Академический Документы

Профессиональный Документы

Культура Документы

CNC Running Checklist

Загружено:

Xuan Phuong HuynhАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

CNC Running Checklist

Загружено:

Xuan Phuong HuynhАвторское право:

Доступные форматы

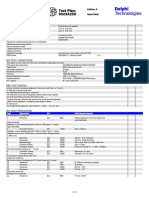

RUNNING TEST CHECKLIST FOR SMITHY CNC MACHINES

Machine Model: ________________ Customer: _______________________________

Serial No.: _____________________ PO No.: ________________ Date: ___________

Test Actual Data &

Test Details Test Target

Number Certified By

Test 1A: Mechanical Inspection List:

a. Spindle Belt Tension a. Tight or Loose

b. Torque to Move X- Axis b. < 10 15 in-lbs

FWD/REV

c. Torque to Move Y-Axis c. < 15 20 in-lbs

FWD/REV

d. Torque to Move Z-Axis UP/DN d. < 25 30 in-lbs

e. Lubrication Supply and e. OK or NOT

Quantity

1

Test 1B: Electrical Inspection List:

a. Spindle VFD Drive Mounting Loose or Not

and Cable

b. Spindle VFD Wire Leads

c. Check Wire connections in the

box

d. Check Cable Connections

e. Operator Panel Switches/

Emergency

Spindle Running Test:

a. 1200 RPM FWD for 10 minutes a. Spindle and Spindle

b. 1200 RPM REV for 10 minutes Housing temperature ruse

c. 2400 RPM FWD for 10 minutes must be less than 1 0F/min

2 d. 2400 RPM REV for 10 minutes but not to exceed 125 0F

e. 3200 RPM FWD for 10 minutes throughout the running

f. 3200 RPM REV for 10 minutes duration

g. 4000 RPM FWD for 10 minutes

h. 4000 RPM REV for 10 minutes b. Spindle noise @4000 RPM

not to exceed 85 db

Axes Running Test:

Test 3A:

3 a. Spindle RPM Fixed at 1200 a. Spindle noise not to exceed

RPM 85 db

b. Axes Rapid Feed for X, Y and Z b. Ball Screw temperature not

at 100% to exceed 120 0F

c. X Motion: +/- 25% of Stroke c. Ball Screw Noise should be

normal

d. Y Motion: +/- 25% of Stroke normal

e. Z Motion: +/- 25% of Stroke d. No Failure of electrical

f. All + and - movement of components

the axes should be e. Program and Motion should

synchronized not stop for any reasons

f. Test stop reasons must be

Total Test Duration: 30 minutes identified and corrected and

started all over again

Test 3B:

a. Spindle RPM Fixed at 2000 a. Spindle noise not to exceed

RPM 85 db

b. Axes Rapid Feed for X,Y and Z b. Ball Screw temperature not

at 50% to exceed 120 0F

c. X Motion: +/- 50% of Stroke c. Ball Screw Noise should be

d. Y Motion: +/- 50% of Stroke normal

e. Z Motion: +/- 50% of Stroke d. No Failure of electrical

f. All + and - movement of components

3 the axes should be e. Program and Motion should

synchronized not stop for any reasons

f. Test stop reasons must be

Total Test Duration: 30 minutes identified and corrected and

started all over again

Test 3C:

a. Spindle RPM Fixed at 4000 a. Spindle noise not to exceed

RPM 85 db

b. Axes Rapid Feed for X, Y, and b. Ball Screw temperature not

Z at 25% to exceed 120 0F

c. X Motion: +/- 100% of stroke c. Ball Screw Noise should be

d. Y Motion: +/- 100% of Stroke normal

e. Z Motion: +/- 100% of Stroke d. No Failure of electrical

f. All + and - movement of components

the axes should be e. Program and Motion should

synchronized not stop for any reasons

f. Test stop reasons must be

Total Test Duration: 30 minutes identified and corrected and

started all over again

Axes Repeatability Test after machine

warm up

Test 4A: X -Axis Test Deviation Target: +/- 0.01 mm Max

a. Rapid Rate: 25% and 100% of

Max

4 b. Deviation: (Input-Actual

Position)

