Академический Документы

Профессиональный Документы

Культура Документы

DM5444-03-M (G3412C) PDF

Загружено:

Hugo CiprianiОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

DM5444-03-M (G3412C) PDF

Загружено:

Hugo CiprianiАвторское право:

Доступные форматы

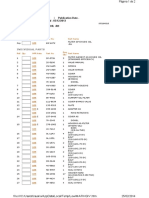

G3412C GAS ENGINE TECHNICAL DATA

ENGINE SPEED: 1800 FUEL: NAT GAS

COMPRESSION RATIO: 11.4:1 FUEL SYSTEM: LPG IMPCO

AFTERCOOLER - MAX. INLET (C): 54

JACKET WATER - MAX. OUTLET (C): 99 FUEL PRESS. RANGE (KPAg): 10.0 - 34.5

COOLING SYSTEM: JW+OC, AC MIN. METHANE NUMBER: 80

IGNITION SYSTEM: EIS RATED ALTITUDE (m): 1500

EXHAUST MANIFOLD: WC AT AIR TO TURBO. TEMP. (C): 25

COMBUSTION: LOW EMISSION NOx EMISSION LEVEL: 800.0 mg/Nm3

FUEL LHV (MJ/Nm3): 35.6

APPLICATION: 60 Hz GENSET

RATING AND EFFICIENCY NOTES LOAD 100% 75% 50%

ENGINE POWER (WITHOUT FAN) (1) KW 475 356 238

GENERATOR POWER (WITH MECH FAN) (2) EKW 375 259 154

ENGINE EFFICIENCY (ISO 3046/1) (3) % 37.0 35.4 32.8

ENGINE EFFICIENCY (NOMINAL) (3) % 36.3 34.7 32.2

THERMAL EFFICIENCY (NOMINAL) (4) % 46.1 48.3 54.2

TOTAL EFFICIENCY (NOMINAL) (5) % 82.4 83.0 86.5

ENGINE DATA

FUEL CONSUMPTION (ISO 3046/1) (6) MJ/bkW-hr 9.74 10.17 10.97

FUEL CONSUMPTION (NOMINAL) (6) MJ/bkW-hr 9.93 10.37 11.18

AIR FLOW (0 C, 101.3 kPa) (7) Nm3/bkW-hr 4.44 4.57 4.41

AIR FLOW (7) kg/bkW-hr 5.73 5.91 5.70

COMPRESSOR OUT PRESSURE kPa (abs) 224 214 160

COMPRESSOR OUT TEMPERATURE C 141 130 93

AFTERCOOLER AIR OUT TEMPERATURE C 65 63 60

INLET MAN. PRESSURE (8) KPAa 201 179 162

INLET MAN. TEMPERATURE (MEASURED IN PLENUM) (9) C 65 63 60

TIMING (10) BTDC 27 27 27

EXHAUST STACK TEMPERATURE (11) C 371 371 386

EXHAUST GAS FLOW (0 C, 101.3 kPa) (12) Nm3/bkW-hr 4.72 4.87 4.73

EXHAUST MASS FLOW (12) kg/bkW-hr 5.95 6.13 5.94

EMISSIONS DATA

NOx (as NO2) (corr. 5% O2) (13) mg/Nm3 (dry) 800 815 2017

CO (corr. 5% O2) (14) mg/Nm3 (dry) 808 784 762

THC (corr. 5% O2), molecular weight of 15.84) (14) mg/Nm3 (dry) 2239 2350 1871

NMHC (corr. 5% O2, molecular weight of 15.84) (14) mg/Nm3 (dry) 336 353 281

EXHAUST O2 (15) % DRY 8.7 8.5 6.9

LAMBDA (15) 1.68 1.66 1.48

HEAT BALANCE DATA

LHV INPUT (16) KW 1310 1026 737

HEAT REJECTION TO JACKET (JW) (17) (22) KW 333 281 244

HEAT REJECTION TO ATMOSPHERE (18) KW 52 41 29

HEAT REJECTION TO LUBE OIL (OC) (19) (22) KW 53 45 39

HEAT REJECTION TO EXHAUST (LHV to 25C) (20) KW 333 260 173

HEAT REJECTION TO EXHAUST (LHV to 120C) (20) KW 219 169 117

HEAT REJECTION TO A/C (AC) (21) (23) KW 64 43 14

