Академический Документы

Профессиональный Документы

Культура Документы

Procedure For PWHT of B

Загружено:

S GoudaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Procedure For PWHT of B

Загружено:

S GoudaАвторское право:

Доступные форматы

PROCEDURE FOR PWHT OF B.F.

TOP CONE

General requirement of PWHT:

1. The top cone shall be heat treated in vertical position.

2. Before starting the insulation operation all the surfaces involved with PWHT to be performed

shall be free from oil, grease and other foreign materials.

3. The heating of each area shall be performed by electrical resistance (Nichrome

Coil wire wound in the form of snake shape) and placed in contact with external surface of the

top cone.

4. Calibrated thermo couple (type-K) shall be used. The thermo couple can be as a pilot and/or

reordering thermo couples. The thermo couples shall be directly fixed to the surface by electrical

discharging equipment. The temperature measured by the thermo couple can be recorded on

multi channel temperature recorder. The number of thermo couple shall be equal to the number

of channels of the temperature recorder.

5. The electrical resistance shall be fixed on the areas to be heat-treated by mechanical fastening

(with the use of temporary fixing elements). The insulation shall be done by mineral wool cloth

(ceramic blanket) to be placed on the electrical resistance coils ( external surface) and on the

inner surface also to cover the area to be heat-treated. The minimum thickness required for

insulation shall be 80 mm for external surface and 50 mm for internal surface.

NDT before PWHT:

1. The constitutional weld joints shall be submitted to radiography (only 60mm thk. Plate joints) to

20% as per QCP.

PWHT process:

1. The PWHT shall be done for total cone in two intervals for each half of total vertical cross

section. I.e. PWHT of CJ-18 & ring 18 VJ (4 nos.) shall be carried out at a stretch, except above

shall be in another stretch (Off take nozzle CJs will be excluded).

2. The electrical resistance shall cover each constitutional weld joints and also the circular and

rectangular nozzles. The insulation shall cover the 100% inner and outer side of the shell top

cone ring (including each nozzle).

Positioning of Thermo couples:

1. The thermo couple on the shell shall be placed in five different concentric sections of top cone

ring. The pilot thermo couples shall be placed on the external side and recording thermo couple

on internal side. The number of thermo couples will be fixed as per the code specification.

2. Where as for each circular nozzle shall have three nos. of equi-distant pilot thermo couples on

external side of the soak band and three nos. of recording thermo couples on the internal side of

the relevant soak band.

3. The main rectangular nozzle shall have six nos. of pilot thermo couples and four nos. of

recording thermo couples. Other nozzles shall have one no. each pilot and recording thermo

couples.

PWHT Parameters:

1. Heating up to 100*- free.

2. Above 100*C, heating rate- 100*C/Hr.

3. Holding temperature- 600*C 20*C.

4. Holding time 3 Hrs & 20 Mins. (For Mean 70mm thk.)

5. Cooling rate (Up to 250*C)- 100*C/Hr.

6. Cooling from 250*C to room temperature free (with insulation intact).

7. PWHT temperature recording.

PWHT Documentation:

1. Identification of items submitted to heat-treatment.

2. Type and no. of PWHT machine/ unit.

3. Type of electrical resistance.

4. Type and position of thermo couples.

5. Time and temperature graph.

6. Maximum heating rate.

7. Holding time and temperature.

8. Maximum cooling rate.

9. Date of execution.

NDT after PWHT:

1. The constitutional weld joints shall be subjected to NDE(100% UT )

2. 100% UT for each nozzle to shell welding

3. Dimensional check of Top cone according to applicable dimensional requirement.

L&T PWIT DCO

UT FOR 12MM Thk. PLATE ON DUST CATCHER MAIN STRUCTURE

Ultrasonic testing on Dust catcher (Ring 31 to 36) is not effectual to reveal volumetric defect

because of the following reasons.

1. Thickness of shell plate is 12 mm.

2. Curved surface.

3.

Вам также может понравиться

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (120)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- Flat Roof TechnicalДокумент7 страницFlat Roof Technicaldynesey50% (2)

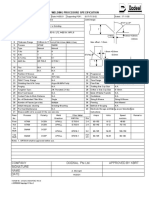

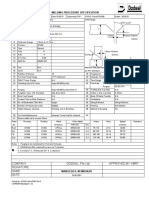

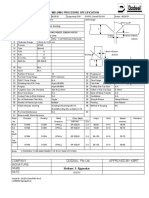

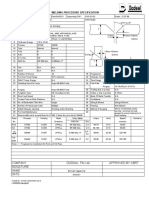

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент2 страницыWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- PP34. Rev.1xlsДокумент1 страницаPP34. Rev.1xlsS GoudaОценок пока нет

