Академический Документы

Профессиональный Документы

Культура Документы

Properties and Grades of Fasteners

Загружено:

chez ezОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Properties and Grades of Fasteners

Загружено:

chez ezАвторское право:

Доступные форматы

Evansville, IN 812-477-0077 Henderson, KY 270-830-0077

Jasper, IN 812-482-5105 Owensboro, KY 270-684-0877

Vincennes, IN 812-882-4090 Mt. Vernon, IL 618-244-7156

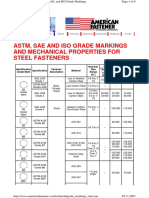

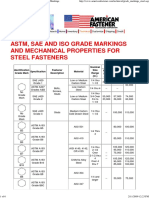

Mechanical Specifications for Externally Threaded

Fasteners with Grade Markings

Specification Material Size Min. Proof Min. Tensile Core Hardness Min. Yield Grade

Range Strength Strength Rockwell Strength Identification

(Inches) (psi) (psi) Min. Max. (psi) Marking

SAE J429-Grade 1 Low or Medium 1/4 - 1-1/2 33,000 60,000 B70 B100 36,000

Carbon

SAE J429-Grade 2 Steel 1/4 - 3/4 55,000 74,000 B80 B100 57,000

7/8 - 1-1/2 33,000 60,000 B70 B100 36,000

ASTM A307-Grade A Low or Medium 1/4-4 60,000 B69 B100

Carbon (see note 1)

Steel

ASTM A307-Grade B Low or Medium 1/4-4 60,000(min) B69 B95

Carbon 100,000(max) (see note 1)

Steel

SAE J429-Grade 5 Medium Carbon 1/4-1 85,000 120,000 C25 C34 92,000

ASTM A449-Type 1 Steel: Quenched 1-1/8 - 1-1/2 74,000 105,000 C19 C30 81,000

ASTM A449-Type 1 and Tempered 1-3/4 - 3 55,000 90,000 58,000

See Note 2

ASTM A325-Type 1 Medium Carbon 1/2-1 85,000 120,000 C25 C34 92,000 See

Steel: Quenched 1-1/8 - 1-1/2 74,000 105,000 C19 C30 81,000 Note

& Tempered 5

(see note 3)

ASTM A354 Medium Carbon 1/4 - 2-1/2 105,000 125,000 C26 C36 109,000

Grade BC Alloy Steel: over 2-1/2 - 4 95,000 115,000 C22 C33 99,000

Quenched

& Tempered (see note 2)

ASTM A354 Medium Carbon 1/4 - 2-1/2 120,000 150,000 C33 C39 130,000 See

Grade BD Alloy Steel: over 2-1/2 - 4 105,000 140,000 C31 C39 115,000 Note

Quenched (see note 2) 4

& Tempered

SAE J429 Grade 8 Medium Carbon 1/4 - 1-1/2 120,000 150,000 C33 C39 130,000

Alloy Steel:

Quenched

& Tempered

SAE J429-Grade 8.2 Low Carbon 1/4 - 1 120,000 150,000 C33 C39 130,000

Boron Steel:

Quenched

& Tempered

ASTM A490-Type 1 Medium Carbon 1/2 - 1-1/2 120,000 150,000(min) C33 C38 130,000

Alloy Steel: 170,000(max) (see note 3)

Quenched

& Tempered

ASTM A574 Low Alloy Steel: #0 - 1/2 140,000 180,000 C39 C45

Socket Head Cap Screw Quenched over 1/2 - 2 135,000 170,000 C37 C45

& Tempered

Note 1: No minimum hardness is required on bolts and studs 3 times the diameter and longer.

Note 2: Bolts less than 3 times the diameter in length and studs less than 4 times diameter in length shall have hardness values not less than minimum and not more than

maximum.

Note 3: Bolts 3 times the diameter in length and over are not required to meet minimum hardness requirements.

Note 4: ASTM A354-Grade BD shall be marked with the grade symbol BD and, in addition may be marked with six radial lines.

Note 5: Radial line markings 120 degrees apart are optional.

