Академический Документы

Профессиональный Документы

Культура Документы

scaffoldProcedErectDismant PDF

Загружено:

resaОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

scaffoldProcedErectDismant PDF

Загружено:

resaАвторское право:

Доступные форматы

ENVIRONMENT, SAFETY, HEALTH, AND QUALITY DIVISION

Chapter 15: Ladder and Scaffold Safety

Scaffold Erecting and Dismantling Procedure

Product ID: 521 | Revision ID: 1543 | Date published: 20 September 2013 | Date effective: 20 September 2013

URL: http://www-group.slac.stanford.edu/esh/eshmanual/references/scaffoldProcedErectDismant.pdf

1 Purpose

The purpose of this procedure is to ensure scaffolding is adequate for the work to be performed and

properly erected and dismantled. It covers selecting, erecting, and dismantling all types of scaffolds. It

applies to workers, supervisors, scaffold qualified persons, scaffold custodians, and Facilities.

2 Procedure

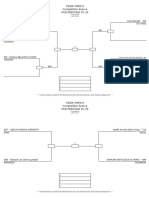

Step Person Action

Scaffold Request

1. Requester Contacts a scaffold qualified person for assistance (Competent and Qualified

Persons and Engineers)

2. Scaffold qualified person Assists the requester in determining the best method of accessing the work

area based on the work to be performed and the location of the work

Determines the need to screen the platform area based on the work being

performed, vehicle or personnel traffic, and other conditions

Requests the assistance of a fall protection competent or qualified person if

needed due to the work location, restrictions in the area or building the work is

located in, and choice of fall protection

3. Requester If a scaffold is to be used:

If requester has an approved standard system scaffold goes to step 6

Otherwise, submits a Facilities Service Desk request by using the Facilities

Service Request System or calling ext. 8901. Informs the Service Desk of the

name of the scaffold qualified person who is assisting with scaffold. (All

requests must contain the word scaffold within the request; presence of the

word scaffold triggers e-mails.)

Note: if a non-standard scaffold is required, enlists, with assistance of the scaffold

qualified person, a qualified engineer to design or review the design of that

scaffold, before submitting request to Facilities

Note: if the scaffold needed is not available at SLAC, follows Ladder and Scaffold

Safety: Scaffold Purchasing Procedure to rent or buy

4. Facilities Service Desk Generates service request documentation

5. Scaffold Is notified by requester (for standard system scaffolds) or Facilities Service Desk of

erector/dismantler request

supervisor

20 September 2013 SLAC-I-730-0A21C-027-R002 1 of 4

SLAC National Accelerator Laboratory

Environment, Safety, Health, and Quality Division

Chapter 15 | Scaffold Erecting and Dismantling Procedure

Step Person Action

6. Scaffold custodian Is contacted by the Facilities Service Desk, the scaffold erector/dismantler

supervisor, or the scaffold qualified person of the need to use the scaffold in his or

her care

Scaffold Erection

7. Scaffold Contacts the scaffold qualified person assisting the requester and the requester to

erector/dismantler Evaluate the work required

supervisor

Inspect the location

Confirm the best scaffold choice

Determine the scaffolds duration

Schedule day, time, and location for the scaffold erection

8. Scaffold Develops work plan

erector/dismantler Includes a scaffold qualified person, and, as appropriate, subject matter

supervisor experts (SMEs) in work planning and control (WPC) (see Chapter 2, Work

Planning and Control)

