Академический Документы

Профессиональный Документы

Культура Документы

3d Measurement and Ffs Assessment For Lta in Pressure Equipment According To Wes2820-2015 PVP2016-63912

Загружено:

Hyune Boom SheenОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

3d Measurement and Ffs Assessment For Lta in Pressure Equipment According To Wes2820-2015 PVP2016-63912

Загружено:

Hyune Boom SheenАвторское право:

Доступные форматы

Proceedings of the ASME 2016 Pressure Vessels & Piping Conference

July 17-21, 2016, Hyatt Regency Vancouver - Vancouver, BC, Canada

PVP2016-63912

3D MEASUREMENT AND FFS ASSESSMENT FOR LTA IN PRESSURE EQUIPMENT

ACCORDING TO WES2820:2015

Takayasu TAHARA Yoshiharu SHIMURA Minoru NIIMURA

Seikowave K.K. IHI Marine Co., Ltd. Seikowave K.K.

Saitama, Japan Tokyo, Japan Tokyo, Japan

ABSTRACT (herein after API/ASME FFS-1) which was published on

The corrosion of pressure equipment such as corrosion under participation with the committee members including one from

insulation, CUI, is the most common problem in refinery and PAJ/JPCA FFS Assessment Committee [4].

petrochemical plants in recent years. From 2012, activities related to FFS assessment technology in

Fitness-For-Service, FFS, assessment technologies for PAJ/JPCA FFS Committee have been transferred into two

pressure equipment have been studied in recent 15 years, and groups;

standardization of a FFS assessment procedure for local thin HPI/Task Group on Metal Loss Assessment based on

area, LTA, has been expected by maintenance engineers of Reliability, HPI TG-MLR

process industries. JWES Task Group on FFS Assessment Procedure for

Based on the verification using extensive burst tests and FEM Pressure Equipment

analysis of LTA, the Japan Welding Engineering Society, JWES, HPI: High Pressure Institute of Japan

developed new FFS standard WES2820 in June 2015.[1] JWES: Japan Welding Engineering Society

This paper presents high lights of WES2820 and a FFS In the past 15 years, series of maintenance standards for

assessment system consisted with 3D optical measurement pressure equipment have been developed in Japan as shown in

method and FFS software for LTA in pressure equipment as a Fig.1. And above new activities are expected to enhance future

new tool for effective inspection and reliable maintenance maintenance system of pressure equipment.

activities. HPI/TG-MLR is now developing HPI/HPIS-TR Metal loss

assessment for pressure equipment based on reliability which

INTRODUCTION was presented in PVP2015-45382, PVP2015-45658 and

There are many process plants such as refineries, PVP2015-45842.[4].[5],[6]

petrochemical production operating more than 40 years in the JWES/WES Task Group on FFS Assessment Procedure issued

world. Pressure equipment such as pressure vessels, piping, the FFS assessment procedure for pressure equipment - Metal

storage tanks have common problems of corrosion metal loss, loss assessment, WES2820, herein after the Standard, on June,

so called LTA and how to assess the integrity of them for 2015 after two years standardizing activities based on FFS

continues safe operation. In order to assess the integrity of assessment standards of LTA developed by PAJ/JPCA FFS

pressure equipment with LTA, it requires to use a proven FFS Assessment Committee.

assessment procedure and reliable flaw sizing method.

1. Concept of WES 2820:2015 [12]

BACKGROUND As of today, It is not allowed to continue operation of pressure

From 2000, Petroleum Association of Japan (PAJ) and Japan equipment with LTA when remaining thickness is less than the

Petrochemical Industry Association (,JPCA) jointly established calculated minimum required thickness according to existing

the PAJ/JPCA FFS Assessment Committee and commenced to regulation such as the High Pressure Gas Safety Act due to FFS

propagate Fitness-For-Service assessment technology into assessment procedure for LTA have not been authorized in

Japanese industries. Through recent 13 years activities, they Japan.

developed FFS Assessment Handbook and FFS assessment The concept of remaining strength factor, RSF which is adopted

standards for fire damage, LTA and high temperature creep in API/ASME FFS-1 is introduced to the Standard as simple

using Omega method based on API579-1/ASME FFS-1, 2007 assessment method for metal loss thinner than minimum

1 Copyright 2016 by ASME

Chiyoda Advanced Solutions

required thickness. FFS assessment procedures as specified in

Part 4 (general metal loss) and Part 5 (local metal loss) in JPA Maintenance Standards JPI-8R-1117

API/ASME FFS-1 are referred as basic concepts of the HPI Z106,107 Risk Based Maintenance Standards

Standard with several features including improvements or

modifications as summarized below considering the specific Inspection/Testing

requirements in the regulation in Japan and users friendliness.