ASTM A36 Material Specification

Specification Material Tensile Strength (psi) Miniumum Yield Strength (psi)

ASTM A36 Carbon Structural Steel 58,000 (min.) - 80,000 (max.) 36,000

Most designers and end users focus on the strength and other characteristics of the bolt or stud. Once having selected the bolt, they must choose the appropriate nut. There

are two simple rules when it comes to selecting the nut:

Rule #1; choose a nut specification compatible with the bolt specification. The bolt specification will usually dictate which nut specification is applicable (ASTM A193 bolts

require ASTM A194 nuts).

Rule #2; choose a nut whose minimum proof strength is greater than or equal to the minimum ultimate tensile strength of the bolt. This ensures us that the bolt will break in

tension prior to the female and/or male threads stripping.

A broken bolt is an obvious failure. Its loose. However, when the threads strip prior to the bolt breaking, we may not notice the failure until after the fastener is put into service.

SAE J429 Bolt and Nut Compatibility

Bolt Grade Recommended Nut Grade (1) Suitable Substitution (2)

SAE J-429 Grade 2 Low Carbon Regular or Heavy Hex Nut SAE J995 Grade 5 or Grade 8 Hex Nut

SAE J-429 Grade 5 SAE J995 Grade 5 Hex Nut SAE J995 Grade 8 Hex Nut

SAE J-429 Grade 8 SAE J995 Grade 8 Hex Nut

(1) Recommended denotes a commercially available nut having the most suitable mechanical properties that will make it possible to obtain the desired bolt load.

(2) Suitable denotes SAE J995 nuts having mechanical properties that will also make it possible to obtain the desired bolt load.

410 Visit us on the WEB @ EBNinc.com

Evansville, IN 812-477-0077 Henderson, KY 270-830-0077

Jasper, IN 812-482-5105 Owensboro, KY 270-684-0877

Vincennes, IN 812-882-4090 Mt. Vernon, IL 618-244-7156

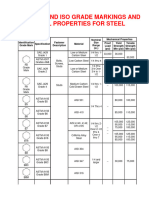

Grade Identification Markings for Nuts

Specification Material Nominal Proof Load Grade

Size Stress Zinc Identification

(Inches) Plain (psi) Coated Min. Max. Marking

ASTM A563 - Grade 0 Carbon Steel 1/4 - 1-1/2 69,000* 52,000* B55 C32

ASTM A563 - Grade A Carbon Steel 1/4 - 1-1/2 90,000* 68,000* B68 C32

ASTM A563 - Grade A Carbon Steel 1/4 - 4 100,000* 75,000* B68 C32

Heavy Hex 90,000* 68,000*

ASTM A563 - Grade C Carbon Steel, 1/4 - 4 144,000 144,000 B78 C38

Heavy Hex May Be Quenched

& Tempered

ASTM A563 - Grade DH Carbon Steel, 1/4 - 4 175,000 150,000 C24 C38

Heavy Hex Quenched

and Tempered

ASTM A194 - Grade 2H Medium 1/4 - 1-1/2 175,000 150,000*** C24 C38

Heavy Hex Carbon Steel

over 1-1/2 C38

ASTM A194 - Grade 8 AISI 304 1/4 - 1-1/2 80,000 B60 B105

Heavy Hex

SAE J995 Grade Indentification for Nuts

Specification Material Nominal Proof Load Grade Identification

Size Stress Marking

(Inches) (psi) Min. Max. Previous Revised

SAE J995 - Grade 5 Mediun Carbon 1/4 - 1 120,000* C32

Steel, Quenched 109,000**

& Tempered over 1 - 1-1/2 105,000* C32

94,000**

SAE J995 - Grade 8 Medium Carbon 1/4 - 5/8 150,000* C24 C32

Alloy Steel, C26 C34

Quenched over 5/8-1 C26 C36

& Tempered over 1 - 1-1/2

* UNC and 8 UN

** UNF 12 UN and Finer

*** When a zinc coated A194 2Hnut is supplied, the zinc coating, overtapping, lubrication and rotation capacity testing shall be in accordance with ASTM A563 and the proof

stress reduced accordingly. Nuts coated with zinc shall have an asterisk (*) marked after the grade symbol. Nuts coated cadmium shall have a plus sign (+) marked after

the grade symbol.