c. Movement: From Home to Mid

Stroke

Test 4B: Y- Axis Test Deviation Target: +/- 0.01 mm Max

a. Rapid Rate: 25% and 100% of

Max

b. Deviation: (Input-Actual

Position)

c. Movement: From Home to Mid

Stroke

Test 4C: Z -Axis Test (Down Stroke Deviation Target: +/- 0.01 mm Max

4 Only)

a. Rapid Rate: 25% and 100% of

Max

b. Deviation: (Input-Actual

Position)

c. Movement: From Home to Mid

Stroke

Note:

No tooling should be mounted on the spindle

Spindle should be started cold in the beginning of the test

Spindle and Axes speed combination should use Spindle/Axes control program

No fixtures or additional weights on the table

Slide axes should be lubricated before torque measurements

Position Accuracy Test and Repeatability Test should be performed earlier in the factory

Smithy Co.

PO Box 1517, Ann Arbor, MI USA 48106-1517

Toll Free 1-800-476-4849 Mon-Fri 8-5 ET

Вам также может понравиться

- AEC-6910 En-50155 Test ReportДокумент29 страницAEC-6910 En-50155 Test Reportd157952Оценок пока нет

- Motor ProtectionДокумент31 страницаMotor ProtectionHadrien FaryalaОценок пока нет

- Spare Feeder - P10 - 2Документ79 страницSpare Feeder - P10 - 2Yogesh JethwaОценок пока нет

- 3340F322 Lionn Auto SoftwaresДокумент2 страницы3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONОценок пока нет

- Overcurrent1:: Test Object - Device SettingsДокумент3 страницыOvercurrent1:: Test Object - Device SettingsFrancisco Javier Bravo BravoОценок пока нет

- BFP Motor: SN DetailsДокумент3 страницыBFP Motor: SN Detailsrbdubey2020Оценок пока нет

- TFT Proview AY565 LCD Service MaunalДокумент30 страницTFT Proview AY565 LCD Service MaunalMarienka JankovaОценок пока нет

- Test Plan: Pump SpecificationДокумент2 страницыTest Plan: Pump SpecificationClarice Alves de FreitasОценок пока нет

- Motor WEG Data SheetДокумент10 страницMotor WEG Data SheetMohamed ElsayedОценок пока нет

- 3349F330Документ2 страницы3349F330marco rod100% (1)

- Question Paper Inst TOCДокумент8 страницQuestion Paper Inst TOCbikas_sahaОценок пока нет

- PW1100 Shaft Eddy Current Evaluation AlmДокумент5 страницPW1100 Shaft Eddy Current Evaluation Almkatie_112885729Оценок пока нет

- Sample: Centrifugal Fire Pump Acceptance Test FormДокумент2 страницыSample: Centrifugal Fire Pump Acceptance Test FormaamedОценок пока нет

- 3230f582T PTДокумент2 страницы3230f582T PTHeitor Gael Alves de FreitasОценок пока нет

- Testplan 3239590Документ2 страницыTestplan 3239590Fx_2050% (1)

- DW 17Документ2 страницыDW 17api-19651544Оценок пока нет

- CUI - Inc.: SpecificationsДокумент5 страницCUI - Inc.: Specificationsmsicoie1851Оценок пока нет

- 3340F401G Plano de Teste DelphiДокумент2 страницы3340F401G Plano de Teste DelphiJunior Iung100% (1)

- Spare Feeder P10Документ80 страницSpare Feeder P10Yogesh JethwaОценок пока нет

- 9521A030H DATA CatalogДокумент3 страницы9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- Test ReportДокумент54 страницыTest ReportSiva NandhamОценок пока нет

- Manual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateДокумент5 страницManual UT Thickness Specific Exam From SAEP-1146 Name: Badge#: DateMohamed IbrahimОценок пока нет

