Академический Документы

Профессиональный Документы

Культура Документы

Course Tentative Syllabus

Загружено:

dineshsirasatАвторское право

Доступные форматы

Поделиться этим документом

Поделиться или встроить документ

Этот документ был вам полезен?

Это неприемлемый материал?

Пожаловаться на этот документАвторское право:

Доступные форматы

Course Tentative Syllabus

Загружено:

dineshsirasatАвторское право:

Доступные форматы

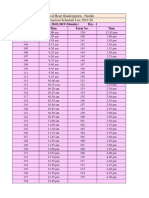

Task Sub Area Topic Sub topic Intended Faculty

task

1 1 Introduction What is pressure vessel ? What is code ASME BPV, BS 5500 , PED, EN 13445, API, IBR and other codes Rajesh

(safety, design or operatiosn) and why followed across globe. What is covered in pressure vessel code,

it is needed? categories and class of pressure equipment, fired and unfired vessel.

1 2 Introduction Listing of different section and brief different section of asme code and brief coverage of each code, code Rajesh

cases introduction

2 1 Design Design Basic PVRC, PLM,Concept of stress, Theory of failure (how material Dinesh

fails),concept of elastic-plastic shakedown, ratcheting, Vessel failure

modes, fatigue, creep, fracture, ductile and brittle failure, concept of

NDTT, carbon equivalent, fracture toughness. Concept of stress

concentration, stress intensity and stress intensification factor, how

thickness affects NDTT & fracture, MDMT, stresses in bolts bolted

joint Design, notch toughness, fracture analysis diagram

2 2 Design Design calculations Thickness calculations, Free body diagram of vessels, thin cylinder Dinesh

theory approximation to thick cylinder theory, Design under external

pressure, lames theory, formed head and calculations. appendix iv

2 3 Design Material Testing (Destructive) Mechanical testing, concept of yield, Creep, fatigue, requirement for Dinesh

impact testing approach followed in ASME, crack arrest temperature

2 4 Design Process basic -welding Iron carbide diagram, transformations and thumb rules for welding, Dinesh

weldability, pre heat, post heat basics from metallurgical perspective,

HAZ, welding failure modes, reason and prevention, Schaeffler

diagram for stainless steel, effect of cooling and HAZ, metallurgy and

heat treatment, stresses in weld joint, role of thermal diffusivity in

controlling distortion

2 5 Design Hydrostatic testing need from design perspective. (detailed covered in separately), MAWP Dinesh

2 6 Design stress factor of safety in present code, basis for setting allowable stress, Dinesh

category primary secondary and peak. Design limits, allowable

stresses, article 4-1,categorisation and stress tables

2 7 Design approach DBR, DBA, stress linearization Dinesh

3 1 NDT NDT Crisp of NDT methods , general understanding of defects and Rajesh

acceptable level of defects, hydrostatic testing requirements

3 2 Certification symbol and stamps N, NA, U, UA etc. Where these stamp applicable Rajesh

3 3 Future and AI, NDT level II, III, welding engineer certification Rajesh

career Path

4 1 Welding welding ASME Section IX, weld configurations, Welding , joint category, weld Rajesh/ Bhushan

joint efficiency and its values, weld qualification positions, F number,

WPS, PQR, AWS D1.1, D1.6 code, Welding qualifications, why need

WPS, PQR, F no. , selection of fillers, dissimilar metals welding, impact

testing code requirement and exemptions, defects and acceptance

criteria, weld repair

4 2 Design Code selection of stresses section II D, section VIII, div 1 and 2, comparison Bhushan

differences and approach, general requirements, limitation of section

viii, brief intro about div 3., various code rules,corrosion allowance,

bolted flange connection Design basics, Nozzle Design basic,

reinforcement and stiffening rules, approach used in area replacement

and ligament efficiency method , bolt material and class, impact

testing charts

4 3 Design PV elite Design examples, Case studies and demo Bhushan

4 4 fabrication Shop Practices thinning criteria,alignment tolerances, mil undertolerance, tolerance bhushan

of formed heads and practical heat treatment cycle, forming

considerations

4 5 piping Piping and heat exchanger Process piping, power piping, TEMA Bhushan

Вам также может понравиться

- Asme Section Viii Div.1Документ87 страницAsme Section Viii Div.1balu100% (7)

- HISC NORSOK Workshop Agreement M-WA-01Rev1Документ18 страницHISC NORSOK Workshop Agreement M-WA-01Rev1naveen_86Оценок пока нет