**** These graded identification markings show the latest revision. Both markings will be acceptable for a transition period.

ASTM Bolt and ASTM A563 Nut Capatibility (ASTM A194 Compatibility

Shown for A325 & A490 Bolts)

ASTM A563 Grade and ANSI Style Nut

Grade Surface Nominal Suitable Substitution (D)

of Bolt (A) Finish (B) Size (In.) Recommended (C) Heavy Hex

ASTM A307 Plain & 1/4 to 1-1/2 Grade A Hex Nut A, C, DH

Grade A Zinc Coated over 1-1/2 to 2 Grade A Heavy Hex Nut C, DH

over 2 to 4 Grade A Heavy Hex Nut C, DH

ASTM A307 Plain & 1/4 to 1-1/2 Grade A Heavy Hex Nut C, DH

Grade B Zinc Coated over 1-1/2 to 2 Grade A Heavy Hex Nut C, DH

over 2 to 4 Grade A Heavy Hex Nut C, DH

ASTM A449 Plain 1/4 to 1-1/2 Grade B Hex Nut C, DH

Types 1 & 2 over 1-1/2 to 3 Grade A Heavy Hex Nut C, DH

Zinc Coated 1/4 to 1-1/2 Grade DH Heavy Hex Nut

over 1-1/2 to 3 Grade DH Heavy Hex Nut

ASTM A325 Plain 1/2 to 1-1/2 Grade C Heavy Hex Nut DH

ASTM A194 2H, Plain

Zinc Coated 1/2 to 1-1/2 Grade DH Heavy Hex Nut

ASTM A354 Plain 1/4 to1-1/2 Grade C Heavy Hex Nut DH

Grade BC over 1-1/2 to 4 Grade C Heavy Hex Nut DH

Zinc Coated 1/4 to 1-1/2 Grade DH Heavy Hex Nut

over 1-1/2 to 4 Grade DH Heavy Hex Nut

ASTM A354 Plain 1/4 to 1-1/2 Grade DH Heavy Hex Nut DH

Grade BD over 1-1/2 to 3 Grade DH Heavy Hex Nut

ASTM A490 Plain 1/2 to 1-1/2 Grade DH Heavy Hex Nut

ASTM A194 2H, Plain

ASTM A193 ASTM A194

Grade B7 Grade 2H Heavy Hex Nut

ASTM A193 ASTM A194

Grade B8 Grade 8

ASTM A193 ASTM A194

Grade B8M Grade 8M

Note: the above chart should not be considered all inclusive for the fasteners listed. The nuts listed are those that are readily available.

(A) Bolt includes all externally threaded types of fasteners.

(B) Zinc coated nuts are nuts intended for use with externally threaded fastners which are hot-dip zinc-coated, mechanically zinc-coated or have a plating or coating of suffi-

cient thickness to require overtapping the nut to provide assembly.

(C) Recommended denotes a commercially available nut having the most suitable mechanical properties and dimensional configuration, or style, that will make it possible

to obtain the desired bolt load.

(D) Suitable denotes nuts having mechanical properties that will make it possible to obtain the desired bolt load, but may require consideration of dimensional configura-

tion, style, suitability and availability.

Visit us on the WEB @ EBNinc.com 411

Evansville, IN 812-477-0077 Henderson, KY 270-830-0077

Jasper, IN 812-482-5105 Owensboro, KY 270-684-0877

Vincennes, IN 812-882-4090 Mt. Vernon, IL 618-244-7156

Fastener Materials Selection Based on the Galvanic Reaction of Metals

Fastener Zinc & Aluminum Steel & Brasses Martensitic Austenitic

Metal Galvanized & Cast Iron Copper Stainless Type Stainless

Steel Aluminum Bronzes & 410 Type

Base Alloys Monel 302/304,

Metal 303, 305

Zinc & 1 2 2 3 3 3

Galvanized Steel

Aluminum 1 1 2 3 Never 2

& Aluminum Recommended

Alloys

Steel & 1,4 1 1 3 3 2

Cast Iron

Teme (lead-tin) 1,4,5 1,5 1,5 3 3 2

Plated

Steel Sheets

Brasses, Copper 1,4,5 1,5 1,5 1 1 2

Bronzes & Monel

Ferritic 1,4,5 1,5 1,5 1 1 1

Stainless Steel

(type 430)