LTA assessment method using RSF concept verified in

WRC Bulletin 505 [14]and adopted in API/ASME FFS-1

Maintenance/Safe Operation

will be acceptable to use FFS assessment for pressure

equipment according to Japanese construction codes Repair/Replacement FFS Assessment

which were also standardized referring ASME B&PV

Codes 1. KHK/PAJ/JPCA S0851(2009) FFS Assessment Standard

WES7700-1,2,3,4

The standard is consisted with main body with detailed 2. PAJ/JPCA FFS Assessment Standards for Pressure

Repair Welding of

assessment flow charts, equations and figures, appendix Pressure Equipment Equipment

for calculating method of shell section for supplemental 3. HPI Z-101-1,-2 Assessment Procedure for Cracklike

loads, and interpretations which includes validation with Flaws in Pressure Equipment

burst tests and example problem in one document. So it is 4. WES2820 FFS Assessment Procedure for

easy to understand how to assess the LTA and also study Pressure EquipmentMetal Loss Assessment 3

background and/or discussion of each requirement. Fig.1 Present status of maintenance standards in Japan (as of

The assessment procedures in the Standard is equivalent to January, 2016) [1],[4],[7],[8],]9],[10],[11]

Level 2 methods for general and local metal loss of

API/ASME FFS-1 which is the most convenient and 2. Specific Requirements in WES2820

practical as FFS assessment to use both manual calculation 2.1 Contents

and computer software from thickness reading using UT The contents of the Standard are as follows.

and also 3D measurement methods. 1. Scope

The recommended methods of thickness measurement are 2. Applicable Codes and Standards

point reading, thickness profile and groove profile. It is 3. Terms and definitions

emphasized to include the lowest point of LTA at the first. 4. Symbol and meaning

Assessment of circumferential direction is based on stress 5. Required information and data for LTA assessment

evaluation at LTA region considering overturning moment 6. Assessment procedure

of pressure equipment due to seismic force. In the case 7. Applicable type of components

when supplemental load is negligible, the Standard 8. Thickness reading

provides higher accuracy of assessment calculating 9. Characterization of LTA

circumferential stress for internal pressure than 10. Calculation of maximum allowable pressure and RSF

API/ASME FFS-1 Part5. 11. Stress calculation of cylindrical shell with LTA subjected

Remediation includes not only methods of rerating, supplemental loads

evaluation of FCA, repair, replacement but also detailed 12. Acceptance criteria

assessment by FEM analysis as Level 3 assessment. 13. Remediation

WES7700-1~4 Repair welding of pressure equipment in Appendix A (Mandatory) Calculation method of cylindrical

2012 developed by the Chemical Plant Welding Research section with LTA subjected supplemental loads

Committee in JWES requires that feasibility of repair Interpretation including validation with burst tests and example

welding should be studied based on FFS assessment of problem

flaws in pressure equipment. An improvement of As of today, WES2820 written in Japanese is published.

reliability in repair welding of pressure equipment is

expected when FFS assessment procedure is clearly 2.2 Assessment procedure

specified in the Standard. LTA in pressure equipment is assessed according to flow as

shown in Fig.2.

2 Copyright 2016 by ASME

as shown in Fig.4.

Classification of component type

Firstly, judgment of longitudinal section is performed to

General Metal determine PMAW from result of RSF. Then circumferential

LTA data Characterization for general metal loss Loss Assessment section is evaluated based on calculated Mesess stress

acceptable

compared with allowable tensile stress a. (Refer to equations in

Judgment 2.6.2 b) .)

c

unacceptable

tmm

Local Metal

LTA data Characterization for local metal loss Loss Assessment

Applicable to

Type A component

acceptable

Judgment s

unacceptable tl

Continous operation a)longitudinal section b)circumferential section

up to next inspection Remediation

Fig. 4 Characterization of local metal loss

Fig.2 Assessment flow of LTA 2.3 Thickness reading

Three methods of thickness reading may be used upon features

The component in which flaws is found is classified in Type A of flaws and damages, type of components and assessment

or B (refer to Table 1) and then LTA assessment according to procedure as shown in Table 2.

the flow which shows that local metal loss assessment is

performed after general metal loss assessment. However, it is Table 2 Methods of thickness reading

applicable to perform local metal loss assessment only. Type of Applicable assessment procedure Thickness reading

flaw

Table1 Classification of pressure component type

Pressure Component Type Uniform Assessment for general metal loss

A metal loss of Type A component

Point thickness

a) Pressure vessel cylindrical and conical shell sections

A

b) Spherical pressure vessels and spherical tanks -Assessment for general metal loss

Locally

A of Type A component

c) Hemispherical, ellipsoidal and dished heads corroded

-Assessment for local metal loss

A

damages

of Type A component

Thickness profile

d) Straight section of piping system or metal

-Assessment for local metal loss

A loss

e) Pipe bends and elbow do not have structural attachments of Type B component

A

f) Cylindrical shell for atmospheric tank Groove Assessment for general metal loss

like flaw of Type A component

Groove profile

B

g) Nozzle connections

B

h) Transition between conical shell and cylindrical shell

B

2.3.1 Point thickness reading

i) Flange joint Point thickness reading is used for metal loss widely extended

(Type A and B are defined as same as API579-1/ASME FFS-1) in the surface. Proper numbers of point are selected to cover

a) Assessment of general metal loss extent and degree of flaw or damages.

