Академический Документы

Профессиональный Документы

Культура Документы

Koin 080T310

Загружено:

PHAM THANH TUОригинальное название

Авторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Koin 080T310

Загружено:

PHAM THANH TUАвторское право:

Доступные форматы

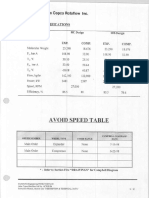

Model: 80RZG

190--600 V Gas

Standard Features

D Kohler Co. provides one-source responsibility for the generating

system and accessories.

D The generator set and its components are prototype-tested,

Ratings Range factory-built, and production-tested.

60 Hz 50 Hz D The 60 Hz generator set offers a UL 2200 listing.

Standby: kW 61--81 55--73 D The generator set accepts rated load in one step.

kVA 61--101 55--87

D A one-year limited warranty covers all systems and components.

Prime: kW 56--75 51--66 Two-, five-, and ten-year extended warranties are also available.

kVA 56--94 51--80

D Alternator features:

d The Fast-Responset III wound field (WF) design alternator

provides excellent voltage response and short-circuit capability

using an auxiliary power brushless exciter.

d The unique Fast-Responset II excitation system delivers

excellent voltage response and short circuit capability using a

permanent magnet (PM)-excited alternator.

d The brushless, rotating-field alternator has broadrange

reconnectability.

D Other features:

d A rugged industrial gas engine delivers rated power at

1800 rpm (60 Hz) and 1500 rpm (50 Hz).

d Controllers are available for all applications. See controller

features inside.

d The electronic, isochronous governor incorporates an

integrated drive-by-wire throttle body actuator delivering

precise frequency regulation.

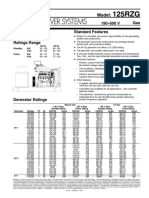

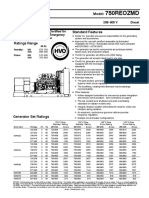

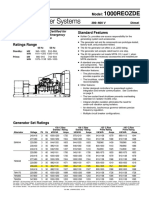

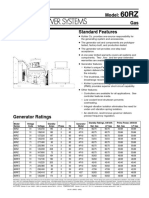

Generator Set Ratings

Natural Gas LP Gas

130_C Rise 105_C Rise 130_C Rise 105_C Rise

Standby Rating Prime Rating Standby Rating Prime Rating

Alternator Voltage Ph Hz kW/kVA Amps kW/kVA Amps kW/kVA Amps kW/kVA Amps

120/208 3 60 80/100 278 73/91 253 80/100 278 73/91 253

127/220 3 60 80/100 262 74/93 243 80/100 262 74/93 243

120/240 3 60 80/100 241 72/90 217 80/100 241 72/90 217

120/240 1 60 61/61 254 56/56 233 61/61 254 56/56 233

139/240 3 60 81/101 244 75/94 226 81/101 244 75/94 226

220/380 3 60 75/94 142 69/86 131 75/94 142 69/86 131

277/480 3 60 81/101 122 75/94 113 81/101 122 75/94 113

347/600 3 60 81/101 97 75/94 90 81/101 97 75/94 90

4S7W/4S7

110/190 3 50 66/82 249 60/75 228 70/87 264 64/80 243

115/200 3 50 66/83 240 61/76 219 70/87 251 64/80 231

120/208 3 50 66/83 230 61/76 211 70/87 241 64/80 222

110/220 3 50 66/82 215 60/75 197 66/83 218 60/75 197

110/220 1 50 55/55 250 51/51 232 55/55 250 51/51 232

220/380 3 50 66/82 125 60/75 114 70/87 132 64/80 122

230/400 3 50 66/83 120 61/76 110 70/87 126 64/80 115

240/416 3 50 66/83 115 61/76 105 70/87 121 64/80 111

120/240 1 60 80/80 333 71/71 296 80/80 333 73/73 304

4V9W/4V9

110/220 1 50 65/65 295 59/59 268 73/73 332 66/66 300

RATINGS: All three-phase units are rated at 0.8 power factor. All single-phase units are rated at 1.0 power factor. Standby Ratings: Standby ratings apply to installations served by a reliable utility source.

The standby rating is applicable to varying loads for the duration of a power outage. There is no overload capability for this rating. Ratings are in accordance with ISO-3046/1, BS 5514, AS 2789, and DIN 6271.