Austenitic 1,4,5 1,5 1,5 1,5 1 1

Stainless Steel

(type 302/304)

Key:

1. The corrosion of the base metal is not increased by the fastener.

2. The corrosion of the base metal is marginally increased by the fastener.

3. The corrosion of the base metal may be considerably increased by the fastener material.

4. The plating on the fastener is rapidly consumed, leaving the bare fastener metal.

5. The corrosion of the fastener is increased by the base metal.

NOTE: Surface treatment and environment can significantly alter activity.

Mechanical Properties of Common Stainless Steel Fasteners

in Accordance with ASTM F593

Stainless Condition Nominal Tensile Core Hardness Minimum Yield Grade

Alloy Group Diameter Strength Rockwell Strength Identification

(Inches) (psi) Min. Max. (psi) Marking

Group 1 CW 1 1/4 - 5/8 100,000 - 150,000 B95 C32 65,000

303, 304, 304L, 305

384, XM1, XM7, 303Se

CW 2 3/4 - 1-1/2 85,000 - 140,000 B80 C32 45,000

Group 2 CW 1 1/4 - 5/8 100,000 - 150,000 B95 C32 65,000

316, and 316L

CW 2 3/4 - 1-1/2 85,000 - 140,000 B80 C32 45,000

CW: Headed and rolled from annealed or solution-annealed stock.

Alloy-Steel and Stainless Steel for use in High Temperature Service

Specification Material Nominal Minimum Tensile Rockwell Minimum Yield Grade

Diameter Strength Hardness Strength Identification

(Inches) (psi) (Maximum) (psi) Marking

ASTM A193 Chromium-Molybdenum Up to 2-1/2 125,000 C35 105,000

Grade B7 (AISI 4140, 4142, Over 2-1/2 - 4 115,000 C33 95,000

4145, 4140H, 4142H, Over 4 - 7 100,000 C29 75,000

4145H)

ASTM A193 AISI 304 1/4 and 75,000 B96 30,000

Grade B8 Larger

Class 1

ASTM A193 AISI 316 1/4 and 75,000 B96 30,000

Grade B8M Larger

Class 1

412 Visit us on the WEB @ EBNinc.com

Вам также может понравиться

- American Fastener - ASTM, SAE, and ISO Grade Markings PDFДокумент6 страницAmerican Fastener - ASTM, SAE, and ISO Grade Markings PDFnate anantathatОценок пока нет

- Astm, Sae and Iso Bolting MaterialДокумент7 страницAstm, Sae and Iso Bolting MaterialSds Mani SОценок пока нет

- ASTM & SAE Grade Markings For Bolts and ScrewsДокумент2 страницыASTM & SAE Grade Markings For Bolts and ScrewsDavid D'AgostinoОценок пока нет

- E Cospace: AE Aterial SpecificationДокумент5 страницE Cospace: AE Aterial SpecificationAsraff Abdul RahmanОценок пока нет

- Mechanical Properties - Bolt, Nut, FastenersДокумент4 страницыMechanical Properties - Bolt, Nut, FastenersmegatornadoОценок пока нет

- 4340Документ2 страницы4340fedaquiОценок пока нет

- Comaparação A572 G50-A992Документ4 страницыComaparação A572 G50-A992Tiago CastelaniОценок пока нет

- ASTM-A563 Fasteners MarkingДокумент1 страницаASTM-A563 Fasteners Markinga04205Оценок пока нет

- WELDING PROCEDURE FOR STEERING BRACKETSДокумент1 страницаWELDING PROCEDURE FOR STEERING BRACKETSViktorОценок пока нет