- Type Tests On Disc Insulator Units & StringsДокумент33 страницыType Tests On Disc Insulator Units & Stringssalsa222100% (8)

- Test Plan: Pump SpecificationДокумент3 страницыTest Plan: Pump SpecificationBaytolgaОценок пока нет

- Test Plan: Pump SpecificationДокумент4 страницыTest Plan: Pump SpecificationBaytolgaОценок пока нет

- The Relay Testing Handbook-Generator Relay Protection Testing TOC-ToF-BibДокумент36 страницThe Relay Testing Handbook-Generator Relay Protection Testing TOC-ToF-BibMartin Goodnough100% (1)

- Tektronix ps-250 Ps Cal ProcedureДокумент14 страницTektronix ps-250 Ps Cal ProcedureSa SaОценок пока нет

- Lab 3 - Slake Durability TestДокумент5 страницLab 3 - Slake Durability TestankeshОценок пока нет

- Standby GeneratorДокумент11 страницStandby Generatortecmak AngolaОценок пока нет

- CEM-1212S Datasheet - Magnetic Buzzer - CUI IncДокумент5 страницCEM-1212S Datasheet - Magnetic Buzzer - CUI IncLUDWINGОценок пока нет

- Test PlanДокумент1 страницаTest PlanOFFICE DANACОценок пока нет

- Model: REM543-CG214CAAA: Generator Protection RelayДокумент7 страницModel: REM543-CG214CAAA: Generator Protection RelaymurugananthameeeОценок пока нет

- All The Current Questions in The BANK: Closed BookДокумент29 страницAll The Current Questions in The BANK: Closed BookZahid MuqaddamОценок пока нет

- Insulator Type Tests PDFДокумент34 страницыInsulator Type Tests PDFsorry2qazОценок пока нет

- Operation of Diesel Generator SetДокумент1 страницаOperation of Diesel Generator SetT P Singh TarunОценок пока нет

- 9323A271G Catalog DATAДокумент4 страницы9323A271G Catalog DATALIONN SOFTWARESОценок пока нет

- Process Dynamics and Control BitsДокумент19 страницProcess Dynamics and Control BitsrajaraghuramvarmaОценок пока нет

- 3042f843 Plano de TesteДокумент1 страница3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- 1967 - Sahaj Solar LTD, Ahmedabad, 4000 KVA, 11-0.800 KV ID OCTC Transformer As Per Is - 1180, 22-03-2024Документ8 страниц1967 - Sahaj Solar LTD, Ahmedabad, 4000 KVA, 11-0.800 KV ID OCTC Transformer As Per Is - 1180, 22-03-2024kanu bhaiОценок пока нет

- Messrs.: Specification For ApprovalДокумент5 страницMessrs.: Specification For Approvalg_1234Оценок пока нет

- CEM-1201 (42) Datasheet - Magnetic Buzzer - CUI IncДокумент5 страницCEM-1201 (42) Datasheet - Magnetic Buzzer - CUI IncLUDWINGОценок пока нет

- Overcurrent:: Test Object - Device SettingsДокумент44 страницыOvercurrent:: Test Object - Device Settingszita aisyahОценок пока нет

- Test Plan: 9521A030: Pump SpecificationДокумент3 страницыTest Plan: 9521A030: Pump Specificationjohnny sabinОценок пока нет

- Test Plan: 9320A530: Pump SpecificationДокумент4 страницыTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovОценок пока нет

- Dynamic Test Report of DECR-S Excitation Devices: ExperimenterДокумент14 страницDynamic Test Report of DECR-S Excitation Devices: ExperimenterSalmanEjazОценок пока нет

- Kindin Lec7 PDFДокумент34 страницыKindin Lec7 PDFAndi SeftyandiОценок пока нет

- Test Plan 8523a320Документ2 страницыTest Plan 8523a320taniaОценок пока нет

- 9320A093GДокумент4 страницы9320A093GKevin TtitoОценок пока нет

- Test Plan Delphi TechnologiesДокумент2 страницыTest Plan Delphi TechnologiesFRANCISCOОценок пока нет