Prime Power Ratings: Prime power ratings apply to installations where utility power is unavailable or unreliable. At varying load, the number of generator set operating hours is unlimited. A 10% overload

capacity is available for one hour in twelve. Ratings are in accordance with ISO-8528/1, overload power in accordance with ISO-3046/1, BS 5514, AS 2789, and DIN 6271. For limited running time and base

load ratings, consult the factory. Obtain the technical information bulletin (TIB-101) on ratings guidelines for the complete ratings definitions. The generator set manufacturer reserves the right to change the

design or specifications without notice and without any obligation or liability whatsoever. GENERAL GUIDELINES FOR DERATION: Altitude: Derate 1.3% per 100 m (328 ft.) elevation above 200 m (656 ft.).

Temperature: Derate 3.0% per 10_C (18_F) temperature above 25_C (77_F). For units having enclosures with enclosed silencers, add 10_C (18_F) to the ambient temperature. Dual fuel engines are optimized

to run on the primary fuel (natural gas) and, as a result, the LPG ratings may not be attained. For dual fuel engines, use the natural gas ratings for both the primary and secondary fuels.

G4-78 (80RZG) 1/06p

Alternator Specifications

Specifications Alternator D NEMA MG1, IEEE, and ANSI standards compliance for

Manufacturer Kohler

temperature rise and motor starting.

Type 4-Pole, Rotating-Field D Sustained short-circuit current of up to 300% of the rated

Exciter type current for up to 10 seconds.

Wound field (WF) Wound Exciter Field

with Separate Excitation D Sustained short-circuit current enabling downstream circuit

Power Winding breakers to trip without collapsing the alternator field.

Permanent magnet (PM) Brushless, Permanent- D Self-ventilated and dripproof construction.

Magnet

Leads: quantity, type D Vacuum-impregnated windings with fungus-resistant epoxy

4S7W/4S7 12, Reconnectable varnish for dependability and long life.

4V9W/4V9 4, 110--120/220--240

D Superior voltage waveform from a two-thirds pitch stator and

Voltage regulator Solid State, Volts/Hz skewed rotor.

Insulation: NEMA MG1

Material Class H D Fast-Responset III wound field (WF) brushless alternator

Temperature rise 130_C, Standby with auxiliary power brushless exciter for excellent load

Bearing: quantity, type 1, Sealed response.

Coupling Flexible Disc D Fast-Responset II brushless alternator with brushless

Amortisseur windings Full exciter for excellent load response.

Voltage regulation, no-load to full-load

Wound field (WF) alternator 0.25% Average

Permanent magnet (PM) alternator 2% Average

550 controller (with 0.5% drift 3-Phase Sensing, Specifications Alternator

due to temperature variation) 0.25%

Peak motor starting kVA: (35% dip for voltages below)

Unbalanced load capability 100% of Rated Standby 480 V, 380 V 4S7W/4S7 (12 lead) 270 (60Hz), 190 (50Hz)

Current

240 V, 220 V 4V9W/4V9 (4 lead) 246 (60Hz), 213 (50Hz)

One-step load acceptance 100% of Rating

Application Data

Engine Engine Electrical

Engine Specifications 60 Hz 50 Hz Engine Electrical System 60 Hz 50 Hz

Manufacturer General Motors Ignition system Individual Coil

Engine: model, type Industrial Powertrain Near Plug Ignition

Vortec 8.1 L, 4-Cycle Battery charging alternator:

Natural Aspiration Ground (negative/positive) Negative

Cylinder arrangement V-8 Volts (DC) 12

Displacement, L (cu. in.) 8.1 (496) Ampere rating 70

Bore and stroke, mm (in.) 108 x 111 (4.25 x 4.37) Starter motor rated voltage (DC) 12

Compression ratio 9.1:1 Battery, recommended cold cranking

amps (CCA):

Piston speed, m/min. (ft./min.) 399 (1311) 332 (1092)

Qty., rating for --18_C (0F) One, 630

Main bearings: quantity, type Alum. Lead Silicon Alloy

Battery voltage (DC) 12

Rated rpm 1800 1500

Max. power at rated rpm, kW (HP) 112 (150) 92 (123) Fuel

Cylinder head material Cast Iron Fuel System 60 Hz 50 Hz

Piston type and material Strutless Flat Top,

Fuel type LP Gas or

Hypereutectic Cast Alum.