CONDITIONS AND DEFINITIONS

ENGINE RATING OBTAINED AND PRESENTED IN ACCORDANCE WITH ISO 3046/1 (STD. REF. CONDITIONS OF 25C, 100

KPA BAROMETRIC PRESSURE, 152 m ALTITUDE). NO OVERLOAD PERMITTED AT RATING SHOWN. CONSULT ALTITUDE

CHARTS FOR APPLICATIONS ABOVE MAXIMUM RATED ALTITUDE AND/OR TEMPERATURE.

EMISSION LEVELS ARE BASED ON THE ENGINE OPERATING AT STEADY STATE CONDITIONS AND ADJUSTED TO THE

SPECIFIED NOx LEVEL AT 100% LOAD. EMISSION TOLERANCES SPECIFIED ARE DEPENDANT UPON FUEL QUALITY.

METHANE NUMBER CANNOT VARY MORE THAN 3. PUBLISHED PART LOAD DATA MAY REQUIRE ENGINE ADJUSTMENT.

ENGINE RATING IS WITH 2 ENGINE DRIVEN WATER PUMPS.

FOR NOTES INFORMATION CONSULT PAGE THREE.

DM5444-03 PAGE 1 OF 3 01-Dec-09

G3412C GAS ENGINE TECHNICAL DATA

FUEL USAGE GUIDE

CAT METHANE NUMBER 30 35 40 45 50 55 60 65 70 75 80 85-100

IGNITION TIMING - - - - - - - - 23 25 27 27

DERATION FACTOR 0 0 0 0 0 0 0 0 1.00 1.00 1.00 1.00

ALTITUDE DERATION FACTORS

50 1.00 1.00 1.00 1.00 0.98 0.95 0.92 0.89 0.86 0.84 0.81 0.78 0.76

45 1.00 1.00 1.00 1.00 1.00 0.97 0.94 0.91 0.88 0.85 0.82 0.80 0.77

AIR 40 1.00 1.00 1.00 1.00 1.00 0.98 0.95 0.92 0.89 0.86 0.84 0.81 0.78

TO 35 1.00 1.00 1.00 1.00 1.00 1.00 0.97 0.94 0.91 0.88 0.85 0.82 0.79

TURBO 30 1.00 1.00 1.00 1.00 1.00 1.00 0.98 0.95 0.92 0.89 0.86 0.84 0.81

25 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.97 0.94 0.91 0.88 0.85 0.82

(C) 20 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.98 0.95 0.92 0.89 0.86 0.84

15 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.97 0.94 0.91 0.88 0.85

10 1.00 1.00 1.00 1.00 1.00 1.00 1.00 1.00 0.99 0.96 0.92 0.89 0.87

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000

ALTITUDE (METERS ABOVE SEA LEVEL)

AFTERCOOLER HEAT REJECTION FACTORS (ACHRF)

50 1.41 1.47 1.54 1.61 1.68 1.75 1.82 1.82 1.82 1.82 1.82 1.82 1.82

45 1.32 1.38 1.45 1.52 1.59 1.66 1.73 1.73 1.73 1.73 1.73 1.73 1.73

AIR 40 1.23 1.29 1.36 1.43 1.49 1.56 1.63 1.63 1.63 1.63 1.63 1.63 1.63

TO 35 1.14 1.20 1.27 1.33 1.40 1.47 1.54 1.54 1.54 1.54 1.54 1.54 1.54

TURBO 30 1.05 1.11 1.18 1.24 1.31 1.38 1.44 1.44 1.44 1.44 1.44 1.44 1.44

25 1.00 1.02 1.09 1.15 1.22 1.28 1.35 1.35 1.35 1.35 1.35 1.35 1.35

(C) 20 1.00 1.00 1.00 1.06 1.12 1.19 1.25 1.25 1.25 1.25 1.25 1.25 1.25

15 1.00 1.00 1.00 1.00 1.03 1.09 1.16 1.16 1.16 1.16 1.16 1.16 1.16

10 1.00 1.00 1.00 1.00 1.00 1.00 1.06 1.06 1.06 1.06 1.06 1.06 1.06

0 250 500 750 1000 1250 1500 1750 2000 2250 2500 2750 3000

ALTITUDE (METERS ABOVE SEA LEVEL)

