Академический Документы

Профессиональный Документы

Культура Документы

0001

Загружено:

phuyang0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров2 страницы30062015135333-0001

Оригинальное название

30062015135333-0001

Авторское право

© © All Rights Reserved

Доступные форматы

PDF или читайте онлайн в Scribd

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документ30062015135333-0001

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

0 оценок0% нашли этот документ полезным (0 голосов)

8 просмотров2 страницы0001

Загружено:

phuyang30062015135333-0001

Авторское право:

© All Rights Reserved

Доступные форматы

Скачайте в формате PDF или читайте онлайн в Scribd

Вы находитесь на странице: 1из 2

DYNA-MAC ENGINEERING SERVICES PTE LTD

45 Gul Road

‘Singapore 629350

WELDING PROCEDURE SPECIFICATION (WPS)

For 22% Cr Duplex Piping

shoot tof?

(Applicable Code ; ASME IX - 2010 Prepared by JIN YONGPEL

QD-SO-MT-SPE-0009 (SPM61006A1) Approved by "ANBARASAN

Project: Quad 204 Turret Fabrication Peer

WPS No. DM - WPS -435 Rev.__8

PQR No. DM - POR - 435, 366 (2G)

DM- POR 436,367 (66)

DM=POR- 448, 455

Welding Process(es) GTAW 7 GTAW (Tip Tig) Types MANUAL (root/hot pass)

felding Position All ‘SEMLAUTO (Tip Tig -hot wire)

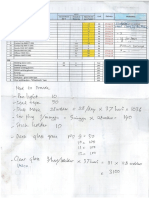

Jomt Besign

JOINTS (QW-402) eae

Loin No: Nia

Line Deion Reker io SR |

backing Mater NIA eos iL

rove Angle Teese Tt] oszomy 15m Ma

cot Sap 35> 80mm tea

Root Face mm

Bilbo Tacking with bale eee Filet

tthod of fit-up same as parent metal a

ge Peperalon ———_ Waciing / Ginn —— 05-1 5mm

loners ne "|

SS _

Branch Connection

JBASE METAL (QW-403)

PN: fo Ge ‘e PN 108 Gr

ceifcaton Type & Grade ns ssieos © uns $1803

lonem Anais TMivogené 0.13018

Base Metal Thickness RengetSut) Sinn to46.5m

pe Diameter Range ‘Al Diameter

[ret and branch connecton Rango(in87h) Unlimited

FILLER METALS (aW:06)

craw rAW Tit

FN 3 3

fano. $ s

FA. No, a 35

posted Metal But) Tamm We amie

Diemer Zann] San omm

Cleseteaton ANS EREOT EN 2TH) ANS ERIS ENDED

Brand Name of SANOVIR DEAL SANDVIRW22.83L

|For tcroda

POSITION (aW-408)

Postion of Groove a

Jelding Progression x uP

eston of tet Au

DYNA-MAC ENGINEERING SERVICES PTE LTD

45 Gul Road

Singapore 629350

[ WELDING PROCEDURE SPECIFICATION (WPS)

7 WPS No: DMawPs.435 REV No.B Sheet 2 0f2

[PREHEAT (Qw-406) ves LJ No POST HEAT Yes[_] Ne be]

Preheat Temp(htin) Remove Moisturtt required)

inerpass Temp(Miex.) 12

IMethod

thers

[POST WELD HEAT TREATMENT (QW-407) YES wo [x

{cas (QW-408) ‘All gases shall comply to AWS 5.32 requirements

ioding sod Purging Gas: “ARGON + NITROGEN ‘Shield Gas Flow Rae (GTAW) 12.20 L/min 26-43 SCFH)

Shielding Ges Composition

[Backing Gas Composition

98% Argon 2% Nitrogen Shield Gas Flow Rate (GTAW-Tip Tig)

‘984 Argon 2% Nivogen Backing Gas Flow Rate

12-20 L/min (26-43 SCFH)

18-30 L/min (38-64 SCFH)

(Co: foene eetp a) + Sie “32m Tye 2 Tard curse “C6000

come peal

ire Fed Spee ip Fats Siete

TECHNIQUE (QW-410), |Note: |

Weld Bead Type ‘Sting Tx] Weave Dx] [4. Bridge Tacking within the bevel area evenly:

feisltisexCiacng : Book SY eufagh] | deomurstomrnne coer ctnostne

corte hep stte j= renee Gey ecusesees as emarsaa orue

fe copra area cei eereme |

Weld Layer} 5, Dia | Type | Ampee | Wire | VoitRange | "Grmimim | Fe! | aie

fa (Class (mm) } Polarity Range | Ampere} o) € ) | acto) Coimm)

ee aag ERS

fe — eames fae ee test we pope if eo

Sere oramen clint apmttonottraya(ancorcue| 40009

sc Crericrcan caeecner hon mame cael ce era acnes sna ear seo

Se tee stn cae eaecien oon ureaeanaimsiee

SE erent siccatueee tense eee ocaan ome

ee re aeicatorcoa cess eee

cn rato a ae aaiareae ae irene

‘Approved by re) ‘Approved by

iJ

OFFSHORE or

sg

% Atohe

exe

ownage /

ee abet “wet 3 /o/2

DYNA-MAC I DNV

loxygen Content “Quygen content not to exceed 0.05% during purging, (Prefer to maintain less than T0Oppm)

Purging should be started at least Smin eallor prior to welding.