Natural Gas

Crankshaft material Cast Nodular Undercut

Rolled Fillet Fuel supply line inlet 1 NPTF

Valve (exhaust) material Int.-A193 Exh. Inconel Natural gas/LPG fuel supply pressure,

measured at the generator set fuel inlet

Governor type Electronic downstream of any fuel system

Frequency regulation, no-load to full-load Isochronous equipment accessories, kPa (in. H2O) 1.74--2.74 (7.0--11.0)

Frequency regulation, steady state 0.5%

Frequency Field-Convertible Fuel Composition Limits * Nat. Gas LP Gas

Air cleaner type, all models Dry Methane, % by volume 90 min.

Ethane, % by volume 4.0 max.

Exhaust Propane, % by volume 1.0 max. 85 min.

Exhaust System 60 Hz 50 Hz Propene, % by volume 0.1 max. 5.0 max.

Exhaust manifold type Dry C4 and higher, % by volume 0.3 max. 2.5 max.

Exhaust flow at rated kW, m3/min. (cfm) 17.5 (620) 13.8 (490) Sulfur, ppm mass 25 max.

Exhaust temperature at rated kW, dry Lower heating value,

exhaust, _C (_F) kJ/m3 (Btu/ft3), min. 26.6 (890) 67.5 (2260)

677 (1250)

* Fuels with other compositions may be acceptable. If your fuel is

Maximum allowable back pressure,

kPa (in. Hg) 10.2 (3.0) outside the listed specifications, contact your local distributor for

further analysis and advice.

Exhaust outlet size at engine hookup,

mm (in.) 89 (3.5)

G4-78 (80RZG) 1/06p

Application Data

Lubrication LP Gas, m3/hr. (cfh) at % load Standby Rating

Lubricating System 60 Hz 50 Hz 100% 12.0 (425) 9.1 (321)

Type Full Pressure 75% 9.8 (345) 7.3 (257)

Oil pan capacity, L (qt.) 7.6 (8.0) 50% 7.4 (261) 5.6 (200)

25% 5.0 (177) 4.0 (142)

Oil pan capacity with filter, L (qt.) 8.0 (8.5)

0% 2.9 (104) 2.2 (79)

Oil filter: quantity, type 1, Cartridge

LP Gas, m3/hr. (cfh) at % load Prime Rating

Cooling 100% 11.2 (396) 8.4 (298)

75% 9.1 (322) 6.8 (241)

Radiator System 60 Hz 50 Hz 50% 7.0 (246) 5.4 (189)

Ambient temperature, _C (_F) 50 (122) 25% 4.8 (170) 3.9 (137)

Engine jacket water capacity, L (gal.) 10.0 (2.6) 0% 2.9 (104) 2.2 (79)

Radiator system capacity, including w Fuel consumption is based on 1015 Btu/standard cu. ft. natural gas.

engine, L (gal.) 25.7 (6.8)

Engine jacket water flow, Lpm (gpm) 125 (33) 102 (27) LP vapor conversion factors:

Heat rejected to cooling water at rated 8.58 ft.3 = 1 lb.

kW, dry exhaust, kW (Btu/min.) 62 (3540) 54 (3080) 0.535 m3 = 1 kg.

Water pump type Centrifugal 36.39 ft.3 = 1 gal.

Fan diameter, including blades, mm (in.) 599 (23.6)

Fan, kWm (HP) 6.7 (9.0) 3.7 (5.0)

Max. restriction of cooling air, intake and Controllers

discharge side of radiator, kPa (in. H2O) 0.125 (0.5)

Remote Radiator System[ 60 Hz 50 Hz

Exhaust manifold type Dry

Connection sizes:

Water inlet, ID hose, mm (in.) 44.45 (1.75)

Water outlet, ID hose, mm (in.) 38.10 (1.50)

Decision-Makert 550 Controller

Static head allowable Audiovisual annunciation with NFPA 110 Level 1 capability.

above engine, kPa (ft. H2O) 4.32 (17.0)

Programmable microprocessor logic and digital display features.

[ Contact your local distributor for cooling system options and Alternator safeguard circuit protection.

specifications based on your specific requirements. 12- or 24-volt engine electrical system capability.

Remote start, remote annunciation, and remote communication options.

Operation Requirements Refer to G6-46 for additional controller features and accessories.

