Академический Документы

Профессиональный Документы

Культура Документы

Tim Wood

Загружено:

ANUSHREE V 1627035Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Tim Wood

Загружено:

ANUSHREE V 1627035Авторское право:

Доступные форматы

The 7 Wastes in Manufacturing

By Group 6,

Anushree V (1627035)

Akhil Jose (1627303)

Souparno Basu (1627128)

Riola Fernandez (1627151)

Ranjith M (1627019)

Vedant Somani (1627337)

Waste elimination is one of the most effective ways to increase the

profitability of any business. Processes either add value or waste to

the production of a good or service. The seven wastes originated in

Japan, where waste is known as muda." "The seven wastes" is a

tool to further categorize muda and was originally developed by

Toyotas Chief Engineer Taiichi Ohno as the core of the Toyota

Production System, also known as Lean Manufacturing. To eliminate

waste, it is important to understand exactly what waste is and where

it exists. While products significantly differ between factories, the

typical wastes found in manufacturing environments are quite

similar. For each waste, there is a strategy to reduce or eliminate its

effect on a company, thereby improving overall performance and

quality.

The seven wastes consist of:

1. Overproduction

Simply put, overproduction is to manufacture an item before it is

actually required. Overproduction is highly costly to a manufacturing

plant because it prohibits the smooth flow of materials and actually

degrades quality and productivity. The Toyota Production System is

also referred to as Just in Time (JIT) because every item is made

just as it is needed. Overproduction manufacturing is referred to as

Just in Case. This creates excessive lead times, results in high

storage costs, and makes it difficult to detect defects. The simple

solution to overproduction is turning off the tap; this requires a lot of

courage because the problems that overproduction is hiding will be

revealed. The concept is to schedule and produce only what can be

immediately sold/shipped and improve machine changeover/set-up

capability.

2. Waiting

Whenever goods are not moving or being processed, the waste of

waiting occurs. Typically more than 99% of a product's life in

traditional batch-and-queue manufacture will be spent waiting to be

processed. Much of a products lead time is tied up in waiting for the

next operation; this is usually because material flow is poor,

production runs are too long, and distances between work centers

are too great. Goldratt (Theory of Constraints) has stated many

times that one hour lost in a bottleneck process is one hour lost to

the entire factorys output, which can never be recovered. Linking

processes together so that one feeds directly into the next can

dramatically reduce waiting.

3. Transporting

Transporting product between processes is a cost incursion which

adds no value to the product. Excessive movement and handling

cause damage and are an opportunity for quality to deteriorate.

Material handlers must be used to transport the materials, resulting

in another organizational cost that adds no customer value.

Transportation can be difficult to reduce due to the perceived costs

of moving equipment and processes closer together. Furthermore, it

is often hard to determine which processes should be next to each

other. Mapping product flows can make this easier to visualize.

4. Inappropriate Processing

Often termed as using a sledgehammer to crack a nut, many

organizations use expensive high precision equipment where simpler

tools would be sufficient. This often results in poor plant layout

because preceding or subsequent operations are located far apart. In

addition they encourage high asset utilization (over-production with

minimal changeovers) in order to recover the high cost of this

equipment. Toyota is famous for their use of low-cost automation,

combined with immaculately maintained, often older machines.

Investing in smaller, more flexible equipment where possible;

creating manufacturing cells; and combining steps will greatly reduce

the waste of inappropriate processing.

5. Unnecessary Inventory

Work in Progress (WIP) is a direct result of overproduction and

waiting. Excess inventory tends to hide problems on the plant floor,

which must be identified and resolved in order to improve operating

performance. Excess inventory increases lead times, consumes

productive floor space, delays the identification of problems, and

inhibits communication. By achieving a seamless flow between work

centers, many manufacturers have been able to improve customer

service and slash inventories and their associated costs.

6. Unnecessary / Excess Motion

This waste is related to ergonomics and is seen in all instances of

bending, stretching, walking, lifting, and reaching. These are also

health and safety issues, which in todays litigious society are

becoming more of a problem for organizations. Jobs with excessive

motion should be analyzed and redesigned for improvement with the

involvement of plant personnel.

7. Defects

Having a direct impact to the bottom line, quality defects resulting in

rework or scrap are a tremendous cost to organizations. Associated

costs include quarantining inventory, re-inspecting, rescheduling, and

capacity loss. In many organizations the total cost of defects is often

a significant percentage of total manufacturing cost. Through

employee involvement and Continuous Process Improvement (CPI),

there is a huge opportunity to reduce defects at many facilities.