- Azure:: Test Object - Device SettingsДокумент8 страницAzure:: Test Object - Device SettingsArul KumarОценок пока нет

- Electronics Engineering For Oct 2012Документ136 страницElectronics Engineering For Oct 2012anna kulasaОценок пока нет

- 9323a251g PTДокумент3 страницы9323a251g PTClarice Alves de FreitasОценок пока нет

- AC Motor Datasheet 2020Документ5 страницAC Motor Datasheet 2020bmanojkumar16Оценок пока нет

- Assistant Executive Engineer 2018 TEST PDFДокумент12 страницAssistant Executive Engineer 2018 TEST PDFMuhammad Umair AslamОценок пока нет

- FPSC ElectricalДокумент12 страницFPSC ElectricalMustafa ShaykhОценок пока нет

- Solucionador de Problemas VibroДокумент8 страницSolucionador de Problemas Vibrojavier lopezОценок пока нет

- Mechanical Aptitude & Spatial Relations Practice QuestionsОт EverandMechanical Aptitude & Spatial Relations Practice QuestionsОценок пока нет

- Analog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignОт EverandAnalog Circuit Design Volume 2: Immersion in the Black Art of Analog DesignОценок пока нет

- 110 Waveform Generator Projects for the Home ConstructorОт Everand110 Waveform Generator Projects for the Home ConstructorРейтинг: 4 из 5 звезд4/5 (1)

- Design, Analysis and Development of Hydraulic Scissor LiftДокумент8 страницDesign, Analysis and Development of Hydraulic Scissor Liftmohit talrejaОценок пока нет

- 0000007913.6039 en 1212Документ64 страницы0000007913.6039 en 1212Jesus N RodriguezОценок пока нет

- Tolerances All About The Exacast Precision Casting Process: Degree of Accuracy D2 Tolerance Zone D3 Tolerance ZoneДокумент1 страницаTolerances All About The Exacast Precision Casting Process: Degree of Accuracy D2 Tolerance Zone D3 Tolerance ZoneXuan Phuong HuynhОценок пока нет

- Ball Transfer Units PDFДокумент40 страницBall Transfer Units PDFHyundianto AgОценок пока нет

- SMS Sheet Metal TolerancesДокумент1 страницаSMS Sheet Metal TolerancesXuan Phuong HuynhОценок пока нет

- 304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFДокумент16 страниц304 - Fms - Transilon Calculation Methods Conveyor Belts - en PDFAndressa EgerОценок пока нет

- FAMSUN Main Machine Catalogue 2014Документ40 страницFAMSUN Main Machine Catalogue 2014marsovac100100% (1)

- On Studying Different Types of Pelletizing System For Fish FeedДокумент6 страницOn Studying Different Types of Pelletizing System For Fish FeedXuan Phuong HuynhОценок пока нет

- Industrie 4.0:: Cyber-Physical Production Systems For Mass CustomizationДокумент55 страницIndustrie 4.0:: Cyber-Physical Production Systems For Mass CustomizationXuan Phuong HuynhОценок пока нет

- Computational Analysis and Design of Single Screw Extruders Having Screws of Complex Geometry With Mixing ElementsДокумент31 страницаComputational Analysis and Design of Single Screw Extruders Having Screws of Complex Geometry With Mixing ElementsXuan Phuong HuynhОценок пока нет

- Commercial Aquaculture Feed Production (Floating Feeds) : Kurt A. Rosentrater, PH.DДокумент57 страницCommercial Aquaculture Feed Production (Floating Feeds) : Kurt A. Rosentrater, PH.DXuan Phuong HuynhОценок пока нет

- Aquafeed Extrudate Flow Rate and Pellet Characteristics From Low-Cost Single-Screw ExtruderДокумент14 страницAquafeed Extrudate Flow Rate and Pellet Characteristics From Low-Cost Single-Screw ExtruderXuan Phuong HuynhОценок пока нет