Air Requirements 60 Hz 50 Hz

Radiator-cooled cooling air,

m3/min. (scfm)] 198 (7000) 153 (5400)

Cooling air required for generator set

when equipped with city water cooling or

remote radiator, based on 14_C (25_F)

rise and ambient temperature of 29_C

(85_F), m3/min. (cfm) 187 (6600) 162 (5720)

Combustion air, m3/min. (cfm) 5.7 (200) 4.3 (150) Decision-Makert 3+, 16-Light Controller

Heat rejected to ambient air: Audiovisual annunciation with NFPA 110 Level 1 capability.

Engine, kW (Btu/min.) 40 (2300) 32 (1820) Microprocessor logic, AC meters, and engine gauge features.

Alternator, kW (Btu/min.) 11.8 (670) 13.3 (755) 12- or 24-volt engine electrical system capability.

] Air density = 1.20 kg/m3 (0.075 lbm/ft3) Remote start, prime power, and remote annunciation options.

Refer to G6-30 for additional controller features and accessories.

Fuel Consumptionw 60 Hz 50 Hz

Natural Gas, m3/hr. (cfh) at % load Standby Rating

100% 28.7(1012) 24.7 (873)

75% 23.5 (831) 19.3 (680)

50% 18.9 (667) 14.1 (498)

25% 12.4 (437) 9.5 (337)

0% 7.3 (257) 5.6 (198)

Natural Gas, m3/hr. (cfh) at % load Prime Rating

Decision-Makert 1 Controller

100% 26.8 (946) 22.7 (803)

Single-light annunciation and basic controls with NFPA capability.

75% 22.3 (786) 17.9 (631)

Relay logic, AC meters, and engine gauge features.

50% 17.7 (625) 13.3 (469)

12-volt engine electrical system capability only.

25% 11.9 (420) 9.2 (324) Remote or automatic start options.

0% 7.3 (257) 5.6 (198) Refer to G6-29 for additional controller features and accessories.

Note: Not available with 600-volt alternator.

G4-78 (80RZG) 1/06p

KOHLER CO., Kohler, Wisconsin 53044 USA Kohler Power Systems

Phone 920-565-3381, Fax 920-459-1646 Asia Pacific Headquarters

For the nearest sales and service outlet in the 7 Jurong Pier Road

US and Canada, phone 1-800-544-2444 Singapore 619159

KohlerPowerSystems.com Phone (65) 6264-6422, Fax (65) 6264-6455

Additional Standard Features Literature and Maintenance

D Alternator Protection (standard with 550 controller) - General Maintenance Literature Kit

D Battery Rack and Cables - Maintenance Kit (includes standard air, oil, and fuel filters)

D Electronic, Isochronous Governor - NFPA 110 Literature

D Gas Fuel System (includes fuel mixer, secondary gas regulator, - Overhaul Literature Kit

gas solenoid valve, and flexible fuel line between the engine

and the skid-mounted fuel system components) - Production Literature Kit

D Integral Vibration Isolation Controller (550 and 16-Light)

D Oil Drain Extension - Common Failure Relay Kit

D Operation and Installation Literature - Communication Products and PC Software (550 controller only)

- Customer Connection Kit

Available Accessories - Dry Contact Kit (isolated alarm)

Enclosed Unit - Engine Prealarm Sender Kit

- Sound Enclosure (with enclosed critical silencer) - Local Emergency Stop Kit

- Weather Enclosure (with enclosed critical silencer) - Prime Power Switch (550 controller only)

- Weather Housing (with roof-mounted silencer) - Remote Annunciator Panel

- Remote Audiovisual Alarm Panel

Open Unit

- Remote Emergency Stop Kit

- Exhaust Silencer, Critical (kits: PA-324292, PA-324470)

- Remote Mounting Cable

- Flexible Exhaust Connector, Stainless Steel

- Run Relay Kit

Cooling System

Miscellaneous Accessories

- Block Heater

[recommended for ambient temperatures below 10C (50F)] - _______________________________________________

- City Water Cooling - _______________________________________________

- Radiator Duct Flange - _______________________________________________

- Remote Radiator Cooling - _______________________________________________

- _______________________________________________

Fuel System

- _______________________________________________

- Automatic Changeover (natural gas to LP gas) - _______________________________________________

- Flexible Fuel Line - _______________________________________________

(required when the generator set skid is spring mounted)

- Gas Filter

- LP Gas Liquid Withdrawal

- Manual Valve

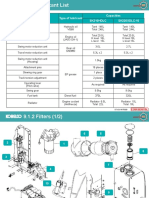

Dimensions and Weights

Overall Size, L x W x H, mm (in.):