FUEL USAGE GUIDE:

This table shows the derate factor required for a given fuel. Note that deration occurs as the methane number decreases. Methane number is a scale to measure

detonation characteristics of various fuels. The methane number of a fuel is determined by using the Caterpillar Methane Number Calculation program.

ALTITUDE DERATION FACTORS:

This table shows the deration required for various air inlet temperatures and altitudes. Use this information along with the fuel usage guide chart to help

determine actual engine power for your site.

ACTUAL ENGINE RATING:

It is important to note that the Altitude/Temperature deration and the Fuel Usage Guide deration are not cumulative. They are not to be added together. The

same is true for the Low Energy Fuel deration (reference the Caterpillar Methane Number Program) and the Fuel Usage Guide deration. However, the

Altitude/Temperature deration and Low Energy Fuel deration are cumulative; and they must be added together in the method shown below. To determine

the actual power available, take the lowest rating between 1) and 2).

1) (Altitude/Temperature Deration) + (Low Energy Fuel Deration)

2) Fuel Usage Guide Deration

Note: For NA's always add the Low Energy Fuel deration to the Altitude/Temperature deration. For TA engines only add the Low Energy Fuel

deration to the Altitude/Temperature deration whenever the Altitude/Temperature deration is less than 1.0 (100%). This will give the actual rating

for the engine at the conditions specified.

AFTERCOOLER HEAT REJECTION FACTORS (ACHRF):

Aftercooler heat rejection is given for standard conditions of 25C and 152 m altitude. To maintain a constant air inlet manifold temperature, as the air to turbo

temperature goes up, so must the heat rejection. As altitude increases, the turbocharger must work harder to overcome the lower atmospheric pressure. This

increases the amount of heat that must be removed from the inlet air by the aftercooler. Use the aftercooler heat rejection factor (ACHRF) to adjust for ambient

and altitude conditions. Multiply this factor by the standard aftercooler heat rejection. Failure to properly account for these factors could result in detonation and

cause the engine to shutdown or fail.

DM5444-03 PAGE 2 OF 3 01-Dec-09

G3412C GAS ENGINE TECHNICAL DATA

NOTES

1 ENGINE RATING IS WITH 2 ENGINE DRIVEN WATER PUMPS. TOLERANCE IS 3% OF FULL LOAD.

2 GENERATOR POWER DETERMINED WITH AN ASSUMED GENERATOR EFFICIENCY OF 93% AND POWER FACTOR OF

0.8 [GENERATOR POWER = ENGINE POWER x GENERATOR EFFICIENCY].

3 ISO 3046/1 ENGINE EFFICIENCY TOLERANCE IS (+)0, (-)5% OF FULL LOAD % EFFICIENCY VALUE. NOMINAL ENGINE

EFFICIENCY TOLERANCE IS 3% OF FULL LOAD % EFFICIENCY VALUE.

4 THERMAL EFFICIENCY: JACKET HEAT + LUBE OIL HEAT + EXH. HEAT TO 120C.

5 TOTAL EFFICIENCY = ENGINE EFF. + THERMAL EFF. TOLERANCE IS 10% OF FULL LOAD DATA.

6 ISO 3046/1 FUEL CONSUMPTION TOLERANCE IS (+)5, (-)0% OF FULL LOAD DATA. NOMINAL FUEL CONSUMPTION

TOLERANCE IS 3 % OF FULL LOAD DATA.