Reviews and includes procedures required by manufacturer as determined by

the type of scaffolding

Includes in the work plan the hold and inspection points the scaffold qualified

person requires

Has a toe board installed for platforms over 6 feet in height or as determined by

the scaffold qualified person

Ensures wood used in wood scaffolding, used indoors, is approved by the fire

marshal before its use

Ensures scaffold is guyed, tied-off, or braced if its height to base ratio exceeds

three to one

9. Scaffold Contacts the building / area manager to arrange for WPC release

erector/dismantler

supervisor

10. Scaffold Conducts pre-job/tailgate meeting with erectors/dismantlers to cover the work,

erector/dismantler hazards, and mitigations (scaffold qualified person may attend)

supervisor

11. Scaffold Supervises, with assistance of and scaffold qualified person, scaffold assembly to

erector/dismantler ensure standards and regulatory requirements are met

supervisor

12. Scaffold Erects scaffold per the instructions from the scaffold erector/dismantler

erector/dismantler supervisor, the scaffold qualified person, and training

Advises scaffold erector/dismantler supervisor when finished

13. Scaffold As soon as the scaffold is self-supporting, contacts the scaffold qualified person to

erector/dismantler inspect the scaffold before its release for use

supervisor

14. Scaffold qualified person Inspects scaffold and attaches at the access point(s) the appropriate tag:

Red: DO NOT USE, SCAFFOLD IS BEING ERECTED OR DISMANTLED

20 September 2013 SLAC-I-730-0A21C-027-R002 2 of 4

SLAC National Accelerator Laboratory

Environment, Safety, Health, and Quality Division

Chapter 15 | Scaffold Erecting and Dismantling Procedure

Step Person Action

Yellow: SCAFFOLD DOES NOT MEET OSHA REQUIREMENTS. WORKERS

MUST USE FALL PROTECTION WHEN WORKING FROM THIS SCAFFOLD

Green: SCAFFOLD IS OK FOR USE

Tag must include the scaffold capacity:

Light duty: 25 pounds per square foot

Medium duty: 50 pounds per square foot

Heavy duty: 75 pounds per square foot

Special duty: greater than 75 pounds per square foot as determined by a

qualified engineer

Places name, signature, and date of the inspection on the tag

15. Scaffold qualified person Informs the worker of the hazards, mitigations, and allowed uses of the scaffolding

16. Worker Uses the scaffold following requirements of Ladder and Scaffold Safety: Scaffold

Use Procedure

Scaffold Dismantling

17. Worker Informs requester that the work requiring a scaffold has ended

18. Requester Repeats steps 3 and 5, indicating the scaffold is to be dismantled

19. Scaffold Repeats steps 7 through 11

erector/dismantler Ensures the work site is left in a clean and safe condition

supervisor

Requests inspection from scaffold qualified person

20. Scaffold Dismantles scaffold per the instructions from the scaffold erector/dismantler

erector/dismantler supervisor, the scaffold qualified person, and training

Advises scaffold erector/dismantler supervisor when finished

21. Scaffold Ensures the work site is left in a clean and safe condition

erector/dismantler Requests inspection from scaffold qualified person

supervisor

22. Scaffold qualified person Inspects scaffold, requests changes or modifications if necessary to comply

with regulations, standards, and requirements

If scaffold requires maintenance or repair, informs the scaffold custodian and

places a DO NOT USE tag on the scaffold. Disposition of the scaffold is

performed in consultation with the scaffold custodian.

23. Scaffold custodian Ensures scaffold maintenance is performed if needed

Stores the scaffold according the manufacturers recommendations and/or as

instructed by the scaffold qualified person

3 Forms

The following forms are required by this procedure:

A scaffold tag, indicating status and capacity of the scaffold, and name and signature of the scaffold

qualified person and date of inspection

20 September 2013 SLAC-I-730-0A21C-027-R002 3 of 4

SLAC National Accelerator Laboratory

Environment, Safety, Health, and Quality Division

Chapter 15 | Scaffold Erecting and Dismantling Procedure

4 Recordkeeping

The following recordkeeping requirements apply for this procedure:

A scaffold tag must be attached to the scaffold as soon as possible by the scaffold qualified person

responsible for the scaffold. The scaffold tag is required for the duration of the scaffolds erection, use,

and dismantling.

