Академический Документы

Профессиональный Документы

Культура Документы

I A P P

Загружено:

Carl FranksОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

I A P P

Загружено:

Carl FranksАвторское право:

Доступные форматы

IAPP

International Air Pollution Prevention

INDEX

Page

1. General Introduction to MARPOL ANNEX VI 2

2. Bunker Delivery Requirements / MARPOL 3

Specification Form

3. Bunker Sampling Procedure 4

4. Packing Sealing and Dispatch of Bunker Sample 5

5. Procedure for Changing FO to Main Engines 7

6. Diagram of Fuel Oil Lines for Main Engines 8

7. Procedure for Changing FO to Auxiliary Engines 9

8. Diagram of Fuel Oil Lines for Auxiliary Engines 10

9. Procedure for Changing FO to Boiler 11

10. Diagram of Fuel Oil Lines for Boiler 12

11. Details of OZONE Depleting Substances on Board 13

12. Handling of OZONE Depleting Substances 13

M.V. Ships Name

Manual created by Capt. Pawanexh Kohli Environmental Management System

1. GENERAL

From May 19th 2005 the first piece of MARPOL Annex VI came into force.

Essentially this first piece of legislation limits the Sulfur level of bunkers used on board ships

to 4.5%.

As from this same date, Suppliers have a duty to provide the ship with a Bunker Delivery

receipt containing the following information:

1. Name & IMO number of Receiving Ship

2. Bunker Port

3. Date of commencement of delivery

4. Name, Address & Telephone number of Supplier

5. Product Name

6. Quantity Metric Tons

7. Density @ 15C

8. Sulfur content (% m/m)

9. A Declaration signed and certified by the fuel Suppliers representative that the fuel oil

supplied is in conformity with the MARPOL Regulations (see Sample on next page)

Test methods for Density & Sulfur are to be ISO 3675 & ISO 8754.

The Supplier must take a representative sample of the bunkers supplied; the MARPOL

recommendation is that this sample be taken by continuous drip at the ships receiving

manifold. This sample needs to be signed and sealed by the Supplier and be marked

MARPOL. The seal number on this sample should be written on the Bunker Receipt.

The MARPOL sample must be retained on board the ship with the Bunker Delivery receipt for

at least one year. This sample must not be used for testing. It should only be released to an

officer representing a Port or State authority, if requested. If this sample or any Bunker receipt

is handed over to such a person, the Captain must obtain a signature for custody transfer.

The new requirements do not change the situation regarding the taking of commercial

samples. Ships staff should continue to take samples at their receiving manifold. One sample

is sent for testing, one is issued to the Supplier and the other retained on board for future

testing if required. It is also possible that the Supplier may issue another sample to the ship, in

the usual manner. This (not the MARPOL sample) may be used for testing in case of any

quality dispute.

It is not recommend that the Ships staff take charge of obtaining, labeling, and sealing the

MARPOL sample; this is the duty of the Supplier. If the MARPOL sample is taken by Ship's

staff and later found to be not representative, the Supplier could blame the Ship and a

complicated legal dispute could arise. However, we have included the additional bottle for the

MARPOL sample to assist the process if the Supplier does not have a proper bottle.

According to MARPOL Annex VI, the Supplier has to provide an extra bottle of the fuel

supplied for the C/E to keep onboard the vessel. This is the dedicated MARPOL sample and

should be kept onboard under safe custody for a minimum of one year. The volume of the

bottle should be at least 400 ml. The bottle label should contain the following information:

2 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

1) Location at which and the method by which, the sample was taken

2) Bunker Date

3) Bunker Port

4) Name of Bunker Barge / bunker installation

5) Name and IMO no. of the vessel

6) Supplier Name

7) Name and Signatures of Supplier's representative and Ship's representative

8) Details of Seal Identification

9) Bunker Grade

Although it is the Suppliers responsibility to take this sample and provide this extra bottle,

vessel is also able to provide an extra bottle, should the Supplier not have a proper bottle.