[ELECTRICAL CHARACTERISTIC (QW-409) |

[Tungsten Electrode (CTAW) = Size 24mm _ Type _2% Thoriatod Cup Size: 05.06

Вам также может понравиться

- ESAB - SAW Wires - Fluxes MIG-MAG-TIG Wires-Cored Wires PDFДокумент71 страницаESAB - SAW Wires - Fluxes MIG-MAG-TIG Wires-Cored Wires PDFphuyangОценок пока нет

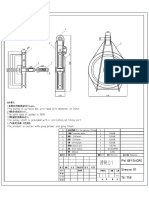

- Rectangular WasherДокумент1 страницаRectangular WasherphuyangОценок пока нет

- S36BW 418100513450Документ1 страницаS36BW 418100513450phuyangОценок пока нет

- S36BW 418072809231Документ1 страницаS36BW 418072809231phuyangОценок пока нет

- Tanda Tanda PenyakitДокумент6 страницTanda Tanda PenyakitYUDHA AGUNG PratamaОценок пока нет

- Snatch Block For 76mm SWL120tДокумент1 страницаSnatch Block For 76mm SWL120tphuyangОценок пока нет

- S36BW 418042714330Документ1 страницаS36BW 418042714330phuyangОценок пока нет

- Welder Qualification PlanДокумент3 страницыWelder Qualification PlanphuyangОценок пока нет

- KL Jack Fasteners-Technical Data and ChartsДокумент32 страницыKL Jack Fasteners-Technical Data and ChartsphuyangОценок пока нет

- 02 Potential Indonesian Overseas Workers PDFДокумент24 страницы02 Potential Indonesian Overseas Workers PDFphuyangОценок пока нет

- BusbarДокумент1 страницаBusbarphuyangОценок пока нет

- Basis DesignДокумент121 страницаBasis DesignphuyangОценок пока нет

- 84508-9700-9B-010 - Basis of Design PDFДокумент121 страница84508-9700-9B-010 - Basis of Design PDFphuyangОценок пока нет

- Standard MetricWrenchChart PDFДокумент1 страницаStandard MetricWrenchChart PDFphuyangОценок пока нет

- Jalan Puri IndahДокумент1 страницаJalan Puri IndahphuyangОценок пока нет

- Iso Trnsmital DWGДокумент250 страницIso Trnsmital DWGphuyangОценок пока нет

- Free Printable 2018 Muslim Planner PDFДокумент125 страницFree Printable 2018 Muslim Planner PDFPujja Sari Purnama100% (1)

- Salary Guide 2018 - FinalДокумент48 страницSalary Guide 2018 - FinalAria ImamОценок пока нет

- C02651 3 - SR 700L (E)Документ8 страницC02651 3 - SR 700L (E)albertcitra1Оценок пока нет

- Machinist Course - Milling Machine OperationsДокумент81 страницаMachinist Course - Milling Machine Operationsmerlinson192% (12)

- Psikotes 2Документ25 страницPsikotes 2phuyangОценок пока нет

- Tugas Budaya NovalДокумент2 страницыTugas Budaya NovalphuyangОценок пока нет

- TABEL Material European Standard - JISДокумент81 страницаTABEL Material European Standard - JISphuyangОценок пока нет

- Kebutuhan Material Besi Untuk Survey Side Scan Sonar Dan Multibeam - MeindoДокумент4 страницыKebutuhan Material Besi Untuk Survey Side Scan Sonar Dan Multibeam - MeindophuyangОценок пока нет

- Abrasive Blasting Operation (Engineering Control and Work Practices Manual)Документ78 страницAbrasive Blasting Operation (Engineering Control and Work Practices Manual)kanakarao1100% (1)

- 542-Shredder or Grinder Maintenance Checks - SOP-finalДокумент11 страниц542-Shredder or Grinder Maintenance Checks - SOP-finalphuyangОценок пока нет

- ErectionstrategyritДокумент21 страницаErectionstrategyritphuyangОценок пока нет

- 2 - 3dmax PhotoCs Corel MsProjectДокумент16 страниц2 - 3dmax PhotoCs Corel MsProjectalifananiОценок пока нет

- The Yellow House: A Memoir (2019 National Book Award Winner)От EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Рейтинг: 4 из 5 звезд4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceОт EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceРейтинг: 4 из 5 звезд4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeОт EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeРейтинг: 4 из 5 звезд4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingОт EverandThe Little Book of Hygge: Danish Secrets to Happy LivingРейтинг: 3.5 из 5 звезд3.5/5 (400)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaОт EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaРейтинг: 4.5 из 5 звезд4.5/5 (266)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureОт EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureРейтинг: 4.5 из 5 звезд4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItОт EverandNever Split the Difference: Negotiating As If Your Life Depended On ItРейтинг: 4.5 из 5 звезд4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryОт EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryРейтинг: 3.5 из 5 звезд3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerОт EverandThe Emperor of All Maladies: A Biography of CancerРейтинг: 4.5 из 5 звезд4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyОт EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyРейтинг: 3.5 из 5 звезд3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersОт EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersРейтинг: 4.5 из 5 звезд4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnОт EverandTeam of Rivals: The Political Genius of Abraham LincolnРейтинг: 4.5 из 5 звезд4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaОт EverandThe Unwinding: An Inner History of the New AmericaРейтинг: 4 из 5 звезд4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreОт EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreРейтинг: 4 из 5 звезд4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)От EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Рейтинг: 4.5 из 5 звезд4.5/5 (121)