5 References

SLAC Environment, Safety, and Health Manual (SLAC-I-720-0A29Z-001)

Chapter 15, Ladder and Scaffold Safety

Ladder and Scaffold Safety: Scaffold Use Procedure (SLAC-I-730-0A21C-029)

Ladder and Scaffold Safety: Scaffold Purchasing Procedure (SLAC-I-730-0A21C-028)

Chapter 2, Work Planning and Control

Chapter 45, Fall Protection

Other SLAC Documents

Competent and Qualified Persons and Engineers

Facilities Service Request System

20 September 2013 SLAC-I-730-0A21C-027-R002 4 of 4

Вам также может понравиться

- Sample Scaffold Erecting and Dismantling Procedure 1 PurposeДокумент4 страницыSample Scaffold Erecting and Dismantling Procedure 1 PurposegrandeОценок пока нет

- HSE Scaffold ChecklistДокумент3 страницыHSE Scaffold Checklisthalfbreed07Оценок пока нет

- Checklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingДокумент13 страницChecklist - Planning The Safe Use, Erection and Dismantling of Prefabricated or Modular ScaffoldingNoor Aimi Ayunie Mohd AzmiОценок пока нет

- RA Tower 0004 Dec 2011Документ8 страницRA Tower 0004 Dec 2011grandeОценок пока нет

- Saf 076Документ11 страницSaf 076celsocarvalhОценок пока нет

- Risk Assesment Form For ScaffoldingДокумент1 страницаRisk Assesment Form For Scaffoldingchandanprakash30Оценок пока нет

- Design Scaffold Instruction REV3Документ9 страницDesign Scaffold Instruction REV3le huy100% (1)

- Safety Precautions Durring Dismentling of StructresДокумент83 страницыSafety Precautions Durring Dismentling of StructresshujaОценок пока нет

- Working at HeightДокумент28 страницWorking at HeightazerОценок пока нет

- 7-26 Scaffold Procedure (RV)Документ7 страниц7-26 Scaffold Procedure (RV)Lee JungОценок пока нет

- Frames Erection ProcДокумент18 страницFrames Erection Procrobby_hipОценок пока нет

- Lufkin ME: Audit ChecklistДокумент18 страницLufkin ME: Audit ChecklistmohammedОценок пока нет

- HSE-Method Statement ScaffoldingДокумент32 страницыHSE-Method Statement ScaffoldingihsanОценок пока нет

- EHS Calendar For October 2019: SUN MON TUE WED THU FRI SATДокумент1 страницаEHS Calendar For October 2019: SUN MON TUE WED THU FRI SATSiddharth RanaОценок пока нет

- Accident CausationДокумент4 страницыAccident CausationJoe Mark Costan AvilaОценок пока нет

- CDM 2015 Simplified - What You Need To KnowДокумент118 страницCDM 2015 Simplified - What You Need To KnowAchilleas21Оценок пока нет

- Checklist For Scaffolding: Construction of Srr2-Construction Management ServicesДокумент3 страницыChecklist For Scaffolding: Construction of Srr2-Construction Management ServicesChayank TiwariОценок пока нет

- Confined SpaceДокумент19 страницConfined SpaceAamerОценок пока нет

- Work Procedure For The Construction of CO2 Cylinder HouseДокумент9 страницWork Procedure For The Construction of CO2 Cylinder HouseJoyce GordonioОценок пока нет

- 1414.01: Definition of Terms.: Republic of The PhilippinesДокумент50 страниц1414.01: Definition of Terms.: Republic of The PhilippinesRollie MimisОценок пока нет

- 5a Hazard ManagementДокумент45 страниц5a Hazard ManagementChoa Pei ShuangОценок пока нет

- Code of Construction Practice Part A: General Requirements - Revised 12 February 2014Документ124 страницыCode of Construction Practice Part A: General Requirements - Revised 12 February 2014thamestunnelОценок пока нет