The responsibility for the Supplier's MARPOL sample rests with the Supplier. If ship-staff draw

the sample and give it to the Supplier, he could very well say that it is not his sample. Please

recognize this important intent of the MARPOL VI regulation.

To ensure Compliance with MARPOL specifications, the vessel strictly adheres to the

following

A defined sample collecting procedure

A defined oil sample dispatch procedure.

Proper Labeling and dispatch & storing of oil samples

2. Bunker Delivery Note

MARPOL SPECIFICATION FORM

SHIP NAME SHIP IMO NUMBER

BUNKER PORT BUNKER DATE

SUPPLIER NAME SUPPLIER ADDRESS

DATE OF COMMENCEMENT OF BARGE NAME

DELIVERY

BUNKER INFO

SULPHUR: % m/m

FUEL GRADE:

QUANTITY: MTons DENSITY: kg/m @ 15C

This is to certify that the fuel oil supplied conforms to MARPOL regulations.

______________________ _____________________________

Signature of Chief Engineer Signature of Supplier Representative

3 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

3. SAMPLING PROCEDURE

Sampling is carried out by the continuous drip method throughout the period of fuel transfer.

At the beginning of bunkering; 4 to 5 liters of fuel are flushed into a waste container by

opening the needle valve completely. The needle valve on the probe is adjusted to the

appropriate setting to ensure collection of a representative sample.

The sample is collected in a thoroughly clean, dry disposable plastic cubitainer, which

supported by a rigid outer box. A 4-liter container is recommended for this purpose. minimum

of 1.5 liters and a maximum of 3 liters of sample are to be collected during bunkering. The

neck of the cubitainer is recessed to minimize storage space. By pulling firmly on the

cubitainer neck, the threaded portion may be extended to allow connection to the brass cap of

the sampler. The valve and the top

of the cubitainer are enclosed the

security mechanism and locked.

See illustration.

In case of any substantial change in

the rate of fuel flow, the valve may

have to be adjusted to compensate

for the change in flow rate.

When bunkering is completed, the

protective casing is unlocked and

opened. If the line fuel is being

sucked by the shore facility shut the

needle valve to prevent cubitainer

contents from getting sucked back.

The needle valve is opened fully to

allow the oil in the sampler to drain

into the cubitainer. The cubitainer is

removed and capped. It is then

shaken vigorously for a minimum of

30 seconds to ensure homogeneity

of the sample.

The contents of the cubitainer may then be poured into sample bottles. When filling the

bottles, the sample should be distributed evenly among the sample bottles in three or four

passes, filling each bottle partially with each pass. Each sample bottle is then sealed and

labeled for identification. One bottle is sent to the VLC laboratory for testing. One bottle is

given to the supplier or his representative. One bottle is to be stored in a safe place in case of

any contingency and for future reference.

4 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

5 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

Labeling of FO Samples

Name and Address of

Oil Analysis Laboratory

VISWA LAB

OIL SAMPLE FOR ANALYSIS

Vessel Owner

Vessel Name

IMO No.

Port / Location

Sampling Date / Grade

Supplier

Barge / Terminal

Sample Pt. / Method

Seal # Qty Mtons

Remarks

Vessel Rep Supplier Rep

Name: Name:

Sign Sign

6 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

5. Procedure for Changing FO to Main Engines

1. Close the Steam inlet and return valves to the M/E Fuel oil heaters.

2. Let the temperature in the fuel circuit fall down to about 100 degrees Celsius. This

will take approximately 55 minutes.

3. Start reducing the ME RPM to 80.

4. When at 80 RPM, change over the Change over (3 Way) inlet valve (between IFO

service tank and MDO service tank) to MDO position.

5. Return line to be kept to Mixing tank for proper mixing and subsequent filling with

MDO.

6. Check the FO return line to confirm that line contains MDO.

For faster change over, the return line to the Mixing tank can be diverted to the HFO Service

tank. Though, once MDO is confirmed in the return line, this should then be re-routed to return

to the Mixing tank.