The LTA is characterized as uniform general metal loss and a) In the case when COV of measured data is greater than

calculated minimum required thickness tmin or maximum 10%, it is judged that point reading method is not suitable

allowable pressure PMAW for judgment of continuous operation for assessment of general metal loss due to large surface

up to next inspection as shown in Fig.3.. irregularity, and then thickness profile method should be

selected.

b) The distance from gross structural discontinuity to the flaw

flaw Characterization

shall be measured, and if it is less than 1.8 Dt c ,assessment

for local metal is not applicable.

t t c) Assessment for local metal loss is not applicable when the

tam results of thickness profile and groove profile fall into

Fig.3 Characterization of general metal loss following cases

b) Assessment of local metal loss 1) Shell parameter c of circumferential direction is larger

The LTA is characterized as local rectangular LTA and then than 9

judged capability of continuous operation up to next inspection 2) Bottom radius of groove like flaws is less than groove

3 Copyright 2016 by ASME

depth Longitudinal length of flaw s

s

2.3.2 Thickness profile Length of thickness averaging, L

L

The thickness profile method is used for locally corroded flaws

or damages as shown in Fig.5. The measurement grid may be

set with space ( ls min 0.36 Dt min , 2t ) t

t m1

s

t m2

s

t mm

t m1

s

t m2

s

t mm

measured thickness t am

s

flaw

flaw

Longitudinal average

flaw

3

Fig.7 Characterization of general metal loss by thickness

C1 M1

C1

C2 C2 M2 profiling

C3 C3 M3 2.4.1 Characterization of local metal loss

C1

C2

The longitudinal thickness and length of local metal loss are

C3

M1 M2 M3 M1 M2 M3 determined in all subsections as shown in Fig.8

Optional

22 points si si+1 Optional 2 points

2

i) shell

1)Cylindrical ii)

2)Conical shell iii)

3)Spherical shell

Fig. 5 Thickness profile reading

tc

2.3.3 Critical thickness profile, CTP Ai Ai+1

C1 C2 C3 C4 C5 C6 C7

C1 M1

C2 C3 C4 C5 C6 C7 si

M1

M2

M2 M3 Circum. CTP

CTP

M3

M4

M4 tc

M5 tli

M5

sitli=Aitli

Pass of max. metal loss

si + 1

tc tli + 1

CTP

Longi. CTP si+1tli+1=Ai+1tli+1

Fig. 6 Critical thickness profile

Fig.8 Subdivision process for determining the RSF

The CTP of longitudinal direction is developed from the profile

(Effective area method)

connected lowest points of each circumferential section of grid

as shown in Fig.6. The CTP of circumferential direction also

2.5 Calculation of RSF

developed as same method as above.

RSF is defined as follows

RSF= LDC/LUC

2.4Characterization for general metal loss

LDC : limit or plastic collapse load of the damaged

a) Characterization of general metal loss from point reading

component with flaws

Mean measured thickness is calculated from thickness reading

LUC : limit or collapse load of the undamaged component

of each point and then characterized as uniform metal loss.

RSF is utilized to define the acceptability of a component for

continued service and means the degree of remaining strength

b) Characterization of general metal loss from thickness

of the component due to flaws in case of judgment for

profile

assessment of local metal loss.

Compute the length of thickness averaging, L from

Allowable remaining strength factor, RSFa = 0.9, is provided as

longitudinal CTP and determine the average measured

same as Table 2.3 of API 579-1/ASME FFS-1 Part 4

thickness tam as shown in Fig.7.

considering basis of Japanese pressure vessel code equivalent to

L Q Dt c which is same as defined in API 579-1/ASME ASME BPV Codes.

FFS-1 Part 4 RSF is determined from profile of metal loss with following

It is possible to apply simple and conservative assessment of the formula

flaw characterized as uniform metal loss.

Rt

RSF

1

1

Mt

1 Rt

4 Copyright 2016 by ASME

RSF: remaining strength factor,RSF, of the component Fs My

Rt: remaining thickness ratio p

F MT MT F

Mt: Folias factor based on the longitudinal extent of LTA Mx

Mx

2.6 Acceptance criteria

The acceptance criteria of component with flows for My Fs

continuous operation to next inspection are defined as follows

My

2.6.1 General metal loss tmm-tFCA

A

Characterized LTA

a) For Type A component tc

B c

(B)

The smaller of Equations below

tam tFCA 0.9tmin

Df

F Mx

D

MT

Do

tmm tFCA 0.5tmin

Fig.9 Circumferential section subjected

t F C A : future corrosion allowance supplemental load

t min : minimum required thickness 2.7 Remediation

tam : average measured thickness of LTA When result of LTA assessment is not acceptable, continuous

use of the pressure equipment is not feasible, suitable

b)For Type B component remediation methods must be considered as listed below.