- Technical Brief: Avoiding Bolt Failures: F E A T U R EДокумент2 страницыTechnical Brief: Avoiding Bolt Failures: F E A T U R EkanosriОценок пока нет

- Worldwide Engineering Standards: Material Specification Finish GMW4700Документ4 страницыWorldwide Engineering Standards: Material Specification Finish GMW4700Miguel Queiros100% (4)

- SFD API RP 2A WSD 22ndДокумент19 страницSFD API RP 2A WSD 22ndputra wiraОценок пока нет

- EEMUA 159 Corrigendum Imprint 04 2015 PDFДокумент22 страницыEEMUA 159 Corrigendum Imprint 04 2015 PDFAlfian Ibnu Pratama100% (1)

- Guideline For Weld Reject Rate Reduction: Table of ContentsДокумент14 страницGuideline For Weld Reject Rate Reduction: Table of ContentsMohammad Irfandi100% (1)

- Acceptance Criteria For Weld Defects - Welding & NDTДокумент11 страницAcceptance Criteria For Weld Defects - Welding & NDTKevin ThomasОценок пока нет

- Asme Sec Viii Div 1 Vs Asme Viii Div 2Документ3 страницыAsme Sec Viii Div 1 Vs Asme Viii Div 2Jignesh ShahОценок пока нет

- Welding Defects - Classification, Causes and Remedies - Welding & NDTДокумент11 страницWelding Defects - Classification, Causes and Remedies - Welding & NDTadel100% (1)

- PLANS Folding KayakДокумент15 страницPLANS Folding KayakecalzoОценок пока нет

- Pressure Vessel Code Asme Section Viii Division 1Документ84 страницыPressure Vessel Code Asme Section Viii Division 1Sam Low100% (1)

- Static Equipment Training ModulesДокумент3 страницыStatic Equipment Training ModulesMohit SinghОценок пока нет

- Datasheet For Vent ScrubberДокумент5 страницDatasheet For Vent ScrubbercliffrajjoelОценок пока нет

- TechnipFMC Summer Trainee ProgrammeДокумент1 страницаTechnipFMC Summer Trainee Programmeanon_660004464Оценок пока нет

- Ronnel AC Design Solution 2Документ36 страницRonnel AC Design Solution 2Xype LanderОценок пока нет

- ASME Y14.5-2009, Geometric Boundaries 2Документ9 страницASME Y14.5-2009, Geometric Boundaries 2Keith Admin60% (5)

- Parker O-Ring Material Guide-2008Документ72 страницыParker O-Ring Material Guide-2008Ian Pillay50% (2)

- Polarity of Molecules Hand-OutДокумент1 страницаPolarity of Molecules Hand-OutMaria Di MakaototОценок пока нет

- Fluid Mechanics (Chapter 1)Документ31 страницаFluid Mechanics (Chapter 1)alsahariОценок пока нет

- SAP2000-Steel Design-API RP2A PDFДокумент23 страницыSAP2000-Steel Design-API RP2A PDFiwanguna71Оценок пока нет

- A Seminar On Material-SelectionДокумент39 страницA Seminar On Material-SelectionThirukkumaranBalasubramanianОценок пока нет

- Caltrans Seismic Design Spec Steel Bridges 2nd Ed 2016Документ110 страницCaltrans Seismic Design Spec Steel Bridges 2nd Ed 2016diogogrebОценок пока нет

- 1 4945413584441049168Документ17 страниц1 4945413584441049168MohsenОценок пока нет

- SFD API RP 2a WSD 22ndДокумент19 страницSFD API RP 2a WSD 22ndRoberto Andrés Fernández DomínguezОценок пока нет

- ASME Sec VIII Div 1 vs. Div 2Документ4 страницыASME Sec VIII Div 1 vs. Div 2autobahn123Оценок пока нет

- PDFДокумент3 страницыPDFVishalVaishОценок пока нет

- Chapetti2012 PDFДокумент11 страницChapetti2012 PDFKmilo GuerreroОценок пока нет

- BMP - Metal WorkingДокумент17 страницBMP - Metal Workingmantra2010Оценок пока нет

- BMP PDFДокумент17 страницBMP PDFmantra2010Оценок пока нет

- Metal Forming Process and DefectsДокумент7 страницMetal Forming Process and DefectsPradeep Kumar BowmarajuОценок пока нет