- Secondary Gas Solenoid Valve Wide Skid 2400 x 1040 x 1484 (94.5 x 40.9 x 58.4)

Electrical System Narrow Skid 2400 x 865 x 1484 (94.5 x 34.1 x 58.4)

Weight (radiator model), wet, kg (lb.): 1134 (2500)

- Battery

- Battery Charger, Equalize/Float Type

- Battery Heater

Engine and Alternator

- Alternator, Wound Field (WF)

- Alternator, Permanent Magnet (PM)

H

- Air Cleaner Restrictor Indicator

- Alternator Strip Heater

- CSA Certification

- Engine Fluids (oil and coolant) Added

- Line Circuit Breaker (NEMA1 enclosure) W L

- Line Circuit Breaker with Shunt Trip (NEMA1 enclosure) NOTE: This drawing is provided for reference only and should not be used for planning

installation. Contact your local distributor for more detailed information.

- Optional Alternators

DISTRIBUTED BY:

- Rated Power Factor Testing

- Rodent Guards

- Safeguard Breaker (not available with 550 controller)

- Voltage Regulation, 1%

- Voltage Regulator Sensing, 3-Phase

2000, 2001, 2002, 2003, 2004, 2005, 2006 by Kohler Co. All rights reserved.

G4-78 (80RZG) 1/06p

Вам также может понравиться

- SsangYong Actyon Service Manual PDFДокумент2 172 страницыSsangYong Actyon Service Manual PDFVictor Abel Ovalle Retamal94% (35)

- CFmoto - 150T - E-Jewel - Maintenance - Manual PDFДокумент241 страницаCFmoto - 150T - E-Jewel - Maintenance - Manual PDFAnna Ryan33% (3)

- Kohler Model 45rz 45kw Natural Gas Generator SetДокумент4 страницыKohler Model 45rz 45kw Natural Gas Generator SetRebecca Winfrey100% (1)

- VR843C PartsДокумент540 страницVR843C PartsVictor Manuel Rivera80% (5)

- Kohler Model 80rozj Spec SheetДокумент4 страницыKohler Model 80rozj Spec SheetDewis100% (1)

- Kohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFДокумент4 страницыKohler 30REOZJB John Deere 3029TF150 Spec Sheet PDFEric LaguipoОценок пока нет

- TM 9-1803A Incl EngineДокумент76 страницTM 9-1803A Incl Enginegwa4940% (1)

- Honda CBF600 Owner's Manual 2006Документ148 страницHonda CBF600 Owner's Manual 2006solerviОценок пока нет

- Kohler 80RZG Spec SheetДокумент4 страницыKohler 80RZG Spec SheetRomanvi1980Оценок пока нет

- Kohler 125rzg Spec SheetДокумент4 страницыKohler 125rzg Spec SheetRomanvi1980Оценок пока нет

- 125 RZG Technical Data Sheet - Prime DutyДокумент4 страницы125 RZG Technical Data Sheet - Prime DutyAdewunmi OlufemiОценок пока нет

- Kohler 2000ROZD4 Spec SheetДокумент4 страницыKohler 2000ROZD4 Spec SheetKhaled KamelОценок пока нет

- Kholer Generator 750REOZMD Spec SheetДокумент4 страницыKholer Generator 750REOZMD Spec SheetNicholas BrennanОценок пока нет

- Kohler 150RZGB Spec SheetДокумент4 страницыKohler 150RZGB Spec SheetRomanvi1980Оценок пока нет

- Kohler 800rozmc SpecДокумент4 страницыKohler 800rozmc Speclilama45-1Оценок пока нет

- 1000REOZDEДокумент4 страницы1000REOZDELanh TranОценок пока нет

- Reozjd: ModelДокумент4 страницыReozjd: ModelluislunarОценок пока нет

- Reozje: ModelДокумент4 страницыReozje: ModelLuis LunarОценок пока нет

- 1500REOZDBДокумент4 страницы1500REOZDBRodrigoОценок пока нет

- Kohler 50rozj Spec SheetДокумент4 страницыKohler 50rozj Spec SheetRomanvi1980Оценок пока нет

- Ratings Range: Tier 2 EPA-Certified For Stationary Emergency ApplicationsДокумент6 страницRatings Range: Tier 2 EPA-Certified For Stationary Emergency ApplicationsBryan FrancoОценок пока нет

- Reozjc: Standard Features Ratings RangeДокумент4 страницыReozjc: Standard Features Ratings RangeJulio CesarОценок пока нет