- AMADA Fiber Laser Technology To Create The FutureДокумент1 страницаAMADA Fiber Laser Technology To Create The FutureXuan Phuong HuynhОценок пока нет

- Accepted Manuscript: MesopotamicusДокумент34 страницыAccepted Manuscript: MesopotamicusXuan Phuong HuynhОценок пока нет

- 2014 Ali DesignandAnalysisofSingleScrewДокумент9 страниц2014 Ali DesignandAnalysisofSingleScrewXuan Phuong HuynhОценок пока нет

- A. El-Sonbati - Thermoplastic Elastomers-Intech (2012) PDFДокумент428 страницA. El-Sonbati - Thermoplastic Elastomers-Intech (2012) PDFXuan Phuong HuynhОценок пока нет

- Effects of Combined Shear and Thermal Forces On deДокумент7 страницEffects of Combined Shear and Thermal Forces On deXuan Phuong HuynhОценок пока нет

- APV Pharma Conference Presentation PDFДокумент76 страницAPV Pharma Conference Presentation PDFXuan Phuong HuynhОценок пока нет

- Aquafeed Magazine April 2019 - Page 69 Good Dryer Design For Production of High Quality Aquafeed PDFДокумент3 страницыAquafeed Magazine April 2019 - Page 69 Good Dryer Design For Production of High Quality Aquafeed PDFXuan Phuong HuynhОценок пока нет

- Development of Aquatic Feeds by Extrusion Cooking: Oseph EarnsДокумент3 страницыDevelopment of Aquatic Feeds by Extrusion Cooking: Oseph EarnsXuan Phuong HuynhОценок пока нет

- Extrusion Processing of Wheat Gluten Bioplastic: Effect of The Addition of Kraft LigninДокумент11 страницExtrusion Processing of Wheat Gluten Bioplastic: Effect of The Addition of Kraft LigninXuan Phuong HuynhОценок пока нет

- A Design and Fabrication of Fish Feed Pelleting MachineДокумент7 страницA Design and Fabrication of Fish Feed Pelleting MachineXuan Phuong HuynhОценок пока нет

- Engineering Analysis of Tandem Extruder System For Foam ManufacturingДокумент6 страницEngineering Analysis of Tandem Extruder System For Foam ManufacturingXuan Phuong HuynhОценок пока нет

- Beijing CAAS Presentation With ChineseДокумент33 страницыBeijing CAAS Presentation With ChineseXuan Phuong HuynhОценок пока нет

- A. El-Sonbati - Thermoplastic Elastomers-Intech (2012) PDFДокумент428 страницA. El-Sonbati - Thermoplastic Elastomers-Intech (2012) PDFXuan Phuong HuynhОценок пока нет

- InTech-Thermoplastic Extrusion in Food ProcessingДокумент26 страницInTech-Thermoplastic Extrusion in Food ProcessingCarlos SilvaОценок пока нет

- Things Your Screw Designer Never Final PDFДокумент6 страницThings Your Screw Designer Never Final PDFXuan Phuong HuynhОценок пока нет

- United States Patent (19) : 4R 5: 5 13. A 96 8.d4 or 89Документ12 страницUnited States Patent (19) : 4R 5: 5 13. A 96 8.d4 or 89Xuan Phuong HuynhОценок пока нет

- United States Patent (10) Patent No.: US 8.246,240 B2Документ19 страницUnited States Patent (10) Patent No.: US 8.246,240 B2Xuan Phuong HuynhОценок пока нет

- United States Patent: (10) Patent No.: (45) Date of PatentДокумент25 страницUnited States Patent: (10) Patent No.: (45) Date of PatentXuan Phuong HuynhОценок пока нет

- Schematic 1 - : CMDB-B01.00-9b-L9-1 NTS CMDB-B01.00-9a-L9-1Документ1 страницаSchematic 1 - : CMDB-B01.00-9b-L9-1 NTS CMDB-B01.00-9a-L9-1Michael Camit EsoОценок пока нет