7 UNDRIED AIR. FLOW TOLERANCE IS 5 %

8 INLET MANIFOLD PRESSURE TOLERANCE IS 5 %

9 INLET MANIFOLD TEMPERATURE TOLERANCE IS 5C.

10 TIMING INDICATED IS FOR USE WITH THE MINIMUM FUEL METHANE NUMBER SPECIFIED. CONSULT THE

APPROPRIATE FUEL USAGE GUIDE FOR TIMING AT OTHER METHANE NUMBERS.

11 EXHAUST STACK TEMPERATURE TOLERANCE IS (+)35C, (-)30C.

12 WET EXHAUST. FLOW TOLERANCE IS 6 %

13 NOX VALUES ARE SET POINTS AND WILL VARY WITH OPERATING CONDITIONS.

14 CO, CO2, THC, and NMHC VALUES ARE "NOT TO EXCEED".

15 O2% TOLERANCE IS 0.5; LAMBDA TOLERANCE IS 0.05. LAMBDA AND O2 LEVEL ARE THE RESULT OF ADJUSTING

THE ENGINE TO OPERATE AT THE SPECIFIED NOX LEVEL.

16 LHV INPUT TOLERANCE IS 3%.

17 HEAT REJECTION TO JACKET TOLERANCE IS 10 % OF FULL LOAD DATA, BASED ON TREATED WATER.

18 HEAT REJECTION TO ATMOSPHERE TOLERANCE IS 50% OF FULL LOAD DATA, BASED ON TREATED WATER.

19 HEAT REJECTION OF LUBE OIL TOLERANCE IS 20% OF FULL LOAD DATA, BASED ON TREATED WATER.

20 HEAT REJECTION TO EXHAUST TOLERANCE IS 10% OF FULL LOAD DATA, BASED ON TREATED WATER.

21 HEAT REJECTION TO A/C TOLERANCE IS 5 % OF FULL LOAD DATA, BASED ON TREATED WATER.

SITE SPECIFIC COOLING SYSTEM SIZING EQUATIONS (WITH TOLERANCES)

22 TOTAL JACKET CIRCUIT (JW+OC) = (JW x 1.1) + (OC x 1.2).

23 TOTAL AFTERCOOLER CIRCUIT (AC) = AC x ACHRF x 1.05.

DM5444-03 PAGE 3 OF 3 01-Dec-09

Вам также может понравиться

- Tabela de Gases 3516BДокумент2 страницыTabela de Gases 3516Bwagner_guimarães_1Оценок пока нет

- Gas Engine Technical Data: Rating Notes Load 100% 75% 50%Документ4 страницыGas Engine Technical Data: Rating Notes Load 100% 75% 50%Isaac MuñozОценок пока нет

- Dm8542 00 M CompletoДокумент5 страницDm8542 00 M CompletoJorge Daniel HernandezОценок пока нет

- Bio Gas G3516 Technical Data - S02!35!03Документ2 страницыBio Gas G3516 Technical Data - S02!35!03Fatah FatanОценок пока нет

- Gas Engine Technical Data G3406Документ4 страницыGas Engine Technical Data G3406Djebali MouradОценок пока нет

- Application 72201560552 PM 637Документ3 страницыApplication 72201560552 PM 637ratheeshОценок пока нет

- G3412C TA: Gas Engine Technical DataДокумент3 страницыG3412C TA: Gas Engine Technical DataGabriel Paco LunaОценок пока нет

- CHP Gas Engine Tech Data G3412TA 350 KW 21 G NOx DM5441 00 EДокумент3 страницыCHP Gas Engine Tech Data G3412TA 350 KW 21 G NOx DM5441 00 ERyan PatraОценок пока нет

- G3516H - Tech Data StandardДокумент5 страницG3516H - Tech Data StandardShankar RajaОценок пока нет

- Gas DM8670 06 GS Epg M 31090256Документ5 страницGas DM8670 06 GS Epg M 31090256Suresh kumar ChockalingamОценок пока нет

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyДокумент3 страницыGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDmitryОценок пока нет