- 63530b32af2a5a8cd858fc94 Kohler 80REOZJB GeneratorДокумент4 страницы63530b32af2a5a8cd858fc94 Kohler 80REOZJB GeneratorYennifer HernandezОценок пока нет

- KohleerДокумент6 страницKohleerJuan RenteriaОценок пока нет

- 1600reozm 0318Документ3 страницы1600reozm 0318Xuân Huy NguyễnОценок пока нет

- Detroit Diesel Spectrum 600DS 4 Spec Sheet PDFДокумент4 страницыDetroit Diesel Spectrum 600DS 4 Spec Sheet PDF6PMK IecaОценок пока нет

- Kohler 150rozj Spec Sheet PDFДокумент4 страницыKohler 150rozj Spec Sheet PDFjuan_samaniego_60Оценок пока нет

- 1600REOZMДокумент4 страницы1600REOZMperi irawanОценок пока нет

- Kohler 60RZ Spec SheetДокумент4 страницыKohler 60RZ Spec SheetRomanvi1980Оценок пока нет

- 300reozd S60Документ4 страницы300reozd S60David J SandersОценок пока нет

- Kohler 60reozjb Spec SheetДокумент4 страницыKohler 60reozjb Spec SheetJessica Tatiana Muñoz OrtizОценок пока нет

- 1600reozm 0720Документ3 страницы1600reozm 0720paksongchoiОценок пока нет

- Specifications g5587Документ6 страницSpecifications g5587spamnest2Оценок пока нет

- 1250reozm 0318Документ3 страницы1250reozm 0318Xuân Huy NguyễnОценок пока нет

- Reozk: Standard Features Ratings RangeДокумент4 страницыReozk: Standard Features Ratings RangeAzizullahОценок пока нет

- 1250reozm 0720Документ3 страницы1250reozm 0720paksongchoiОценок пока нет

- G4-277 (7-18b) 60RCLA (KG6208) SpecДокумент4 страницыG4-277 (7-18b) 60RCLA (KG6208) SpecService Brags & Hayes, Inc.Оценок пока нет

- 2250reozm 0720Документ3 страницы2250reozm 0720paksongchoiОценок пока нет

- 800reozm 0318Документ3 страницы800reozm 0318Xuân Huy NguyễnОценок пока нет

- Reozt Reozt: Model: ModelДокумент4 страницыReozt Reozt: Model: Modelrendi valentinoОценок пока нет

- kg100r Spec SheetДокумент4 страницыkg100r Spec SheetFranklin Alfredo Colmenares MarchanОценок пока нет

- KOHLER - g4287Документ4 страницыKOHLER - g4287Edmund LimОценок пока нет

- G4-276 (7-18b) 48RCLB (KG6208) SpecДокумент4 страницыG4-276 (7-18b) 48RCLB (KG6208) SpecService Brags & Hayes, Inc.Оценок пока нет

- 1800reozm Specification KohlerДокумент4 страницы1800reozm Specification KohlerTrần Quang TuyênОценок пока нет

- Model:: Gas 110 - 600 VДокумент4 страницыModel:: Gas 110 - 600 VTomás GonzalezОценок пока нет

- Manual Kohler 30RYGДокумент4 страницыManual Kohler 30RYGjtamez2009Оценок пока нет

- Industrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantДокумент7 страницIndustrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantXuân Huy Nguyễn100% (1)

- 1800reozm 0720Документ3 страницы1800reozm 0720paksongchoiОценок пока нет

- 2000reozm4 10aДокумент4 страницы2000reozm4 10aShahzad AliОценок пока нет

- Cummins 3000 Kva Qsk78 Series Diesel Generator c3000d5Документ4 страницыCummins 3000 Kva Qsk78 Series Diesel Generator c3000d5Douglas Alberto Gomez MartinezОценок пока нет

- Thong So Ky ThuatДокумент6 страницThong So Ky ThuatBảo GiaОценок пока нет

- Generator Specifications PDFДокумент6 страницGenerator Specifications PDFjohn patrick camoОценок пока нет

- 2000reozm 0318Документ3 страницы2000reozm 0318Xuân Huy NguyễnОценок пока нет

- Perkins Diesel Generator P640pu 580kwДокумент4 страницыPerkins Diesel Generator P640pu 580kwKalam TukimanОценок пока нет