p pMAW a) Evaluation of future corrosion allowance, FCA determined

from future operation plan, timing of next inspection or

p : pressure for evaluation applicable corrosion protection system

pM A W:maximum allowable working pressure calculated b) Weld repair of LTA such as weld overlay refer to

WES7700-1~4

from tam - t FCA c) Renewal or replacement of the component

2.6.2 Local metal loss d) Rerating of operating pressure and/or temperature

a) Maximum allowable working pressure e) Evaluation of structural integrity of the component by

(for longitudinal section) detailed mechanical assessment such as FEM

R

p min SF pMAW , pMAW 3 3D Optical Measurement and FFS Assessment of

0.9 LTA

b)Allowable stress (for circumferential section) As reported in PVP2015-45658 for round robin test of

max eA , eB H f a

thickness reading of LTA in the pipe by ultrasonic testing,

contact points of UT transducer may be varied and make large

0.9 scattering of measured values, especially in case of corrosion at

pMAW : maximum allowable working pressure calculated from outer surface of pipe, variation of thickness reading may occur

t - tFCA due to surface irregularity in LTA/CUI (corrosion under

insulation) as shown in Fig.10.

a :allowable tensile stress of the material

H f =1.0 for stress raised by supplemental load is negligible

=3.0for stress raised by supplemental load is the sum of

primary and secondary stress

e eB : Mises stress subjected supplemental loads at Pint A

A

and B (refer to Fig.9.)

t measured thickness of uncorroded portion

Fig. 10 example of mean values vs. standard deviation of

thickness reading of the pipe with CUI by UT [5]

The various tools measuring corrosion have been studied and

developed longtime in US pipeline industries.

In recent years, 3D optical measurement system such as laser

light-section method, photogrammetry method and 3D

5 Copyright 2016 by ASME

structured light method have been utilized considering

effective measurement and quick decision making based on

FFS assessment.

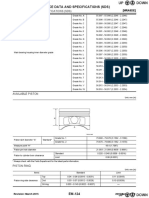

3D structured light method using LED is recommendable with Table 4 Specification of pipe with LTA

advantages as listed Table 3. O.D. Thk Service

Design Design Allowable

Pipe Temp. Pressure stress

(mm) (mm) (Year) 2

with (Deg-C) (MPa) (N/mm )

LTA

Table 3 Advantages of 3D structured light method 165 7.2 37 85 4.2 92

Item Advantages of 3D structured light method

Setting Very easy to set. Objects just need to be in

the range of the specified working distance.

Time to capture 0.3 sec *

Time to point cloud 3 seconds *

Resolution XY resolution with 300K

camera : 0.2mm~0.4mm.

Unable object to Objects with no specula reflection.

scan

Errors Multiple of resolution.

Best fitting objects Objects in short range.

Training Half day training required for better scanning

*: in the case of Seikowave method,3D TOOLBOXTM [12]

3D optical measurement system can measure surface exposed

profile of LTA but cannot directly measure remaining

thicknesses. In order to determine remaining thickness at LTA,

it is necessary to measure thickness at the portion other than

Fig.11 Measurement of LTA in pipe using 3D structured light

LTA by other method such as UT and deduct depth of LTA

method

measured by 3D structured light method. In case of

measurement of internal corrosion, inside diameter of the pipe

needs to be large enough to enter the system

(approx.300mm),otherwise the pipe cut in half to expose the

corroded surface if it is allowed.

Using same pipe with LTA for round robin test as shown in

Fig.10 with specification listed in Table 4, LTA in the pipe

was measured by 3D structured light method

Fig.11 shows measurement of LTA in pipe using

3D structured light method. Phase-shifted pattern is projected to

the target surface.

Fig.12 shows 3D data with no texture of outer surface of pipe.

It is easy to develop colored map of LTA depth in short time as

shown in Fig.13. Fig.12 3D data (no texture)

6 Copyright 2016 by ASME

CSV data is directly transferred to FFS assessment software.

Fig.16 shows data of grid points transferred from CSV data.

Based on input data as shown in Fig.17 and measured

remaining thickness data from CSV , the judgment of FFS

assessment of the pipe based on WES2820-2015 is easily

obtained using the computer software, uni-FitnessTMTM as

shown in Fig.18. .

In this case, general metal loss assessment shows acceptable.

Fig.19 shows FFS assessment after future 3 years operation.

When FCA for future 3 years operation is set 0.30 mm, general

metal loss assessment shows not acceptable, but local metal loss

assessment shows acceptable in both MAWP and allowable

stress.

CONCLUDING REMARKS

1) WES2820-2015 was developed for FFS assessment method

Fig.13 Colored map of LTA depth of pressure equipment with metal loss in Japan.