- Urethane UB-7 Catalog 2013Документ32 страницыUrethane UB-7 Catalog 2013yfontalvОценок пока нет

- Module Pool Select OptionДокумент53 страницыModule Pool Select Optionajit sahuОценок пока нет

- DAY Monday Tuesday Wednesday Thursday Friday: Hinigaran National High SchoolДокумент10 страницDAY Monday Tuesday Wednesday Thursday Friday: Hinigaran National High SchoolHelen LaurelОценок пока нет

- Computational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)Документ441 страницаComputational Organometallic Chemistry (Cundari, Thomas R.) (1st Edition, 2001) (0824704789) (428p)EisernesHerzОценок пока нет

- Caterpillar Service ManualДокумент242 страницыCaterpillar Service Manualsmudger197390% (52)

- Table StructureДокумент180 страницTable StructureVictor PathakОценок пока нет

- Effect of Impurities On Freezing and Boiling PointsДокумент6 страницEffect of Impurities On Freezing and Boiling PointssakthivelОценок пока нет

- CT v2.0 UnderstandingДокумент36 страницCT v2.0 UnderstandingAbel Chaiña GonzalesОценок пока нет

- SQAP For Pumps 2017Документ79 страницSQAP For Pumps 2017MukeshОценок пока нет

- ATM SecurityДокумент87 страницATM SecurityHristo Dokov100% (1)

- Engine Test CellДокумент44 страницыEngine Test Cellgrhvg_mct8224Оценок пока нет

- Eurotrace Installation Instructions: Installation On A PipeДокумент6 страницEurotrace Installation Instructions: Installation On A PipeNicolas150956Оценок пока нет

- Table 1. Data Set and CalculationДокумент5 страницTable 1. Data Set and CalculationliliОценок пока нет

- Denmark Bye LawsДокумент10 страницDenmark Bye LawshimaniwatalОценок пока нет

- Wind Load Calculation As Per ASCE 7 10Документ8 страницWind Load Calculation As Per ASCE 7 10ani145yadav100% (1)

- NPT Thread Dimensions PDFДокумент1 страницаNPT Thread Dimensions PDFRamnandan MahtoОценок пока нет

- Ryobi RLT254CDSO User ManualДокумент48 страницRyobi RLT254CDSO User ManualPaul WilsonОценок пока нет

- KMJT's Goldfarming GuideДокумент36 страницKMJT's Goldfarming GuideAnonymous oe4U3HCcОценок пока нет

- 10 Famous Shipping Canals of The WorldДокумент7 страниц10 Famous Shipping Canals of The Worldparth_upadhyay_1Оценок пока нет

- Mixed Grabar b2Документ1 страницаMixed Grabar b2lynОценок пока нет

- Tally Erp 9.0 Material Control Centre in Tally Erp 9.0Документ27 страницTally Erp 9.0 Material Control Centre in Tally Erp 9.0Raghavendra yadav KMОценок пока нет

- Vineeth - Curriculum VitaДокумент8 страницVineeth - Curriculum VitaVineeth NBОценок пока нет

- D 2564 - 96 - Rdi1njqtotzb PDFДокумент5 страницD 2564 - 96 - Rdi1njqtotzb PDFAndre CasteloОценок пока нет

- fr19 21Документ8 страницfr19 21ErmanОценок пока нет

- Analysis+of+Non Symmetrical+Flapping+AirfoilsДокумент18 страницAnalysis+of+Non Symmetrical+Flapping+AirfoilsAsif HameedОценок пока нет

- Ricoh Shotmaster ZoomДокумент17 страницRicoh Shotmaster Zoommanana mappleОценок пока нет

- Positector Calibration ProcedureДокумент6 страницPositector Calibration ProcedureluigimasterОценок пока нет

- T30 T10 Intelligent Flight Battery User Guide v1.2 10langsДокумент85 страницT30 T10 Intelligent Flight Battery User Guide v1.2 10langstamerОценок пока нет

- CostingДокумент5 страницCosting83pankajОценок пока нет