- Falling Hazards in The Workplace - Protection & OSHA Standards PDFДокумент4 страницыFalling Hazards in The Workplace - Protection & OSHA Standards PDFMuhammad MalikОценок пока нет

- Scaffolding Plan - UGDC (FINAL) (3865)Документ13 страницScaffolding Plan - UGDC (FINAL) (3865)Ali hassanОценок пока нет

- Fire Prevention ChecklistДокумент1 страницаFire Prevention ChecklistJosiahОценок пока нет

- Subcontractor Competence / Resource Questionnaire: Commercial Services To CompleteДокумент31 страницаSubcontractor Competence / Resource Questionnaire: Commercial Services To CompleteNaba majeadОценок пока нет

- HSE-P-11 Planned General Inspection Issue 2.1Документ5 страницHSE-P-11 Planned General Inspection Issue 2.1eng20072007Оценок пока нет

- Company Name: Sacffold Location Completed By: Date: TimeДокумент1 страницаCompany Name: Sacffold Location Completed By: Date: Timesadashiv puneОценок пока нет

- Toolboxtalk2 Housekeeping PDFДокумент2 страницыToolboxtalk2 Housekeeping PDFSajid HussainОценок пока нет

- Scaffolding CertificatesДокумент1 страницаScaffolding CertificatesRAZAОценок пока нет

- Fall ProtectДокумент225 страницFall ProtectmadazОценок пока нет

- Risk Assessment Method Statement Documents: April 2007Документ11 страницRisk Assessment Method Statement Documents: April 2007Tamilchelvam MurogayahОценок пока нет

- E-Fact 02 - Preventing Vehicle Accidents in ConstructionДокумент9 страницE-Fact 02 - Preventing Vehicle Accidents in ConstructionAntonio LeiteОценок пока нет

- Doka FormworkДокумент124 страницыDoka FormworkTranタオОценок пока нет

- Site Inspection Workplace Trasport ChecklistДокумент6 страницSite Inspection Workplace Trasport ChecklisttipuОценок пока нет

- 13 Emergency Response: Project Employer Engineer ContractorДокумент9 страниц13 Emergency Response: Project Employer Engineer ContractorcenkunalОценок пока нет

- JHA Maintenance Tech HVACДокумент2 страницыJHA Maintenance Tech HVACMdavaОценок пока нет

- OHS PROC 113 BarricadesДокумент9 страницOHS PROC 113 BarricadesPhillip L100% (1)

- Appendix-B - Construction Safey Manual at ProjectsДокумент112 страницAppendix-B - Construction Safey Manual at ProjectsvinodОценок пока нет

- Scaffold Plan TOIPL PDFДокумент11 страницScaffold Plan TOIPL PDFDinesh Kanukollu100% (1)

- Painting, Taping, Texturing or Epoxy CoatingsДокумент1 страницаPainting, Taping, Texturing or Epoxy CoatingsHenryOdohОценок пока нет

- BG Tunisia: Maintenance DepartmentДокумент17 страницBG Tunisia: Maintenance Departmentghazi kallelОценок пока нет

- LSR Confined Space Toolbox TalkДокумент14 страницLSR Confined Space Toolbox TalkThura Aung100% (1)

- How To Document Accident ReportДокумент5 страницHow To Document Accident Reportcristina23Оценок пока нет

- Electrical Hazards ConstructionДокумент77 страницElectrical Hazards Constructiondh25881Оценок пока нет

- Msds of OxygenДокумент7 страницMsds of OxygensahilchemОценок пока нет

- Work at Height Rescue PlanДокумент5 страницWork at Height Rescue Plananthony murphyОценок пока нет

- Safe Working Procedure ExcavationsДокумент4 страницыSafe Working Procedure ExcavationsMunaku TafadzwaОценок пока нет

- Mobile Scaffold Inspection ChecklistДокумент3 страницыMobile Scaffold Inspection Checklistanthony murphyОценок пока нет