- ME407E - M - DSGNДокумент9 страницME407E - M - DSGNAyush LolusareОценок пока нет

- Birla Institute of Technology and Science, Pilani Instruction Division Second Semester 2017-18 Course Handout Part IIДокумент3 страницыBirla Institute of Technology and Science, Pilani Instruction Division Second Semester 2017-18 Course Handout Part IIMAYANK MAYANKОценок пока нет

- Materials Science Books: Guide To Submitting Your ProposalДокумент4 страницыMaterials Science Books: Guide To Submitting Your ProposalKhalid HafezОценок пока нет

- Text: 1) Steel Structures, Design & Behavior (4Документ6 страницText: 1) Steel Structures, Design & Behavior (4Jhamir Castro HuamánОценок пока нет

- Rilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteДокумент17 страницRilem TC 162-Tdf: Test and Design Methods For Steel Fibre Reinforced ConcreteJaniele MoreiraОценок пока нет

- Detail Syllabus For Static Equipment DesignДокумент9 страницDetail Syllabus For Static Equipment DesignGuru KguruОценок пока нет

- TM6004 Teknik Pemboran Lanjut (English)Документ3 страницыTM6004 Teknik Pemboran Lanjut (English)aciОценок пока нет

- Difference Between ASME Sec VIII Div. 1 and Div. 2 (With PDF) - What Is PipingДокумент3 страницыDifference Between ASME Sec VIII Div. 1 and Div. 2 (With PDF) - What Is PipingCem DufourОценок пока нет

- 1.1 Process Equipment - An OverviewДокумент45 страниц1.1 Process Equipment - An Overviewrodrigoperezsimone100% (1)

- BMP - Electric Arc WeldingДокумент91 страницаBMP - Electric Arc Weldingsujay nayakОценок пока нет

- BMP - IntroductionДокумент130 страницBMP - Introductionmantra2010Оценок пока нет

- Pressure Vessel Code Asme Section Viii D PDFДокумент85 страницPressure Vessel Code Asme Section Viii D PDFNhật Quang PhạmОценок пока нет

- English For Welding 2Документ3 страницыEnglish For Welding 2MOSES7 WISEОценок пока нет

- BMP - ForgingДокумент31 страницаBMP - Forgingmantra2010Оценок пока нет

- Piping Seminar NotesДокумент204 страницыPiping Seminar NotespritamОценок пока нет

- BMP - RollingДокумент46 страницBMP - Rollingmantra2010Оценок пока нет

- BMP - DrawingДокумент22 страницыBMP - Drawingmantra2010Оценок пока нет

- BMP - Other Welding ProcessesДокумент76 страницBMP - Other Welding Processessujay nayakОценок пока нет

- Sample UdsДокумент8 страницSample UdsPrince SharmaОценок пока нет

- Ed.) Salman & Johnson. 2) Manual of Steel Construction (LRFD) AISC (3 Ed.)Документ4 страницыEd.) Salman & Johnson. 2) Manual of Steel Construction (LRFD) AISC (3 Ed.)Adrian Yanqui SantosОценок пока нет

- BMP - CastingДокумент217 страницBMP - Castingmantra2010Оценок пока нет

- BMP - ExtrusionДокумент24 страницыBMP - Extrusionmantra2010Оценок пока нет

- 4 Code Requeriments For Nuclear Safety Related Concrete StructuresДокумент89 страниц4 Code Requeriments For Nuclear Safety Related Concrete StructuresRavi Teja Polisetti0% (1)

- 2019 - 3.3 Projektovanje Zav. I Zalemljenog SpojaДокумент21 страница2019 - 3.3 Projektovanje Zav. I Zalemljenog SpojaticmaОценок пока нет

- Level VII CE CoursesДокумент38 страницLevel VII CE CoursesGSGSGОценок пока нет

- COURSE HANDOUT - FJDSFSDJFDДокумент7 страницCOURSE HANDOUT - FJDSFSDJFDsandeshОценок пока нет

- Uncoated Stress Relieved Low Relaxation Seven-Wire (Ply) Strand For Prestressed Concrete - SpecificationДокумент16 страницUncoated Stress Relieved Low Relaxation Seven-Wire (Ply) Strand For Prestressed Concrete - SpecificationStandardtec EngineersОценок пока нет

- Midas Release NoteДокумент12 страницMidas Release NoteLoka GaneshanОценок пока нет