- Industrial Diesel Generator Set - 50 HZ - Fuel Consumption OptimizedДокумент7 страницIndustrial Diesel Generator Set - 50 HZ - Fuel Consumption OptimizedXuân Huy NguyễnОценок пока нет

- Ratings Range: Tier 4 EPA-Certified For Stationary, Prime, Continuous ApplicationsДокумент6 страницRatings Range: Tier 4 EPA-Certified For Stationary, Prime, Continuous Applicationsayman saberОценок пока нет

- Industrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantДокумент7 страницIndustrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantXuân Huy NguyễnОценок пока нет

- Industrial Diesel Generator Set - : 50 HZ - Fuel Consumption OptimizedДокумент7 страницIndustrial Diesel Generator Set - : 50 HZ - Fuel Consumption OptimizedXuân Huy NguyễnОценок пока нет

- Industrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantДокумент8 страницIndustrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantXuân Huy NguyễnОценок пока нет

- Industrial Diesel Generator Set - : 50 HZ - Fuel Consumption OptimizedДокумент8 страницIndustrial Diesel Generator Set - : 50 HZ - Fuel Consumption OptimizedXuân Huy NguyễnОценок пока нет

- 38RCLДокумент4 страницы38RCLAdmin BisnisОценок пока нет

- Industrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantДокумент8 страницIndustrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantXuân Huy NguyễnОценок пока нет

- Industrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantДокумент7 страницIndustrial Diesel Generator Set - 50 HZ - Emission Optimized - EPA Tier 2 CompliantXuân Huy NguyễnОценок пока нет

- CMGPP-FD-EL-LST-0001 - Electrical Load List - Rev.0Документ11 страницCMGPP-FD-EL-LST-0001 - Electrical Load List - Rev.0PHAM THANH TUОценок пока нет

- 12 Data Required For The Estimate For Exact EstimateДокумент1 страница12 Data Required For The Estimate For Exact EstimatePHAM THANH TUОценок пока нет

- CMGPP-FD-EL-SPE-0001 Specification For AC Induction Motor - Rev.0Документ14 страницCMGPP-FD-EL-SPE-0001 Specification For AC Induction Motor - Rev.0PHAM THANH TUОценок пока нет

- Solar Analytical TroubleshootingДокумент2 страницыSolar Analytical TroubleshootingPHAM THANH TUОценок пока нет

- 9 Strainer Pressurehydro TestДокумент1 страница9 Strainer Pressurehydro TestPHAM THANH TUОценок пока нет

- 14 Experience List of FASECO CoДокумент8 страниц14 Experience List of FASECO CoPHAM THANH TUОценок пока нет

- 18 Screen Weld SPECДокумент2 страницы18 Screen Weld SPECPHAM THANH TUОценок пока нет

- 8 Everything in The Strainer Spare PartsДокумент1 страница8 Everything in The Strainer Spare PartsPHAM THANH TUОценок пока нет

- Tees Trainers Proof 2Документ12 страницTees Trainers Proof 2Juan P RuizОценок пока нет

- 17 Pros and Cons of Y Type and T TypeДокумент3 страницы17 Pros and Cons of Y Type and T TypePHAM THANH TUОценок пока нет

- 20 What Is Opening RatioДокумент1 страница20 What Is Opening RatioPHAM THANH TUОценок пока нет

- 6Документ1 страница6PHAM THANH TUОценок пока нет

- Dụng Cụ Lắp Vào Đai Ốc Cân Bằng K-02: Section N-N Scale 1: 3Документ1 страницаDụng Cụ Lắp Vào Đai Ốc Cân Bằng K-02: Section N-N Scale 1: 3PHAM THANH TUОценок пока нет

- Speaking Sample Task - Part 1 PDFДокумент1 страницаSpeaking Sample Task - Part 1 PDFwaheed_iiuiОценок пока нет

- GrassДокумент1 страницаGrassPHAM THANH TUОценок пока нет

- Grass StrawДокумент1 страницаGrass StrawPHAM THANH TUОценок пока нет

- Lam Them KCM 28.09Документ2 страницыLam Them KCM 28.09PHAM THANH TUОценок пока нет

- Speaking Sample Task - Part 1 PDFДокумент1 страницаSpeaking Sample Task - Part 1 PDFwaheed_iiuiОценок пока нет

- Cavitation Corrosion/Erosion Engine Conditions Effect LinersДокумент2 страницыCavitation Corrosion/Erosion Engine Conditions Effect LinersPHAM THANH TU100% (1)