In the latest edition of the Lean Manufacturing classic Lean Thinking,

Underutilization of Employees has been added as an eighth waste to

Ohnos original seven wastes. Organizations employ their staff for

their nimble fingers and strong muscles but forget they come to work

everyday with a free brain. It is only by capitalizing on employees'

creativity that organizations can eliminate the other seven wastes

and continuously improve their performance.

Вам также может понравиться

- Concept of MUDAДокумент2 страницыConcept of MUDAMehran Rasheed GorayaОценок пока нет

- Total Quality ManagementДокумент7 страницTotal Quality ManagementmansoorliveОценок пока нет

- Lean ManufacturingДокумент13 страницLean ManufacturingMohammad Shaniaz IslamОценок пока нет

- 00the 7 MFG WasteДокумент15 страниц00the 7 MFG WasteRohit PrakashОценок пока нет

- Ten Kaizen PrinciplesДокумент4 страницыTen Kaizen PrinciplesDamien CosgroveОценок пока нет

- Lean Manufacturing, or Lean Production DefinitionДокумент8 страницLean Manufacturing, or Lean Production DefinitionAnjan KumarОценок пока нет

- 5S 7W TPM OeeДокумент59 страниц5S 7W TPM OeeKaushik BarmanОценок пока нет

- What Is Lean ManufacturingДокумент5 страницWhat Is Lean Manufacturingaishwary ranaОценок пока нет

- 7 Wastes 5s LeanДокумент12 страниц7 Wastes 5s LeanJulio Cesar Gonzalez MendezОценок пока нет

- 7 Types of Waste PDFДокумент20 страниц7 Types of Waste PDFjogedhayalОценок пока нет

- Manufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesОт EverandManufacturing Wastes Stream: Toyota Production System Lean Principles and ValuesРейтинг: 4.5 из 5 звезд4.5/5 (3)

- 8 WasteДокумент1 страница8 WasteNaresh YadavОценок пока нет

- How to Create Continuous Production Flow?: Toyota Production System ConceptsОт EverandHow to Create Continuous Production Flow?: Toyota Production System ConceptsРейтинг: 5 из 5 звезд5/5 (1)

- Creating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowОт EverandCreating a One-Piece Flow and Production Cell: Just-in-time Production with Toyota’s Single Piece FlowРейтинг: 4 из 5 звезд4/5 (1)

- Chapter 5 Lean Enterprise Sakichi ToyodaДокумент10 страницChapter 5 Lean Enterprise Sakichi ToyodaAMIEL TACULAOОценок пока нет

- What Is LeanДокумент18 страницWhat Is LeanraunОценок пока нет

- Lean OutlookДокумент24 страницыLean OutlookcucumucuОценок пока нет

- Chapter 10-Lean ManufacturingДокумент6 страницChapter 10-Lean ManufacturingMovie 6890Оценок пока нет

- 7 Wastes Lean & 5s Lean: Lluvia Olibarria HernandezДокумент7 страниц7 Wastes Lean & 5s Lean: Lluvia Olibarria HernandezLluvia Olibarria HernandezОценок пока нет

- 5S Visual Workplace: Dr. Syed Amir IqbalДокумент42 страницы5S Visual Workplace: Dr. Syed Amir IqbalNOSHEEN MEHFOOZОценок пока нет

- 7 WastesДокумент13 страниц7 WastesNicko SarcenОценок пока нет

- Lean SystemДокумент2 страницыLean SystemVENESHNEEОценок пока нет

- Lean Manufacturing Full Seminar Report 123456 1Документ22 страницыLean Manufacturing Full Seminar Report 123456 1Mandhara KsОценок пока нет

- Toyota Production System: 1. TransportДокумент9 страницToyota Production System: 1. TransportRaja PandiОценок пока нет

- Lean Manufacturing Tools andДокумент11 страницLean Manufacturing Tools andbestmadeeasyОценок пока нет

- Cut To Box Module FinalДокумент26 страницCut To Box Module FinalMukund NarayanОценок пока нет

- Lean-based Production Management: Practical Lean ManufacturingОт EverandLean-based Production Management: Practical Lean ManufacturingОценок пока нет