- 024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFДокумент1 страница024 - Mechanical Properties of Fasteners Made of Carbon Steel and Alloy Steel PDFRonak RanaОценок пока нет

- Ispat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsДокумент4 страницыIspat Industries Limited, Kalmeshwar - Nagpur (India) : Specification For Cold Rolled Steel Sheets & CoilsAbhi Sheoran100% (2)

- GTAW Welding of CP Titanium and Ti6Al4VДокумент1 страницаGTAW Welding of CP Titanium and Ti6Al4VDeepak KumarОценок пока нет

- Aircraft Steel Data SheetДокумент4 страницыAircraft Steel Data Sheetrodryguo74Оценок пока нет

- Kaiser Aluminum 6061 Pipe Tube PDFДокумент2 страницыKaiser Aluminum 6061 Pipe Tube PDFgerrzen64Оценок пока нет

- Fastener PDFДокумент12 страницFastener PDFdiegomilitojОценок пока нет

- Spec alloy steel wire grade SAE 52100Документ6 страницSpec alloy steel wire grade SAE 52100Nour Saad EdweekОценок пока нет

- DIN ISO Equivalent FastenersДокумент12 страницDIN ISO Equivalent FastenersGunnie PandherОценок пока нет

- Guidelines for Specification, Welding and Inspection of Stainless Alloy PipingДокумент19 страницGuidelines for Specification, Welding and Inspection of Stainless Alloy Pipingafr5364Оценок пока нет

- Fasteners (Bolts and Nuts)Документ17 страницFasteners (Bolts and Nuts)Manojkumar Thilagam100% (1)

- INDUSTRIAL STANDARDS COMPARISON GUIDEДокумент20 страницINDUSTRIAL STANDARDS COMPARISON GUIDEAzzah Dyah PramataОценок пока нет

- C43Документ1 страницаC43rudramansingh123Оценок пока нет

- Sample MTC: Material Test CertificateДокумент2 страницыSample MTC: Material Test CertificateSameer KmОценок пока нет

- Ferrous Metals: General Grade Cast IronsДокумент8 страницFerrous Metals: General Grade Cast IronskkamalakannaОценок пока нет

- Hebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEДокумент1 страницаHebei Jufeng Huachun Heat Insulatied Materials Co.,Ltd: Mill Test Certificate EN10204 3.1 CERTIFICATEAnonymous TPoO5u8MeОценок пока нет

- Spec Grade Number Symbol Number Symbol Asme (Astm) KS JISДокумент50 страницSpec Grade Number Symbol Number Symbol Asme (Astm) KS JISVinay TrivediОценок пока нет

- MTC - Astm A36 - Jis400 - Q235Документ2 страницыMTC - Astm A36 - Jis400 - Q235nayeemОценок пока нет

- Steel BookДокумент104 страницыSteel BookMave75Оценок пока нет

- C15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesДокумент2 страницыC15E2C - 1.1132 Non-Alloy Special Steel - Equivalent, Chemical Composition, PropertiesPaulo Henrique NascimentoОценок пока нет

- Aluminum 5083Документ2 страницыAluminum 5083razormebackОценок пока нет

- Vishal Nadcap Process - JulioДокумент33 страницыVishal Nadcap Process - JulioEr. Ramji TripathiОценок пока нет

- Astm A827-14Документ3 страницыAstm A827-14Артем Титов100% (1)

- Hastelloy B2 Alloy B2 UNS N10665 DIN 2.4617Документ3 страницыHastelloy B2 Alloy B2 UNS N10665 DIN 2.4617SamkitОценок пока нет

- Astm A269 PDFДокумент1 страницаAstm A269 PDFRahulОценок пока нет

- Data Sheet HV-HR ItДокумент3 страницыData Sheet HV-HR ItKemo TufoОценок пока нет

- Ssab Emea Ab, Se-613 80 Oxelösund, Sweden: Carbon Equivalent Etc C93-C99Документ1 страницаSsab Emea Ab, Se-613 80 Oxelösund, Sweden: Carbon Equivalent Etc C93-C99fernandojОценок пока нет