- Acetylene and Oxygen Safe Use For WeldingДокумент16 страницAcetylene and Oxygen Safe Use For WeldingShirishОценок пока нет

- Schedule For Inspection Nov 19Документ1 страницаSchedule For Inspection Nov 19Siddharth RanaОценок пока нет

- JSA #28 - Use of Hand ToolsДокумент1 страницаJSA #28 - Use of Hand ToolsSubham SohalОценок пока нет

- 1.0 Driver Induction, Agreements & ChecklistДокумент10 страниц1.0 Driver Induction, Agreements & Checklistdave.muir.25Оценок пока нет

- Ev02 - Brief Program For New Work at Height CampaignДокумент2 страницыEv02 - Brief Program For New Work at Height CampaignFrancis Enriquez TanОценок пока нет

- HSEQ - Calibration KitdddeeДокумент4 страницыHSEQ - Calibration KitdddeeSalim MuftahОценок пока нет

- De-Shuttering PermitДокумент1 страницаDe-Shuttering PermitHariharan Muthukrishanan100% (1)

- Toolbox Talk FormДокумент4 страницыToolbox Talk FormPrem Preetham DsouzaОценок пока нет

- Scaffold Erecting and Dismantling Procedure 1 PurposeДокумент4 страницыScaffold Erecting and Dismantling Procedure 1 PurposeHu Hin AngОценок пока нет

- 12 Des 2019Документ1 страница12 Des 2019resaОценок пока нет

- Lantai Bead Wire-ModelДокумент1 страницаLantai Bead Wire-ModelresaОценок пока нет

- Combine Drawing D11Документ4 страницыCombine Drawing D11resaОценок пока нет

- 16 Des 2019Документ2 страницы16 Des 2019resaОценок пока нет

- Pt. Pamayu Balimula Asri: QuotationДокумент4 страницыPt. Pamayu Balimula Asri: QuotationresaОценок пока нет

- Lantai Bead Wire-ModelДокумент1 страницаLantai Bead Wire-ModelresaОценок пока нет

- 12 PDFДокумент2 страницы12 PDFresaОценок пока нет

- CrepДокумент2 страницыCrepresaОценок пока нет

- Atap Transfarant SSWP PrintДокумент16 страницAtap Transfarant SSWP PrintresaОценок пока нет

- Atap Akar: Griya Bukit Jaya Block A.9 No.6 (Belakang Superindo)Документ2 страницыAtap Akar: Griya Bukit Jaya Block A.9 No.6 (Belakang Superindo)resaОценок пока нет

- Transfer Tank Cap. 1,5 TonsДокумент1 страницаTransfer Tank Cap. 1,5 TonsresaОценок пока нет

- QoutДокумент5 страницQoutresaОценок пока нет

- Pengecoran Jalan Area Gudang 1Документ1 страницаPengecoran Jalan Area Gudang 1resaОценок пока нет

- 12Документ2 страницы12resaОценок пока нет

- Summary SuitsДокумент18 страницSummary SuitsRajendra KumarОценок пока нет

- Francisco vs. House of Representatives: TOPIC: Political QuestionДокумент3 страницыFrancisco vs. House of Representatives: TOPIC: Political QuestionArlando G. ArlandoОценок пока нет

- Labatagos Vs Sandiganbayan, 183 SCRA 415Документ4 страницыLabatagos Vs Sandiganbayan, 183 SCRA 415AddAllОценок пока нет

- Nonimmigrant Visa - Confirmation PageДокумент2 страницыNonimmigrant Visa - Confirmation PageHemanth Kumar SОценок пока нет

- State of Wisconsin v. Thomas G. SmithДокумент142 страницыState of Wisconsin v. Thomas G. SmithDell CameronОценок пока нет

- Civil Liberties Union V Executive Secretary Case DigestДокумент2 страницыCivil Liberties Union V Executive Secretary Case DigestCharmaine Mejia100% (1)