- SFD API RP 2A WSD 21stДокумент23 страницыSFD API RP 2A WSD 21stputra wiraОценок пока нет

- Chapter Wise Mapping With Course Outcomes: Date: / / Page: 1 of 3 Department:Mechanical EngineeringДокумент4 страницыChapter Wise Mapping With Course Outcomes: Date: / / Page: 1 of 3 Department:Mechanical EngineeringMitul patelОценок пока нет

- متطلبات تخصص الصيانة الكهروميكانيكة العامةДокумент68 страницمتطلبات تخصص الصيانة الكهروميكانيكة العامةibraheemОценок пока нет

- Composite Engineering Show 12 11 14Документ22 страницыComposite Engineering Show 12 11 14AliОценок пока нет

- Engineering Standards: Material Specification Metals GM6435MДокумент6 страницEngineering Standards: Material Specification Metals GM6435MAkmal NizametdinovОценок пока нет

- De ZG631 Course HandoutДокумент7 страницDe ZG631 Course HandoutmzaidpervezОценок пока нет

- Corrosion Nov10 (1) 1Документ4 страницыCorrosion Nov10 (1) 1Agnes ChongОценок пока нет

- M 2.1.9 Enginerring Critical AssessmentДокумент11 страницM 2.1.9 Enginerring Critical AssessmentIr FankovicОценок пока нет

- Design of Prestressed Conc. Structures Course HandoutДокумент4 страницыDesign of Prestressed Conc. Structures Course HandoutHarshit BadhwarОценок пока нет

- Union Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhДокумент1 страницаUnion Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhdineshsirasatОценок пока нет

- Roll No.: Venue Code: Registration No.: Progarmme Applied For: Name and Address: Venue of ExaminationДокумент2 страницыRoll No.: Venue Code: Registration No.: Progarmme Applied For: Name and Address: Venue of ExaminationdineshsirasatОценок пока нет

- Antiviral Research: A A A B BДокумент4 страницыAntiviral Research: A A A B BUssr NavyОценок пока нет

- DrSavkar HealthДокумент2 страницыDrSavkar HealthdineshsirasatОценок пока нет

- Maharashtra State Road Transport Corpora On E-Reserva On TicketДокумент1 страницаMaharashtra State Road Transport Corpora On E-Reserva On TicketdineshsirasatОценок пока нет

- Sacred Heart Kindergarten, Nashik Interaction Schedule List 2019-20Документ5 страницSacred Heart Kindergarten, Nashik Interaction Schedule List 2019-20dineshsirasatОценок пока нет

- Diat Rules and Regulations For The Award of The Degree of Doctor of Philosophy (2016)Документ48 страницDiat Rules and Regulations For The Award of The Degree of Doctor of Philosophy (2016)dineshsirasatОценок пока нет

- ToДокумент2 страницыTodineshsirasatОценок пока нет

- Union Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhДокумент1 страницаUnion Public Service Commission: La?K Yksd Lsok VK KSX) /kksyiqj GKML) 'KKGTGK¡ JKSM) Ubz FnyyhdineshsirasatОценок пока нет

- 1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSДокумент1 страница1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSdineshsirasatОценок пока нет

- Commented - Atmanirbhar Bharat in Archery - FinalДокумент3 страницыCommented - Atmanirbhar Bharat in Archery - FinaldineshsirasatОценок пока нет

- ApprciationДокумент1 страницаApprciationdineshsirasatОценок пока нет

- To 2Документ2 страницыTo 2dineshsirasatОценок пока нет

- Instrumentation Control, Data Acquisition and Processing With MATLABДокумент1 страницаInstrumentation Control, Data Acquisition and Processing With MATLABdineshsirasatОценок пока нет

- DocumentДокумент2 страницыDocumentdineshsirasatОценок пока нет

- Standard Pipe Sizes ME303-4.1.1Документ5 страницStandard Pipe Sizes ME303-4.1.1manashbdОценок пока нет

- 1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSДокумент1 страница1000 NB SS304 Metallic Axial Expansion Bellows - QTY: 06 NOSdineshsirasatОценок пока нет

- New Text DocumentДокумент1 страницаNew Text DocumentdineshsirasatОценок пока нет

- Using The ETDR Word Template: Masters Theses and ReportsДокумент22 страницыUsing The ETDR Word Template: Masters Theses and ReportsdineshsirasatОценок пока нет