Other approximate parameters taken into account are:

Volume of oil in Pipelines: 170 Liters.

Volume of oil in pumps & other accessories: 45 Liters

Fuel consumption: 1.4 MT/Hour

Time taken for c/o: 95 Minutes)

Note: The values quoted in this procedure are when changing over from IFO 500

Refer to Line diagram on next Page.

7 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

Vent

Sunil Saini

v/v

Return

Hot

MAIN Tank

I.F.O. Pressure Filters

Service Adjusting ENGINE 3 way

Tank Valve Valve

pKohli-DFFI

DAMPER

to Service

Quick Tank

Closing

Valve

Filter

F.O. Viscometer

Change Mixing

Over Tank

Valve Heater

#1

M/E Feed

Pumps Heater

Flow Meter #2

Quick

Closing

Valve

Bypas

s

F.O. Booster

M.D.O. Pumps

Service Drawing by

Capt. Pawanexh Kohli

Tank

M.E. Fuel Oil Line Diagram

M.V. Dole

ShipsCalifornia

Name

8 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

7. Procedure for Changing FO to Auxiliary Engines

AA.

When required to change over FO to a particular Auxiliary Engine:

a. Confirm the particular AEs on which FO requires to be changed over.

b. Ensure that the MDO feed pumps are running.

c. On this (or each) particular AE, the change over can be affected by using the

individual change over valves on its inlet and return lines.

Note: In case of blackout/initial start up the Boiler MDO tank can be used to have gravity head

pressure in the MDO lines.

BB.

When required to change over FO to all Auxiliary Engines:

a. Close the steam inlet and return valves to the AE Fuel oil heaters.

b. Let the temperature in the circuit fall down to about 100 degrees Celsius.

(approximately 120 minutes)

c. Change over the 3 way inlet valve (between IFO service tank and MDO service

tank) to MDO position.

d. Run the AEs on load for at least 90 minutes.

e. Check the return lines to confirm that the line contains MDO.

f. Return line should be set to return FO to the mixing tank.

Approximate parameters taken into account are:

Volume of oil in pipelines: 400 Liters.

Volume of oil in pumps & other accessories: 50 Liters.

Time taken for complete c/o: 2 hours.

Refer to Line diagram on next Page.

9 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

Individual

M.D.O. I.F.O. C/O valves

Feed Mixing

Service Service Pumps Tank

Tank Tank AE # 1

Filter AE # 2

AE # 3

Quick Quick Filter

Closing Booster

Closing

Valve Pumps

Valve AE # 4

AE # 5

Recirculation

AE # 6

3-Way

C/O

Valve Hot

Pressure Filter

Adj.Valve

Boiler

MDO Flow

Tank Mete

r Heaters

1&2

D.O. For

Feed Emergency

P/ps Use

Filter

Viscotherm

Filters

Drawing by

MDO Return Line

Capt. Pawanexh Kohli

A.E. Fuel Oil Line Diagram

M.V. Dole

ShipsCalifornia

Name

10 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

9. Procedure for Changing FO to Boiler

The Boiler can be fired directly on MDO.

Ensure the following have been adopted:

a. On the change over Block A the position to be set for MDO intake.

b. The MDO feed pump to be kept running.

Ships Name

Refer to Enlarged Line diagram on next Page

11 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

Pressure

I.F.O. M.D.O. Adj.Valve

Service Service Boiler

Tank Tank Filter D.O.

Tank

Change Over D.O.

Block A Pump

Filter

F.O.

Pumps

Filter

Pump for

Pilot Burner BOILER

H

E

A Change Over

T Block B pKohli-dffi

E

R Main Burner

to from

Mixing Mixing

Tank Tank

Boiler Fuel Oil Line Diagram

Pressure

Adj.Valve M.V. Dole

ShipsCalifornia

Name

12 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

11. Details of OZONE Depleting Substances on Board

UTILITY Refrigerants are the only substances specified as Ozone depleting on

board the vessel. The following list details the services using ozone depleting

substances (refrigerants).