- 22 - Amicus Brief For Mark Ridley-Thomas Appeal by Former California Public OfficialsДокумент26 страниц22 - Amicus Brief For Mark Ridley-Thomas Appeal by Former California Public OfficialsCeleste FremonОценок пока нет

- Dickie Freling Wimmer v. County Commission President Woodrow Cook Chief Sheriff Harold L. Hatfield Chief Deputy Sheriff Jimmy Craft Jailer Dorthe Bolt Jailer Nancy Rust Jailer Brenda Perdue, 774 F.2d 68, 4th Cir. (1985)Документ12 страницDickie Freling Wimmer v. County Commission President Woodrow Cook Chief Sheriff Harold L. Hatfield Chief Deputy Sheriff Jimmy Craft Jailer Dorthe Bolt Jailer Nancy Rust Jailer Brenda Perdue, 774 F.2d 68, 4th Cir. (1985)Scribd Government DocsОценок пока нет

- Administrative LawДокумент216 страницAdministrative Lawzahids2kОценок пока нет

- Parliamentary PrivilegesДокумент3 страницыParliamentary PrivilegesPrasun TiwariОценок пока нет

- BUSA 3000 Final Study GuideДокумент13 страницBUSA 3000 Final Study GuideKhadija MemonОценок пока нет

- Tendernotice 1Документ16 страницTendernotice 1vijyant2512100% (1)

- Health and Safety CommitteeДокумент26 страницHealth and Safety CommitteeFlorence GonzalezОценок пока нет

- Hire Purchase AgreementДокумент4 страницыHire Purchase AgreementJosphine WaruiОценок пока нет

- Gauck v. KaramianДокумент16 страницGauck v. KaramianEric GoldmanОценок пока нет

- Tasik Open 6 Hari Ke 3Документ70 страницTasik Open 6 Hari Ke 3Andhika Purnama HerwindoОценок пока нет

- Potsdam Village Police Dept. Blotter Sept. 4, 2016Документ4 страницыPotsdam Village Police Dept. Blotter Sept. 4, 2016NewzjunkyОценок пока нет

- Ancient GraveyardsДокумент48 страницAncient Graveyardsalicjalicja100% (1)

- Notice 11 FINAL Charges and PresentmentДокумент81 страницаNotice 11 FINAL Charges and PresentmentPennLive100% (21)

- Prohibition On Insider Trading of Securities As Per Companies Act, 2013Документ2 страницыProhibition On Insider Trading of Securities As Per Companies Act, 2013Praneeth Srinivasa GundapuneediОценок пока нет

- Annex C.1Документ1 страницаAnnex C.1Eric OlayОценок пока нет

- Presentation TLEДокумент17 страницPresentation TLEMissy T. LopeОценок пока нет

- SOCIAL SCIENCE-Q&A-RationalizationДокумент37 страницSOCIAL SCIENCE-Q&A-RationalizationCza Mae ArsenalОценок пока нет

- Varadero V Insular LumberДокумент4 страницыVaradero V Insular LumbernikoОценок пока нет

- Persons 15 48Документ195 страницPersons 15 48penelopeОценок пока нет

- People V Dela CernaДокумент3 страницыPeople V Dela CernaSocОценок пока нет

- Chem 16 Review Question 3rd Long Exam - Answer KeyДокумент8 страницChem 16 Review Question 3rd Long Exam - Answer KeyWeaverly Colleen LeeОценок пока нет

- FAQ Career in Switzerland For Foreign Graduates - ENДокумент4 страницыFAQ Career in Switzerland For Foreign Graduates - ENMichael KuchapinОценок пока нет

- Philippine Constitution QuizДокумент8 страницPhilippine Constitution QuizKurt Patrick VillanuevaОценок пока нет

- Manila Standard Today - April 27, 2012 IssueДокумент18 страницManila Standard Today - April 27, 2012 IssueManila Standard TodayОценок пока нет