- Tungsten ElectrodesДокумент2 страницыTungsten ElectrodesSyed Furqan Rehmani0% (2)

- Ralin Group Brochure 2013Документ3 страницыRalin Group Brochure 2013n1ghtfallОценок пока нет

- Thermal Power Project Weld Inspection ReportДокумент1 страницаThermal Power Project Weld Inspection ReportAshwani DograОценок пока нет

- Welding Rod For c5 & f5 - Er 80s-b6Документ1 страницаWelding Rod For c5 & f5 - Er 80s-b6SatyamEngОценок пока нет

- Complete Immersion Phosphating LineДокумент8 страницComplete Immersion Phosphating LineStay AwayОценок пока нет

- Sau - MTC 0001-002163 - Acc.aºcºДокумент24 страницыSau - MTC 0001-002163 - Acc.aºcºrosa aurora montesano somarribaОценок пока нет

- Nip Material ComparsionДокумент1 страницаNip Material ComparsionRob WillestoneОценок пока нет

- ASTM-A572 Grade 50 Steel Chemical & Mechanical PropertiesДокумент1 страницаASTM-A572 Grade 50 Steel Chemical & Mechanical PropertiesMinhas ArshadОценок пока нет

- MTC Sample Dia 36 Inch Heat 639914 4130Документ2 страницыMTC Sample Dia 36 Inch Heat 639914 4130emadabdelsattarОценок пока нет

- Standard Bolt Identification Markings: No Grade MarkДокумент8 страницStandard Bolt Identification Markings: No Grade MarkDerick MendozaОценок пока нет

- Outokumpu: Si MN P S CR NiДокумент3 страницыOutokumpu: Si MN P S CR NiDarkedgeОценок пока нет

- AISI 1040: General Purpose Mild Steel for Forging, Machining & Heat TreatingДокумент2 страницыAISI 1040: General Purpose Mild Steel for Forging, Machining & Heat Treatingho_chauhanОценок пока нет

- Aisi 1018Документ1 страницаAisi 10188085roОценок пока нет

- Geomet 500 PDFДокумент2 страницыGeomet 500 PDFKaran Chadha100% (1)

- Impact AR500 PlateДокумент2 страницыImpact AR500 PlateMario Diez100% (1)

- AWS specifications for selecting electrodes for welding various material gradesДокумент1 страницаAWS specifications for selecting electrodes for welding various material gradesmohammedetaОценок пока нет

- Mig WireДокумент10 страницMig WireSathishkumar SrinivasanОценок пока нет

- Properties and Grades of FastenersДокумент4 страницыProperties and Grades of Fastenerschez ezОценок пока нет

- American FastenersДокумент6 страницAmerican Fastenersashraf elsayedОценок пока нет

- Pernos ASTMДокумент6 страницPernos ASTMpatricio wachtendorffОценок пока нет

- Grades of Bolts - Bolt Grade Marking Chart _ AFT FastenersДокумент3 страницыGrades of Bolts - Bolt Grade Marking Chart _ AFT FastenersheartofdixieОценок пока нет

- American Fastener - ASTM, S..Документ6 страницAmerican Fastener - ASTM, S..Lee GPОценок пока нет

- Propiedades Mecanicas - FastenerДокумент4 страницыPropiedades Mecanicas - FastenerEHT pipe100% (1)

- FastenersДокумент6 страницFastenersbaburaogtrwОценок пока нет

- Hex Bolt Head MarkingsДокумент5 страницHex Bolt Head MarkingscarangoretrepoОценок пока нет

- PTFE Seals Parker 5340 - 2008Документ170 страницPTFE Seals Parker 5340 - 2008john kasich100% (1)

- MGPG 1 - Measurement of Uniaxial Bending in Low Cycle Fatigue TestingДокумент50 страницMGPG 1 - Measurement of Uniaxial Bending in Low Cycle Fatigue Testingchez ezОценок пока нет

- SealДокумент80 страницSealsandeshpetareОценок пока нет

- MGPG 2 - Measurement and Analysis of Creep in PlasticsДокумент36 страницMGPG 2 - Measurement and Analysis of Creep in Plasticschez ezОценок пока нет