Quantity of

# Service Location Model Refrigerant Used Refrigerant

Used

1. Accommodation AC Plant 1 E/R 1st Flat Stbd Ford xyz R22 (HCFC 22) 71.0 Kg

2. Accommodation AC Plant 2 E/R 1st Flat Stbd Ford xyz R22 (HCFC 22) 71.0 Kg

3. ECR AC Plant 1 Main Deck aft of ECR xyz R22 (HCFC 22) -

4. ECR AC Plant 2 Main Deck aft of ECR xyz R22 (HCFC 22) -

5. Provision Room Plant 1 E/R 1st Flat Port Ford xyz R22 (HCFC 22) 19.5 Kg

6. Provision Room Plant 2 E/R 1st Flat Port Ford xyz R22 (HCFC 22) 19.5 Kg

TOTAL Refrigerant in Use on Board: 180.8 Kg

REFRIGERANT STORE (Recharging bottles)

o Refrigerant Stored at: Freon Storage Room

o Located At: Main Deck Port aft of Central Store

o Quantity Stored: 5 bottles x 60 kg each

REFRIGERANT RECOVERY EQUIPMENT

Equipment to recover refrigerant has been installed on board. Details are as follows:

o Manufacturer: ABCXYZ

o Capacity: 58 Ltrs.

12. Handling Of Ozone Depleting Substances

o No Ozone depleting substance is allowed to escape to atmosphere.

o Refrigerant Recovery Equipment is used to recover refrigerant from services as

and when required.

o If refrigerant is not contaminated, it is reused to recharge.

o When refrigerant is contaminated, it is landed for authorized disposal.

o Operating Manual of the recovery equipment is attached.

All copyrights to this manual exclusive to Capt. P. Kohli as no material sale made or compensation remunerated by users.

Names and data modified for sample use. Drawings are indicative only.

13 of 13

Environmental Management System M.V. Ships Name

by Capt. Pawanexh Kohli

Вам также может понравиться

- IAPPДокумент13 страницIAPPMohd ShajiОценок пока нет

- Bunkers Quality and Quantity ClaimsДокумент36 страницBunkers Quality and Quantity ClaimsParthiban NagarajanОценок пока нет

- Nglo Astern Roup: Qhse Management MV "Harmonious"Документ1 страницаNglo Astern Roup: Qhse Management MV "Harmonious"Ankit Kumar SinghОценок пока нет

- VPS FQT Instruction Manual SUMMARY-1Документ16 страницVPS FQT Instruction Manual SUMMARY-1gilar herliana putraОценок пока нет

- 1 ATTACH DRAFT 2019guidelines For Onboard Sampling PPR6Документ3 страницы1 ATTACH DRAFT 2019guidelines For Onboard Sampling PPR6ΑΝΝΑ ΒΛΑΣΣΟΠΟΥΛΟΥОценок пока нет

- MEO Question and AnsДокумент221 страницаMEO Question and AnsVikram Singh100% (1)

- Spe 124609 MsДокумент21 страницаSpe 124609 Msthabnh1Оценок пока нет

- UK Club Bunkers - Quality - and - Quantity - ClaimsДокумент28 страницUK Club Bunkers - Quality - and - Quantity - Claimswalter.dekkersОценок пока нет

- B-17-Prov B.W.M.PДокумент58 страницB-17-Prov B.W.M.Pcatenaccio.skОценок пока нет

- CGO 001 Before OperationsДокумент2 страницыCGO 001 Before OperationsAbu Syeed Md. Aurangzeb Al MasumОценок пока нет

- Bunkers: A Guide To Quality and Quantity Claims: Ukdc Is Managed by ThomasДокумент20 страницBunkers: A Guide To Quality and Quantity Claims: Ukdc Is Managed by Thomasiomerko100% (1)

- Best Practice For Storing Bunker SamplesДокумент3 страницыBest Practice For Storing Bunker SamplesHorobets DmytroОценок пока нет