- E4352 Caterpillar G3406 Engines BrochureДокумент3 страницыE4352 Caterpillar G3406 Engines BrochureShakeel Ahmed KayaniОценок пока нет

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyДокумент3 страницыGas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyAM76Оценок пока нет

- Gas DM8970 07 VS Pet M 9388180Документ4 страницыGas DM8970 07 VS Pet M 9388180Mohamed AbdelazimОценок пока нет

- Engine-Tech Spec 3616Документ3 страницыEngine-Tech Spec 3616ChiefОценок пока нет

- Gas DM8811 07 GS Epg M 10069210 1Документ5 страницGas DM8811 07 GS Epg M 10069210 1coolcaryyanОценок пока нет

- Standard Tec Data - G3516 LEДокумент4 страницыStandard Tec Data - G3516 LEAlfredoОценок пока нет

- DATA SheetДокумент5 страницDATA SheetKhalifaОценок пока нет

- Cat G3512H - 1500 KW 1Документ5 страницCat G3512H - 1500 KW 1Yousuf AliОценок пока нет

- Gas DM8924 02 GS Epg M 13100177Документ5 страницGas DM8924 02 GS Epg M 13100177HossenОценок пока нет

- Gas Engine Technical Data: Rating Notes Load 100% 75% 50%Документ4 страницыGas Engine Technical Data: Rating Notes Load 100% 75% 50%Victor SОценок пока нет

- CAT G3612 A4 Gas Engine Technical Data Sheet PDFДокумент4 страницыCAT G3612 A4 Gas Engine Technical Data Sheet PDFEustacio MenesesОценок пока нет

- Gas DM8670 06 GS Epg e 31090256Документ5 страницGas DM8670 06 GS Epg e 31090256Suresh kumar ChockalingamОценок пока нет

- Performance Data-1 PDFДокумент4 страницыPerformance Data-1 PDFlubangjarumОценок пока нет

- Cat G3516B LeДокумент2 страницыCat G3516B LeMercy ChemutaiОценок пока нет

- 4ZS01350 Data Sheet DM8605 G3606 A3Документ5 страниц4ZS01350 Data Sheet DM8605 G3606 A3MitulОценок пока нет

- 3516b Performance DataДокумент4 страницы3516b Performance Dataguddy1Оценок пока нет

- 8635 g3520cДокумент4 страницы8635 g3520cМарсель БашировОценок пока нет

- Engine Technical Data Sheet G3616 3100-3400 KW 900 RPMДокумент2 страницыEngine Technical Data Sheet G3616 3100-3400 KW 900 RPM巴啦啦Оценок пока нет

- Performance Demar Offshore HOKA 800 KWДокумент3 страницыPerformance Demar Offshore HOKA 800 KWJuan Almanza MosquedaОценок пока нет

- 4-SLW - VHP - G825 - C6.3 - EngCalc L5794GSIДокумент3 страницы4-SLW - VHP - G825 - C6.3 - EngCalc L5794GSIJose FavaОценок пока нет

- SFGLD 480 1800: Gas Ic-G-B-48-033 IcДокумент1 страницаSFGLD 480 1800: Gas Ic-G-B-48-033 IccihanОценок пока нет

- Ficha Tecnica Equipo Gas CAT G3516Документ5 страницFicha Tecnica Equipo Gas CAT G3516MarioAndrésRamirezC.Оценок пока нет

- G3520HДокумент4 страницыG3520HAM76Оценок пока нет

- D-6409f - Marketing C2000 GAS HSK78Документ2 страницыD-6409f - Marketing C2000 GAS HSK78Edwin Fernando Ariza QuirogaОценок пока нет

- G3520 GZM00214 EM0111-02-E Engine Perf DataДокумент4 страницыG3520 GZM00214 EM0111-02-E Engine Perf Datatua aggrekoОценок пока нет

- Gas Engine Site Specific Technical Data Non-CurrentДокумент4 страницыGas Engine Site Specific Technical Data Non-CurrentDanny PalaceОценок пока нет

