Lamps

Lamps

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Fast

Fast Idle

Idle Check

Check Engine

Engine Engine

Engine retarder

retarder

Fan

Fan switch

switch Fan PTO

PTO Inlet

Inlet air

air heater

heater

Fan & & inlet

inlet Warning

Warning

air

air heater

heater

Slide # 175

Lamps Additional outputs are lamps that indicate modes or conditions. Some

examples are: fast idle, P.T.O., Warning, Check Engine, or Inlet Air

Heater lamps.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 248 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

ECM 0-12v

0-12v IAPCV

IAPCV

Personality Module

Speedo/Tach 95-105v

95-105v EUI

EUI

Speedo/Tach Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches Lamps

Lamps

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Fast

Fast Idle

Idle Check

Check Engine

Engine Engine

Engine retarder

retarder

Fan

Fan switch

switch Fan PTO

PTO Inlet

Inlet air

air heater

heater

Fan & & inlet

inlet Warning

Warning

air

air heater

heater

Slide # 176

Speedo/Tach - The ECM may also control the speedometer and / or tachometer. We

special tests will see some special tests for these outputs in the diagnostic tooling lab

later today.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 249 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

J1587

J1587 Data

Data links

links HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

J1922

J1922 ECM

J1939

J1939 0-12v

0-12v IAPCV

IAPCV

Personality Module

Speedo/Tach 95-105v

95-105v EUI

EUI

Speedo/Tach Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches Lamps

Lamps

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Fast

Fast Idle

Idle Check

Check Engine

Engine Engine

Engine retarder

retarder

Fan

Fan switch

switch Fan PTO

PTO Inlet

Inlet air

air heater

heater

Fan & & inlet

inlet Warning

Warning

air

air heater

heater

Slide # 177

Data Links Data links are used more and more frequently with newer engines for a

multitude of functions. Some examples are:

Communication ABS (Antilock Braking System) has been required on all trucks since

with ABS, the 1999 model year. A separate ECM is used for ABS. It can control

heating/AC, our engine in some cases. For example, if ABS sees wheel slip, it can

transmission

signal our ECM to shut off cruise control and derate the engine to

prevent an accident.

Heating and air conditioning systems may have their own ECM that

communicates with the engine ECM via the data link.

A transmission ECM communicates with the engine ECM.

Corrupted signal If something on the data link is corrupted, engine problems can result.

use process of

The best way to troubleshoot this is to start unhooking components. If

elimination

the engine trouble goes away when you unhook a component from the

data link, it is not an engine problem. It is a problem with the

disconnected component.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 250 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor,,

sensor Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

J1587

J1587 Data

Data links

links HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

J1922

J1922 ECM

J1939

J1939 0-12v

0-12v IAPCV

IAPCV

Personality Module

Speedo/Tach 95-105v

95-105v EUI

EUI

Speedo/Tach Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches Lamps

Lamps

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Fast

Fast Idle

Idle Check

Check Engine

Engine Engine

Engine retarder

retarder

Fan

Fan switch

switch Fan PTO

PTO Inlet

Inlet air

air heater

heater

Fan & & inlet

inlet Warning

Warning

air

air heater

heater 24

24 components

components

Slide # 178

Missing one So far, by grouping some items together, we have a list of twenty four

component? components. We have left out one major item, which would round out

the number to twenty five.

Can anyone think of what the last component might be?

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 251 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor,,

sensor Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

J1587

J1587 Data

Data links

links HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

J1922

J1922 ECM

J1939

J1939 0-12v

0-12v IAPCV

IAPCV

Personality Module Engine

Engine

Speedo/Tach 95-105v

95-105v EUI

EUI Harness

Harness

Speedo/Tach Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches Lamps

Lamps

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Fast

Fast Idle

Idle Check

Check Engine

Engine Engine

Engine retarder

retarder

Fan

Fan switch

switch Fan PTO

PTO Inlet

Inlet air

air heater

heater

Fan & & inlet

inlet Warning

Warning

air

air heater

heater 25

25 total

total components

components

Slide # 179

Harness - approx. The harness is the final component for our list. It is one of the most

80% of problems important items to consider when troubleshooting. Perhaps 80% of all

electronic problems occur in the harness or the connectors.

Although we have mentioned a lot of different components, many of

them are similar enough (or we troubleshoot them in a similar enough

way) that we can lump them together. An analogy might be a residential

electrician who knows how to install a simple, two-way switch in a

lighting circuit. There may be fifty or more brands of two-way switches,

but if he can work with one of them we can work with any of them.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 252 - Slide/Text Reference

8/02

Symptoms

Will

Will not

not Cranks will Will

Cranks will Will not

not Starts

Starts Speed

Speed Poor

Poor Shutdown

Shutdown

crank

crank not

not start

start communicate

communicate but

but stalls

stalls burps

burps performance Fault

performance Fault codes

codes

+Battery

+Battery 8v

8v eng.

eng. speed

speed sensor

sensor Transducer

-Battery PEEC has 8 Transducer

-Battery Pressure

Pressure sensors

sensors

Starter

Starter ECM 5v/2v

5v/2v Shut-

Shut-off solenoid

Shut-off solenoid Temperature

Temperature sensors

sensors

VSS

VSS

Harness

Harness Personality Module 00-4v

-4v Rack

Rack BTM/Actuator

BTM/Actuator +5v

+5v &

& +8v

+8v

Switches

Switches Parameters

Fuses 5v/8v

5v/8v Rack

Rack position

position sensor,

sensor, Timing

Timing pos.

pos.