- Bunkers Sampling GuidelinesДокумент2 страницыBunkers Sampling GuidelinesgamronОценок пока нет

- 4.7 Cargo Sampling ProcedureДокумент7 страниц4.7 Cargo Sampling ProcedureHasan CosalevОценок пока нет

- 5 Ballast SequenceДокумент46 страниц5 Ballast Sequenceนัทเดช เรืองสวนОценок пока нет

- Kang 2011Документ7 страницKang 2011RicardoОценок пока нет

- Delivering Quality Bulk Marine GasoilДокумент30 страницDelivering Quality Bulk Marine Gasoilventa kevara100% (1)

- 4.7 Cargo Sampling and Ullaging Procedure OkДокумент6 страниц4.7 Cargo Sampling and Ullaging Procedure OkHasan CosalevОценок пока нет

- LESSON 7 Bunkering OperationsДокумент12 страницLESSON 7 Bunkering OperationsPotin LerotiboОценок пока нет

- Spe 145027 MSДокумент6 страницSpe 145027 MSShahad KhadadaОценок пока нет

- TWPST026 Ship Recycling Compliance SurveyДокумент8 страницTWPST026 Ship Recycling Compliance Surveyene oanaОценок пока нет

- MEO Class 2 Orals Safety Q & AДокумент9 страницMEO Class 2 Orals Safety Q & Aneeraj118593% (14)

- Bunker SampleДокумент4 страницыBunker Sampledassi99Оценок пока нет

- 202207291234447380693draft Circular 29 07 22Документ5 страниц202207291234447380693draft Circular 29 07 22RISHI NARENDRANОценок пока нет

- Bunkering Process Adopted by The Present Vessel: Magnus Carriers CorporationДокумент1 страницаBunkering Process Adopted by The Present Vessel: Magnus Carriers CorporationIhwan AsrulОценок пока нет

- Bunkering ProcedureДокумент4 страницыBunkering ProcedureVinay Gupta100% (2)

- SPE 89382 A Guide To Chemical Oil Recovery For The Independent OperatorДокумент11 страницSPE 89382 A Guide To Chemical Oil Recovery For The Independent OperatormsmsoftОценок пока нет

- Bunkers & Bunkering-GARD PDFДокумент48 страницBunkers & Bunkering-GARD PDFshishir4870Оценок пока нет

- Mehr OtraДокумент13 страницMehr OtraThomas JoseОценок пока нет

- Checklist For Compliance With The 0 50 Mass by Mass MM Sulphur Cap - 0919 - 1Документ2 страницыChecklist For Compliance With The 0 50 Mass by Mass MM Sulphur Cap - 0919 - 1ΑΝΝΑ ΒΛΑΣΣΟΠΟΥΛΟΥОценок пока нет

- DNVPS Fuel Testing Procedures Part 2Документ18 страницDNVPS Fuel Testing Procedures Part 2KaiОценок пока нет

- Bunker Log BookДокумент19 страницBunker Log Bookene oanaОценок пока нет

- Mar Env:: Protection of The Marine EnvironmentДокумент9 страницMar Env:: Protection of The Marine EnvironmentHaeisy SimsuangcoОценок пока нет

- Guide Bunker Quality Disputes - Part 1Документ4 страницыGuide Bunker Quality Disputes - Part 1Parthiban NagarajanОценок пока нет

- Well Control for Completions and InterventionsОт EverandWell Control for Completions and InterventionsРейтинг: 4 из 5 звезд4/5 (10)

- MN 7 of 2020 - Lessons Learned From A Recent Fuel Oil Spill in PortДокумент5 страницMN 7 of 2020 - Lessons Learned From A Recent Fuel Oil Spill in PortDivan YonОценок пока нет

- GEST 79 79 Edition 4 (Transfer of Liquid Chlorine by Padding With A Chlorine Compressor)Документ15 страницGEST 79 79 Edition 4 (Transfer of Liquid Chlorine by Padding With A Chlorine Compressor)Anonymous 20VAruОценок пока нет