2) In order to perform FFS assessment of LTA in pressure

Fig. 14 shows critical thickness profile, CTP, of the LTA in equipment in short time with the highest reliability, the

pipe for FFS assessment of LTA. assessment system combined with LTA measurement using

Fig.15 shows LTA map by CSV (Excel) 3D structured light method and FFS assessment software

(CSV: Comma Separated Value) according to WES2820 was also developed.

3) LTA measurement using 3D LED system is very effective

in case of detailed measurement and continuous FFS

assessment in short time.

Top views

References

[1] WES2820-2015, Fitness-For-Service assessment procedure

for pressure equipment Metal loss assessment

[2] API579-1/ASME FFS-1, Fitness-For-Service, 2007

[3] FFS Assessment Standards for Pressure Equipment,

PAJ/JPCA FFS-S, 2011

[4] T.Kaida et al., Development of Fitness-For-Service standard

Longitudinal CTP for pressure equipment with metal loss based on reliability,

PVP2015-45832

Fig. 14 CTP of LTA in Pipe. [5] T.Tahara et al., Study on LTA measurement for FFS

assessment, PVP2015-45658

[6] M.Ozaki et al., Buckling strength of towers having partial

metal loss on shell under overturning moment, PVP2015-

45842

[7] JPI Standards JPI-8R-11~17, Japan Petroleum Institute

[8] Risk Based Maintenance, HPIS Z106, Z107, High Pressure

Institute of Japan

[9] Repair welding of pressure equipment, Part 1~4, WES7700

-1~-4, The Japan Welding Engineering Society

[10] Standards to determine next inspection interval based on

Fitness-For-Service assessment for high pressure gas

equipment, KHK/PAJ/JPCA S 0851(2009)

[11] Assessment Procedure for Crack-Like Flaws in Pressure

Equipment-Level1 and Level2, HPIS Z 101-1 and -2, 2011

[12] US Patent, US8, 976, 362B2, Seikowave Inc., USA

Fig.15 LTA map by CSV (Excel) [13] IHI Marine Co., Ltd., Japan

It takes almost 0.3 second for point captured and 30 second [14] J.L.Janelle et al., An overview and validation of the

for point cloud. Fitness-For-Service assessment procedures for local thin

areas, WRC Bulletin 505

7 Copyright 2016 by ASME

Fig. 16 Input data of the pipe Fig. 18 Judgment of FFS assessment of the pipe

Fig.17 Data of grid points transferred from CSV data Fig.19 Assessment after future 3 years operation

8 Copyright 2016 by ASME

Вам также может понравиться

- Turbine Traning ManualДокумент103 страницыTurbine Traning Manualmitra100685% (13)

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОт EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionОценок пока нет

- Hechmer 1991Документ7 страницHechmer 1991rahulОценок пока нет

- In Elastic Buckling of Geometrically Imperfect TubesДокумент16 страницIn Elastic Buckling of Geometrically Imperfect TubesSiva RajОценок пока нет

- Fundamentals of Water System Design - SIДокумент281 страницаFundamentals of Water System Design - SItran duy100% (2)

- BradleyДокумент247 страницBradleythomas duncan eelesОценок пока нет

- SB 150Документ4 страницыSB 150AnilОценок пока нет

- Simulations of The DARPA Suboff Submarine Including Self-PropulsiДокумент59 страницSimulations of The DARPA Suboff Submarine Including Self-Propulsijasonhaung100% (1)

- Failure Analysis of Fibre Reinforced Composite Laminates: 1. Use of The Program 1.1 1.1.1 General NotesДокумент47 страницFailure Analysis of Fibre Reinforced Composite Laminates: 1. Use of The Program 1.1 1.1.1 General Notesjunjie yiОценок пока нет

- Cylinder BucklingДокумент56 страницCylinder BucklingSJLeemansОценок пока нет

- Stress Concentration Factor - An Overview - ScienceDirect Topics PDFДокумент20 страницStress Concentration Factor - An Overview - ScienceDirect Topics PDFbhaskarrajusa8034Оценок пока нет

- Huebel Hartwig 15992Документ16 страницHuebel Hartwig 15992Ranu guptaОценок пока нет

- Stress Classification TechniqueДокумент12 страницStress Classification TechniqueAndrew FerrierОценок пока нет

- Strathprints006351 PDFДокумент86 страницStrathprints006351 PDFJohann Barcelos100% (1)

- Annex 6: FDS DOC (2001) 06 (Rev.3) Annex 6 / 297Документ39 страницAnnex 6: FDS DOC (2001) 06 (Rev.3) Annex 6 / 297Vasil GeorgievОценок пока нет

- Failure Modes of Fibre Reinforced Laminates: 1. NotationДокумент14 страницFailure Modes of Fibre Reinforced Laminates: 1. Notationjunjie yiОценок пока нет