- Design ConditionДокумент1 страницаDesign ConditionPHAM THANH TUОценок пока нет

- RegulatorsДокумент32 страницыRegulatorslaalvarezmОценок пока нет

- T1553 60Документ8 страницT1553 60Tu PhamОценок пока нет

- New Process DataДокумент2 страницыNew Process DataPHAM THANH TUОценок пока нет

- CC-01 Design SpecificationДокумент1 страницаCC-01 Design SpecificationPHAM THANH TUОценок пока нет

- C13TE3AДокумент2 страницыC13TE3AAhmed Sherif CupoОценок пока нет

- Cooling and Preheating SystemДокумент3 страницыCooling and Preheating SystemHema RajОценок пока нет

- Loader 14t - Sandvik Lh514-Specification-Sheet-EnglishДокумент16 страницLoader 14t - Sandvik Lh514-Specification-Sheet-EnglishBBBBBBОценок пока нет

- 4000S Diesel Install PDFДокумент105 страниц4000S Diesel Install PDFnisar_shaqurri100% (3)

- Starting Motor CrankingДокумент6 страницStarting Motor CrankingAnastasiya AbbyazovaОценок пока нет

- HX145CR, LCR PDFДокумент688 страницHX145CR, LCR PDFГригорий Григорян100% (1)

- EK Series PDFДокумент8 страницEK Series PDFImpulsora DemaОценок пока нет

- HSC User ManualДокумент47 страницHSC User ManualReza Jafari50% (6)

- Catalog May Phat Dien Mitsubishi MHI3Документ80 страницCatalog May Phat Dien Mitsubishi MHI3Trần Việt HoàngОценок пока нет

- SECTION 1.. Manual - Balanced Pressure Proportioning Pump SkidДокумент45 страницSECTION 1.. Manual - Balanced Pressure Proportioning Pump SkidANGE VANESSA DIAZ QUINTEROОценок пока нет

- Integrated Automatic Heating - Air-Conditioning System (IHKA), Basic and HighДокумент13 страницIntegrated Automatic Heating - Air-Conditioning System (IHKA), Basic and HighPeter HorvathОценок пока нет

- ASV Posi-Track PT-70 Track Loader Master Parts Catalogue Manual PDFДокумент13 страницASV Posi-Track PT-70 Track Loader Master Parts Catalogue Manual PDFfisekkkdОценок пока нет

- Change LogДокумент30 страницChange LogTudor ROОценок пока нет

- GUIA de Reusabilidad 3600Документ5 страницGUIA de Reusabilidad 3600Victor NunezОценок пока нет

- Components Type of Lubricant Capacities SK210HDLC SK220XDLC-10Документ4 страницыComponents Type of Lubricant Capacities SK210HDLC SK220XDLC-10ashish gautamОценок пока нет

- JCB 3CX - 4CX - 214 - 214e - 215 - 217 PDF Service Manual - Part178Документ5 страницJCB 3CX - 4CX - 214 - 214e - 215 - 217 PDF Service Manual - Part178mojbarОценок пока нет

- D475a, D475asd 5e0Документ18 страницD475a, D475asd 5e0João MariaОценок пока нет

- TA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753TДокумент22 страницыTA-2 Visual & Technical Inspection For Wheel Loaders: SMCS - Job Code - 540 Component Code - 753Tahmed el sayedОценок пока нет

- Standard-triumph-Vanguard - 1950s - Triumph Renown Owners HandbookДокумент100 страницStandard-triumph-Vanguard - 1950s - Triumph Renown Owners HandbookcoutinholopesОценок пока нет

- Chapter 6AДокумент22 страницыChapter 6Amaninder_khasria100% (3)

- 3500 TroubleshootingSEK PDFДокумент33 страницы3500 TroubleshootingSEK PDFMargaret Daugherty50% (2)

- WDM2 LOCO REPORT - Manoj Kr. KataraДокумент23 страницыWDM2 LOCO REPORT - Manoj Kr. KataraAbhinav AgarwalОценок пока нет

- Paver SUPER 1800-3 BrochureДокумент22 страницыPaver SUPER 1800-3 BrochureMohammad Younes100% (1)

- Komatsu Index For Parts OverviewДокумент27 страницKomatsu Index For Parts Overviewmello06100% (2)

- Brochure - D125, 150, 180Документ11 страницBrochure - D125, 150, 180Györök PeterОценок пока нет