- Trelleborg Seal GuideДокумент308 страницTrelleborg Seal Guidechez ezОценок пока нет

- Parker Fluid Power Seal Design Guide 5370Документ300 страницParker Fluid Power Seal Design Guide 5370edwardsheridan0% (1)

- Dos and Donts For Seal Engineering (Esp ROD SEALS)Документ6 страницDos and Donts For Seal Engineering (Esp ROD SEALS)chez ezОценок пока нет

- Rotary Seal Design GuideДокумент434 страницыRotary Seal Design GuideBhargav Suvagiya100% (3)

- Hate Crime and Hate Speech in Europe (EU Biased)Документ312 страницHate Crime and Hate Speech in Europe (EU Biased)chez ezОценок пока нет

- NASA - Durability and Damage Methodology PDFДокумент20 страницNASA - Durability and Damage Methodology PDFchez ezОценок пока нет

- Mechanical Assemblies Their Design Manufacture and Role in Product Development PDFДокумент573 страницыMechanical Assemblies Their Design Manufacture and Role in Product Development PDFIsmael Naranjo Veléz100% (1)

- Gear Materials, Properties, and ManufactureДокумент347 страницGear Materials, Properties, and ManufactureFrançois Steinmetz91% (11)

- Apollo 17 - Mission Operations ReportДокумент349 страницApollo 17 - Mission Operations Reportchez ezОценок пока нет

- Leadership of The North Korean Kim DynastyДокумент356 страницLeadership of The North Korean Kim Dynastychez ezОценок пока нет

- Apollo 15 - Mission ReportДокумент286 страницApollo 15 - Mission Reportchez ezОценок пока нет

- Why Do Europeans Ban Hate SpeechДокумент41 страницаWhy Do Europeans Ban Hate Speechchez ezОценок пока нет

- Thermo-Fisher Evaluating-The-Chemistry of Brake Pads White-PaperДокумент9 страницThermo-Fisher Evaluating-The-Chemistry of Brake Pads White-Paperchez ezОценок пока нет

- Apollo 11 - Mission Report (PAO - Updated Summary) PDFДокумент10 страницApollo 11 - Mission Report (PAO - Updated Summary) PDFchez ezОценок пока нет

- Development of Components and Tribo Systems For Diesel PDFДокумент290 страницDevelopment of Components and Tribo Systems For Diesel PDFchez ezОценок пока нет

- (1994) GDNT Self Eval Test - Level 1Документ5 страниц(1994) GDNT Self Eval Test - Level 1chez ezОценок пока нет

- (1994) GDNT Self Eval Test - Level 10Документ6 страниц(1994) GDNT Self Eval Test - Level 10chez ezОценок пока нет

- Bolt Torque Tests in A VacuumДокумент16 страницBolt Torque Tests in A Vacuumchez ezОценок пока нет

- Experimental Analysis of Low Prof Flange Connections PDFДокумент87 страницExperimental Analysis of Low Prof Flange Connections PDFchez ezОценок пока нет

- Torque Vs Tension For A286 BoltsДокумент59 страницTorque Vs Tension For A286 Boltschez ez100% (1)

- Apollo 17 - Mission Operations ReportДокумент349 страницApollo 17 - Mission Operations Reportchez ezОценок пока нет

- Exp Analysis of Thread Movement Due To VibrationsДокумент176 страницExp Analysis of Thread Movement Due To Vibrationschez ezОценок пока нет

- Apollo 15 - Mission ReportДокумент286 страницApollo 15 - Mission Reportchez ezОценок пока нет

- Apollo 17 - Mission Operations ReportДокумент349 страницApollo 17 - Mission Operations Reportchez ezОценок пока нет

- Apollo 16 - Mission Operations ReportДокумент393 страницыApollo 16 - Mission Operations Reportchez ezОценок пока нет

- Processing and Fish PreservationДокумент13 страницProcessing and Fish PreservationAbdiqadir JibrilОценок пока нет