- Extension of The Uniform Material Law For High Strength Steels by Sinan Korkmaz PDFДокумент74 страницыExtension of The Uniform Material Law For High Strength Steels by Sinan Korkmaz PDFHemant MishraОценок пока нет

- Asme - PVP2005-71724Документ11 страницAsme - PVP2005-71724sagar1503Оценок пока нет

- Report No 9 - Hot Spot/notch Stress Analysis - Using FEMAPДокумент21 страницаReport No 9 - Hot Spot/notch Stress Analysis - Using FEMAPnima1977Оценок пока нет

- Recommended Hot Spot Analysis Procedure For Structural Details of FPSOs and Ships Based On Round-Robin FE AnalysesДокумент8 страницRecommended Hot Spot Analysis Procedure For Structural Details of FPSOs and Ships Based On Round-Robin FE AnalysesgnjzyyОценок пока нет

- Improved Analysis of External Loads On Flanged JointsДокумент1 страницаImproved Analysis of External Loads On Flanged JointsTiHoRОценок пока нет

- Finite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Документ6 страницFinite Element Analysis of Butterfly Valve Disc IJERTV2IS70790Aswaja313Оценок пока нет

- 05Документ56 страниц05batmanbittuОценок пока нет

- Investigations of Butterfly Control Valve Flow CharacteristicsДокумент16 страницInvestigations of Butterfly Control Valve Flow CharacteristicsKalimuthu Ps100% (1)

- Linearizing StressДокумент6 страницLinearizing Stressbo cambellОценок пока нет

- Approximate Calculation of U-Shaped BellowsДокумент5 страницApproximate Calculation of U-Shaped BellowsGicuОценок пока нет

- Ch18 Hexaedron ElementДокумент10 страницCh18 Hexaedron Elementlittle-wing100% (2)

- Annex 3-F Design Fatigue Curves (Smooth Bar)Документ1 страницаAnnex 3-F Design Fatigue Curves (Smooth Bar)ข้าวเม่า ทอดОценок пока нет

- A Reinterpretation of The Palmgren-Miner Rule For Fatigue Life PredictionДокумент25 страницA Reinterpretation of The Palmgren-Miner Rule For Fatigue Life PredictionodjakmОценок пока нет

- FreeseДокумент15 страницFreeseBrandon HaleОценок пока нет

- Non Linear Analysis 2019 290719Документ32 страницыNon Linear Analysis 2019 290719Stefano MilaniОценок пока нет

- Thesis - Fatigue Behavior and Life Pridictions of Con RodДокумент263 страницыThesis - Fatigue Behavior and Life Pridictions of Con RodMallikarjun Rao PanabakaОценок пока нет

- Fracture Mechanics in Ansys R16: Session Will Begin at 10:00 AM (Pacific Day Time)Документ36 страницFracture Mechanics in Ansys R16: Session Will Begin at 10:00 AM (Pacific Day Time)rockmanqhОценок пока нет

- Annex B2-Recommendations For Linearization of Stress Results ForДокумент20 страницAnnex B2-Recommendations For Linearization of Stress Results ForMarlon VillarrealОценок пока нет

- Analytical Considerations The Code Qualification Piping SystemsДокумент17 страницAnalytical Considerations The Code Qualification Piping SystemsMahendra RathoreОценок пока нет

- Alloy CuCr1ZrДокумент53 страницыAlloy CuCr1ZrPrashant PuriОценок пока нет

- Hobbacher-2015-Recommendations For Fatigue Design of Welded Joints and ComponentsДокумент26 страницHobbacher-2015-Recommendations For Fatigue Design of Welded Joints and Componentsbalaji817150Оценок пока нет

- Burst & Gross Plastic Deformation Limit StateДокумент8 страницBurst & Gross Plastic Deformation Limit StateMichelle GrossОценок пока нет

- MFC 8M 2001Документ26 страницMFC 8M 2001Joel CieltoОценок пока нет

- ETBX Stress-Life Fatigue Analysis ModuleДокумент11 страницETBX Stress-Life Fatigue Analysis ModuleLeonardo Da Rosa GonçalvesОценок пока нет

- The C-E All Welded Test Boiler Drum: A National Historic Mechanical Engineering LandmarkДокумент17 страницThe C-E All Welded Test Boiler Drum: A National Historic Mechanical Engineering LandmarkIpong Darma Putra TambaОценок пока нет

- Datasheet DMV 347 HFGДокумент4 страницыDatasheet DMV 347 HFGClaudia MmsОценок пока нет

- End Effects of Elbows Subjected To Moment LoadingsДокумент75 страницEnd Effects of Elbows Subjected To Moment LoadingsA. VenugopalОценок пока нет

- Fea SR CouplingsДокумент67 страницFea SR CouplingsAna Isabel Aguilar ReyesОценок пока нет

- COADE's Application of Welding Research Council Bulletins 107, 297 and 368Документ3 страницыCOADE's Application of Welding Research Council Bulletins 107, 297 and 368shivabtowin3301100% (3)

- Nonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceОт EverandNonlinear Finite Element Analysis and Adina: Proceedings of the 4th ADINA ConferenceОценок пока нет

- Numerical Solution of Partial Differential Equations—II, Synspade 1970: Proceedings of the Second Symposium on the Numerical Solution of Partial Differential Equations, SYNSPADE 1970, Held at the University of Maryland, College Park, Maryland, May 11-15, 1970От EverandNumerical Solution of Partial Differential Equations—II, Synspade 1970: Proceedings of the Second Symposium on the Numerical Solution of Partial Differential Equations, SYNSPADE 1970, Held at the University of Maryland, College Park, Maryland, May 11-15, 1970Bert HubbardОценок пока нет

- Production Gas Carburising: The Pergamon Materials Engineering Practice SeriesОт EverandProduction Gas Carburising: The Pergamon Materials Engineering Practice SeriesОценок пока нет

- Adiabatic Shear Localization: Frontiers and AdvancesОт EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddОценок пока нет

- Introduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Документ25 страницIntroduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007ANILОценок пока нет

- PVP2014-28451 Mods Proposed To API 579-1Документ13 страницPVP2014-28451 Mods Proposed To API 579-1jbloggs2007Оценок пока нет

- Introduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Документ25 страницIntroduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Rob WillestoneОценок пока нет

- Introduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Документ25 страницIntroduction To Fitness-For-Service (FFS) API 579-1 / ASME FFS-1 2007Rabindra RaiОценок пока нет

- IntroductionДокумент10 страницIntroductionMarlon VillarrealОценок пока нет

- Api RP 579 FSSДокумент25 страницApi RP 579 FSSNdomadu100% (1)

- Fitness For Service AssessmentДокумент13 страницFitness For Service Assessmentwsjouri2510Оценок пока нет

- The API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadДокумент32 страницыThe API 579 Fitness-for-Service Standard - The Current State of Technology and A Ten Year Look AheadthiagopontualОценок пока нет

- Thesis 01 YpmaДокумент223 страницыThesis 01 YpmaAbdulОценок пока нет

- Seismic Design For Application of LNG Storage TankДокумент10 страницSeismic Design For Application of LNG Storage TankHyune Boom SheenОценок пока нет

- fatigue - knowledge - 14 ソケット溶接継手の疲労に関する既存の知見について PDFДокумент23 страницыfatigue - knowledge - 14 ソケット溶接継手の疲労に関する既存の知見について PDFHyune Boom SheenОценок пока нет

- Publication 12 18109 228Документ4 страницыPublication 12 18109 228Hyune Boom SheenОценок пока нет

- Fracture Mechanics & Material Behaviour: Department of Mechanical Engineering Coursework Assignment Cover SheetДокумент1 страницаFracture Mechanics & Material Behaviour: Department of Mechanical Engineering Coursework Assignment Cover SheetHyune Boom SheenОценок пока нет

- Corrosion Basics PDFДокумент19 страницCorrosion Basics PDFAdityaRamaОценок пока нет

- 7S19-VP-T7703-044 Rev 1 A3Документ1 страница7S19-VP-T7703-044 Rev 1 A3Hyune Boom SheenОценок пока нет

- Torsional Vibrations of Synchronous Motor Driven Trains Using P Method PDFДокумент9 страницTorsional Vibrations of Synchronous Motor Driven Trains Using P Method PDFHyune Boom SheenОценок пока нет

- Data / Requisition Sheet For: Eccn Ear99 Design Book No: Contr. Job No: Mesc NoДокумент3 страницыData / Requisition Sheet For: Eccn Ear99 Design Book No: Contr. Job No: Mesc NoHyune Boom SheenОценок пока нет

- Generation of Residual Stresses in Rotary Swaging ProcessДокумент9 страницGeneration of Residual Stresses in Rotary Swaging ProcessHyune Boom SheenОценок пока нет

- Understanding Amplitude Phase in Rotating Machinery LinkedДокумент20 страницUnderstanding Amplitude Phase in Rotating Machinery LinkedrfriosEPОценок пока нет

- Vendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantДокумент18 страницVendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantHyune Boom SheenОценок пока нет

- Vendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantДокумент22 страницыVendor Document Cover Sheet: Project: Ar4 4 Aromatics PlantHyune Boom SheenОценок пока нет

- Assy No. Type of Work Platform Use Test WeightДокумент1 страницаAssy No. Type of Work Platform Use Test WeightHyune Boom SheenОценок пока нет

- Equipment: Plant: Consignee:: C OfmДокумент1 страницаEquipment: Plant: Consignee:: C OfmHyune Boom SheenОценок пока нет

- Analysis of Hanford Double Shell Tank Concrete AnchoragesДокумент22 страницыAnalysis of Hanford Double Shell Tank Concrete AnchoragesHyune Boom SheenОценок пока нет