- GERP Program On G3406NA EngineДокумент7 страницGERP Program On G3406NA EngineFrancisco Rodriguez G.Оценок пока нет

- 6-SLW - VHP - G450 - L0.4 Engine Out - ICWT60Документ3 страницы6-SLW - VHP - G450 - L0.4 Engine Out - ICWT60Syafiq MuhammadОценок пока нет

- 2-SLW - VHP - G1200 - L10 - EngCalc L7044GSI-S5Документ3 страницы2-SLW - VHP - G1200 - L10 - EngCalc L7044GSI-S5mashfiqul islamОценок пока нет

- 1.C2000N5CD Datasheet NOx 250mgДокумент6 страниц1.C2000N5CD Datasheet NOx 250mgforuzzОценок пока нет

- 1.HSK78 2MW DatasheetДокумент6 страниц1.HSK78 2MW Datasheetnunukidsshop 0869478221Оценок пока нет

- Lehe1568 02Документ2 страницыLehe1568 02LuisОценок пока нет

- 02 190 0012 MK 062Документ9 страниц02 190 0012 MK 062phuchau nguyenОценок пока нет

- Apg1000 Specs 74hc595 NXPДокумент7 страницApg1000 Specs 74hc595 NXPNatgas WebmasterОценок пока нет

- Data Sheet 1750kWДокумент7 страницData Sheet 1750kWIsaac MartinezОценок пока нет

- Gas Engine Site Specific Technical DataДокумент4 страницыGas Engine Site Specific Technical Datavlcmstne04Оценок пока нет

- Compressor Specifications - © Bristol Compressors International, IncДокумент1 страницаCompressor Specifications - © Bristol Compressors International, IncWall Art VenezuelaОценок пока нет

- Datasheet Cummins C1000Документ6 страницDatasheet Cummins C1000Alejandro TorrresОценок пока нет

- Nirvana: Engineering ManualДокумент2 страницыNirvana: Engineering ManualYerko Muñoz NuОценок пока нет

- Generator Set Data Sheet 1160 KW Continuous: Fuel Consumption (ISO3046/1)Документ4 страницыGenerator Set Data Sheet 1160 KW Continuous: Fuel Consumption (ISO3046/1)Maximiliano SanchezОценок пока нет

- Eds-208 6CTA8.3-G2 PDFДокумент1 страницаEds-208 6CTA8.3-G2 PDFthainarimeОценок пока нет

- TGI Sabana Gas Transport: Operating Conditions Normal D E F A B CДокумент3 страницыTGI Sabana Gas Transport: Operating Conditions Normal D E F A B Chernan plazasОценок пока нет

- EMR100HLC 115-127 V 60 HZ 1Документ4 страницыEMR100HLC 115-127 V 60 HZ 1Jose MaciasОценок пока нет

- NEK2160U 220-240 V 50 HZ 1Документ3 страницыNEK2160U 220-240 V 50 HZ 1ciprian ilieОценок пока нет

- Design DataДокумент29 страницDesign DatakalyanikishoreОценок пока нет

- TD 20V 4000 L64FNER - NT-GMK 58 Grad - 93800052331 - en - GBДокумент2 страницыTD 20V 4000 L64FNER - NT-GMK 58 Grad - 93800052331 - en - GBMohammad NezaminiaОценок пока нет

- Compressor Technical DataДокумент3 страницыCompressor Technical DataGabriel RodriguezОценок пока нет

- IC E1 IC-G-B-36-059 GAS Power Rating: Genset: SGE-36SL Speed: 1500 Fuel Type: Natural GasДокумент1 страницаIC E1 IC-G-B-36-059 GAS Power Rating: Genset: SGE-36SL Speed: 1500 Fuel Type: Natural Gasz018125Оценок пока нет

- Cat Electronic Technician 2020A v1.0 Product Status ReportДокумент53 страницыCat Electronic Technician 2020A v1.0 Product Status ReportHugo CiprianiОценок пока нет