- 11 Care and Maintenance of Cargo Cargo Equipments OkДокумент4 страницы11 Care and Maintenance of Cargo Cargo Equipments OkHasan CosalevОценок пока нет

- Spe 208168 MsДокумент27 страницSpe 208168 MsMursal ZeynallıОценок пока нет

- Management PlanДокумент75 страницManagement PlantaqiiftikharОценок пока нет

- Activity of ClayДокумент6 страницActivity of ClayAsep TheaОценок пока нет

- CEOR Polymer FloodingДокумент47 страницCEOR Polymer FloodingAli AlrfaeОценок пока нет

- BunkeringДокумент29 страницBunkeringChirag Gupta100% (2)

- Marpol Annex VI - Testing ProcedureДокумент2 страницыMarpol Annex VI - Testing ProcedureOana Lupsa100% (1)

- Bunker Sampling MEPC 182 59 ISO 13739 ExxonMobil MarineДокумент2 страницыBunker Sampling MEPC 182 59 ISO 13739 ExxonMobil MarineRameez FaroukОценок пока нет

- Bunker Note of Protest PDFДокумент1 страницаBunker Note of Protest PDFMichael Epshtein100% (1)

- Optimized Polymer Enhanced Foam Flooding For Ordinary Heavy Oil Reservoir After Cross-Linked Polymer FloodingДокумент9 страницOptimized Polymer Enhanced Foam Flooding For Ordinary Heavy Oil Reservoir After Cross-Linked Polymer Floodingجمال المغبشيОценок пока нет

- 4.4 Handling of Bunker DisputesДокумент3 страницы4.4 Handling of Bunker Disputessonakshi.sundhukumarОценок пока нет

- SPE 181142 MS Successful Application of Root Cause Analysis On ProgressiveДокумент21 страницаSPE 181142 MS Successful Application of Root Cause Analysis On Progressivejainrakeshj4987Оценок пока нет

- INTERTANKO Guidance On Monitoring and Sampling For Compliance With The 2013 VGPДокумент25 страницINTERTANKO Guidance On Monitoring and Sampling For Compliance With The 2013 VGPCharalampos ChatzivasileiouОценок пока нет

- MIM1191.601 CARE AND MAINTENANCE OF FOAM FIRE FIGHTING SYSTEMS ON MARINE VESSELS, Dec 2014 PDFДокумент6 страницMIM1191.601 CARE AND MAINTENANCE OF FOAM FIRE FIGHTING SYSTEMS ON MARINE VESSELS, Dec 2014 PDFGrenoite GrenoiteОценок пока нет

- BunkerДокумент3 страницыBunkerAhmed AL BatalОценок пока нет

- TechUpd 2023 - 10 - 11 Contaminated VLSFO Bunkers From NOLA - An UpdateДокумент1 страницаTechUpd 2023 - 10 - 11 Contaminated VLSFO Bunkers From NOLA - An UpdateLazar Petre-GabrielОценок пока нет

- Report On The Surveys Concerning International Oil Pollution Prevention CertificateДокумент3 страницыReport On The Surveys Concerning International Oil Pollution Prevention CertificateSUNILОценок пока нет

- Spe 183440 MSДокумент10 страницSpe 183440 MSMohammed KelkouliОценок пока нет

- Oil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsОт EverandOil Spill Remediation: Colloid Chemistry-Based Principles and SolutionsОценок пока нет

- Unconventional Shale Gas Development: Lessons LearnedОт EverandUnconventional Shale Gas Development: Lessons LearnedRouzbeh G. MoghanlooОценок пока нет

- Ship Hydrodynamics NUMECAДокумент87 страницShip Hydrodynamics NUMECACarl FranksОценок пока нет

- Marine Department Notice No. 76 of 2004 (Miscellaneous Information)Документ2 страницыMarine Department Notice No. 76 of 2004 (Miscellaneous Information)Carl FranksОценок пока нет

- Rarch1Ef: David W. Taylor Naval ShipДокумент615 страницRarch1Ef: David W. Taylor Naval ShipCarl FranksОценок пока нет