- Ebsco Ebooks: Ebook Petroleum Engineering CollectionДокумент1 страницаEbsco Ebooks: Ebook Petroleum Engineering CollectionHyune Boom SheenОценок пока нет

- A Comparison Study of Pressure Vessel Design Using Different StandardsДокумент319 страницA Comparison Study of Pressure Vessel Design Using Different StandardsHyune Boom SheenОценок пока нет

- Stair Case Design - at Design OfficeДокумент14 страницStair Case Design - at Design OfficeShamen AmarasekaraОценок пока нет

- Copper Nickel Pipe Fittings CatalogДокумент8 страницCopper Nickel Pipe Fittings CatalogAli FarzadmaneshОценок пока нет

- Wsat-Xee: Installation Use and Maintenance ManualДокумент68 страницWsat-Xee: Installation Use and Maintenance ManualAncuta CosmanОценок пока нет

- P82 HPU&Deck Box& Solenoid Rack SpecificationДокумент32 страницыP82 HPU&Deck Box& Solenoid Rack SpecificationAzhaghiaОценок пока нет

- S 1611018 Chapter2Документ36 страницS 1611018 Chapter2Adji SetiaОценок пока нет

- Climatology: - Ar. Akshay GuptaДокумент43 страницыClimatology: - Ar. Akshay GuptaYogendra SinghОценок пока нет

- The Copperbelt University: School of TechnologyДокумент40 страницThe Copperbelt University: School of TechnologyMU Len GAОценок пока нет

- SA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02Документ5 страницSA-980-P-11444 - API 685 Fuel Hydrant Pump PZ - Vert02altipatlarОценок пока нет

- Vibration Control in Washing Machine With The Help of Suspension SystemДокумент14 страницVibration Control in Washing Machine With The Help of Suspension Systempradeep eliОценок пока нет

- Finetrol Rotary Control Valve: Added SecurityДокумент14 страницFinetrol Rotary Control Valve: Added SecurityAmine KhОценок пока нет

- Máy SliceДокумент15 страницMáy SliceHoang NguyenОценок пока нет

- DR Ashok K Jain Former Professor IIT Roorkee PDFДокумент43 страницыDR Ashok K Jain Former Professor IIT Roorkee PDFAtul Kumar EngineerОценок пока нет

- Unit 3 Electric Vehicle Drive Train: Department of Mechanical EngineeringДокумент64 страницыUnit 3 Electric Vehicle Drive Train: Department of Mechanical EngineeringPraveen RathodОценок пока нет

- Lec 05Документ48 страницLec 05Sam VergaraОценок пока нет

- 3408 Timing GeaarsДокумент4 страницы3408 Timing Geaarsmanu luvungaОценок пока нет

- Lennox AC Remote Controller Owners Manual 20pp - Jan 2012Документ8 страницLennox AC Remote Controller Owners Manual 20pp - Jan 2012Meselao LeeОценок пока нет

- CL Vibration ClampДокумент2 страницыCL Vibration ClampEduardo RodriguezОценок пока нет

- Shipyard Welding ProcessesДокумент6 страницShipyard Welding ProcessesPawan KumarОценок пока нет

- Forged Valves - Operation & Maintenance ManualДокумент16 страницForged Valves - Operation & Maintenance ManualKoolkrayzeh KLОценок пока нет

- Reintjes Selection Guide 2012Документ45 страницReintjes Selection Guide 2012Anh Nguyen100% (3)

- Replacement Parts List: Indoor Air Handler (B5, GB5) SeriesДокумент12 страницReplacement Parts List: Indoor Air Handler (B5, GB5) SeriesAlvaro GarciaОценок пока нет

- Model C and CHD Tubing Spider ManualДокумент16 страницModel C and CHD Tubing Spider ManualEdgar Moreira FernandezОценок пока нет

- Especificaciones Acumulador de Direccion CAT789C Prueba y CargaДокумент8 страницEspecificaciones Acumulador de Direccion CAT789C Prueba y CargaRafael RodriguezОценок пока нет

- Hull As A BeamДокумент17 страницHull As A BeamCemGülerОценок пока нет

- PartB Dynamics of Rotors and Fundations-1993Документ195 страницPartB Dynamics of Rotors and Fundations-1993Rohit TamrakarОценок пока нет

- List of Recomended ManufacturersДокумент16 страницList of Recomended ManufacturersMostafa SalemОценок пока нет

- Annular Pressure Management - OISD Well Integrity Workshop, Nov., 2013Документ20 страницAnnular Pressure Management - OISD Well Integrity Workshop, Nov., 2013azareiforoush0% (1)

- 2015 Nissan Sentra Fe + S 1.8l, l4, Des Mra8de, Ee. Uu. 2Документ2 страницы2015 Nissan Sentra Fe + S 1.8l, l4, Des Mra8de, Ee. Uu. 2Misa GamezОценок пока нет