- Common Engine Bearing ClearancesДокумент1 страницаCommon Engine Bearing ClearancesHugo CiprianiОценок пока нет

- The 6-Steps Maintenance Planning and Scheduling ProcessДокумент14 страницThe 6-Steps Maintenance Planning and Scheduling ProcessHugo CiprianiОценок пока нет

- Protect Your Machinery and Minimize Down TimeДокумент20 страницProtect Your Machinery and Minimize Down TimeHugo CiprianiОценок пока нет

- 150-0023 Control Gp-Engine ElectronicДокумент2 страницы150-0023 Control Gp-Engine ElectronicHugo CiprianiОценок пока нет

- 1.44. 7C-4711 Pan Gp-OilДокумент2 страницы1.44. 7C-4711 Pan Gp-OilHugo CiprianiОценок пока нет

- 1.40. 1n-4421 Lines Gp-Water - LowerДокумент1 страница1.40. 1n-4421 Lines Gp-Water - LowerHugo CiprianiОценок пока нет

- 1.30.1. 327-9372 Transformer GP - IgnitionДокумент2 страницы1.30.1. 327-9372 Transformer GP - IgnitionHugo CiprianiОценок пока нет

- 1.42. 4p-8354 Lines Gp-Water - UpperДокумент3 страницы1.42. 4p-8354 Lines Gp-Water - UpperHugo CiprianiОценок пока нет

- 1.24. 2W-8772 Flywheel GPДокумент2 страницы1.24. 2W-8772 Flywheel GPHugo CiprianiОценок пока нет

- 1.22. 7n-1875 Filler Gp-Engine OilДокумент2 страницы1.22. 7n-1875 Filler Gp-Engine OilHugo CiprianiОценок пока нет

- 1.12. 9y-6123 Cover Gp-Cylinder Block - Central StructureДокумент2 страницы1.12. 9y-6123 Cover Gp-Cylinder Block - Central StructureHugo CiprianiОценок пока нет

- 1.17. 115-5159 Cylinder Block GPДокумент3 страницы1.17. 115-5159 Cylinder Block GPHugo CiprianiОценок пока нет

- 1.16. 8n-0337 Crankshaft GPДокумент2 страницы1.16. 8n-0337 Crankshaft GPHugo CiprianiОценок пока нет

- 1.14. 4p-8305 Cover Gp-Front HousingДокумент2 страницы1.14. 4p-8305 Cover Gp-Front HousingHugo CiprianiОценок пока нет

- 1.23. 4w-6874 Filter Gp-Engine Oil - RHДокумент3 страницы1.23. 4w-6874 Filter Gp-Engine Oil - RHHugo CiprianiОценок пока нет

- 1.13. 4p-8309 Cover Gp-Flywheel Housing - Rear StructureДокумент2 страницы1.13. 4p-8309 Cover Gp-Flywheel Housing - Rear StructureHugo CiprianiОценок пока нет

- 1.9. 4p-7316 Control Gp-CarburetorДокумент4 страницы1.9. 4p-7316 Control Gp-CarburetorHugo CiprianiОценок пока нет

- 1.10.1. 141-1484 Control Gp-Engine ElectronicДокумент3 страницы1.10.1. 141-1484 Control Gp-Engine ElectronicHugo CiprianiОценок пока нет

- 1.7.1. 100-7478 Carburetor AsДокумент2 страницы1.7.1. 100-7478 Carburetor AsHugo CiprianiОценок пока нет

- Performance Task 1Документ3 страницыPerformance Task 1Jellie May RomeroОценок пока нет

- Enochian Dragon Ritual PDFДокумент4 страницыEnochian Dragon Ritual PDFDenis NantelОценок пока нет

- Tesco True Results Casing Running in China Results in Total Depth PDFДокумент2 страницыTesco True Results Casing Running in China Results in Total Depth PDF123456ccОценок пока нет

- Review On AlgebraДокумент29 страницReview On AlgebraGraziela GutierrezОценок пока нет

- Pidsdps 2106Документ174 страницыPidsdps 2106Steven Claude TanangunanОценок пока нет