- PP34. Rev.1xlsДокумент1 страницаPP34. Rev.1xlsS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент2 страницыWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Документ2 страницыWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент2 страницыWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаCompany Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Документ2 страницыWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaОценок пока нет

- Welding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979Документ1 страницаWelding Procedure Specification: Dodsal Pte LTD Q-Chem Ethylene Project Doha, Qatar Job No: 7979S GoudaОценок пока нет

- Welding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1Документ1 страницаWelding Procedure Specification: Format No: DOD/Q-Chem/F082 Rev 0 c:/DIR00001/wps/pp20-1S GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateДокумент1 страницаWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaОценок пока нет

- Design and Construction Standards: Technical SpecificationДокумент8 страницDesign and Construction Standards: Technical SpecificationolivaresjhonОценок пока нет

- Calculation of Insulation Thickness For PipesДокумент2 страницыCalculation of Insulation Thickness For PipesnarmathaОценок пока нет

- 9666 PDFДокумент2 страницы9666 PDFrahimi mohamadОценок пока нет

- Q A BoilerДокумент19 страницQ A Boilerlavpandey8719Оценок пока нет

- Simultaneous Use of Liquid and Solid Foaming Agents by A Nonconventional Technique To Obtain A High-Strength Glass Foam With Fine PorosityДокумент7 страницSimultaneous Use of Liquid and Solid Foaming Agents by A Nonconventional Technique To Obtain A High-Strength Glass Foam With Fine PorosityMarius DragoescuОценок пока нет

- HMT Unit-1 PDFДокумент3 страницыHMT Unit-1 PDFAnkita MishraОценок пока нет

- Vip 45.3Документ17 страницVip 45.3BūvfizikaОценок пока нет

- Rockwool Rocktech Section Pipe Insulation: General Product InformationДокумент4 страницыRockwool Rocktech Section Pipe Insulation: General Product Informationramy abazaОценок пока нет

- DELMON ProfileДокумент77 страницDELMON ProfileFAIYAZ AHMEDОценок пока нет

- Lecture of Unit Operation Economics (Optimization)Документ24 страницыLecture of Unit Operation Economics (Optimization)Julius Claro TorlaoОценок пока нет

- C 680 - 03 Qzy4mc0wmwДокумент16 страницC 680 - 03 Qzy4mc0wmwB rgОценок пока нет

- QCS-2010 Section 19 Part 2 Water DistributionДокумент12 страницQCS-2010 Section 19 Part 2 Water Distributionbryanpastor106100% (1)

- Glass Block TechnicalДокумент18 страницGlass Block TechnicalPrunici IonОценок пока нет

- Vulcanic Liquid HeatingДокумент65 страницVulcanic Liquid HeatingJavier Conesa OutedaОценок пока нет

- GCR 910 Beyler Fire ResistanceДокумент154 страницыGCR 910 Beyler Fire ResistancevytoОценок пока нет

- FRP PipingДокумент19 страницFRP PipingprocesspipingdesignОценок пока нет

- Insulation From Wood ShavingsДокумент1 страницаInsulation From Wood ShavingstОценок пока нет

- !indx PipДокумент18 страниц!indx PipCharles JacobОценок пока нет

- F'edtu: Standard Specification FOR Ceramic Fibre BlanketsДокумент6 страницF'edtu: Standard Specification FOR Ceramic Fibre BlanketsAnonymous dmMjTmyIОценок пока нет

- Seminar ReportДокумент15 страницSeminar ReportLikhit NaikОценок пока нет

- Heat and Mass Transfer WorksheetДокумент5 страницHeat and Mass Transfer WorksheetBISRAT YIHUNОценок пока нет

- MS For PPR Pipes For Water SupplyДокумент19 страницMS For PPR Pipes For Water Supplysadiq100% (2)

- Experiment 6Документ6 страницExperiment 6Muhammad AsimОценок пока нет

- ACC WE DA0060 Thermal Insulation 1-0 Mar 2008Документ12 страницACC WE DA0060 Thermal Insulation 1-0 Mar 2008Iim Hilmi ArifОценок пока нет

- Man Climate & Architecture 1Документ15 страницMan Climate & Architecture 1diegomedranoОценок пока нет

- Whatever Is Updated and RevisedДокумент14 страницWhatever Is Updated and RevisedWan Ah-LunОценок пока нет

- Sustainable Solar Housing - (Vol 1) - ManteshДокумент287 страницSustainable Solar Housing - (Vol 1) - ManteshGoku KakarotoОценок пока нет

- Water Proofing Damp Proofing AND Thermal InsulationДокумент19 страницWater Proofing Damp Proofing AND Thermal InsulationgauriОценок пока нет

- E2488 092014 Standard Guide ForДокумент8 страницE2488 092014 Standard Guide ForBAN ZANGHANAОценок пока нет