- Licence: Subscribe To OurДокумент183 страницыLicence: Subscribe To OurCarl FranksОценок пока нет

- National Standard For Commercial Vessels: Australian Transport CouncilДокумент26 страницNational Standard For Commercial Vessels: Australian Transport CouncilCarl FranksОценок пока нет

- Ministry of Communications and Works Department of Merchant Shipping LemesosДокумент8 страницMinistry of Communications and Works Department of Merchant Shipping LemesosCarl FranksОценок пока нет

- See-Berufsgenossenschaft Hamburg D 4 Guidelines Concerning Stability Measuring InstallationsДокумент5 страницSee-Berufsgenossenschaft Hamburg D 4 Guidelines Concerning Stability Measuring InstallationsCarl FranksОценок пока нет

- Marine Department Notice No. 91 of 2004 (Miscellaneous Information)Документ1 страницаMarine Department Notice No. 91 of 2004 (Miscellaneous Information)Carl FranksОценок пока нет

- Ministry of Communications and Works Department of Merchant ShippingДокумент3 страницыMinistry of Communications and Works Department of Merchant ShippingCarl FranksОценок пока нет

- Current Bahamas Merchant Shipping Act PDFДокумент147 страницCurrent Bahamas Merchant Shipping Act PDFCarl FranksОценок пока нет

- Republic of The Marshall Islands Office of The Maritime AdministratorДокумент6 страницRepublic of The Marshall Islands Office of The Maritime AdministratorCarl FranksОценок пока нет

- Republic of The Marshall Islands Office of The Maritime AdministratorДокумент5 страницRepublic of The Marshall Islands Office of The Maritime AdministratorCarl FranksОценок пока нет

- Republic of Liberia Bureau of Maritime AffairsДокумент13 страницRepublic of Liberia Bureau of Maritime AffairsCarl FranksОценок пока нет

- Republic of Liberia Bureau of Maritime AffairsДокумент9 страницRepublic of Liberia Bureau of Maritime AffairsCarl FranksОценок пока нет

- 3452345534534Документ24 страницы3452345534534Carl FranksОценок пока нет

- No Other Models of Calculators Are Permitted in The Exam RoomДокумент1 страницаNo Other Models of Calculators Are Permitted in The Exam RoomCarl FranksОценок пока нет

- 46584686684Документ520 страниц46584686684Carl FranksОценок пока нет

- Crew Boat Requirements Circular Letter No. 5 - April 7, 1982Документ5 страницCrew Boat Requirements Circular Letter No. 5 - April 7, 1982Carl FranksОценок пока нет

- Panama Decree Law No. 45 PDFДокумент2 страницыPanama Decree Law No. 45 PDFCarl FranksОценок пока нет

- Annex I Simplified Method For Determining Transferse Watertigh SubdivisionДокумент1 страницаAnnex I Simplified Method For Determining Transferse Watertigh SubdivisionCarl FranksОценок пока нет

- Refrigerant System Chemistry: Component TestsДокумент12 страницRefrigerant System Chemistry: Component TestsFlorin OnucОценок пока нет

- Handbook TDG Grasas PDFДокумент358 страницHandbook TDG Grasas PDFjizu100% (1)

- DAIKIN Modular Inverter Air Cooled Chiller: R410A R410A R410AДокумент12 страницDAIKIN Modular Inverter Air Cooled Chiller: R410A R410A R410AJose CuevasОценок пока нет

- (2PRD-003A) Refrigerant ComparisonДокумент31 страница(2PRD-003A) Refrigerant ComparisonKyaw San OoОценок пока нет

- R134a Properties and ApplicationsДокумент2 страницыR134a Properties and ApplicationsxesОценок пока нет

- Danfoss Light Commercial B, U, L, P, X, S Ranges - 60Hz: Refrigeration CompressorsДокумент48 страницDanfoss Light Commercial B, U, L, P, X, S Ranges - 60Hz: Refrigeration CompressorsCain PeñaОценок пока нет