Fuses VSB

VSB

Relays

Relays wont

wont shut

shut down

down sensor

sensor

Maybe

Maybe all

all OEM

OEM EUI has 6 13.2v

13.2v Timing

Timing BTM

BTM

Mech.

Mech. & & Elect

Elect Eng

Eng ECM 12.5v

12.5v

Not

Not engine

engine problem

problem Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Personality Module Brake

VSS

VSS 95-105v Saver

Saver

TPS Parameters 95-105v EUI

EUI

TPS

13.2v

13.2v Exhaust

Exhaust

J1587

J1587 Data

Data links

links HEUI has 7 Passive

Passive eng.

eng. speed/timing

speed/timing sensor

sensor Brake

Brake

J1922

J1922 ECM

J1939

J1939 0-12v

0-12v IAPCV

IAPCV

Personality Module Engine

Engine

Speedo/Tach 95-105v

95-105v EUI

EUI Harness

Harness

Speedo/Tach Parameters

Exhaust

Exhaust

Brake

Brake switch

switch General

General Switches

Switches Lamps

Lamps

PTO

PTO switch

switch Brake,

Brake, Clutch,

Clutch, Cruise

Cruise Fast

Fast Idle

Idle Check

Check Engine

Engine Engine

Engine retarder

retarder

Fan

Fan switch

switch Fan PTO

PTO Inlet

Inlet air

air heater

heater

Fan & & inlet

inlet Warning

Warning

air

air heater

heater 25

25 total

total components

components

Slide # 180

25 total This completes our chart of the 25 total components. We will now look

components at how to catergorize these components.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 253 - Slide/Text Reference

8/02

Electronic Components

All electronic Components fit into one of

three categories .

Input

Sensors, switch inputs, ground, power

Control

Personality module, parameters, ECM, Data links

Output

Injectors, actuators,warning lights, gages

Slide # 181

3 catergories Although there are many different electronic components, they can all

be sorted into one of three major categories.

They are either an input device, an output device, or a control device.

Examples of input devices are the sensors, switches, ground

Input devices connections, power connections (such as switched or unswitched battery

power).

Control devices Examples of control devices are the p/m, parameters, ECM, or data

links.

Output devices Examples of output devices are the injectors, rack actuators, warning

lights, and gages.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 254 - Slide/Text Reference

8/02

25 Key Components

14 Engine Components

Input Control Output

- Engine speed sensor - ECM - Shutoff solenoid

- Rack position sensor - PM - BTM (2)

- Speed/timing sensor - Parameters - Injectors

- 8 volt sensors - Harness and - IAPCV

- 5 volt sensors Connectors - Retarder (Jake)

11 OEM Components Outputs are two wire

- Throttle position sensor - Data links - Speedo / Tack

- Vehicle speed - Fan switch (Diagnostic tools) - Lamps

- Speed buffer - Engine brake (Gauge panel) - Drivers

- Switches - PTO

Slide # 182

Here is a chart that lists the twenty five components. The list is sorted

into input, output, and control columns.

It is also sorted into components that are physically located on the

engine, versus the components that are located off the engine.

Of all the twenty five electronic components, fourteen are located on the

engine, and eleven are located off the engine.

No engine will have all of the twenty five components. Typically, there

will be about fifteen. Taken from this perspective, the troubleshooting

process does not seem quite so bleak.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 255 - Slide/Text Reference

8/02

Components Needed To Start

PEEC has 8 #5 Speed sensor

#1 POWER

#2 ECM #6 Shut-off solenoid

++ Battery

Battery

#3 P.M.

-- Battery

Battery #7 BTM

#4 Parameters

#8 Rack position

position sensor

sensor

Slide # 183

It is worthwhile to memorize the requirements needed to start each of

the three types of engines.

PEEC has the eight requirements shown here.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 256 - Slide/Text Reference

8/02

Components Needed To Start

EUI has 6 #5 Speed/Timing sensor

#1 POWER

#2 ECM #6 Good Injectors

++ Battery

Battery

#3 P.M.

-- Battery

Battery

#4 Parameters

Slide # 184

EUI has the six requirements shown here.

LAST PRINT SECTION EXIT MAIN NEXT

SEGQ4031 - 257 - Slide/Text Reference

8/02

Components Needed To Start

HEUI has 7 #5 Speed/Timing sensor

#1 POWER

#2 ECM #6 Good Injectors

++ Battery

Battery

#3 P.M.

-- Battery

Battery #7 IAPCV

#4 Parameters

Slide # 185