- Assignment On Lean Manufacturing and Six SigmaДокумент10 страницAssignment On Lean Manufacturing and Six SigmaRatul BhowmikОценок пока нет

- MUDA (7 Waste)Документ3 страницыMUDA (7 Waste)Shamshair Ali100% (1)

- Ion For LeanДокумент8 страницIon For LeanDarshan AshokkumarОценок пока нет

- Saumitra Thakur - (4th-10th July)Документ3 страницыSaumitra Thakur - (4th-10th July)SAUMITRA THAKURОценок пока нет

- SCM Assignment DoneДокумент12 страницSCM Assignment DoneAdarsh Kumar RoyОценок пока нет

- 5 Wastes of LeanДокумент4 страницы5 Wastes of LeanBalkirat SinghОценок пока нет

- 10 1 1 848 4658 PDFДокумент7 страниц10 1 1 848 4658 PDFKevin Yolvi Alvarez CáceresОценок пока нет

- 8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Документ8 страниц8 Forms of Waste in A Foundry Shop and Strategies For Elimination 1Muhammad UsmanОценок пока нет

- Lean Manufacturing The Way To Manufacturing ExcellenceДокумент24 страницыLean Manufacturing The Way To Manufacturing ExcellenceGarmentLearner100% (2)

- Six Sigma Lean Principles 152Документ13 страницSix Sigma Lean Principles 152starsankarОценок пока нет

- Identifying Mura-Muri-Muda in the Manufacturing Stream: Toyota Production System ConceptsОт EverandIdentifying Mura-Muri-Muda in the Manufacturing Stream: Toyota Production System ConceptsРейтинг: 5 из 5 звезд5/5 (1)

- Lean IntroДокумент12 страницLean IntroShirley OmbrogОценок пока нет

- Unit 6Документ5 страницUnit 6vikrant gulhaneОценок пока нет

- 367 ErpBookДокумент13 страниц367 ErpBooksravankumar248Оценок пока нет

- Lean Manufacturing Full Seminar Report 123456 1Документ14 страницLean Manufacturing Full Seminar Report 123456 1Rajeev TRОценок пока нет

- Lean ManufacturingДокумент24 страницыLean ManufacturingRaghunath VeeramaniОценок пока нет

- A Brief HistoryДокумент26 страницA Brief HistoryHarshit AgarwalОценок пока нет

- Lean Production: Project Management Production ManagementДокумент18 страницLean Production: Project Management Production ManagementHemant VermaОценок пока нет

- Pull Production System 1Документ38 страницPull Production System 1shailesh_tiwari_mechОценок пока нет

- LeanДокумент21 страницаLeanlorraine SandyОценок пока нет

- Jit, Waiting Line, 5 S, Kaizen Qualiyty MGMT TechniquesДокумент10 страницJit, Waiting Line, 5 S, Kaizen Qualiyty MGMT Techniquesamitrao1983Оценок пока нет

- Lean Manufacturing 2017Документ15 страницLean Manufacturing 2017Relu CosteaОценок пока нет

- Quality ManagementДокумент6 страницQuality ManagementNickesh ShahОценок пока нет

- Transitioning To Lean SystemДокумент8 страницTransitioning To Lean SystemDonita SotolomboОценок пока нет

- Q 1Документ9 страницQ 1mintesinot denekewОценок пока нет

- What Is Lean Manufacturing?: 1. Specify Value. Identify The Value of A Specific Product From The Customer'sДокумент8 страницWhat Is Lean Manufacturing?: 1. Specify Value. Identify The Value of A Specific Product From The Customer'sVijay KumarОценок пока нет

- Manufacturing Excellence Through JIT ApproachДокумент11 страницManufacturing Excellence Through JIT ApproachInternational Journal of Application or Innovation in Engineering & ManagementОценок пока нет

- JIT & BackflushДокумент7 страницJIT & BackflushAnis AbdullahОценок пока нет

- Just Time: Presented by Gsba StudentsДокумент32 страницыJust Time: Presented by Gsba StudentsMichelle Del RosarioОценок пока нет

- Waste EliminationДокумент3 страницыWaste EliminationVishnu Rayapeddi100% (3)

- Manufacturing: Inventory Control SystemДокумент4 страницыManufacturing: Inventory Control SystemshakilliyaОценок пока нет

- 142-5045 Lean ManufacturingДокумент7 страниц142-5045 Lean Manufacturing2b-or-not2bОценок пока нет