- Carrier - SystemsДокумент43 страницыCarrier - SystemsKagitha TirumalaОценок пока нет

- GreenChill Best Practices GuidelineДокумент50 страницGreenChill Best Practices Guidelinezzingenieros pruebaОценок пока нет

- PDBTurkishPlasmaSingle 5400704002 2009Документ76 страницPDBTurkishPlasmaSingle 5400704002 2009jannowakaa52Оценок пока нет

- Catalogo ChillerДокумент8 страницCatalogo ChillerJoan Sebastian DazaОценок пока нет

- Muz A18 26yv (OB346E)Документ52 страницыMuz A18 26yv (OB346E)Selçuk özkutluОценок пока нет

- Chemours Freon R 22 MSDSДокумент12 страницChemours Freon R 22 MSDSKhairul Muzamil100% (1)

- Honeywell Genetron Refrigerants Overview BrochureДокумент6 страницHoneywell Genetron Refrigerants Overview Brochurearky rizki syaniОценок пока нет

- Manual For Ref. SystemДокумент134 страницыManual For Ref. SystemPresunto CulpableОценок пока нет

- Trane Service Screw Compressors Replacement Solutions by Trane RSP Slb110 en 01012004Документ6 страницTrane Service Screw Compressors Replacement Solutions by Trane RSP Slb110 en 01012004Modussar IlyasОценок пока нет

- R410a GuideДокумент18 страницR410a Guideapi-19789368Оценок пока нет

- Manual AWHP UdemodulДокумент186 страницManual AWHP Udemodulscribdbugmenot1919Оценок пока нет

- R22 Phase Out and F-Gas RegulationsДокумент19 страницR22 Phase Out and F-Gas Regulationsamarnath jagirdarОценок пока нет

- Energy-Exergy Performance Evaluation of New HFO Refrigerants in The Modified Vapour Compression Refrigeration SystemsДокумент9 страницEnergy-Exergy Performance Evaluation of New HFO Refrigerants in The Modified Vapour Compression Refrigeration SystemsIjrei JournalОценок пока нет

- Classification of RefrigerantsДокумент5 страницClassification of RefrigerantsOscar BallartaОценок пока нет

- Condensation in Horizontal Tubes, Part 2: New Heat Transfer Model Based On Ow RegimesДокумент23 страницыCondensation in Horizontal Tubes, Part 2: New Heat Transfer Model Based On Ow RegimesalagaruОценок пока нет

- Greening of Industry Under The Montreal ProtocolДокумент30 страницGreening of Industry Under The Montreal ProtocolKarl AttardОценок пока нет

- Mxz-2a20na & Mxz-3a30na Ob444aДокумент77 страницMxz-2a20na & Mxz-3a30na Ob444aSLAMET PAMBUDIОценок пока нет

- R290 SplitAC ResourceGuide ProklimaДокумент56 страницR290 SplitAC ResourceGuide ProklimaKamalesh BeraОценок пока нет

- Industrial Refrigeration Best Practices Guide PDFДокумент19 страницIndustrial Refrigeration Best Practices Guide PDFManoj TiwariОценок пока нет

- The Difference Between R22 and R410A Refrigerant - AND ServicesДокумент3 страницыThe Difference Between R22 and R410A Refrigerant - AND ServicesHumayun BaigОценок пока нет

- Emerson Compressor Refrigerant Oil List 93-11Документ2 страницыEmerson Compressor Refrigerant Oil List 93-11hvactrg1Оценок пока нет

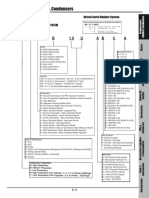

- Compressors, Chillers & Condensers: H 2 9 B 1 9 U AB C AДокумент3 страницыCompressors, Chillers & Condensers: H 2 9 B 1 9 U AB C ALionder GarciaОценок пока нет

- Refrigerants - Physical PropertiesДокумент3 страницыRefrigerants - Physical PropertiesEder PereiraОценок пока нет