- Performance Task 2 Melting and Boiling PointsДокумент1 страницаPerformance Task 2 Melting and Boiling PointsVannie MonderoОценок пока нет

- 3404 10153 1 PBДокумент6 страниц3404 10153 1 PBSergio Fabian NavarroОценок пока нет

- Lab Rules Q and AДокумент18 страницLab Rules Q and Ana-chanОценок пока нет

- Synthesis, Properties, and Applications of Magnetic Iron Oxide NanoparticlesДокумент24 страницыSynthesis, Properties, and Applications of Magnetic Iron Oxide NanoparticlessimoОценок пока нет

- Compilation Part 2 (11-19)Документ100 страницCompilation Part 2 (11-19)Joshua Zuniga50% (2)

- Vertical forces-WPS OfficeДокумент2 страницыVertical forces-WPS OfficeJesusa EstradaОценок пока нет

- Strain Gauges DatasheetДокумент100 страницStrain Gauges DatasheetSantiago UrgilesОценок пока нет

- CARB in Industrial FansДокумент8 страницCARB in Industrial FansJurun_Bidanshi100% (1)

- 09 Safe Handling of ChemicalsДокумент23 страницы09 Safe Handling of ChemicalsOladimeji Taiwo100% (1)

- ACI 207.1R-05 Guide To Mass ConcreteДокумент31 страницаACI 207.1R-05 Guide To Mass ConcreteLukusa Badimuena100% (3)

- Steerable AntennaДокумент44 страницыSteerable AntennaKenNediaОценок пока нет

- Maximum Equivalent Stress Safety ToolДокумент2 страницыMaximum Equivalent Stress Safety ToolDonfack BertrandОценок пока нет

- Alternative-Refrigerants R22 GBДокумент12 страницAlternative-Refrigerants R22 GBMon PerezОценок пока нет

- BC7068 E-TdsДокумент3 страницыBC7068 E-TdsHoài NguyễnОценок пока нет

- Integrate Planck's Function Using Gamma FunctionДокумент14 страницIntegrate Planck's Function Using Gamma FunctionMaxtron Evelyn MoonОценок пока нет

- Ammonia: Latent Heat of OFДокумент34 страницыAmmonia: Latent Heat of OFCastoriadisОценок пока нет

- Dowtherm Vent CondenserДокумент1 страницаDowtherm Vent Condensersushant_jhawerОценок пока нет

- Operation and Maintenance ManualДокумент39 страницOperation and Maintenance Manualhdf17Оценок пока нет

- Analisis Karbohidrat MetodeДокумент28 страницAnalisis Karbohidrat MetodearikuraОценок пока нет

- Infill-Wall CalculationДокумент10 страницInfill-Wall CalculationPrakash Singh RawalОценок пока нет

- Week - q1 State of MatterДокумент21 страницаWeek - q1 State of Matterjustine alinaОценок пока нет

- Chemistry Form 4 Lesson 12Документ8 страницChemistry Form 4 Lesson 12Sakinah SaadОценок пока нет

- Temperature Recovery FactorsДокумент64 страницыTemperature Recovery FactorsGokul NathОценок пока нет

- NEET-2021 (Paper Analysis) FinalДокумент32 страницыNEET-2021 (Paper Analysis) FinalMahasina BegumОценок пока нет

- AMIE Project Synopsis ReportДокумент10 страницAMIE Project Synopsis ReportpavanОценок пока нет

- Phase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsДокумент8 страницPhase Inversion of W/O Emulsions by Adding Hydrophilic Surfactant - A Technique For Making Cosmetics ProductsAsshole FuckerОценок пока нет

- TSR81 Standard Single Screw Extruder Start Up-Shutdown and Emergency Shutdown ProceduresДокумент4 страницыTSR81 Standard Single Screw Extruder Start Up-Shutdown and Emergency Shutdown ProceduresahumairОценок пока нет

- HVAC Validation TestsДокумент4 страницыHVAC Validation TestsemonwreОценок пока нет

- Shear Friction MattockДокумент10 страницShear Friction MattockSisina Anish100% (1)