- Man As God Created Him, ThemДокумент3 страницыMan As God Created Him, ThemBOEN YATORОценок пока нет

- Speech On Viewing SkillsДокумент1 страницаSpeech On Viewing SkillsMera Largosa ManlaweОценок пока нет

- Activity Title: Learning Targets: Reference (S)Документ5 страницActivity Title: Learning Targets: Reference (S)Jhev LeopandoОценок пока нет

- WarringFleets Complete PDFДокумент26 страницWarringFleets Complete PDFlingshu8100% (1)

- C2 - Conveyors Diagram: Peso de Faja Longitud de CargaДокумент1 страницаC2 - Conveyors Diagram: Peso de Faja Longitud de CargaIvan CruzОценок пока нет

- Mechanical Production Engineer Samphhhhhle ResumeДокумент2 страницыMechanical Production Engineer Samphhhhhle ResumeAnirban MazumdarОценок пока нет

- Sociology As A Form of Consciousness - 20231206 - 013840 - 0000Документ4 страницыSociology As A Form of Consciousness - 20231206 - 013840 - 0000Gargi sharmaОценок пока нет

- Economic Review English 17-18Документ239 страницEconomic Review English 17-18Shashank SinghОценок пока нет

- National Anthems of Selected Countries: Country: United States of America Country: CanadaДокумент6 страницNational Anthems of Selected Countries: Country: United States of America Country: CanadaHappyОценок пока нет

- Recitation Math 001 - Term 221 (26166)Документ36 страницRecitation Math 001 - Term 221 (26166)Ma NaОценок пока нет

- Applications SeawaterДокумент23 страницыApplications SeawaterQatar home RentОценок пока нет

- Obligatoire: Connectez-Vous Pour ContinuerДокумент2 страницыObligatoire: Connectez-Vous Pour ContinuerRaja Shekhar ChinnaОценок пока нет

- Advanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsДокумент74 страницыAdvanced Chemical Engineering Thermodynamics (Cheg6121) : Review of Basic ThermodynamicsetayhailuОценок пока нет

- Design of Combinational Circuit For Code ConversionДокумент5 страницDesign of Combinational Circuit For Code ConversionMani BharathiОценок пока нет

- Lesson 3 - ReviewerДокумент6 страницLesson 3 - ReviewerAdrian MarananОценок пока нет

- The cardioprotective effect of astaxanthin against isoprenaline-induced myocardial injury in rats: involvement of TLR4/NF-κB signaling pathwayДокумент7 страницThe cardioprotective effect of astaxanthin against isoprenaline-induced myocardial injury in rats: involvement of TLR4/NF-κB signaling pathwayMennatallah AliОценок пока нет

- Catedral de SevillaДокумент28 страницCatedral de SevillaAnonymous LkgNmKeОценок пока нет

- Topic 3Документ21 страницаTopic 3Ivan SimonОценок пока нет

- Cooperative Learning: Complied By: ANGELICA T. ORDINEZAДокумент16 страницCooperative Learning: Complied By: ANGELICA T. ORDINEZAAlexis Kaye GullaОценок пока нет

- The Covenant Taken From The Sons of Adam Is The FitrahДокумент10 страницThe Covenant Taken From The Sons of Adam Is The FitrahTyler FranklinОценок пока нет

- NCP - Major Depressive DisorderДокумент7 страницNCP - Major Depressive DisorderJaylord Verazon100% (1)

- Wner'S Anual: Led TVДокумент32 страницыWner'S Anual: Led TVErmand WindОценок пока нет

- 20-Admission of PatientДокумент3 страницы20-Admission of Patientakositabon100% (1)

- Lecture 14 Direct Digital ManufacturingДокумент27 страницLecture 14 Direct Digital Manufacturingshanur begulaji0% (1)

- Meno's Paradox of Inquiry and Socrates' Theory of RecollectionДокумент10 страницMeno's Paradox of Inquiry and Socrates' Theory of RecollectionPhilip DarbyОценок пока нет