- Seminar On Optimisation of Process Parameters For Lean Manufacturing in Medium and Large Industries - An Indian PerspectiveДокумент42 страницыSeminar On Optimisation of Process Parameters For Lean Manufacturing in Medium and Large Industries - An Indian PerspectivesataooОценок пока нет

- Quality Requirements New Format-06.04.13Документ1 страницаQuality Requirements New Format-06.04.13beeyesyemОценок пока нет

- Student Safety Sheets: EthanolДокумент1 страницаStudent Safety Sheets: EthanolNina FairuzОценок пока нет

- E831BДокумент4 страницыE831BDenis JimenezОценок пока нет

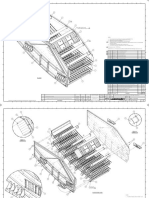

- Partition ManualДокумент42 страницыPartition ManualAnonymous SblBDN0Оценок пока нет

- Pile ReportДокумент14 страницPile ReportChen E LikОценок пока нет

- Chapter 3 Study Guide KeyДокумент3 страницыChapter 3 Study Guide KeyKaren YОценок пока нет

- 100 Ways To Save The EnvironmentДокумент3 страницы100 Ways To Save The EnvironmentSarvesh JaiswalОценок пока нет

- Project TitleДокумент2 страницыProject TitleDENNIS RAMIREZОценок пока нет

- 3D Printing of Reduced Graphene Oxide NanowiresДокумент5 страниц3D Printing of Reduced Graphene Oxide NanowiresDuniaОценок пока нет

- E FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFДокумент9 страницE FSS5 Attm3 Tooling-manual-Lathe Rev1 090330 PDFonnoОценок пока нет

- New Company ProfileДокумент14 страницNew Company Profileanamika tripathiОценок пока нет

- ISO 1459 Hots Dip GalvanizingДокумент4 страницыISO 1459 Hots Dip GalvanizingLe Van TamОценок пока нет

- Specifications Virgin Fuel Oil D6: Method Units Test Result UnitДокумент1 страницаSpecifications Virgin Fuel Oil D6: Method Units Test Result UnitDavid garzaОценок пока нет

- ST014 Sod - MetasilicateДокумент1 страницаST014 Sod - MetasilicateAreIf Cron BmxStreetОценок пока нет

- Xfmea MfmeaДокумент6 страницXfmea Mfmeabojanmarkovic88Оценок пока нет

- DV 06 ActuationДокумент6 страницDV 06 ActuationAbhishek SaraswatОценок пока нет

- Pentapharm Brochure (En) 3.17.14Документ12 страницPentapharm Brochure (En) 3.17.14imakantisОценок пока нет

- Raichu R 2000Документ7 страницRaichu R 2000Shawn StevensОценок пока нет

- 1301A01422 Zaranda 3500Документ2 страницы1301A01422 Zaranda 3500Edgar FloresОценок пока нет

- Randhol - Ensuring Well Integrity in Connection With CO2 InjectionДокумент59 страницRandhol - Ensuring Well Integrity in Connection With CO2 InjectionLauren AndersonОценок пока нет

- PuneДокумент564 страницыPuneANSHUMANОценок пока нет

- Impact TestДокумент5 страницImpact TestGolden ChanОценок пока нет

- Products DatabaseДокумент104 страницыProducts DatabaseAlexОценок пока нет

- Focus On The Fundamentals of Shielded MV Power CableДокумент3 страницыFocus On The Fundamentals of Shielded MV Power CableMrОценок пока нет

- API 600 Trim No.Документ19 страницAPI 600 Trim No.SUBHASISH BHATTACHARYYAОценок пока нет

- Substation Equipment Failure Report October 14 To August 15Документ95 страницSubstation Equipment Failure Report October 14 To August 15Yogendra SwarnkarОценок пока нет

- Comparitive of Waterproofing WorkДокумент12 страницComparitive of Waterproofing WorkReshik KannanОценок пока нет

- Anugrah Raya: Shear ConnectorДокумент6 страницAnugrah Raya: Shear ConnectordedeОценок пока нет

- DSE501 Data Sheet PDFДокумент2 страницыDSE501 Data Sheet PDFChristopher100% (3)

- K-Tron Premier Rep Catalog Dec 2010 PDFДокумент429 страницK-Tron Premier Rep Catalog Dec 2010 PDFGerardo González33% (3)