- Vatavruksha Apartment: Ravishankar Marg, Vidhate Nagar, Behind INOX, Nasik Pune Road, Nasik - 422006Документ3 страницыVatavruksha Apartment: Ravishankar Marg, Vidhate Nagar, Behind INOX, Nasik Pune Road, Nasik - 422006dineshsirasatОценок пока нет

- Concrete LinksДокумент2 страницыConcrete LinksdineshsirasatОценок пока нет

- CoronaДокумент1 страницаCoronadineshsirasatОценок пока нет

- FasДокумент1 страницаFasdineshsirasatОценок пока нет

- Tips For Filling MAH-LL.B.-3 Yrs. CET - 2020 On Line Application FormДокумент6 страницTips For Filling MAH-LL.B.-3 Yrs. CET - 2020 On Line Application FormdineshsirasatОценок пока нет

- Zoom MeetingДокумент2 страницыZoom MeetingdineshsirasatОценок пока нет

- Motor PoДокумент2 страницыMotor PodineshsirasatОценок пока нет

- ToДокумент1 страницаTodineshsirasatОценок пока нет

- FIR SubmissionДокумент1 страницаFIR SubmissiondineshsirasatОценок пока нет

- Nashik Profile PDFДокумент33 страницыNashik Profile PDFsusegaad100% (1)

- Training Calender 2019-20Документ3 страницыTraining Calender 2019-20dineshsirasatОценок пока нет

- 8 - Inorganic Salt AnalysisДокумент95 страниц8 - Inorganic Salt AnalysisArkaОценок пока нет

- Rendercon ChemДокумент4 страницыRendercon ChemHarshvardhan PathakОценок пока нет

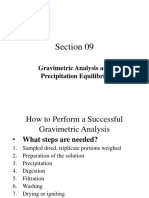

- Gravimetric Analysis and Precipitation - TitrationsДокумент34 страницыGravimetric Analysis and Precipitation - TitrationsElvinОценок пока нет

- Pengajuan Penamaan InfusДокумент1 страницаPengajuan Penamaan InfusNur AzlinОценок пока нет

- Live Class Notes 29 02 20Документ14 страницLive Class Notes 29 02 20SantoshОценок пока нет

- EM - 1110-2-2902 - Cimentacion de Tuberias PDFДокумент87 страницEM - 1110-2-2902 - Cimentacion de Tuberias PDFJose PardoОценок пока нет

- ChemTeam - Combustion Analysis - Problems 1 - 10Документ12 страницChemTeam - Combustion Analysis - Problems 1 - 10David KabuyaniОценок пока нет

- Durehete 1055Документ5 страницDurehete 1055alextentwenty100% (1)

- Characterization of Carbon Nanotubes by Raman SpectrosДокумент9 страницCharacterization of Carbon Nanotubes by Raman SpectrosRoque SanChzОценок пока нет

- 10749-Article Text PDF-30111-3-10-20180322 PDFДокумент13 страниц10749-Article Text PDF-30111-3-10-20180322 PDFTogi HutaОценок пока нет

- Nuclear Energy ConversionДокумент26 страницNuclear Energy ConversionMohd AkhlaqueОценок пока нет

- 730 UlfmДокумент4 страницы730 UlfmTobias Alberto Gonzalez PeresОценок пока нет

- En 13811Документ12 страницEn 13811Dule JovanovicОценок пока нет

- FT Bitumseal enДокумент1 страницаFT Bitumseal enGerman GonzalezОценок пока нет

- QUESTION BANK SCIENCE CLASS-10 2022-23 - KVS AhmedabadДокумент185 страницQUESTION BANK SCIENCE CLASS-10 2022-23 - KVS AhmedabadshamshadОценок пока нет

- HMT QB 2Документ31 страницаHMT QB 2Arunesh TripathiОценок пока нет

- Determination of Arrhenius Kinetic Constants Differential Scanning CalorimetryДокумент5 страницDetermination of Arrhenius Kinetic Constants Differential Scanning CalorimetryNgocDiep PhamОценок пока нет

- Multi Axial Loading - ResourceДокумент29 страницMulti Axial Loading - ResourceEirickTrejozuñigaОценок пока нет

- Processing and Recycling in Mining andДокумент2 страницыProcessing and Recycling in Mining andHenockОценок пока нет

- Astm b117 1973 PDFДокумент10 страницAstm b117 1973 PDFabthakurОценок пока нет